High-nickel ternary positive electrode material coated with lithium iron phosphate nano-powder and preparation method thereof, and applications

A high-nickel ternary material, lithium iron phosphate technology, applied in the field of lithium-ion batteries, can solve problems such as restricting practical applications, short cycle life, and poor high-temperature stability, and achieve improved thermal stability, reduced contact area, and reaction conditions. mild effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Preparation of uncoated LiNi 0.6 co 0.2 mn 0.2 o 2 Ternary cathode material, comprising the following steps:

[0029] 1) Dissolve nickel sulfate, cobalt sulfate, and manganese sulfate in deionized water at a molar ratio of 6:2:2 to prepare a 1mol / L solution, and add the solution with 2mol / L sodium hydroxide and 2mol / L ammonia water at a constant speed In a 10L reactor; control the stirring reaction temperature to 50°C, control the pH of the reaction system to 10.8, control the stirring speed to 1000rmp, the stirring time to 8h, and control the nitrogen flow rate of the reaction protection gas to 10L / min. Aging for 12h after the stirring reaction ended, after filtering, washing and drying, the (Ni 0.6 co 0.2 mn 0.2 )(OH) 2 Precursor;

[0030] 2) Combine LiOH with (Ni 0.6 co 0.2 mn 0.2 )(OH) 2 Weigh 100g and 108g of the precursor and the lithiation ratio of 1:1.08, respectively, and put them into a high-speed mixer for ball milling. The speed is set at 800r / mi...

