Method and device for preparing fertilizer from kitchen garbage

A kitchen waste and fertilizer technology, applied in organic fertilizer, waste fuel, climate change adaptation, etc., can solve the problem of high processing cost, achieve the effect of short time, high efficiency and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

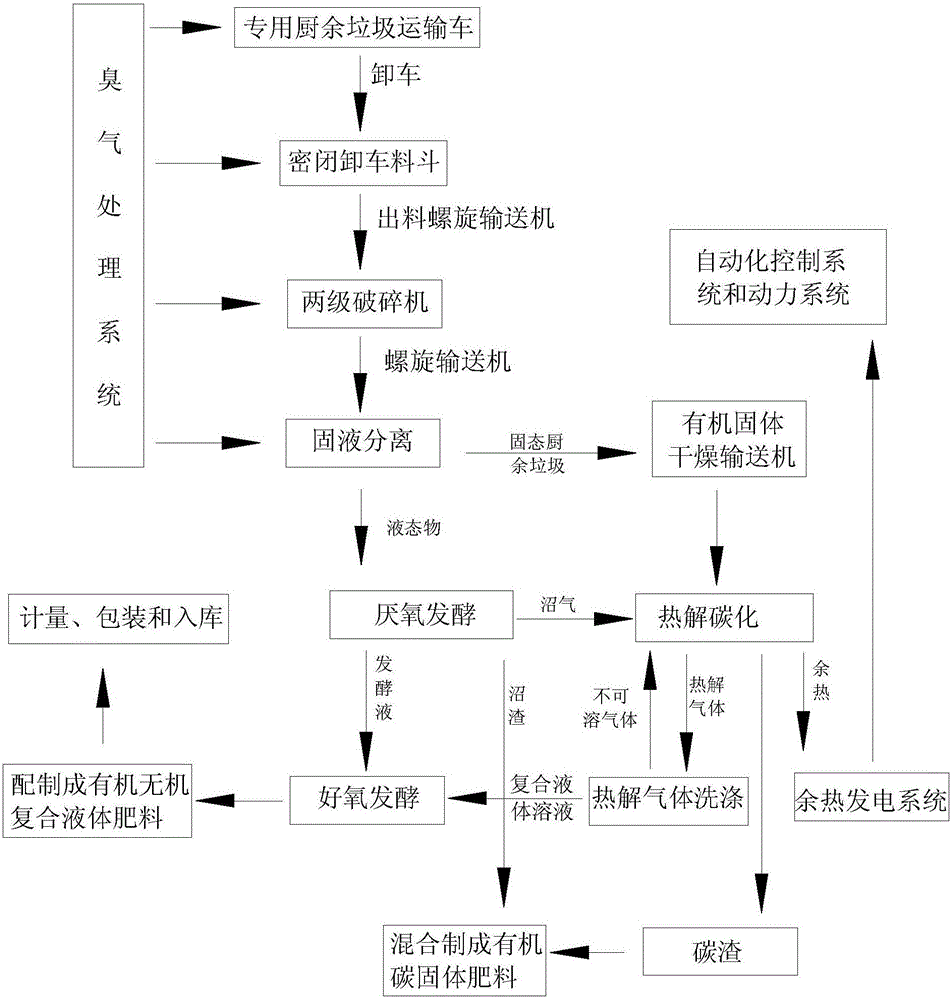

[0042]A method of using kitchen waste to make fertilizer. The kitchen waste is unloaded from a special kitchen waste transport vehicle and loaded into a closed unloading hopper, and then transported to a two-stage crusher by a discharge screw conveyor for crushing, and then enters the extrusion process. type solid-liquid separator for solid-liquid separation to obtain solid kitchen waste and liquid, preferably, the solid kitchen waste is an organic solid, and the liquid is an organic liquid; the solid kitchen waste and the organic liquid are separated resource processing. The present invention is also equipped with an odor treatment system to treat the odor generated by the special kitchen waste transport vehicle, the closed unloading hopper, the two-stage crusher and the whole process of solid-liquid separation.

[0043] Pyrolysis and carbonization of the separated solid kitchen waste to obtain pyrolysis gas and carbon slag, preferably, the carbon slag is biochar;

[0044] T...

