Carbon-lithium peroxide anode for lithium-air battery and preparation method of carbon-lithium peroxide anode

A lithium-air battery, lithium peroxide technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of low stability and cycle performance of lithium-air batteries, and achieve the effects of facilitating promotion, promoting crystallization, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

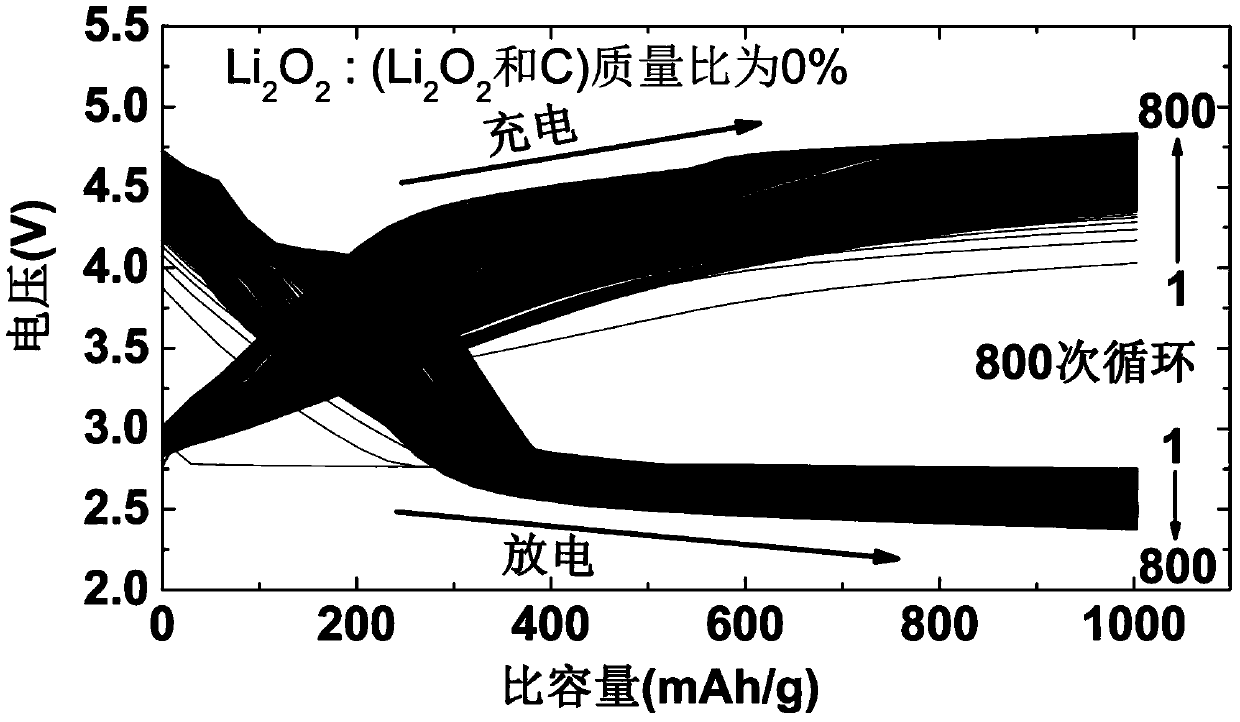

[0038] The ratio of raw materials is 9 grams of carbon, 0 grams of lithium peroxide, 1 gram of polytetrafluoroethylene, and 30 grams of N-methylpyrrolidone (the volume is about 5 times the volume of the mixture of carbon, lithium peroxide and polytetrafluoroethylene) . Firstly, using porous conductive carbon as raw material, it was manually ground with agate mortar or ball mill for 4 hours to make the porous conductive carbon particles uniform, and preliminarily make the pore size distribution reasonable, the material conductivity good and uniform, and the obtained Li 2 o 2Toner with a mass fraction of 0%. Disperse carbon powder into N-methylpyrrolidone (NMP) dispersant, then add polytetrafluoroethylene (PTFE) with a mass of 1 gram, and blend for 4 hours at a temperature of 40-80 ° C in a magnetic heating stirrer to form Viscous suspension containing all positive electrode coating materials. Disperse the viscous suspension evenly on one side of the carbon paper placed on th...

Embodiment 2

[0040] The ratio of raw materials is 7.2 grams of carbon, 1.8 grams of lithium peroxide, 1 gram of polytetrafluoroethylene, and 30 grams of N-methylpyrrolidone. First, use porous conductive carbon and lithium peroxide as raw materials, and use agate mortar to manually grind or ball mill for 4 hours to make the porous conductive carbon and lithium peroxide evenly mixed, and preliminarily make the pore size distribution reasonable and the material conductivity better And uniform, the obtained Li 2 o 2 A homogeneous mixture with a mass fraction of 20%. Disperse the mixture into N-methylpyrrolidone (NMP) dispersant, add polytetrafluoroethylene (PTFE) with a mass of 1 g, and blend for 4 hours at a temperature of 40-80 ° C in a magnetic heating stirrer to form a A viscous suspension of all positive electrode coating materials. Disperse the viscous suspension evenly on one side of the carbon paper placed on the vacuum plate, use strong wind to heat and be driven by an automatic co...

