Preparation method for silicon/graphite/solid electrolyte composite negative electrode material

A technology of solid electrolyte and negative electrode material, applied in the direction of negative electrode, battery electrode, active material electrode, etc., can solve the problems of inability to solve lithium ion battery, poor safety, etc., to improve stability and safety, improve conductivity, reduce effect of dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

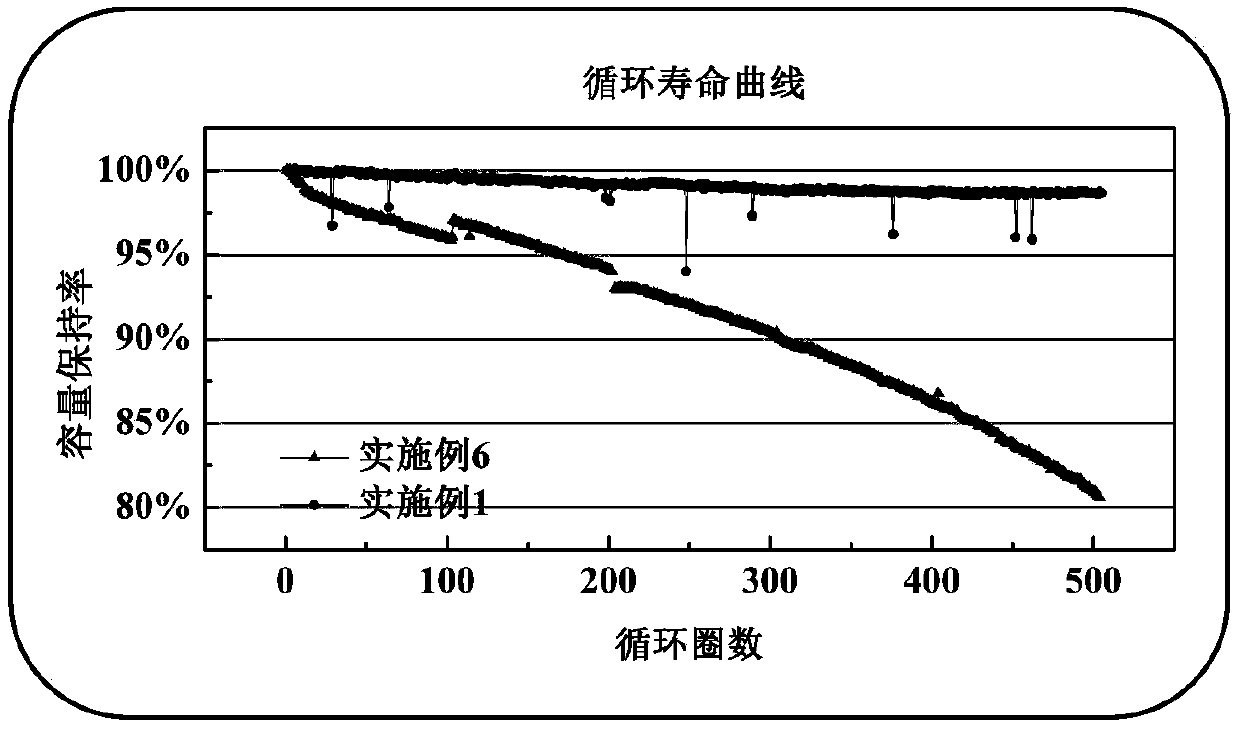

Embodiment 1

[0029] The preparation method steps of the silicon / graphite / solid electrolyte composite material of this embodiment are as follows:

[0030] (1) Preparation of silicon / graphite / solid electrolyte precursor:

[0031] a. Dissolve 50g of binder PEO in 100g of absolute ethanol, and make a solution for later use.

[0032] b. Take 250g of artificial graphite with a particle size D50 of 5 μm, 100 g of nano-silicon powder with a particle size of D50 of 20 nm, 50 g of carbon nanotubes (50-500 nm in diameter, 5-15 μm in length), and 50 g of LATP solid electrolyte into the mixer Carry out dry mixing, and the dry mixing time is 30min.

[0033] c. Add PEO solution and stir for 30 minutes, then add absolute ethanol and continue stirring for 2 hours to adjust the viscosity of the dispersion to 200 mPa·s.

[0034]d. Use a spray granulation dryer to granulate to obtain a silicon / graphite / solid electrolyte precursor.

[0035] (2) Preparation of silicon / graphite / solid electrolyte composite mat...

Embodiment 2

[0039] (1) Preparation of silicon / graphite / solid electrolyte precursor:

[0040] a. Dissolve 50g of binder PPO in 100g of absolute ethanol, and make a solution for later use.

[0041] b. Take 250g of artificial graphite with a particle size D50 of 10μm, 100g of nano-silicon powder with a particle size of D50 of 50nm, 50g of carbon nanotubes (50-500nm in diameter, 5-15μm in length), and 50g of LLTO solid electrolyte into the mixer Dry mixing in 40 minutes.

[0042] c. Add PPO solution, stir for 30 minutes, add absolute ethanol and continue stirring for 4 hours, and adjust the viscosity of the dispersion to 800mPa·s.

[0043] d. Use a spray granulation dryer to granulate to obtain a silicon / graphite / solid electrolyte precursor.

[0044] (2) Preparation of silicon / graphite / solid electrolyte composite material:

[0045] e. Take 50g of high-temperature pitch (particle size D50 is 3 μm), 500g of silicon / graphite / solid electrolyte precursor and add them into the mixer for kneading...

Embodiment 3

[0048] (1) Preparation of silicon / graphite / solid electrolyte precursor:

[0049] a. Dissolve 50g of binder phenolic resin in 100g of absolute ethanol, and make a solution for later use.

[0050] b. Take 250g of natural graphite with a particle size D50 of 15μm, 100g of submicron silicon powder with a particle size of D50 of 500nm, 50g of carbon nanofibers (50-200nm, length 10-20μm), and 50g of LLTO solid electrolyte into the mixer Dry mixing was carried out in the medium, and the dry mixing time was 60 minutes.

[0051] c. Add the phenolic resin solution, stir for 30 minutes, add absolute ethanol and continue stirring for 4 hours, and adjust the viscosity of the dispersion to 200 mPa·s.

[0052] d. Use a spray granulation dryer to granulate to obtain a silicon / graphite / solid electrolyte precursor.

[0053] (2) Preparation of silicon / graphite / solid electrolyte composite material:

[0054] e. Take 50g of high-temperature pitch (particle size D50 is 3 μm), 500g of silicon / grap...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com