Self-supporting nitrogen-doped carbon nanotube lithium air cell cathode and preparation method thereof

A lithium-air battery, nitrogen hybrid carbon technology, applied in battery electrodes, circuits, electrical components, etc., can solve problems such as rigid failure, increase of battery charge and discharge overpotentials, lithium-air battery cycle performance and rate performance degradation, etc. Achieving good reproducibility and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] (1) Cut the foamed nickel into pole pieces with a diameter of 12 mm with a microtome, wash them alternately in absolute ethanol and deionized water for 20-30 minutes, and dry them in an oven at 70-80 ℃ for later use.

[0019] (2) Place the nickel foam pole piece in the middle of the tube furnace, and place the mixture of 50 mg ferrocene and 750 mg melamine on the top of the foam nickel pole piece near the gas inlet, and place it at 15 ℃ / min in a nitrogen atmosphere. To 550 ℃ and keep for 5 min, then at 15 ℃ / min to 650 ℃ and keep for 15 min; natural cooling to room temperature, you can get the aza-carbon nanotube pole piece, dried in a vacuum oven at 80 ℃ overnight .

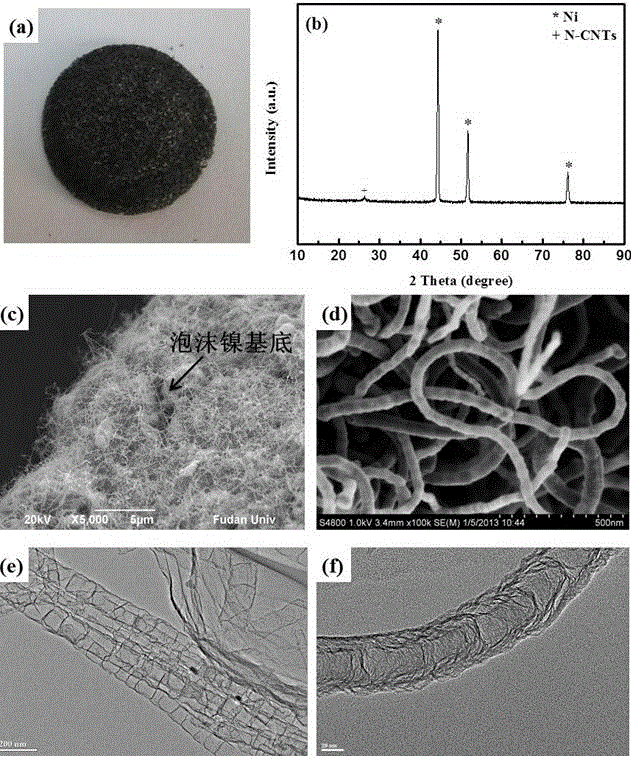

[0020] See the immediate view of the product in this embodiment figure 1 a. It can be seen from the figure that the active material (N-CNTs) formed by the CVD method uniformly covers the surface of the base foam nickel.

[0021] The X-ray diffraction data of the product of this example is shown in figure 1 b.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com