Surface modification method of anode material of lithium ion battery

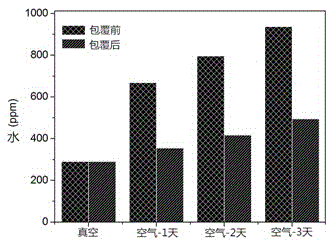

A technology for lithium-ion batteries and positive electrode materials, applied in battery electrodes, positive electrodes, secondary batteries, etc., can solve the problem of low conductivity of ceria, achieve simple hydrophobic treatment methods, improve conductivity, and maintain stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

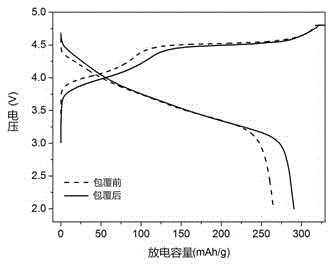

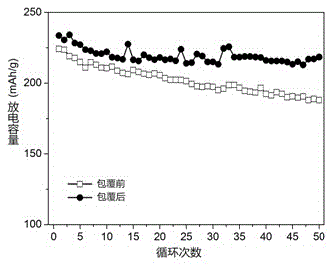

[0030] Embodiment 1: Preparation doped nano ceria coated Li 1.2 mn 0.56 Ni 0.16 co 0.08 o 2

[0031] The finely ground lithium-rich manganese-based cathode material Li 1.2 mn 0.56 Ni 0.16 co 0.08 o 2 Add in the mixed solution that is made up of cerium nitrate and neodymium nitrate, the concentration of cerium nitrate in the mixed solution is 0.02mol / L, cerium element accounts for 2% of the total mass of positive electrode material, and neodymium element accounts for 0.2% of the total mass of positive electrode material; Mix ammonia water with a concentration of 2 mol / L, ultrasonicate the mixed solution for 10 minutes, place it at room temperature for 2 hours, then raise the temperature to 80°C and stir to completely evaporate the water to dryness, and finally place it in an oven at 80°C Dry for 12 hours to obtain a dry sample;

[0032]Press the dry sample into a sheet-like sample, then put the sheet-like sample into a tube furnace, pre-flow oxygen into the tube furna...

Embodiment 2

[0035] Example 2: Preparation of LiMn coated with nanometer ceria 0.2 Ni 0.6 co 0.2 o 2 (NCM-622)

[0036] The ground LiMn 0.2 Ni 0.6 co 0.2 o 2 Add to the mixed solution composed of cerium nitrate and neodymium nitrate, the concentration of cerium nitrate in the mixed solution is 0.01mol / L, the cerium element accounts for 1% of the total mass of the positive electrode material, and the neodymium element accounts for 0.5% of the total mass of the positive electrode material; Ammonia water with a concentration of 2mol / L was mixed, and the mixed solution was ultrasonically treated for 10 minutes, then left at room temperature for 2 hours, then stirred at 60°C until dry, and finally dried in an oven at 100°C for 10 hours to obtain a dry sample;

[0037] Press the dry sample into a sheet-like sample, and then put the sheet-like sample into a tube furnace. Oxygen is passed into the tube furnace for 1 hour in advance, and then the temperature is raised to 400°C at 2°C / min for...

Embodiment 3

[0038] Example 3: Preparation of LiNi coated with nanometer ceria 0.78 co 0.19 al 0.03 o 2 (NCA)

[0039] The ground LiNi 0.78 co 0.19 al 0.03 o 2 Add it to the mixed solution composed of cerium nitrate and neodymium nitrate, the concentration of cerium nitrate in the mixed solution is 0.02mol / L, the cerium element accounts for 0.25% of the total mass of the positive electrode material, and the neodymium element accounts for 0.025% of the total mass of the positive electrode material. Ammonia water with a concentration of 2mol / L was mixed, and the mixed solution was ultrasonically treated for 5 minutes, then left at room temperature for 1 hour, then stirred at 80°C until dry, and finally dried in an oven at 120°C for 6 hours to obtain a dry sample;

[0040] Press the dry sample into a sheet-like sample, then put the sheet-like sample into a tube furnace, pre-flow oxygen into the tube furnace for 1h, then raise the temperature to 500°C at 2°C / min and maintain it for 10h,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com