Three-dimensional nickel hydroxide-graphene composite material, and preparation method and application thereof

A technology of nickel hydroxide and composite materials, applied in nickel storage batteries, electrical components, battery electrodes, etc., can solve the problems of limited practical application of zinc-nickel battery preparation methods, and achieve good cycle stability, simple process, and high repeatability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A three-dimensional nickel hydroxide-graphene composite material, which is prepared through the following steps:

[0033] (1) Mix 500g of nickel hydroxide and 100g of graphene oxide (graphene) (the mass ratio of the two is 5:1), disperse it in 2100g of water, then seal it in a hydrothermal kettle, and react it at 180±5°C for 12 about hours; the photo of the prepared gel is shown in figure 1 .

[0034] (2) Freeze-drying to obtain a solid product, which is a three-dimensional nickel hydroxide-graphene composite material. The result is a spongy porous three-dimensional composite material that forms a conductive network with micropores, mesopores, and macropores.

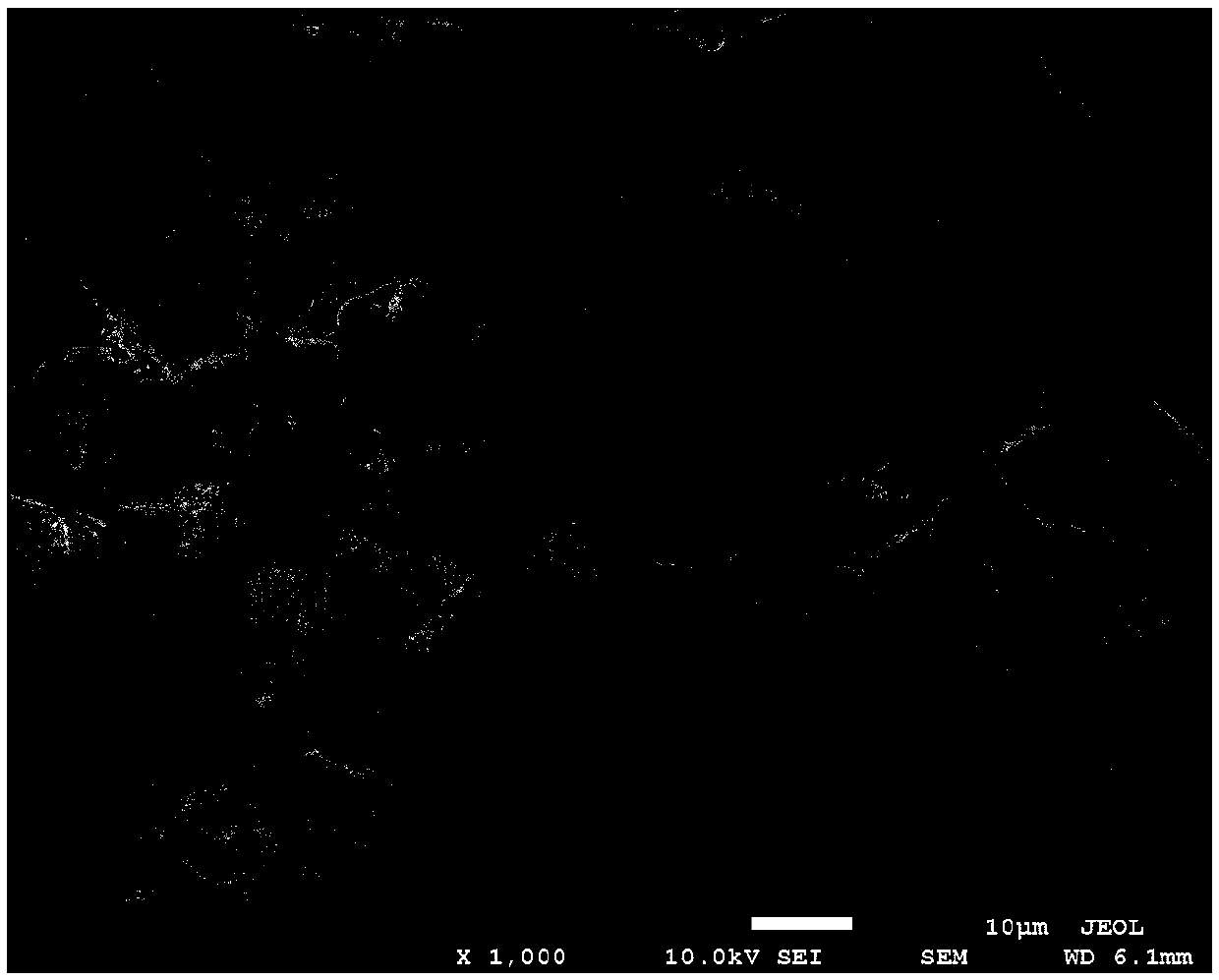

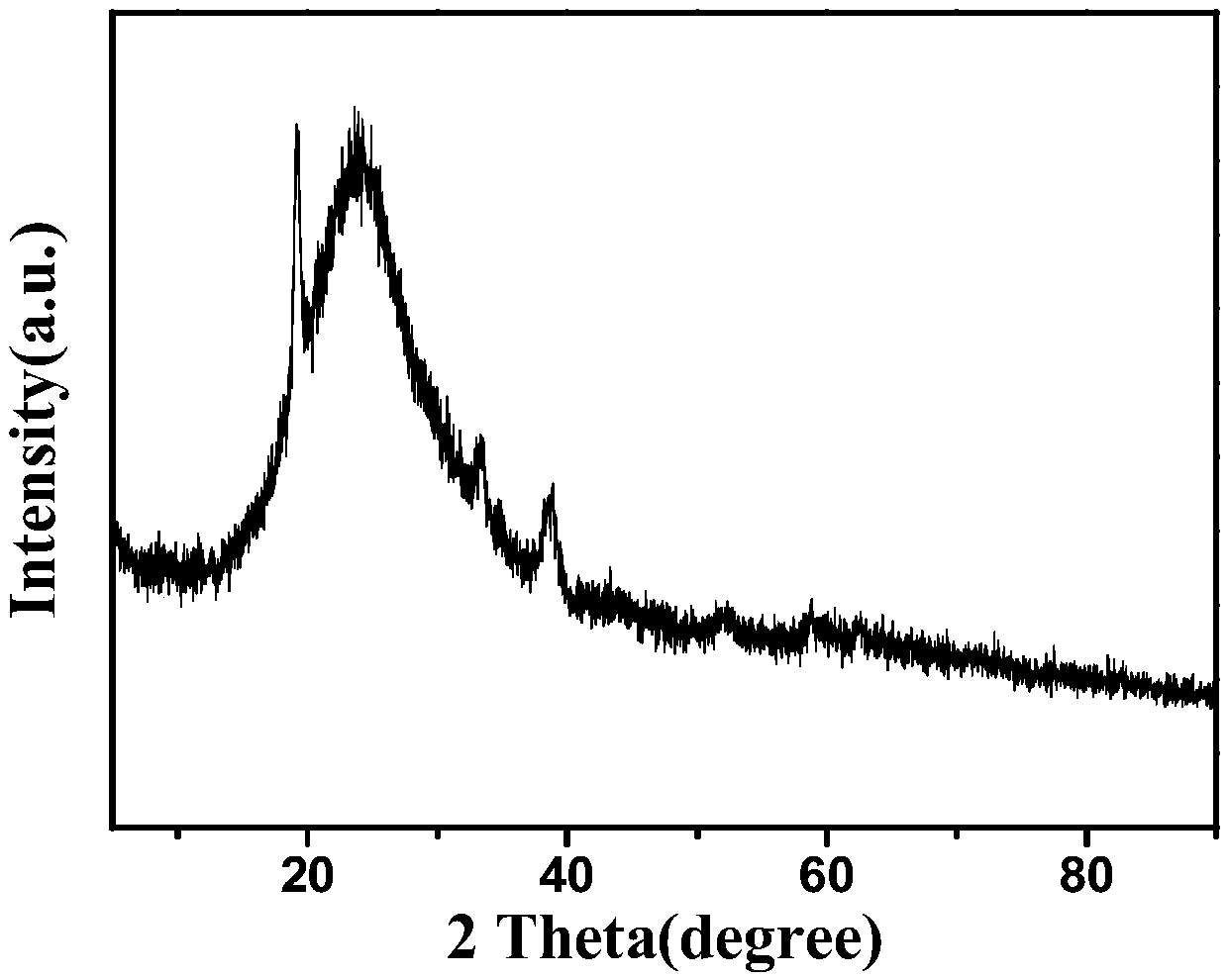

[0035] The morphology of the obtained three-dimensional nickel hydroxide-graphene composite was characterized. figure 2 Showing the microscopic morphology of the material, it can be seen that the three-dimensional nickel hydroxide-graphene composite material is composed of graphene and spherical nickel hydrox...

Embodiment 2

[0043] Embodiment 2 provides a kind of three-dimensional nickel hydroxide-graphene composite material, and its preparation method is basically the same as embodiment 1, and difference is that the mass ratio of its raw material nickel hydroxide and graphene oxide (graphene) is 10:1 . (nickel hydroxide and graphene are respectively 1000 mass parts and 100 mass parts, water 4200 mass parts)

[0044]The three-dimensional nickel hydroxide-graphene composite material is made into a working electrode according to the same method as in Example 1 and the corresponding electrical performance test is carried out. The results are as follows: when charging and discharging at 1C, the stable specific capacity is 200mAh / g; at the above-mentioned rate When charging and discharging under high pressure, the capacity can maintain more than 70% of the initial capacity after 500 times of repeated charging and discharging.

Embodiment 3

[0046] This example provides a kind of three-dimensional nickel hydroxide-graphene composite material, and its preparation method is basically the same as embodiment 1, and difference is that the mass ratio of its raw material nickel hydroxide and graphene oxide (graphene) is 0.5:1 ( Nickel hydroxide and graphene are respectively 50 mass parts and 100 mass parts, water 210 mass parts).

[0047] The three-dimensional nickel hydroxide-graphene composite is made into a working electrode according to the same method as in Example 1 and the corresponding electrical performance test is carried out. The results are as follows: when charging and discharging at 1C, the stable specific capacity is 180mAh / g; at the above-mentioned rate When charging and discharging under high pressure, the capacity can maintain more than 60% of the initial capacity after 500 times of repeated charging and discharging.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Average length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com