High-power long-circulation nickel-cobalt-manganese ternary positive electrode material and preparation method thereof

A cathode material, long-cycle technology, used in chemical instruments and methods, nickel compounds, electrical components, etc., can solve the problem of material power and cycle performance not being well balanced, affecting the service life of materials, and many surface active sites. , to achieve high power and long cycle performance, meet performance requirements, and achieve the effect of stable crystal structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

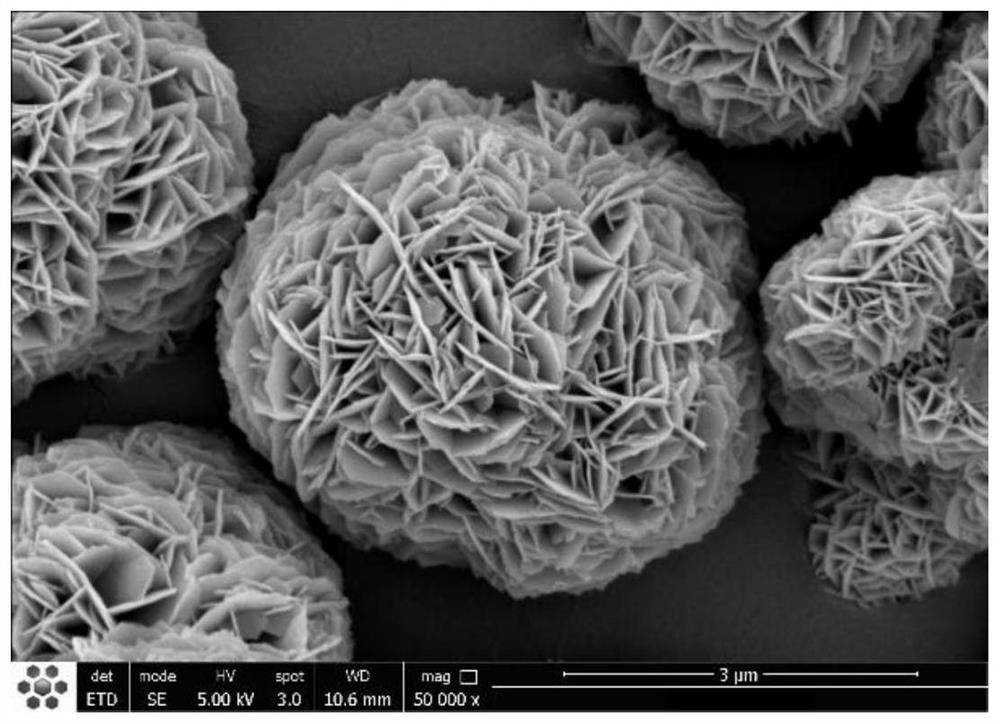

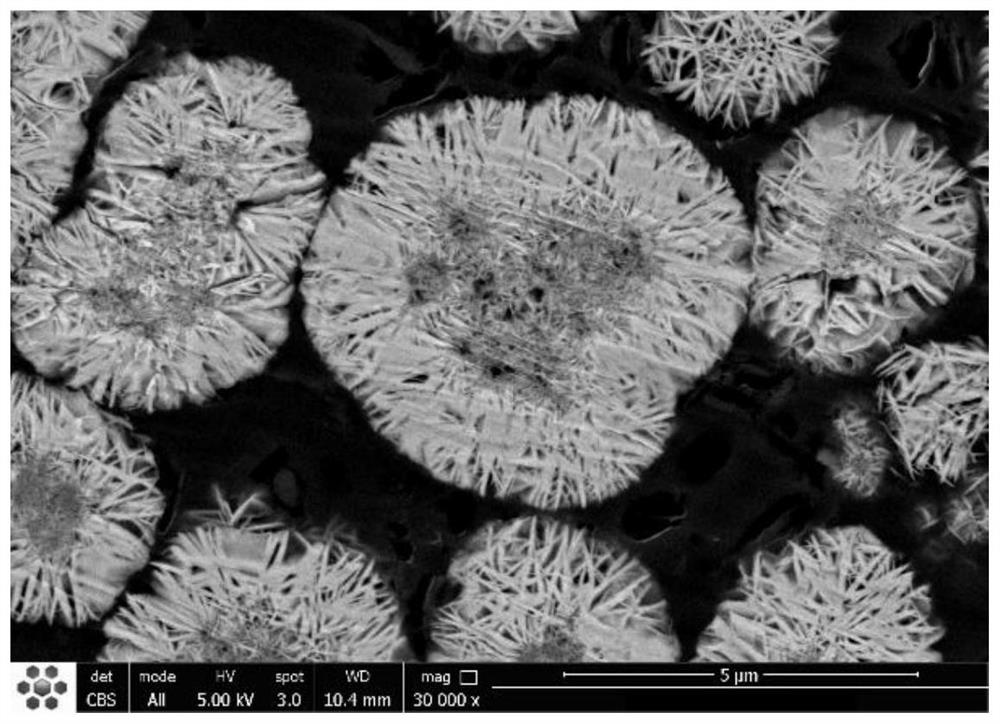

[0041] A high-power long-cycle nickel-cobalt-manganese ternary cathode material, the chemical formula is Li 1.04 Ni 0.592 Co 0.2 Mn 0.2 Zr 0.003 Ta 0.005 O 2 · 0.00075Al 2 O 3 , which is composed of secondary particles, the morphology of the primary particles constituting the secondary particles is elongated, and the primary particles are arranged radially. The D50 particle size of the secondary particles is 4.0 μm and has an inner hollow structure, and the outer wall thickness of the secondary particles is d 1 is 0.8 μm, and the wall-to-hole ratio R of the secondary particles is 0.33, where the wall-to-hole ratio R=d 1 / (D50-2d 1 ).

