Phosphate-coated lithium cobalt oxide positive electrode material and preparation method thereof

A technology for coating lithium cobalt oxide and positive electrode materials with phosphate, applied in positive electrodes, chemical instruments and methods, cobalt compounds, etc., can solve problems such as capacity reduction, affecting storage performance, electrolyte side reactions, etc. Effects of side reactions, improved rate performance, and prevention of capacity fading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

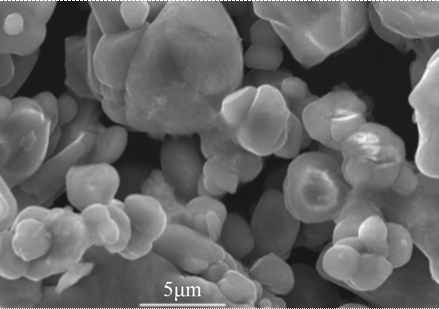

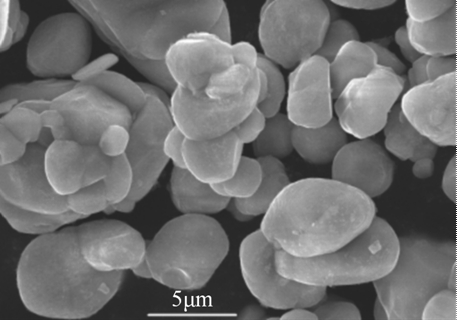

Image

Examples

Embodiment 1

[0041] This example discloses a method for preparing a polymetallic phosphate-coated lithium cobalt oxide positive electrode material. The specific steps are as follows:

[0042] (1) Phosphoric acid, strontium nitrate, lithium hydroxide, aluminum dihydrogen phosphate, tantalum nitrate and zirconium nitrate were prepared into solutions respectively, and the total molar ratio of each substance was n(Sr) : n(Li) : n(Al ) : n(Ta) : n(Zr)= 1.0: 0.85 : 0.05 :0.4 : 0.25, wherein the Li element comes from two parts, one part comes from lithium hydroxide, and the other part comes from the reduction of lithium cobaltate material before and after coating residual lithium. The total mass of the polymetallic phosphate is 2.2% of the mass of the lithium cobalt oxide cathode material matrix. Add strontium nitrate solution, lithium hydroxide solution, tantalum nitrate solution and zirconium nitrate solution into pure water, then add phosphoric acid and aluminum dihydrogen phosphate solution,...

Embodiment 2

[0055] This example discloses a method for preparing a polymetallic phosphate-coated lithium cobalt oxide positive electrode material. The specific steps are as follows:

[0056] (1) Phosphoric acid, strontium nitrate, lithium carbonate, aluminum dihydrogen phosphate, tantalum nitrate and zirconyl nitrate were respectively prepared into solutions, and the total molar ratio of each substance was n(Sr) : n(Li) : n(Al ) : n(Ta) : n(Zr) : = 1.0: 0.85 :0.05 : 0.4 : 0.25, wherein the Li element comes from two parts, one part comes from lithium hydroxide, and the other part comes from the reduction of lithium cobalt oxide material before and after coating of residual lithium. The total mass of polymetallic phosphate is 2.1% of the mass of the lithium cobalt oxide cathode material matrix. Add strontium nitrate solution, lithium carbonate solution, tantalum nitrate solution and zirconium oxynitrate solution into pure water, then add phosphoric acid and aluminum dihydrogen phosphate so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com