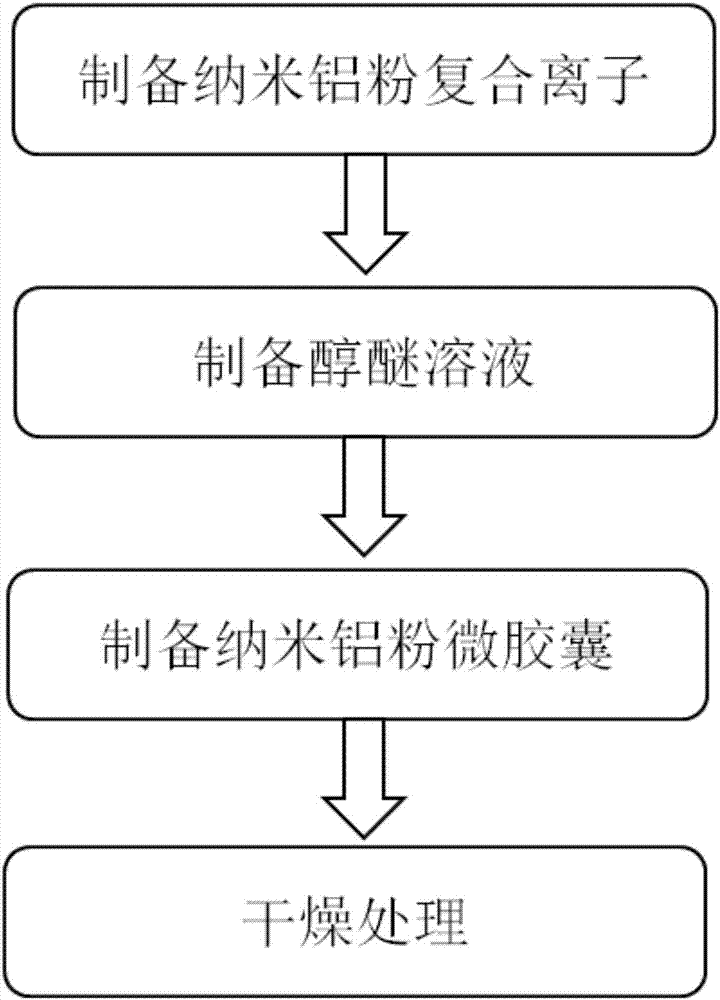

Coating method of nano-aluminum powder

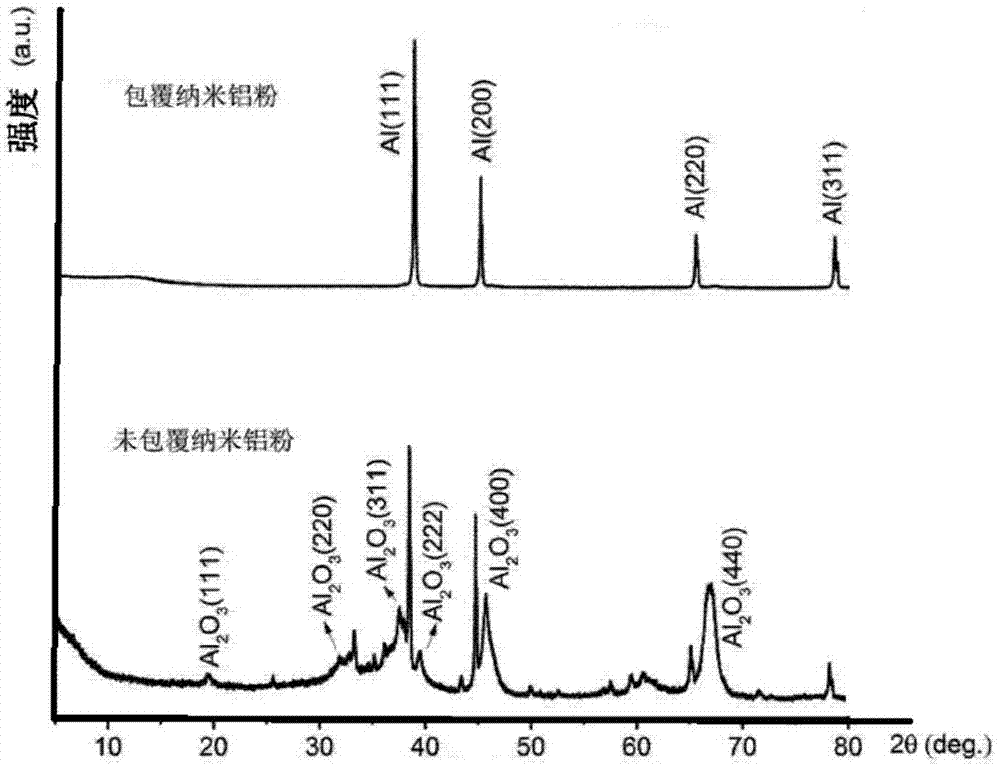

A nano-aluminum powder and coating technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problem of easy oxidation and deactivation of nano-aluminum powder, decrease of active aluminum content, preparation and storage difficulties and other problems, to achieve the effect of convenient operation, guaranteed metal activity, and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0018] 1. Preparation of precursors. Disperse 4.6mmol of anhydrous AlCl3 into 60mL of toluene solution, weigh 4.0g of N(Et)3 (39mmol), and add it dropwise to the above solution. After the solid AlCl3 in the reaction bottle completely disappears, slowly add a certain amount of A large amount of LiAl H4 was reacted for 16 hours, then centrifuged, and the supernatant was the precursor Al H3 N(Et)3 solution, and the LiCl in the precursor was extracted and removed with an appropriate amount of ice methanol (0°C). The reaction equation is as follows:

