Carbon-supported noble metal oxide bifunctional catalyst and preparation method and application thereof

A technology of noble metal oxides and bifunctional catalysts, which is applied in the direction of fuel cell half-cells and secondary battery-type half-cells, electrical components, battery electrodes, etc. good, poor rate performance, etc., to achieve the effect of improved bifunctional catalytic activity, stable cycle performance, and promotion of formation and decomposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

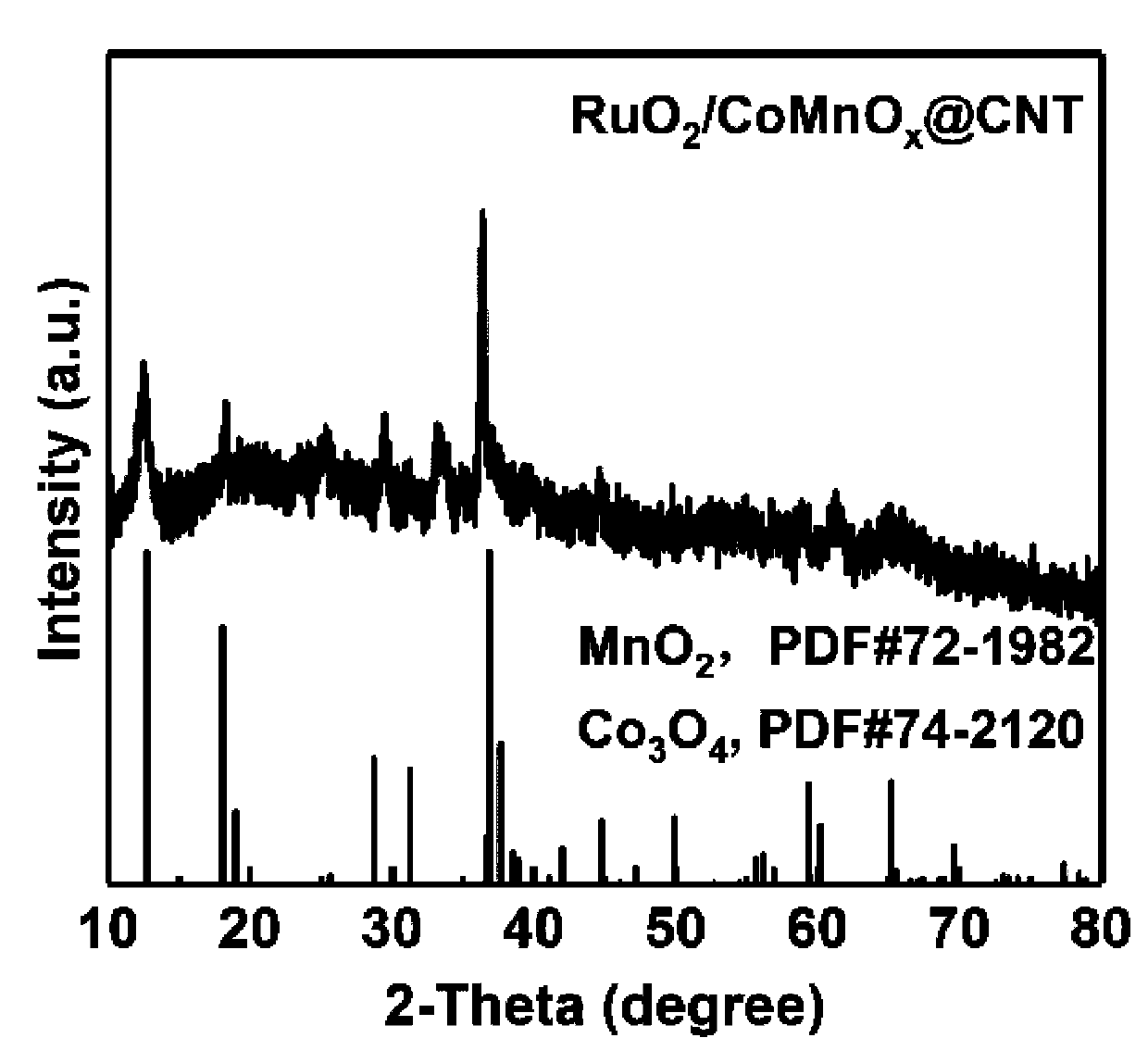

[0038] A method for preparing a carbon-supported noble metal oxide bifunctional catalyst, comprising the steps of:

