High-performance composite binary positive electrode material, preparation method thereof and lithium ion battery

A cathode material, lithium source technology, applied in lithium ion batteries, binary cathode materials, high-performance composite binary cathode materials and their preparation fields, can solve problems such as unfavorable large-scale production, cumbersome preparation process, long process, etc. Improve sample capacity and cycle performance, good cycle performance and low residual alkali

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] In this embodiment, the following method is used to prepare a high-performance composite binary cathode material:

[0065] (1) Weigh 100g of Ni(OH) 2 The precursor is uniformly mixed with alumina at a mass ratio of 100:1, and sintered at 500°C for 5 hours to obtain nickel oxide doped with aluminum;

[0066] (2) Nickel oxide doped with aluminum and lithium hydroxide are mixed uniformly at a molar ratio of 1:1.03, and then sintered at 750°C for 7 hours to obtain a binary nickel aluminate material;

[0067] (3) Mix the binary nickel aluminate material with aluminum isopropoxide in a mass ratio of 100:5 (the mass of aluminum in the aluminum source is 6600 ppm of the binary nickel aluminate material mass), in a hydrogen sulfide atmosphere The composite binary cathode material is obtained by sintering three times for 5 hours at 500°C.

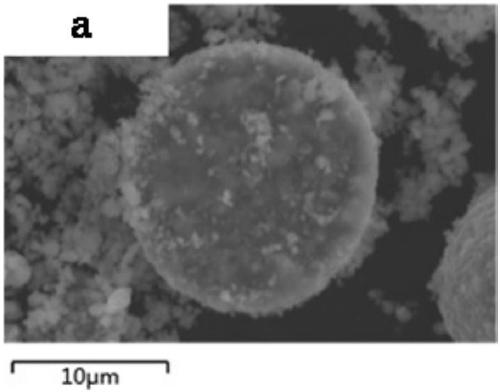

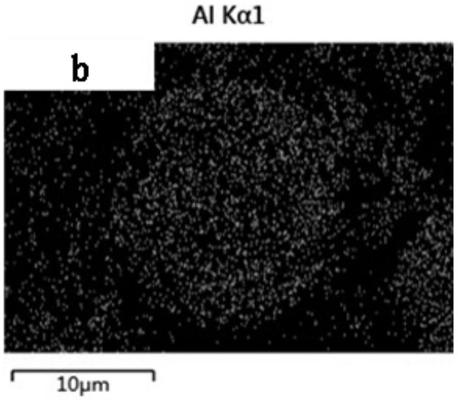

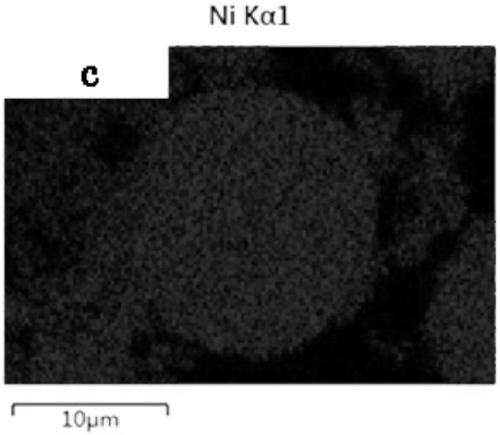

[0068] The composite binary cathode material prepared in this embodiment includes a binary lithium nickel aluminate material and a coating layer coat...

Embodiment 2

[0073] In this embodiment, the following method is used to prepare a high-performance composite binary cathode material:

[0074] (1) Weigh 100g of Ni(OH) 2 The precursor is uniformly mixed with aluminum hydroxide at a molar ratio of 98:1, and sintered at 600°C for 5 hours to obtain nickel oxide doped with aluminum;

[0075] (2) Nickel oxide doped with aluminum and lithium hydroxide are mixed uniformly at a molar ratio of 1:1.05, and then sintered at 730°C for 9 hours to obtain a binary nickel aluminate material;

[0076] (3) Mix the binary nickel aluminate material with aluminum isopropoxide in a mass ratio of 100:3 (the mass of aluminum in the aluminum source is 4000 ppm of the binary nickel aluminate material mass), in a hydrogen sulfide atmosphere The composite binary cathode material is obtained by sintering three times for 5 hours at 700°C.

[0077] The composite binary cathode material prepared in this embodiment includes a binary lithium nickel aluminate material and a coating...

Embodiment 3

[0080] In this embodiment, the following method is used to prepare a high-performance composite binary cathode material:

[0081] (1) Weigh 100g of Ni(OH) 2 The precursor is mixed uniformly with aluminum hydroxide at a molar ratio of 5:1, and sintered at 400°C for 8 hours to obtain nickel oxide doped with aluminum;

[0082] (2) Nickel oxide doped with aluminum and lithium hydroxide are mixed uniformly at a molar ratio of 1:1.1, and sintered at 600°C for 12 hours to obtain a binary nickel aluminate material;

[0083] (3) Add the binary nickel aluminate material and the aluminum source aluminum isopropoxide into the aluminum source according to the mass of aluminum element in the aluminum source as 1000 ppm of the weight of the binary nickel aluminate material, and put it in the hydrogen sulfide atmosphere at 300℃ three times After sintering for 10 hours, the composite binary cathode material is obtained.

[0084] The composite binary cathode material prepared in this embodiment include...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Median particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com