Preparation method of high-purity nano-lithium oxide

A lithium oxide, high-purity technology, applied in the field of chemistry, can solve problems such as environmental pollution, potential safety hazards, and long distillation time, and achieve the effects of reducing production costs, reducing safety, and improving purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

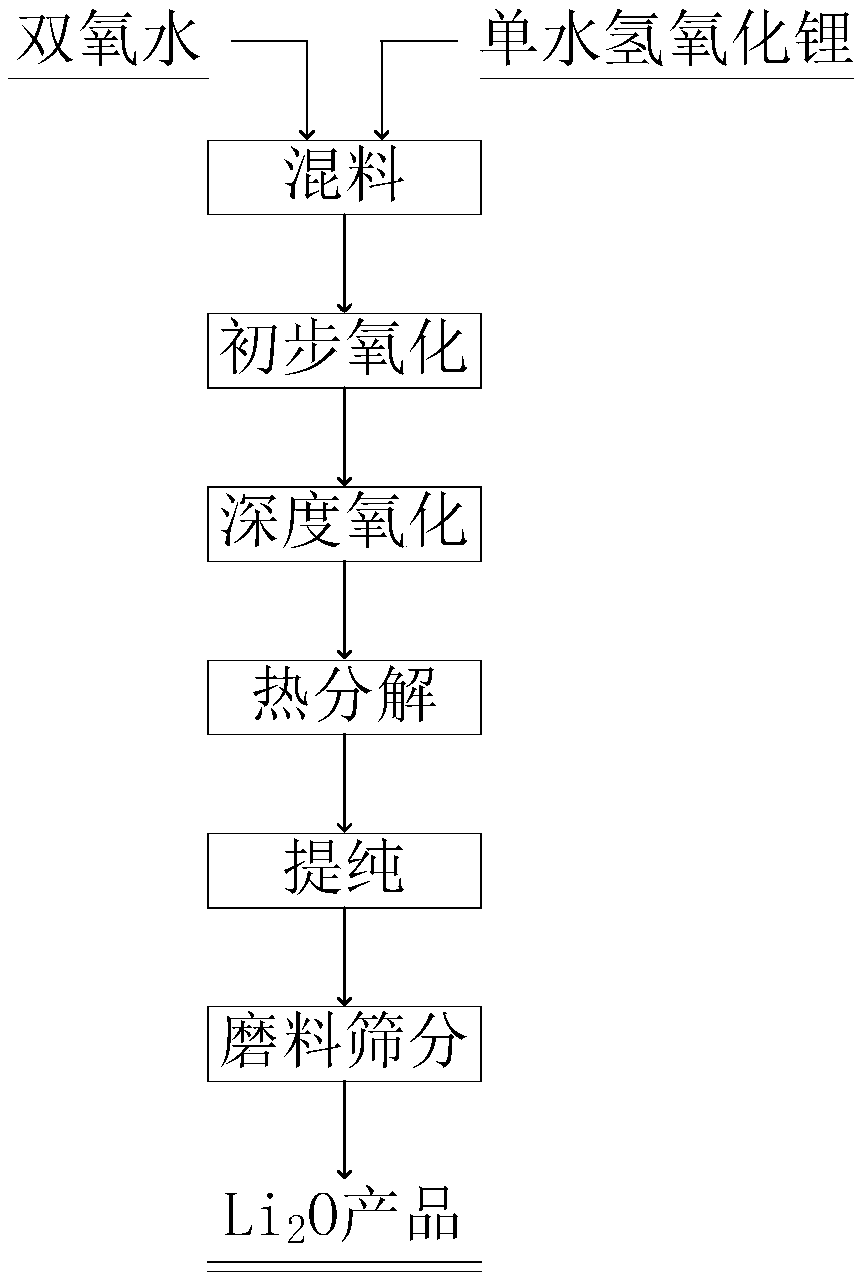

[0025] A kind of preparation method of high-purity nanoscale lithium oxide of the present invention, please refer to figure 1 , which includes the following process flow:

[0026] Mixing: adding hydrogen peroxide with a concentration of 30% into the reaction vessel and stirring, while stirring, slowly adding lithium hydroxide monohydrate with a purity of more than 99% into the reaction vessel to obtain a mixed solution, the mixed solution , calculated by weight percentage, hydrogen peroxide reacts stoichiometrically in excess of 3-20%;

[0027] Preliminary oxidation: place the reaction vessel in a vacuum drying oven, vacuumize, adjust the temperature to 80-120°C and keep it for the first predetermined time to obtain lithium peroxide containing crystal water;

[0028] Deep oxidation: continue vacuuming, adjust the temperature to 130-120°C and keep it for a second predetermined time to obtain lithium peroxide;

[0029] Thermal decomposition: continue vacuuming, adjust the temp...