[0019] AlCl 3 +N(Et) 3 →AlCl 3 ·N(Et) 3 ,

[0020] AlCl 3 ·N(Et) 3 +3N(Et) 3 +3LiAlH 4 →4AlH 3 ·N(Et) 3 +3LiCl↓

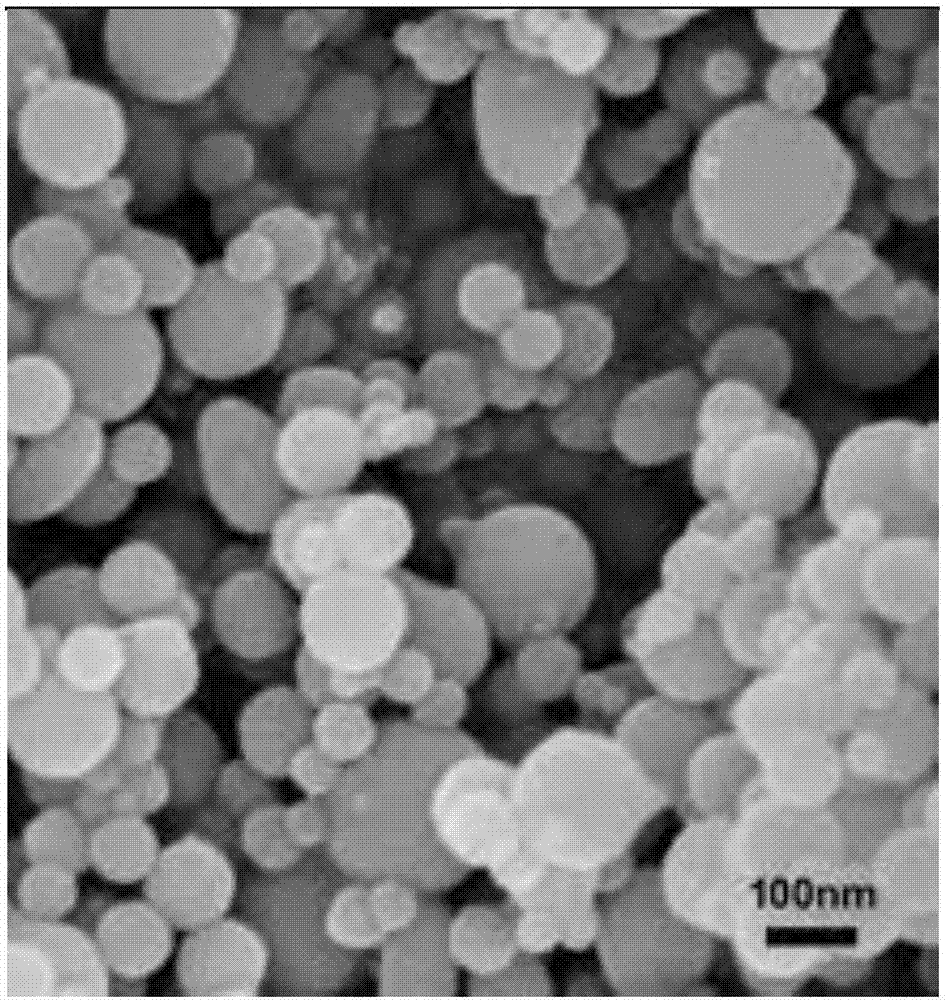

[0021] 2. Catalytic decomposition of precursors to prepare nano-aluminum powder. Pour 60mL of the precursor into a three-necked flask, connect the double-row pipes, vacuumize the system, and circulate argon for 3 times, then heat the solution to a certain temperature, add an appropriate amount of catalyst Ti(O...

Embodiment 1

[0027] Mix 100g of absolute ethanol and 100g of ether to prepare 200g of alcohol ether solution.

[0028] Pour the prepared alcohol ether solution into a stirrer, pour 200g of nano-scale aluminum powder into the stirrer, and stir at room temperature for 1 hour.

[0029] Take out the mixture of aluminum powder and alcohol ether solution that has been stirred, place it on a tray and spread it out.

[0030] Put the spread mixture into a vacuum drying oven, set the drying temperature to 35° C., and dry for 2 hours, then vacuumize to a vacuum degree of -0.07 Mpa, and start the drying oven. Prepare coated nano-aluminum powder, the quality is 202g.

Embodiment 2

[0032] Mix 500g of absolute ethanol and 500g of ether to prepare 1kg of alcohol ether solution.

[0033] Pour the prepared alcohol ether solution into a stirrer, take 1 kg of nano-scale aluminum powder into the stirrer, and stir at room temperature for 2 hours.

[0034] Take out the mixture of aluminum powder and alcohol ether solution that has been stirred in the second step, place it on a tray and spread it out.

[0035] Put the spread mixture into a vacuum drying oven, set the drying temperature to 40° C., and set the drying time to 3 hours. Then, vacuumize to a vacuum degree of -0.07 Mpa, and start the drying oven. Prepare coated nano-aluminum powder with a mass of 1.01 kg.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com