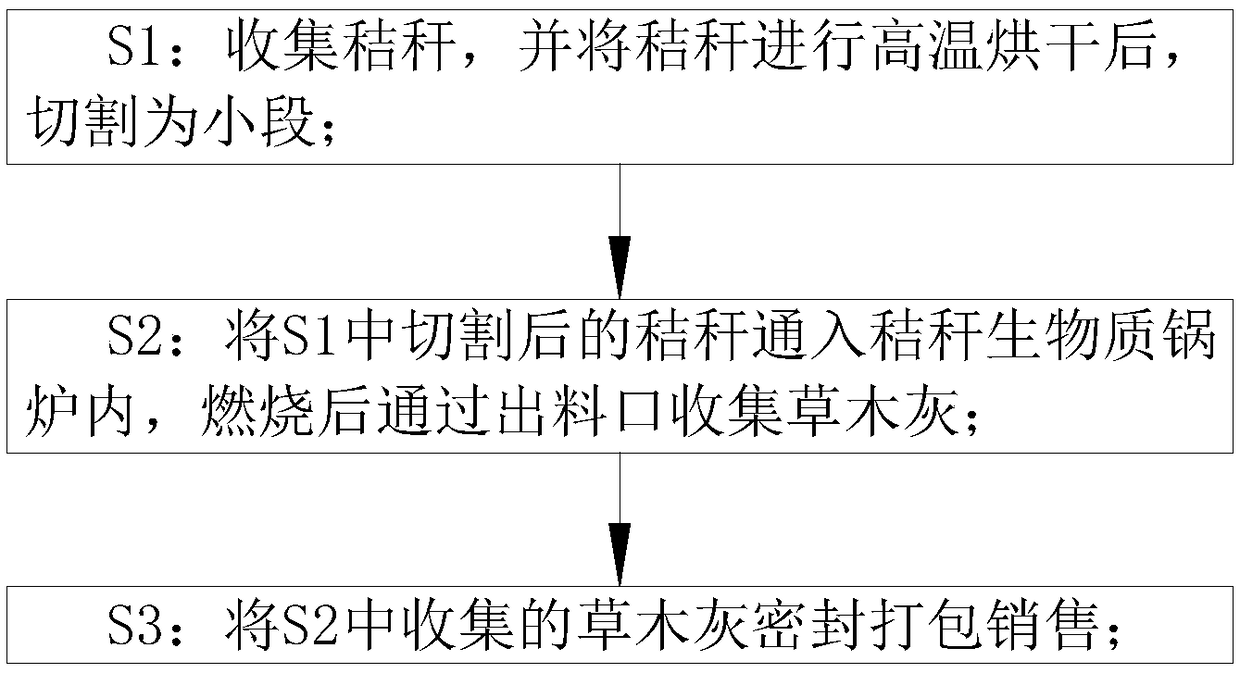

Biomass fertilizer preparation process

A production process and biomass technology, applied in inorganic fertilizers, potash fertilizers, fertilization devices, etc., can solve the problems of low combustion rate, unburnable straw, energy waste, etc., to improve combustion efficiency, increase oxygen content, and speed up combustion efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

