Cellulose fiber-dispersed polyolefin resin composite material, pellet and molded article using same, and method for producing cellulose fiber-dispersed polyolefin resin composite material

A technology of cellulose fiber and polyolefin resin, which is applied in the field of polyolefin resin composite materials, can solve the problems of uneven size and shape, difficulty in resin, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

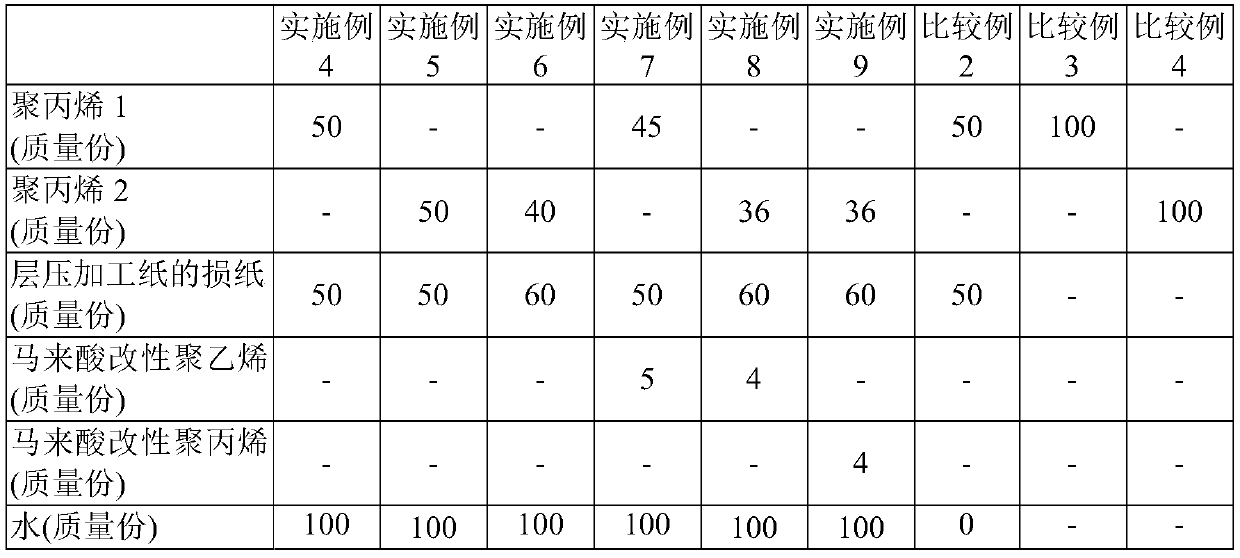

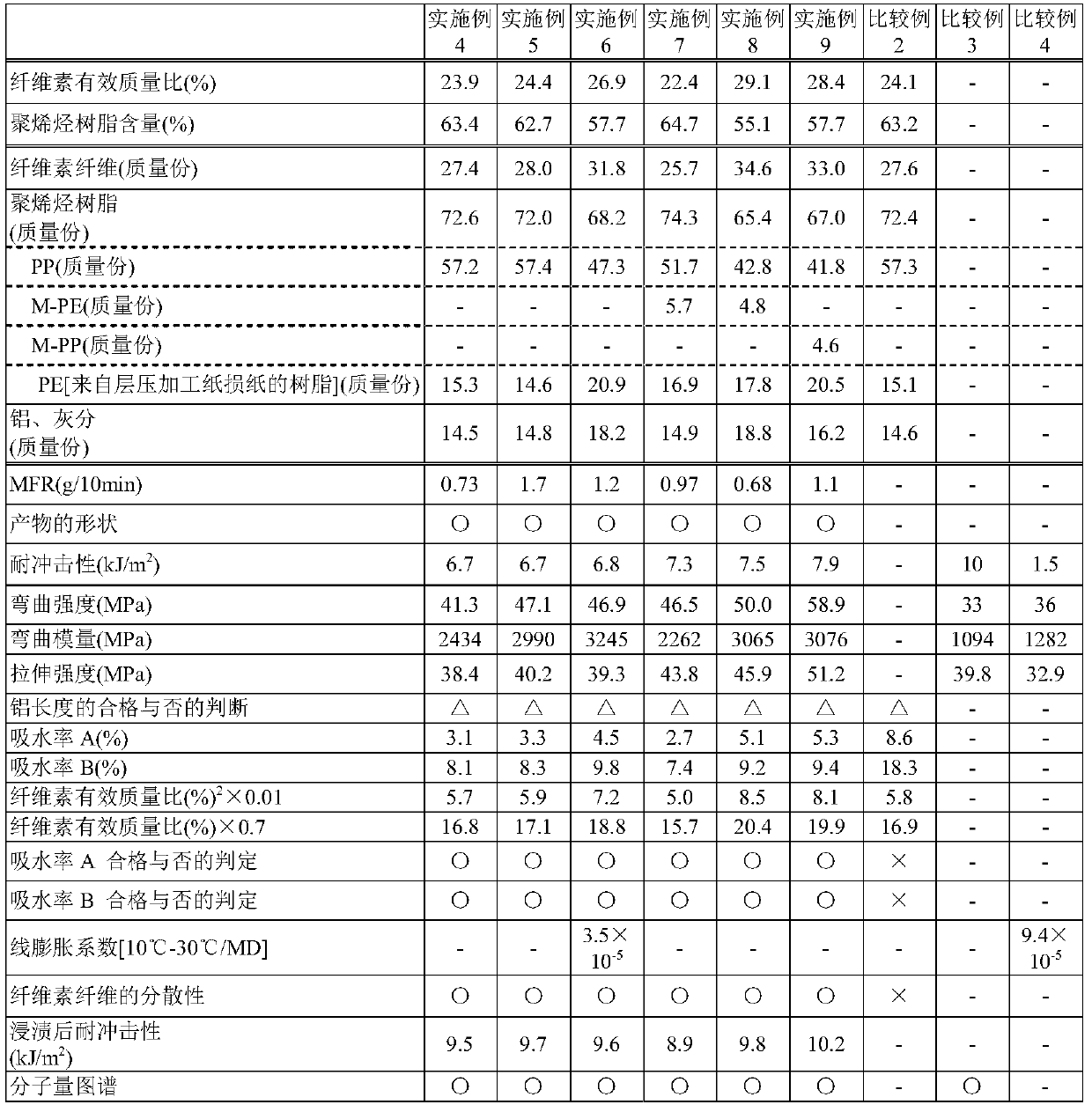

[0245] The present invention is further described based on examples, but the present invention is not limited to these aspects.

[0246] First, the measurement method and evaluation method of each index in the present invention will be described.

[0247] [Melt Flow Rate (MFR)]

[0248] The measurement was carried out in accordance with JIS-K7210 under the conditions of temperature=230° C. and load=5 kgf. The unit of MFR is "g / 10min".

[0249] [Shape of product (polyolefin resin composite material dispersed with cellulose and aluminum)]

[0250] The appearance of the cellulose fiber-dispersed polyolefin resin composite material after kneading was visually evaluated. The state of the bulk (bulk) was regarded as an acceptable product (O), and a powdery substance with a particle size of 2 mm or less, or a substance that ignited significantly after kneading was regarded as a non-acceptable product (×). The bulk specific gravity of the powdery material is small, so it is easy t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| bending strength | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com