Embodiment 2

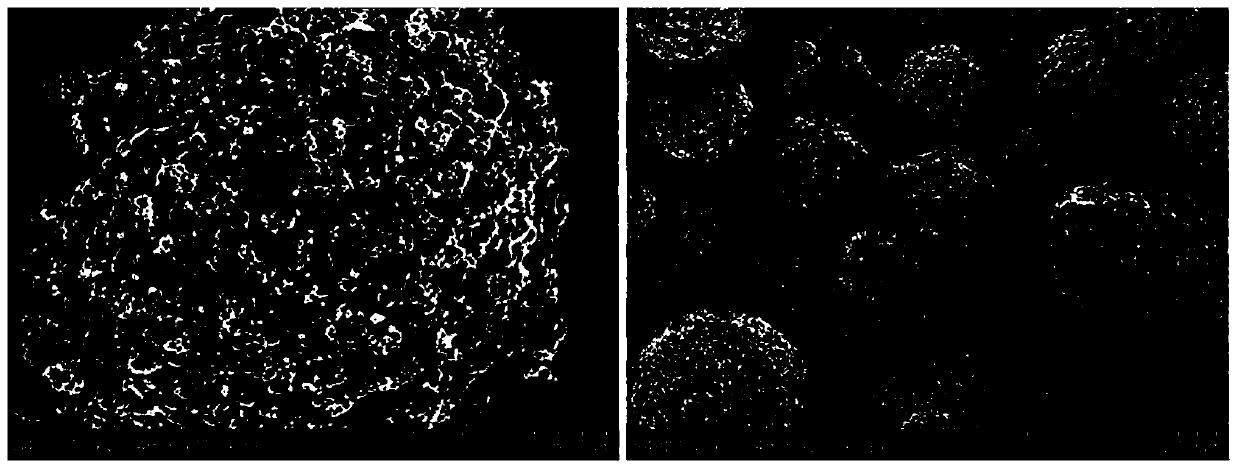

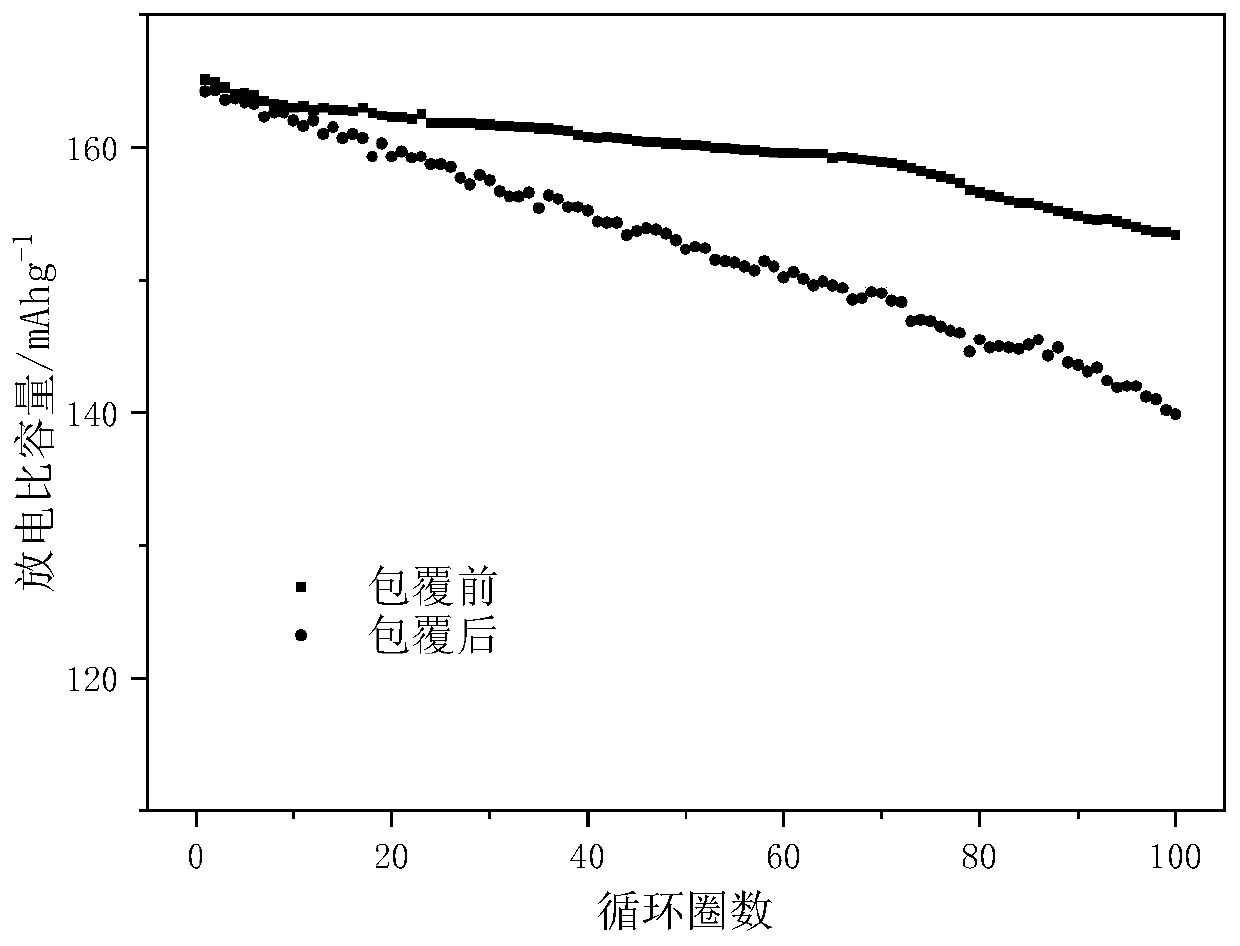

[0033] The present invention proposes a lithium-ion battery high-nickel ternary positive electrode material coated with lithium iron phosphate on the surface, comprising the following steps:

[0034] Step 1)-3) obtains the LiNi that surface does not have coating with embodiment 1 0.6 co 0.2 mn 0.2 o 2 Ternary cathode material.

[0035]4) Weigh 15.48g of PEG2000 and add it into 400ml of deionized water, and add 1g of lithium iron phosphate nanopowder into it under constant temperature stirring at 60°C, and continue stirring for 1h until a sol is formed. Take by weighing 50g step 3) LiNi prepared 0.6 co 0.2 mn 0.2 o 2 The ternary material powder is added to the obtained sol, and the mixture is obtained by stirring at 60° C. for 10 h, and the coating content of the nickel-cobalt-manganese ternary material is controlled to be 2 wt %.

[0036] 5) Dry the mixture obtained in step 4) with a spray device. Under the action of hot air at 100°C to 220°C, the volume of the colloid...

Embodiment 3

[0042] The present invention proposes a lithium-ion battery high-nickel ternary positive electrode material coated with lithium iron phosphate on the surface, comprising the following steps:

[0043] Step 1)-3) obtains the LiNi that surface does not have coating with embodiment 1 0.6 co 0.2 mn 0.2 o 2 Ternary cathode material.

[0044] 4) Weigh 15.48g of PEG2000 and add it into 400ml of deionized water, and add 1g of lithium iron phosphate nanopowder into it under constant temperature stirring at 60°C, and continue stirring for 1h until a sol is formed. Take by weighing 50g step 3) LiNi prepared 0.6 co 0.2 mn 0.2 o 2 The ternary material powder is added into the obtained sol, and the mixture is obtained by stirring at 80° C. for 10 h, and the coating content of the nickel-cobalt-manganese ternary material is controlled to be 2 wt%.

[0045] 5) Dry the mixture obtained in step 4) with a spray device. Under the action of hot air at 100-220°C, the volume of the colloid sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com