Vehicle low-carbon biodiesel

A technology for biodiesel and vehicles. It is applied in the petroleum industry, liquid carbon-containing fuels, and fuels. It can solve the problems of engine cylinder wear, low-carbon low-carbon biodiesel for vehicles, difficulty in starting at low temperature, and corrosion, so as to reduce carbon deposits. , Oxygen rich effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0036] The composition of the prepared fuel and parts by weight thereof are as follows:

[0037] 25.21 parts of methanol, 2 parts of butanol, 3 parts of octanol, 18.05 parts of oleic acid, 37.1 parts of 0# diesel oil, 14 parts of 200# solvent oil, 0.05 parts of N, N'-diisobutylphenylenediamine, petroleum sulfonic acid 0.2 part of sodium, 0.1 part of copper naphthenate, 0.04 part of alkyl acid amine, 0.06 part of ethylene glycol methyl ether, 0.05 part of fatty acid chromium calcium salt mixture, 0.03 part of polyethylene vinyl acetate (T1804), N, N'- 0.05 part of disalicylidene-1,2-propanediamine, 0.08 part of alkyl nitrate.

[0038] At normal temperature and pressure, first mix 25.21 parts of methanol, 18.05 parts of oleic acid, 2 parts of butanol and 3 parts of octanol, then add 0.05 parts of N, N'-diisobutylphenylenediamine, 0.2 parts of petroleum sulfonate Naphthenic acid sodium, 0.1 parts of copper naphthenate are stirred evenly and poured into the blending tank, and the...

example 2

[0043] The prepared fuel composition and parts by weight thereof are as follows:

[0044] 18.21 parts of methanol, 2 parts of butanol, 3 parts of octanol, 17.05 parts of oleic acid, 49.1 parts of 0# diesel oil, 10 parts of 200# solvent oil, 0.05 parts of N, N'-diisobutylphenylenediamine, petroleum sulfonic acid 0.2 part of sodium, 0.2 part of copper naphthenate, 0.04 part of alkyl acid amine, 0.06 part of ethylene glycol methyl ether, 0.05 part of fatty acid chromium calcium salt mixture, 0.03 part of polyethylene vinyl acetate (T1804), N, N'- 0.05 part of disalicylidene-1,2-propanediamine, 0.08 part of alkyl nitrate.

[0045] Under normal temperature and pressure, first mix 18.21 parts of methanol, 17.05 parts of oleic acid, 2 parts of butanol and 3 parts of octanol, then add 0.05 parts of N, N'-diisobutylphenylenediamine and 0.2 parts of sodium petroleum sulfonate , 0.2 parts of copper naphthenate and stir evenly into the blending tank, then mix 10 parts of 200# solvent oil...

Embodiment 2

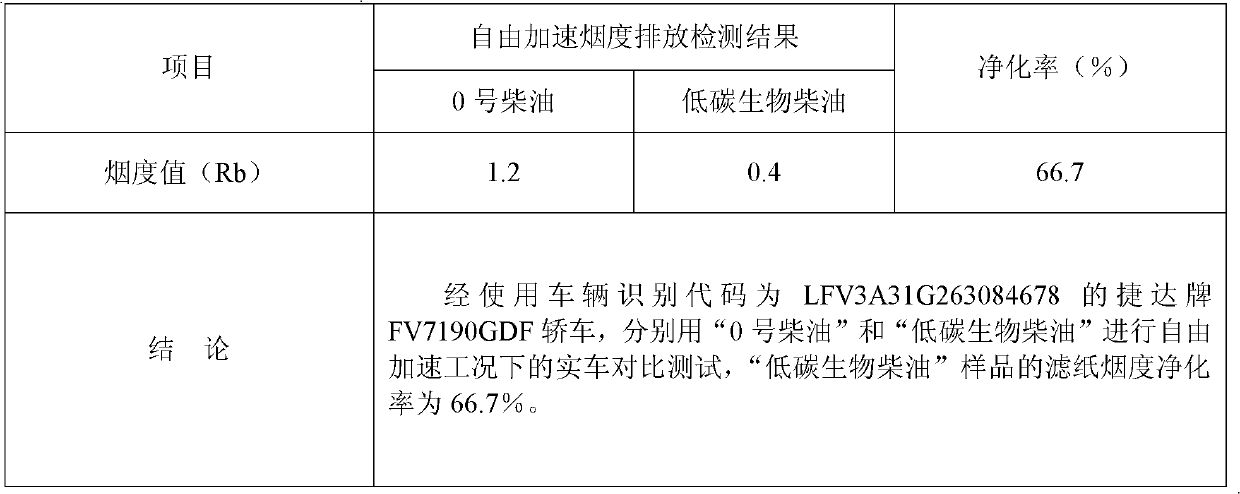

[0049] The motor vehicle exhaust detection data of embodiment 2 fuel:

[0050] Test unit: Guangzhou Motor Vehicle Emission Monitoring Center of the State Environmental Protection Administration

[0051] Test basis: GB 3847-2005 "Vehicle compression ignition engine and compression ignition engine vehicle exhaust smoke emission limits and measurement methods"

[0052] On the same Jetta FV7190GDF car, "0# diesel" was used for exhaust detection, and then "low-carbon biodiesel" was used for comparative exhaust detection. The test results are shown in Table 3.

[0053] Table 3 Comparison of test results

[0054]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com