Patents

Literature

40results about How to "Reduce cut-off" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

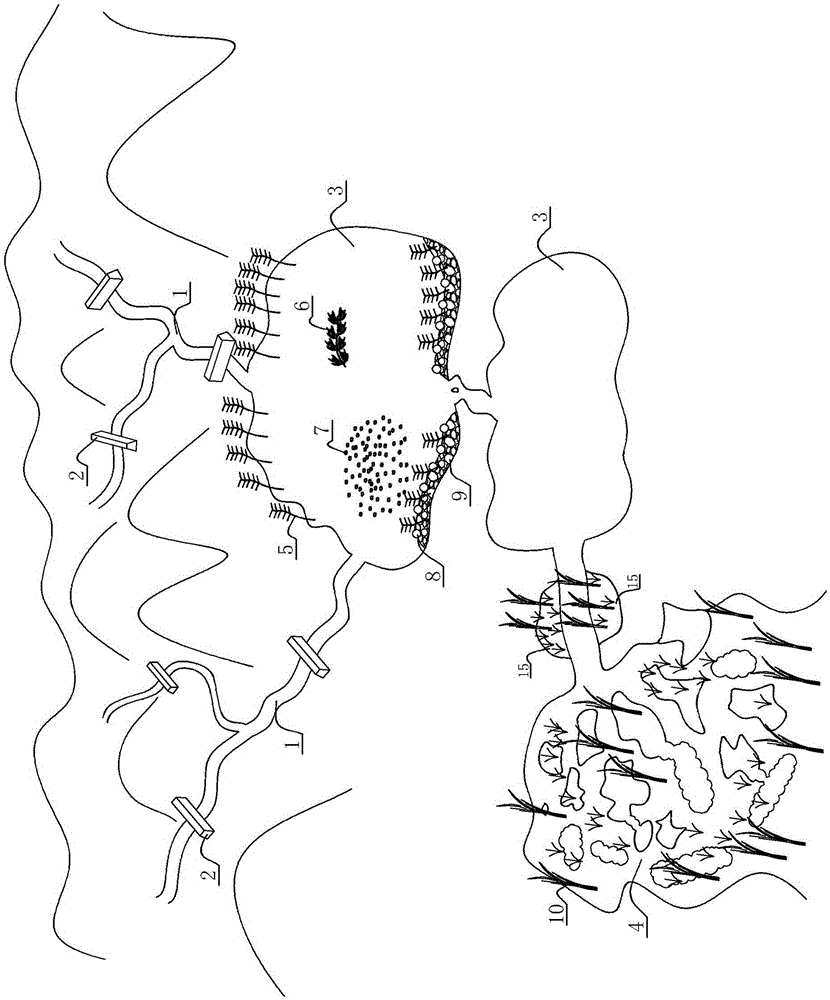

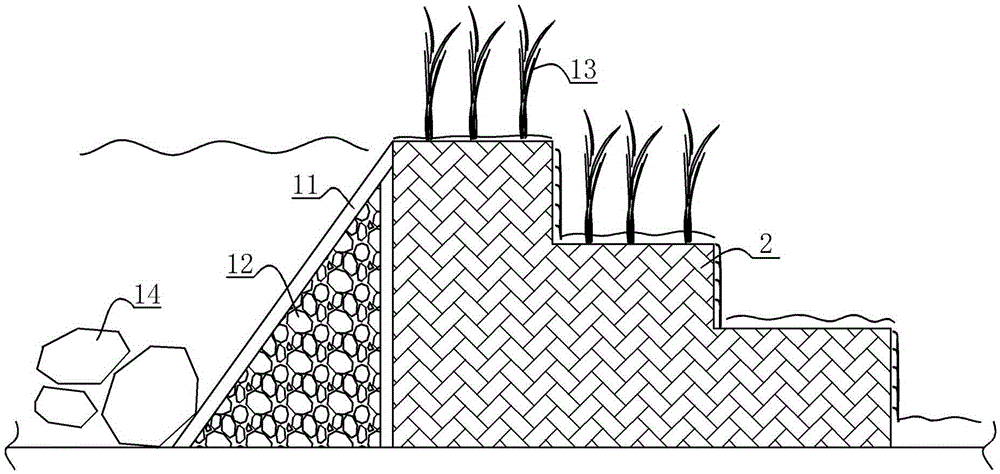

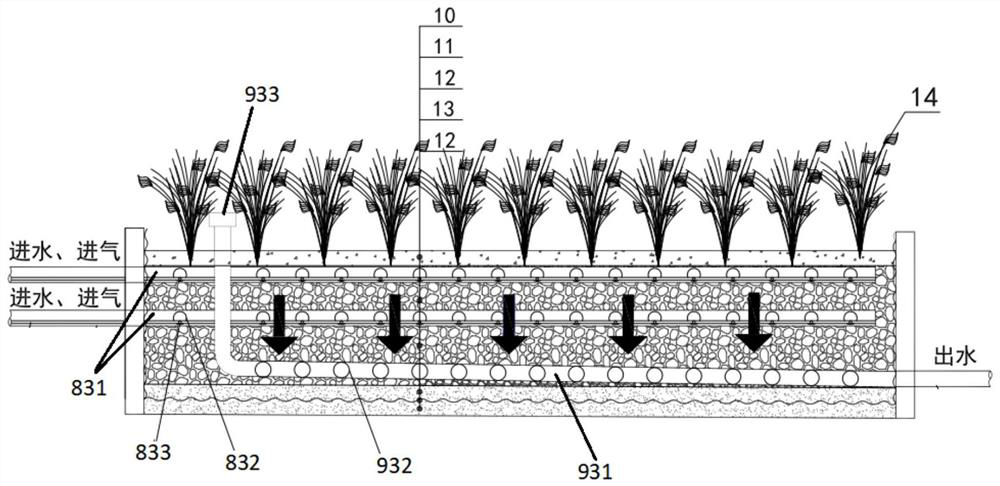

Ecological comprehensive treatment system of northern mountain river channel and construction method thereof

InactiveCN105297671AReduce pollutionImprove stabilityWater resource protectionStream regulationDry seasonFluvial

The invention discloses an ecological comprehensive treatment system of a northern mountain river channel. The system comprises three sub ecological systems of an ecological permeable dike built on the upstream of a main stream and a branch stream of a mountain river, a reservoir pond arranged at the middle and downstream area of the mountain river and a wet land communicated with the reservoir pond, and adopts an ecological treatment mode of closure-storage-preservation. The construction method comprises the steps of: a) building of the ecological permeable dike; b) setting of a triangular pyramidal wood pile stone cage; c) building of the reservoir pond; d) planting of plants of the reservoir pond; e) building of a wet land system; and f) recovery of a river bank band. The system and the construction method can effectively intercept the mountain debris flow and the river non-point source pollution, adjust the river runoff, improve the hydrologic conditions of the mountain river in non-flood season, decrease the dry season of the mountain river, and facilitate to recover the ecological system of the mountain river. Meanwhile, traditional depressions and empty ponds in the mountain river can be used in construction, so that the engineering building cost is reduced, and the self-cleaning capacity of river water is improved.

