Method for electrochemically preparing graphene

A graphene and electrochemical technology, applied in the field of electrochemical preparation of graphene, to achieve the effects of high production efficiency, good economy, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] A method for electrochemically preparing graphene, comprising the steps of:

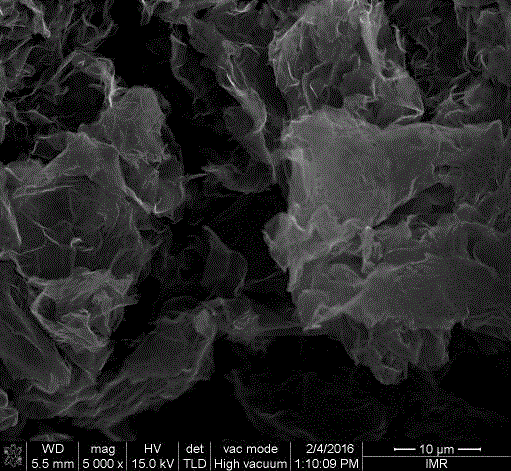

[0044] (1) Use graphite paper as the positive electrode, graphite plate as the negative electrode, and the aqueous solution of the intercalation agent as the electrolyte, and use an electrochemical method to intercalate the graphite paper under the condition of a current density of 0.1mA / g; intercalation After layering is completed, take out the intercalated graphite paper, also in the electrolyte, under the condition of a voltage of 2V, immerse the intercalated graphite paper in the electrolyte at a speed of 1mm / min to expand, after the expansion is completed The porous and worm-like expanded graphite particles suspended in the electrolyte are obtained. Among them, the intercalation process and the expansion process are carried out in the same electrolyte, which greatly simplifies the preparation process.

[0045] The intercalation agent in this step includes a main intercalation agent, and ...

Embodiment 2

[0050] A method for electrochemically preparing graphene, comprising the steps of:

[0051] (1) Use graphite paper as the positive electrode, graphite plate as the negative electrode, and the aqueous solution of the intercalation agent as the electrolyte, and use electrochemical methods to intercalate the graphite paper under the condition of a current density of 30mA / g, and the intercalation is completed Finally, take out the intercalated graphite paper, also in the electrolyte, under the condition of a voltage of 20V, immerse the intercalated graphite paper in the electrolyte at a speed of 5mm / min to expand, and obtain a suspension after the expansion is completed. In the electrolyte, the surface is loose, porous, and worm-like expanded graphite particles. Among them, the intercalation process and the expansion process are carried out in the same electrolyte, which greatly simplifies the preparation process.

[0052] The intercalation agent in this step includes a main inte...

Embodiment 3

[0056] A method for electrochemically preparing graphene, comprising the steps of:

[0057] (1) Use graphite paper as the positive electrode, graphite plate as the negative electrode, and the aqueous solution of the intercalation agent as the electrolyte, and use an electrochemical method to intercalate the graphite paper under the condition of a voltage of 0.5V. After the intercalation is completed , take out the intercalated graphite paper, also in the electrolyte, under the condition of a voltage of 3V, immerse the intercalated graphite paper in the electrolyte at a speed of 20mm / min to expand, after the expansion is completed, the suspension in In the electrolyte, the surface is loose, porous, and worm-like expanded graphite particles. Among them, the intercalation process and the expansion process are carried out in the same electrolyte, which greatly simplifies the preparation process.

[0058] The intercalation agent in this step includes a main intercalation agent, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com