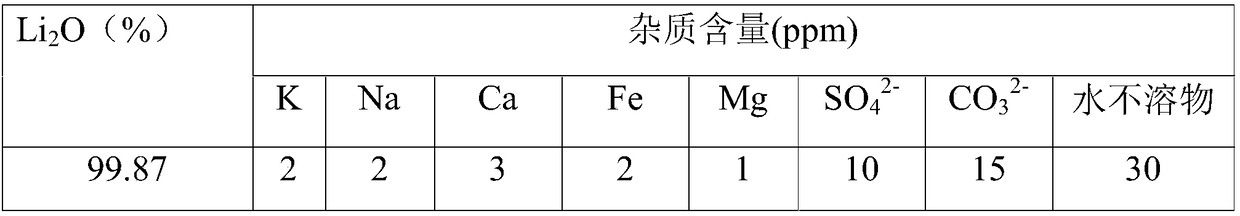

Embodiment 1

[0037] Mixing: Add 2000mL of hydrogen peroxide with a concentration of 30% into the reaction vessel and stir, while stirring, slowly add 1.6kg of lithium hydroxide monohydrate with a purity of 99.9% into the reaction vessel, and continue stirring for 3 minutes after the addition is complete A well-mixed mixed solution was obtained, and the temperature was controlled at about 25° C. by means of an ice bath during the mixing process.

[0038] Preliminary oxidation: place the reaction vessel in a vacuum drying oven, evacuate to -0.01MPa, adjust the temperature to 80°C, and keep it warm for 4 hours to obtain lithium peroxide containing crystal water;

[0039]Deep oxidation: adjust the temperature in the vacuum drying oven to 130°C, keep the vacuum at -0.01MPa, and keep it warm for 4 hours to remove crystal water to obtain lithium peroxide.

[0040] Thermal decomposition: adjust the temperature in the vacuum drying oven to 350°C, keep the vacuum degree at -0.01MPa, and keep the tem...

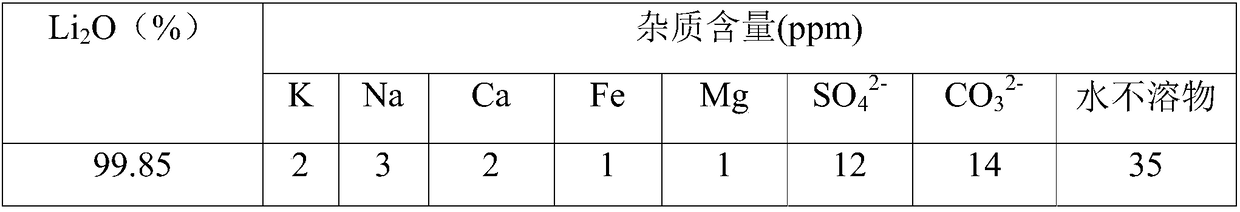

Embodiment 2

[0046] Mixing: Add 5000mL of hydrogen peroxide with a concentration of 30% into the reaction vessel and stir, while stirring, slowly add 3.6kg of lithium hydroxide monohydrate with a purity of 99.5% into the reaction vessel, and continue stirring for 5 minutes after the addition is complete Obtain a well-mixed mixed solution, and use a water bath to control the temperature at about 45°C during the mixing process

[0047] Preliminary oxidation: put the reaction vessel in a vacuum drying oven, evacuate to -0.05MPa, adjust the temperature to 120°C, and keep it warm for 1 hour to obtain lithium peroxide containing crystal water;

[0048] Deep oxidation: adjust the temperature in the vacuum drying oven to 180°C, keep the vacuum at -0.05MPa, and keep it warm for 1 hour to remove crystal water to obtain lithium peroxide.

[0049] Thermal decomposition: adjust the temperature in the vacuum drying oven to 500°C, keep the vacuum degree at -0.05MPa, and keep the temperature for 1 hour to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com