Seamless paper reel

a paper reel and seamless technology, applied in the field of paper reels, can solve the problems of decreasing the quality of conventional paper reels, and achieve the effects of enhancing the quality and stability of paper reels, reducing fabrication costs, and enhancing working efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

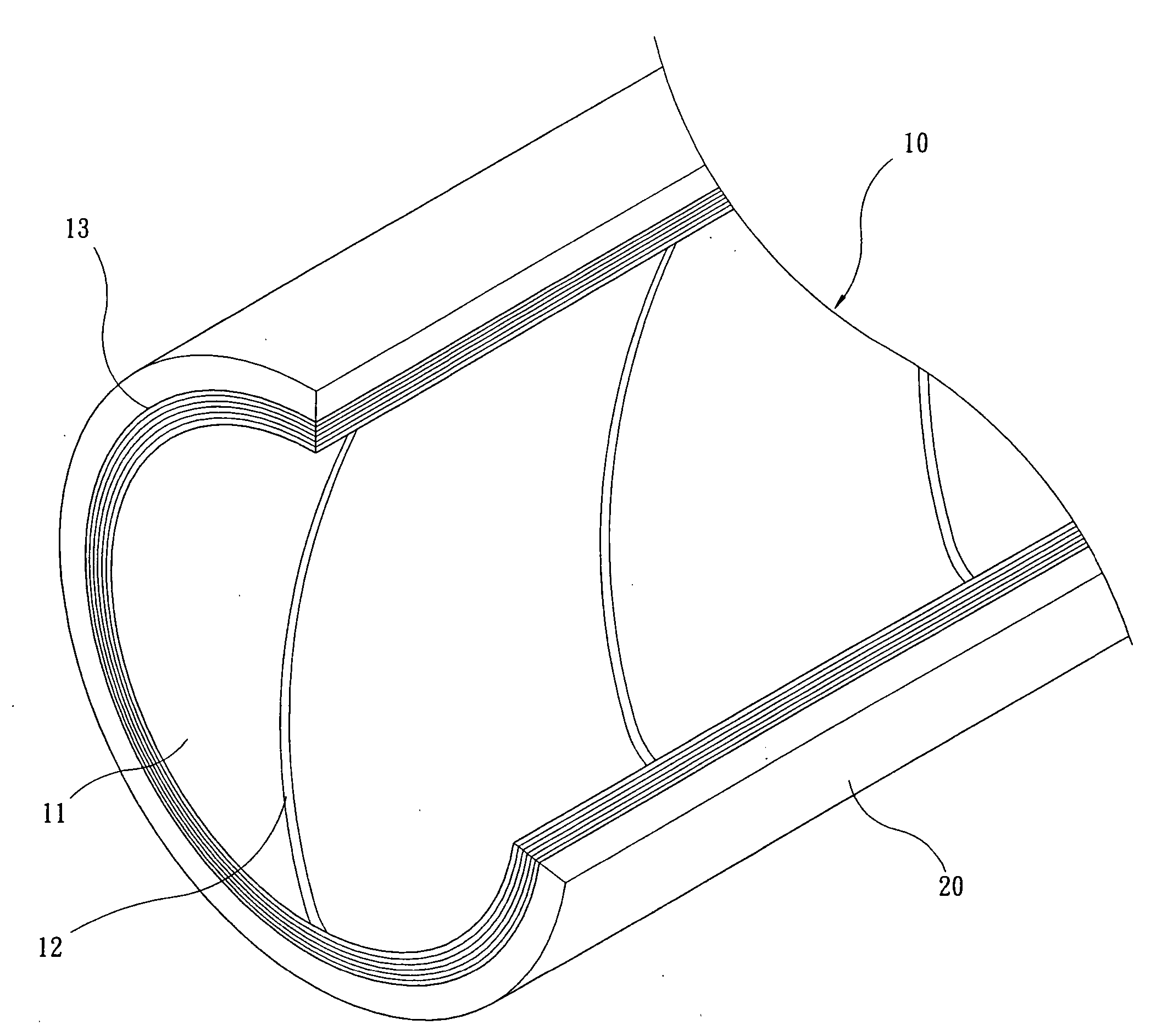

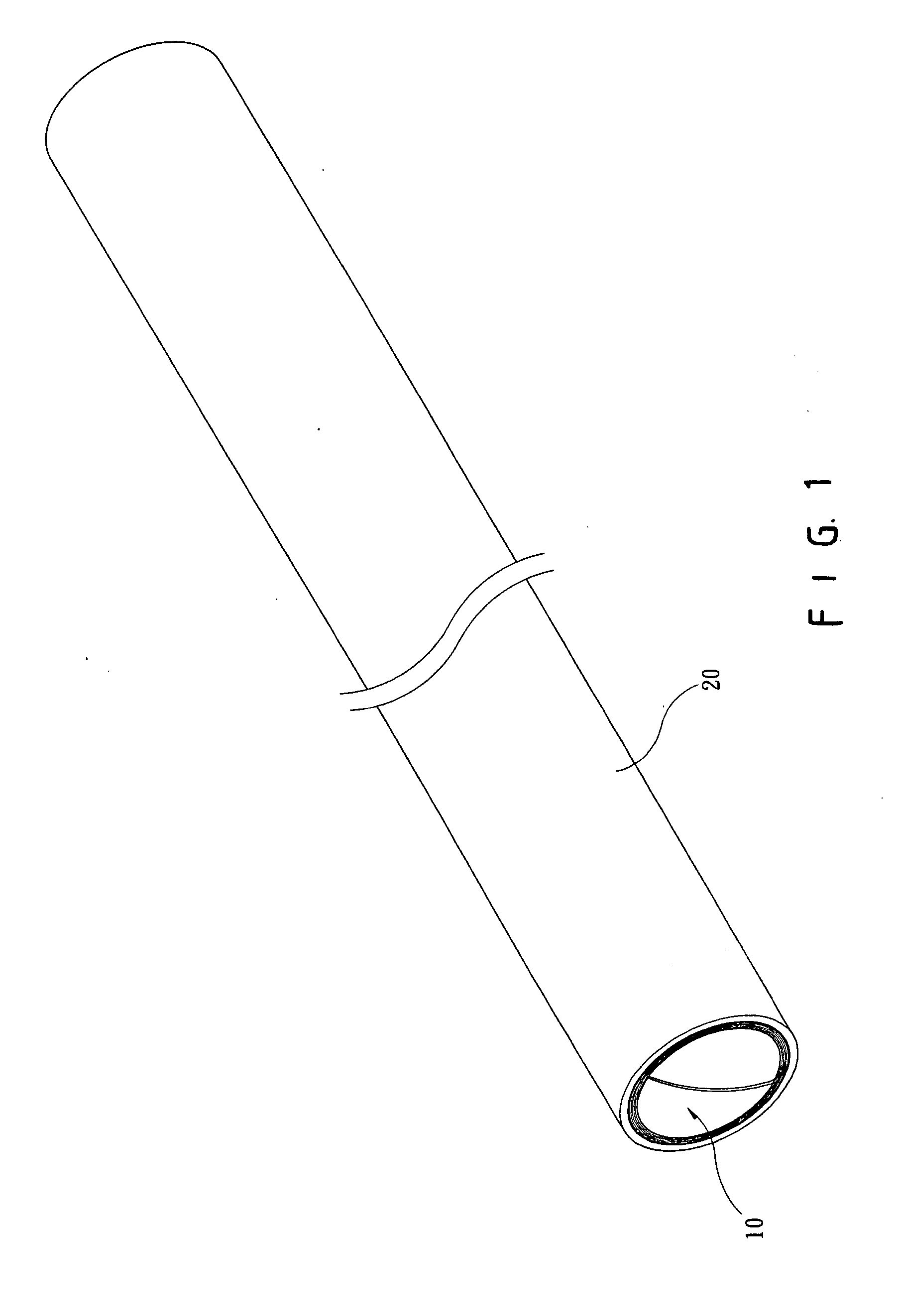

[0016] Referring to the drawings and initially to FIGS. 1-3, a paper reel in accordance with the preferred embodiment of the present invention comprises a lining 10, and an enclosure 20 mounted on a periphery of the lining 10.