[0042] The grain size of the above-mentioned primary particles was 180 nm, the primary particles were dense plate-like and the aspect ratio was 4.44. The specific surface area BET of the ternary cathode material is 0.8m 2 / g.

[0043] The thickness d of the outer wall in the embodiment of the present invention 1 It is the average v...

Embodiment 2

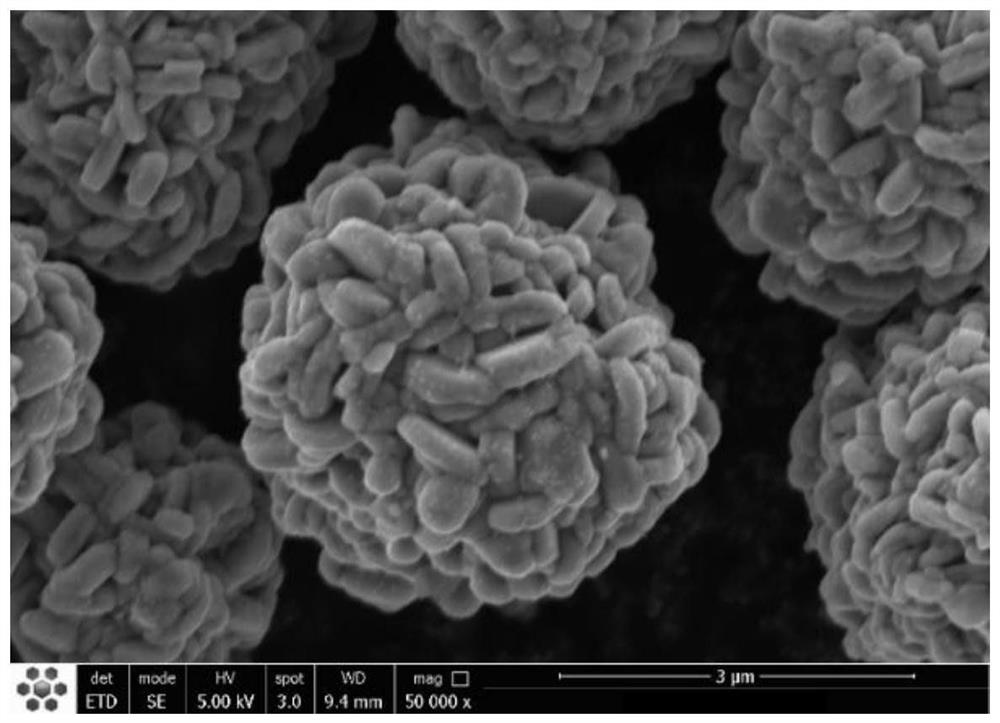

[0055] A high-power long-cycle nickel-cobalt-manganese ternary cathode material, the chemical formula is Li 1.04 Ni 0.592 Co 0.2 Mn 0.2 Zr 0.003 Ta 0.005 O 2 · 0.00075Al 2 O 3 , which is composed of secondary particles, the morphology of the primary particles constituting the secondary particles is elongated, and the primary particles are arranged radially. The D50 particle size of the secondary particles is 3.0 μm and has an inner hollow structure, and the outer wall thickness of the secondary particles is d 1 is 0.5 μm, and the wall-to-hole ratio R of the secondary particles is 0.25, where the wall-to-hole ratio R=d 1 / (D50-2d 1 ).

[0056] The grain size of the above-mentioned primary particles was 172 nm, the primary particles were dense plate-like and the aspect ratio was 2.91. The specific surface area BET of the ternary cathode material is 1.2m 2 / g.

[0057] The preparation method of high-power long-cycle nickel-cobalt-manganese ternary cathode material co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com