Embodiment 2

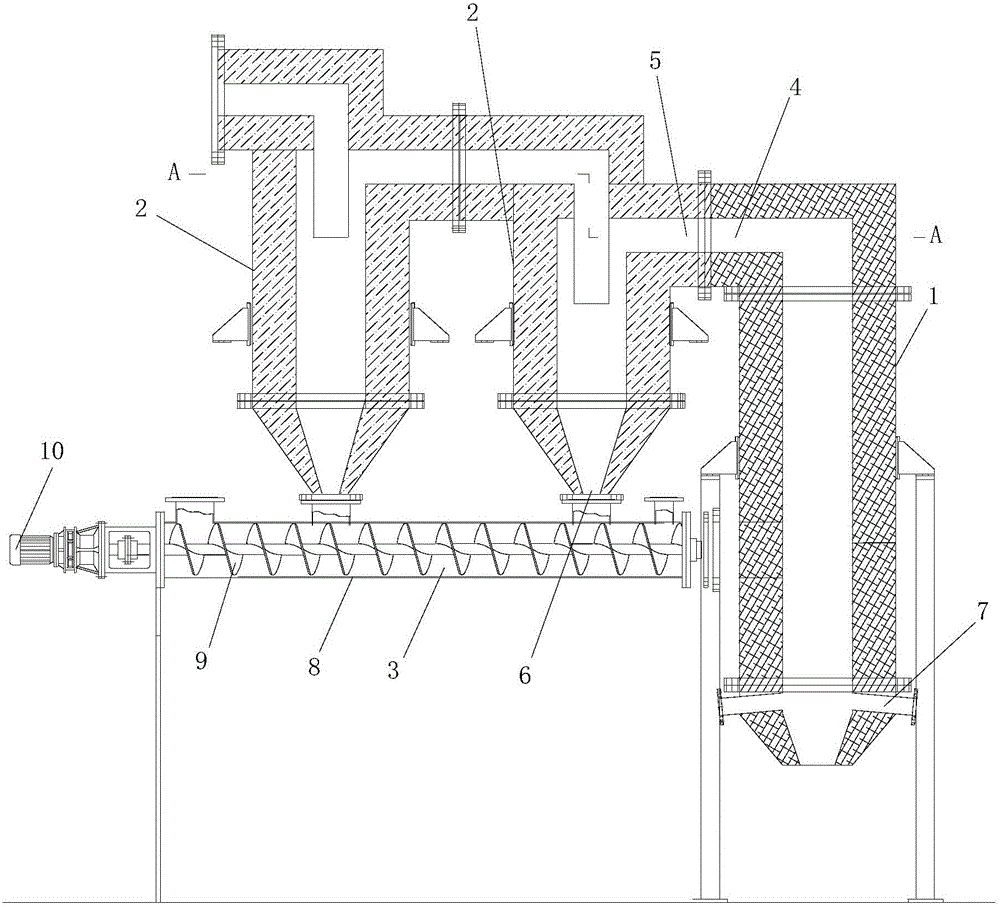

[0054] A pyrolytic carbonization furnace for realizing pyrolytic carbonization in the method for producing fertilizer from kitchen waste described in Embodiment 1, comprising a furnace body 1, a cyclone dedusting furnace 2 and a material conveying device 3, the pyrolysis of the furnace body The gas outlet 4 communicates with the air inlet 5 of the cyclone dust removal furnace, the discharge port 6 of the cyclone dust removal furnace is connected to the material conveying device, and the feeding port of the material conveying device is connected with the feed inlet of the furnace body.

[0055] Preferably, the lower part of the furnace body is inclined upwards with a burner installation opening 7, preferably, the burner installation opening is inclined upwards by 3-10°, more preferably, the burner installation opening is inclined upwards by 5°.

[0056] Preferably, there are multiple burner installation ports, which are respectively opened at equal angles around the circumferent...

Embodiment 3

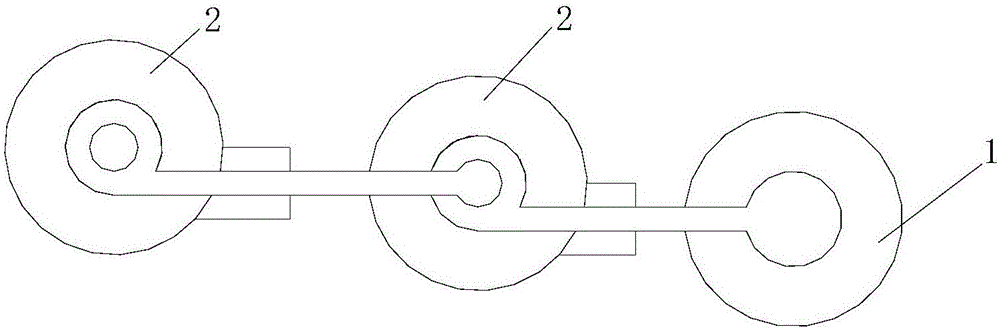

[0070] A conveyor for transporting solid kitchen waste to an organic solid drying conveyor for pyrolysis and carbonization in the method for making fertilizer from kitchen waste described in Embodiment 1, including a conveying pipe 11, a spiral conveying blade 12 and passing through The driving mechanism 13 that drives the spiral conveying blade to rotate and push the material, and the spiral conveying blade is arranged in the conveying pipe.

[0071] Preferably, a material inlet 16 , a material outlet 17 and a steam outlet 18 are provided on the conveying pipe.

[0072] Preferably, there are multiple organic solid drying conveyors, and the material outlets of two adjacent organic solid drying conveyors are connected to the material inlet.

[0073] Preferably, it also includes a body heat medium jacket 14 surrounding the outer surface of the delivery pipe, and a sealed heat medium space 15 is formed between the delivery pipe and the body heat medium jacket, and the heat medium...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com