Two-stroke diesel engine admission passage

A technology for air intakes and diesel engines, applied in mechanical equipment, engine components, combustion engines, etc., can solve problems such as uneven intake and exhaust, achieve uniform pressure distribution, high intake flow rate, and meet design requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

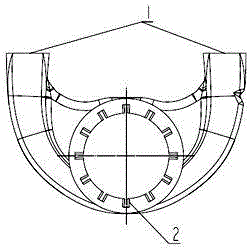

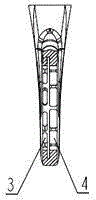

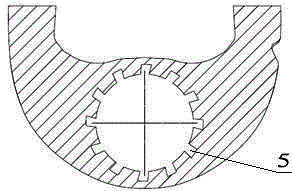

[0012] Such as figure 1 As shown, a two-stroke diesel engine intake port, the intake port is a symmetrical volute structure, the two sides of the volute structure are intake pipes 1 for airflow to enter, and the inside of the intake pipe 1 is a rounded structure. The middle part of the volute structure of the air inlet is provided with a vortex air intake row 3 and a direct current air intake row 4, the vortex air intake row 3 and the direct current air intake row 4 communicate with the intake pipes 1 on both sides of the volute structure, and the vortex air intake The air exhaust 3 and the direct-flow air inlet row 4 form the air outlet 2, wherein the vortex air inlet row 3 is provided with 12 first air ports 5 along the circumference, and the direct-flow air intake row 4 is provided with 12 second air ports 6 along the circumference, and the first air port The angle between 5 and the tangent line in the circumferential direction is 8°, the angle between every two first air p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com