Embodiment 3

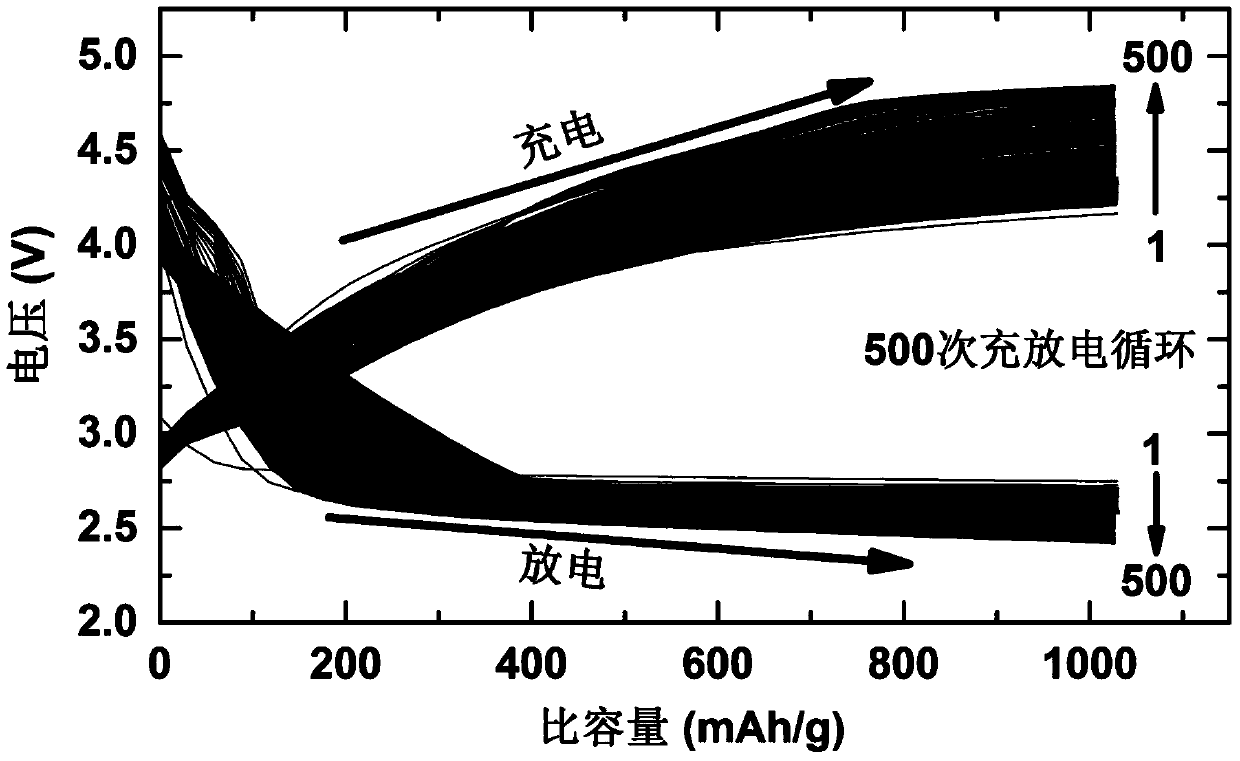

[0042] The ratio of raw materials is 5.4 grams of carbon, 3.6 grams of lithium peroxide, 1 gram of polytetrafluoroethylene, and 30 grams of N-methylpyrrolidone. First, use porous conductive carbon and lithium peroxide as raw materials, and use agate mortar to manually grind or ball mill for 4 hours to make the porous conductive carbon and lithium peroxide evenly mixed, and preliminarily make the pore size distribution reasonable and the material conductivity better And uniform, the obtained Li 2 o 2 A homogeneous mixture with a mass fraction of 40%. Disperse the mixture into N-methylpyrrolidone (NMP) dispersant, add polytetrafluoroethylene (PTFE) with a mass of 1 g, and blend for 4 hours at a temperature of 40-80 ° C in a magnetic heating stirrer to form a A viscous suspension of all positive electrode coating materials. Disperse the viscous suspension evenly on one side of the carbon paper placed on the vacuum plate, use strong wind to heat and be driven by an automatic co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| open-circuit voltage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com