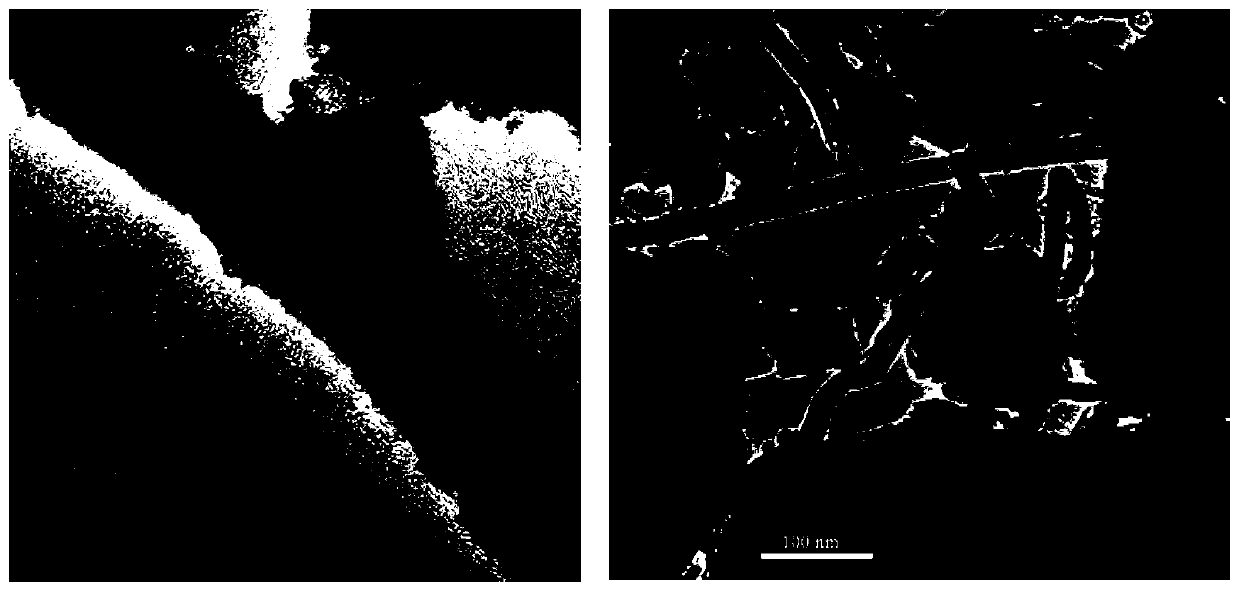

[0039] (1) ultrasonically disperse 25 mg of carbon nanotubes (CNT) in 40 mL of deionized water;

[0040] (2) at room temperature, add 1mmol KMnO to the material obtained in step (1) 4 and 1 mmol CoSO 4 , after fully stirring, put it in a 50mL polytetrafluoroethylene hydrothermal reaction kettle for hydrothermal reaction at 120°C for 5h;

[0041] (3) After naturally cooling the material obtained in step (2), carry out 9000rpm centrifugal washing to separate CoMnO x @CNT, then vacuum dried at 80°C for 10 hours to remove moisture;

[0042] (4) 30mg RuCl 3 Dissolve in 40mL deionized water, then add 100mg of the material obtained in step (3), and carry out ultrasonic dispersion for 30min;

[0043] (5) Add 1mol / L NaOH aqueous solution dropwise to the material obtained in step (4) to pH = 11, then stir at room temperature, and then place it in a 50mL polytetrafluo...

Embodiment 2

[0046]The carbon-supported noble metal oxide bifunctional catalyst prepared in Example 1, conductive acetylene black and binder LA132 (5000cp, 14.9%) were mixed in a mass ratio of 8:1:1, and then mixed with water and isopropanol. The homogeneous slurry was evenly coated on carbon cloth, and vacuum-dried at 90° C. for 12 hours to obtain a lithium-oxygen battery cathode sheet. The prepared lithium-oxygen battery cathode pole piece was assembled with a Li metal anode in an Ar-protected glove box to form a 2025 button battery, and the electrochemical performance was tested.

[0047] The lithium-oxygen battery prepared in this example is an experimental battery, which is used for the performance test of the following effect examples:

[0048] At a current density of 50mA g -1 , with a cut-off capacity of 500mAh g -1 The charge-discharge cycle curve below.

[0049] At a current density of 200mA g -1 , with a cut-off capacity of 500mAh g -1 The charge-discharge cycle curve below...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com