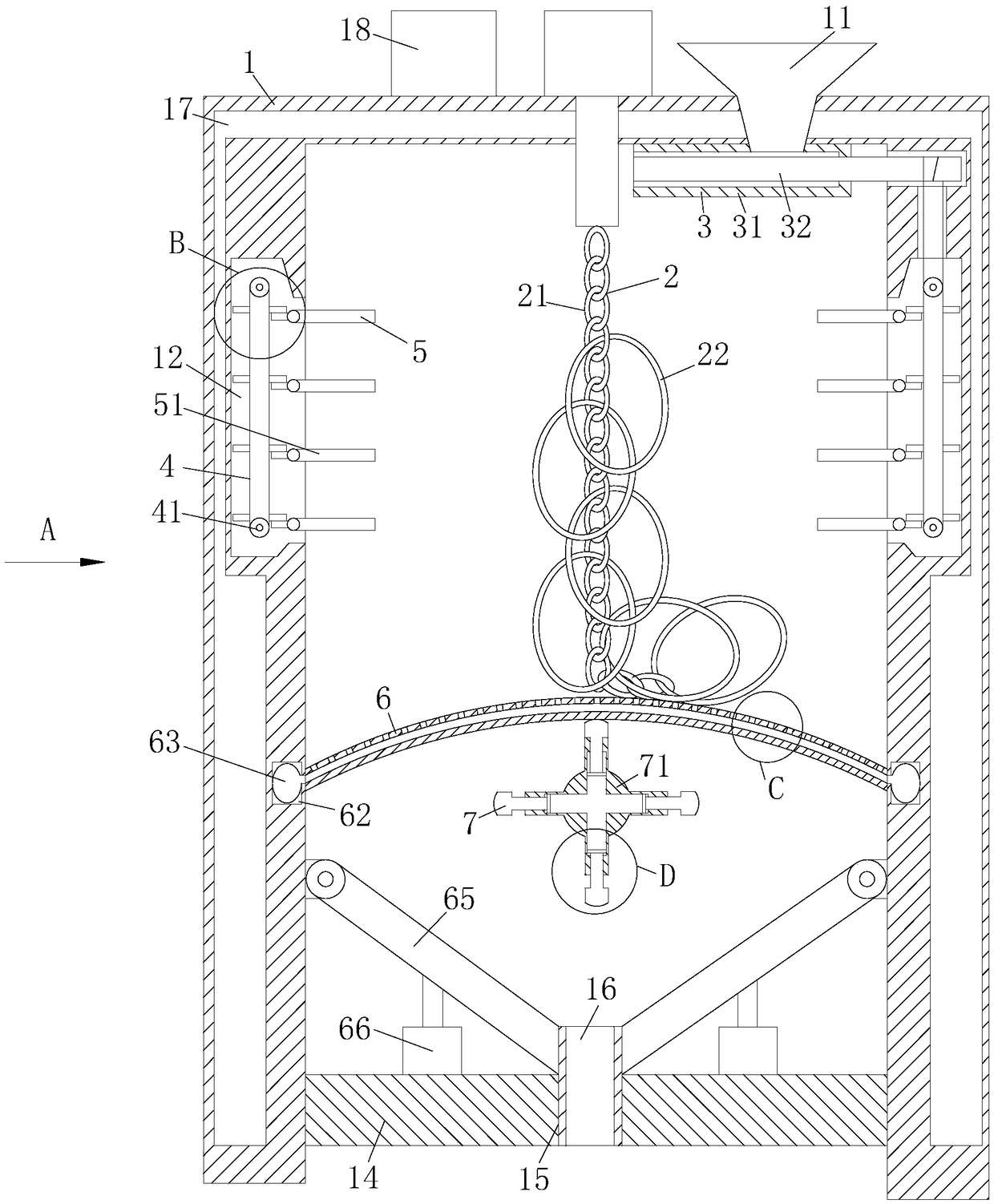

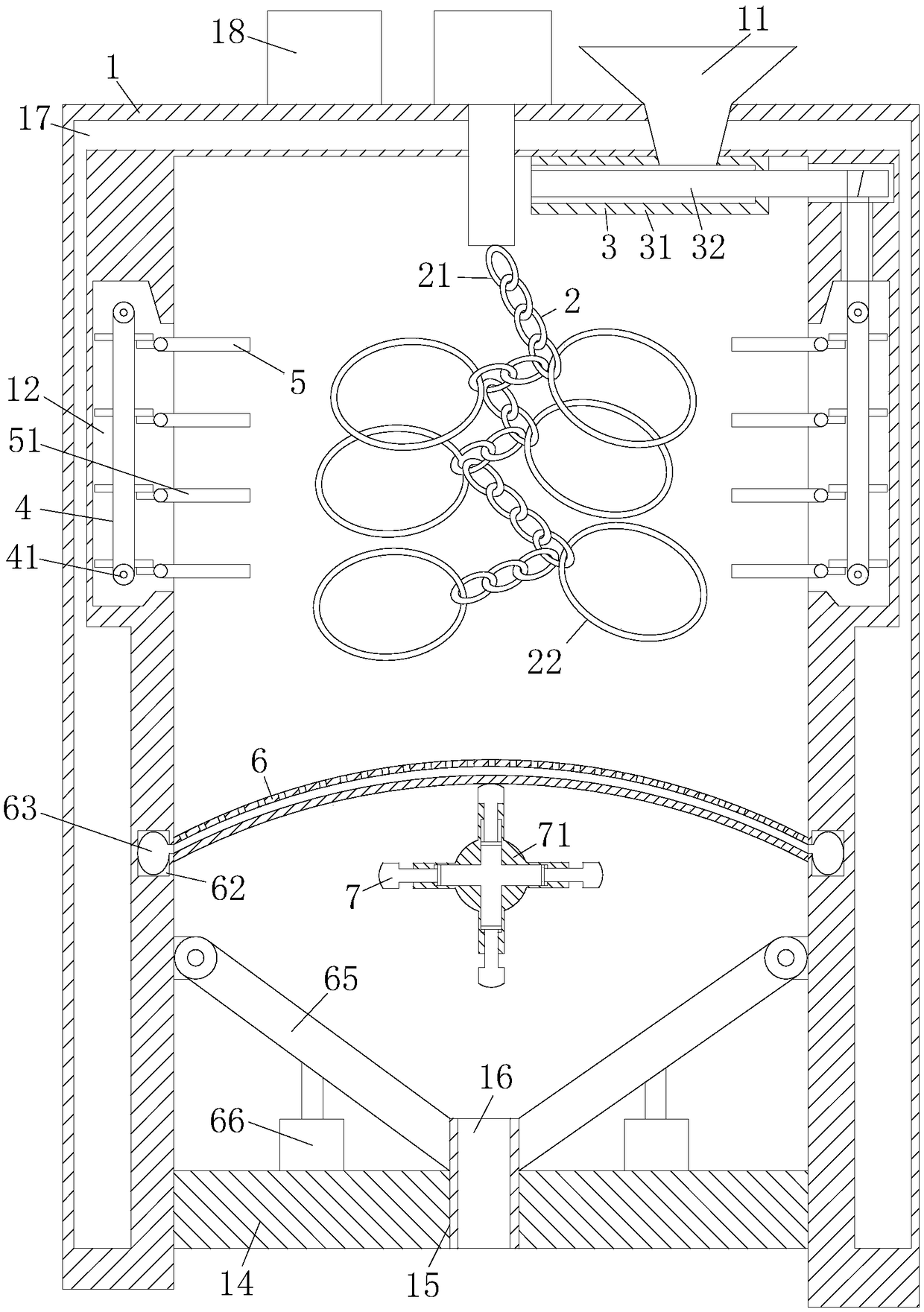

[0040] As an embodiment of the present invention, a water tank 17 is provided on the inner wall of the frame body 1, and the water tank 17 is filled with water; the top of the frame body 1 is provided with a steam generator 18, which is electrically connected to the No. 1 motor; The lower end of the water tank 17 is communicated with the water outlet of the steam generator 18 through a conduit; the upper end of the water tank 17 is communicated with the steam inlet of the steam generator 18 through a conduit; during use, the heat generated in the straw burning process heats the water in the water tank 17 to generate water Steam and water vapor enter the steam generator 18 to generate electricity to provide electric energy for the No. 1 motor to realize the reuse of resources. At the same time, the steam used by the steam generator 18 is re-liquefied and then discharged into the water tank 17 to realize the reuse of water resources.

[0041] When in use, collect straw, dry the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com