Application method of magnetic molybdenum-based catalyst in catalysis of p-nitrophenol

A molybdenum-based catalyst, p-nitrophenol technology, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem of high preparation cost, high catalyst cost, The catalyst is difficult to recover and other problems, so as to achieve the effect of high-efficiency catalysis and high-efficiency separation, reducing catalyst cost and easy industrial application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

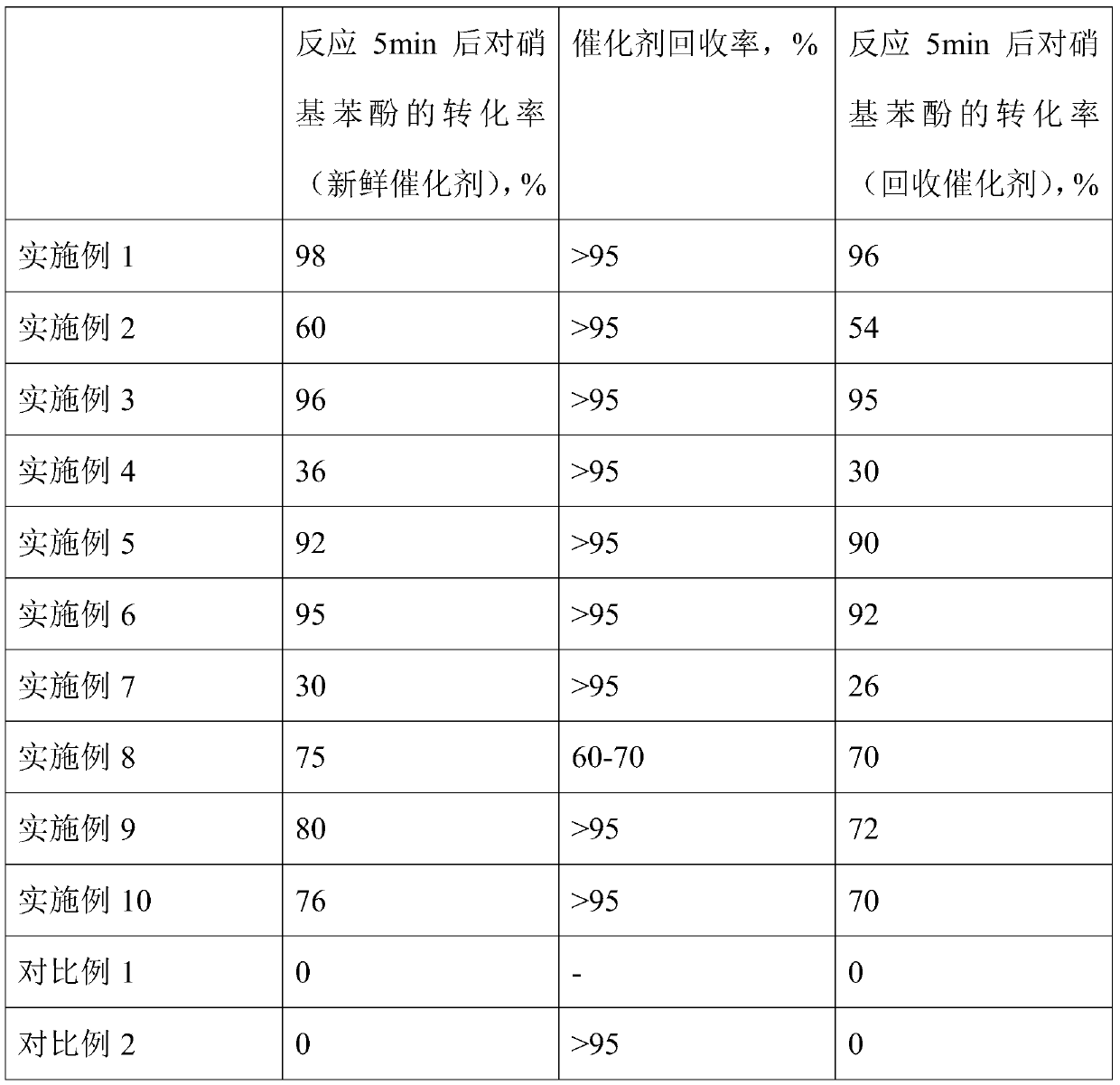

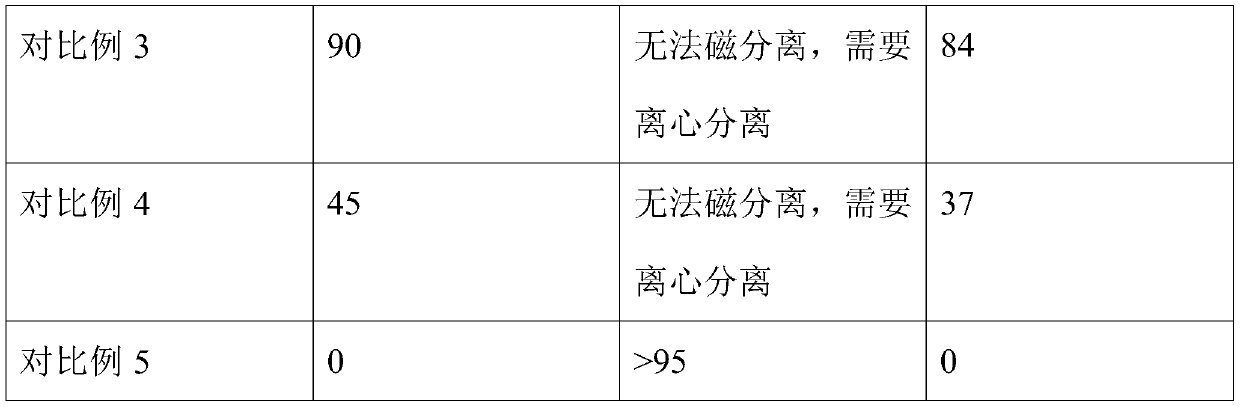

Examples

Embodiment 1

[0054] Application method of magnetic molybdenum-based catalyst in p-nitrophenol catalysis:

[0055] (1) Add 200 mL of p-nitrophenol solution with a concentration of 0.12 mM in the Erlenmeyer flask;

[0056] (2) 0.54g sodium borohydride is added in the solution of step (1);

[0057] (3) adding 1mL of an aqueous catalyst solution with a concentration of 4mg / mL to the solution of step (2);

[0058] (4) Place the Erlenmeyer flask containing the solution described in step (3) in a shaker to carry out the catalytic reduction reaction, the shaker speed is 200 rpm, and the reaction temperature is 25°C.

[0059] The aqueous catalyst solution contains water and a magnetic molybdenum-based catalyst.

[0060] The preparation method of magnetic molybdenum-based catalyst described in the present embodiment is as follows:

[0061] (a) Disperse 1g of magnetic nano ferric oxide in 300mL water to obtain a ferric oxide dispersion;

[0062] (b) add 10g ammonium molybdate tetrahydrate, 18g th...

Embodiment 2

[0066] Compared with Example 1, this example does not add nickel chloride in the step (b) of the preparation process of the magnetic molybdenum-based catalyst, and other conditions are exactly the same as those of Example 1.

Embodiment 3

[0068] Compared with Example 1 in this example, in the step (b) of the preparation process of the magnetic molybdenum-based catalyst, nickel chloride was replaced by an equimolar amount of cobalt chloride, and other conditions were exactly the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com