Owner:SHANDONG ANALYSIS & TEST CENT

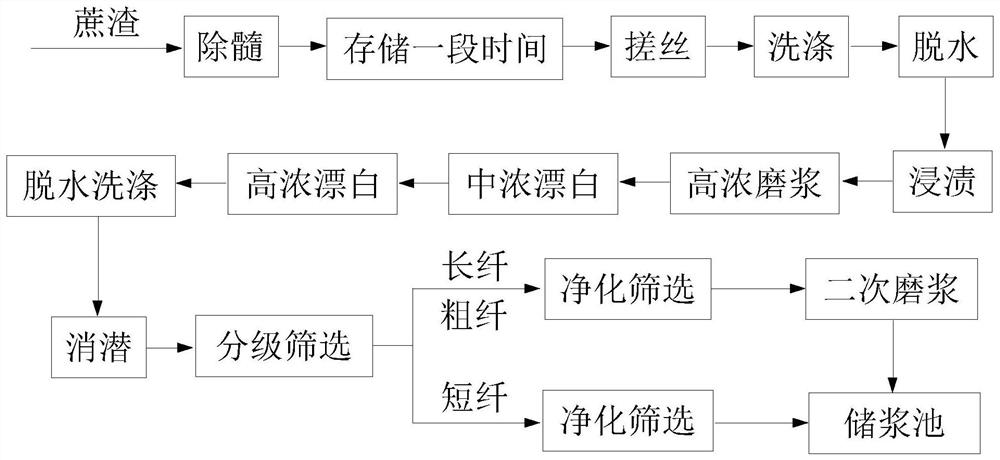

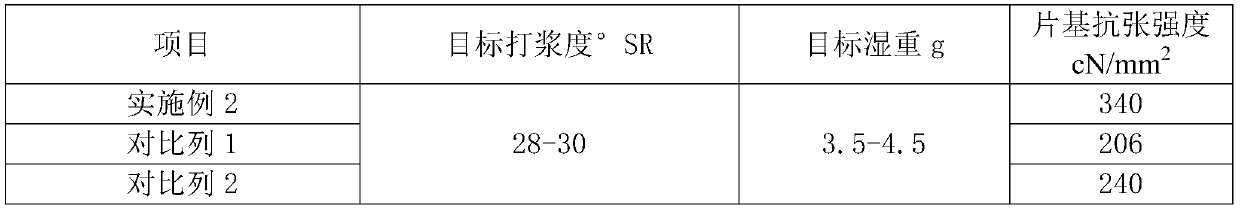

Straw and/ or ryegrass raw material semi-chemical pulp preparation method

InactiveCN101260630AImprove plasticityReduce cut-offPulp de-wateringPulp beating/refining methodsFiberEnergy consumption

The invention discloses a semi-chemical pulp preparation method of a straw and / or wheat straw hood raw material, comprising the following steps that: (1) after the straw and / or wheat straw hood raw material is processed by the chemical pre-dipping treatment or is boiled, the straw and / or wheat straw hood raw material is sent to a hydrabrusher to dilute and disperse, the concentration is added with water to adjusted within the range of 2.5 to 4.5 percent, and the straw and / or wheat straw hood raw material is dispersed into even materials; (2) the diluted and dispersed material is sent to a fluffer by a pump to process, the straw and / or wheat straw hood raw material is dispersed and disintegrated to become a fasciculus; (3) the dewatering and concentrating are performed: the paste after dispersed and disintegrated by the fluffer is transported to a dewatering device to dewater and is concentrated to a solution with a concentration ranging from 6 to 10 percent; (4) the pulping is performed: the dewaterd and concentrated pulp is pumped up to a disk grinder to perform the pulping in order to obtain the pulp for papermaking. The preparation method effectively keeps the fiber length, improves the intensity performance of the paper and has low energy consumption.