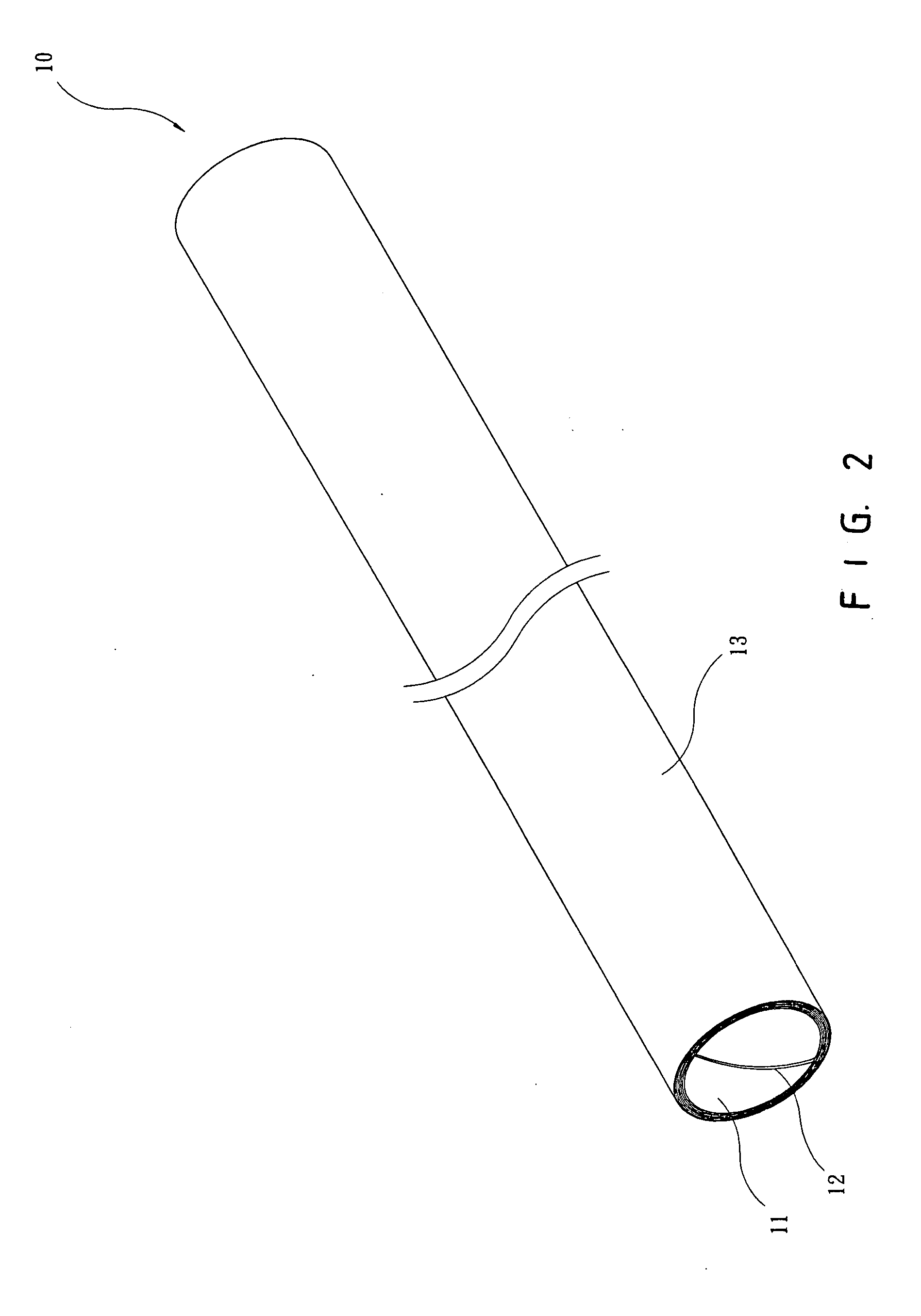

[0017] The lining 10 includes a plurality of paper strips 11 overlapping each other in an oblique manner, and a plurality of grooves 12 located between the paper strips 11 in an oblique manner. Preferably, the grooves 12 of the paper strips 11 are arranged in a helical manner. The paper strips 11 are wound around a helical winding track in an oblique manner so as to form a tubular body. The paper strips 11 are juxtaposed to each other in an oblique manner.

[0018] Referring to FIGS. 1-4, the lining 10 further includes a paper strap 13 mounted between the paper strips 11 and the enclosure 20. The grooves 12 of the paper strips 11 are covered by the paper strap 13 completely. The paper strap 13 is substantially tubular and has a length equal to that of the tubula...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| plastic | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com