Owner:SOUTH CHINA UNIV OF TECH

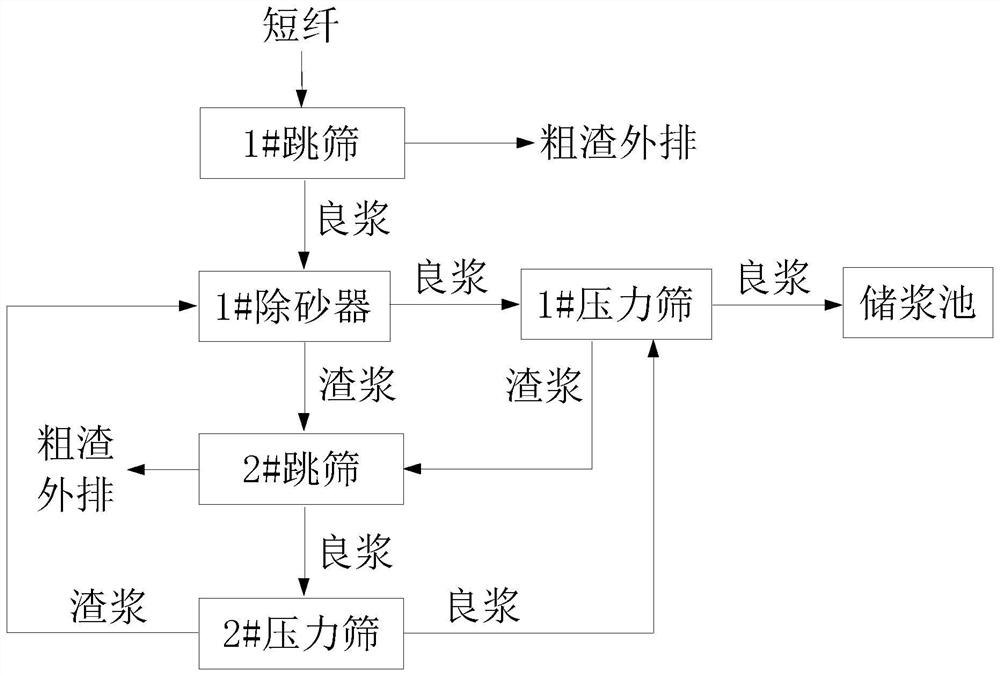

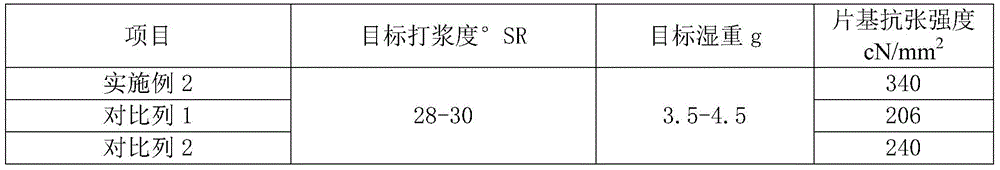

Method for preparing tobacco sheets through tobacco waste materials by papermaking method

InactiveCN102318895AReduce cut-offGood physical propertiesTobacco preparationPapermakingPulp treatment

The invention provides a method for preparing tobacco sheets through tobacco waste materials by a papermaking method, which comprises the following steps of: respectively soaking tobacco powder and mixtures of washed tobacco stems and crumbled tobacco leaves into water, carrying out extraction, respectively obtaining solid tobacco stems, tobacco leaf mixtures, solid smoke powder and two kinds of extraction liquid through solid and liquid separation, and combining two kinds of extraction liquid; regulating the tobacco stem and tobacco leaf mixtures obtained through extraction into the materialconcentration being 15 to 30 percent, and then carrying out defibering; regulating the defibered materials into the concentration being 6 to 12 percent and carrying out pulping treatment; diluting the solid smoke powder and the pulped pulp materials to the required concentration after mixing, and making the materials into substrates by a papermaking method after sieving; and concentrating the combined extraction liquid, using the concentrated extraction liquid as coating liquid to be coated on the substrates, and drying and cutting the substrates into tobacco sheet products. The preparation method provided by the invention has the advantages that the damage to material tissue structures in the preparation process is effectively reduced, the physical performance of the tobacco sheets is improved, the yield is high, and the energy consumption is low.

Owner:SOUTH CHINA UNIV OF TECH +2

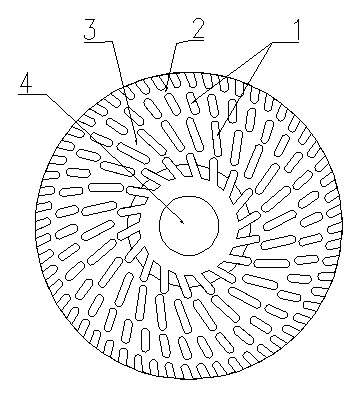

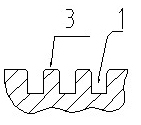

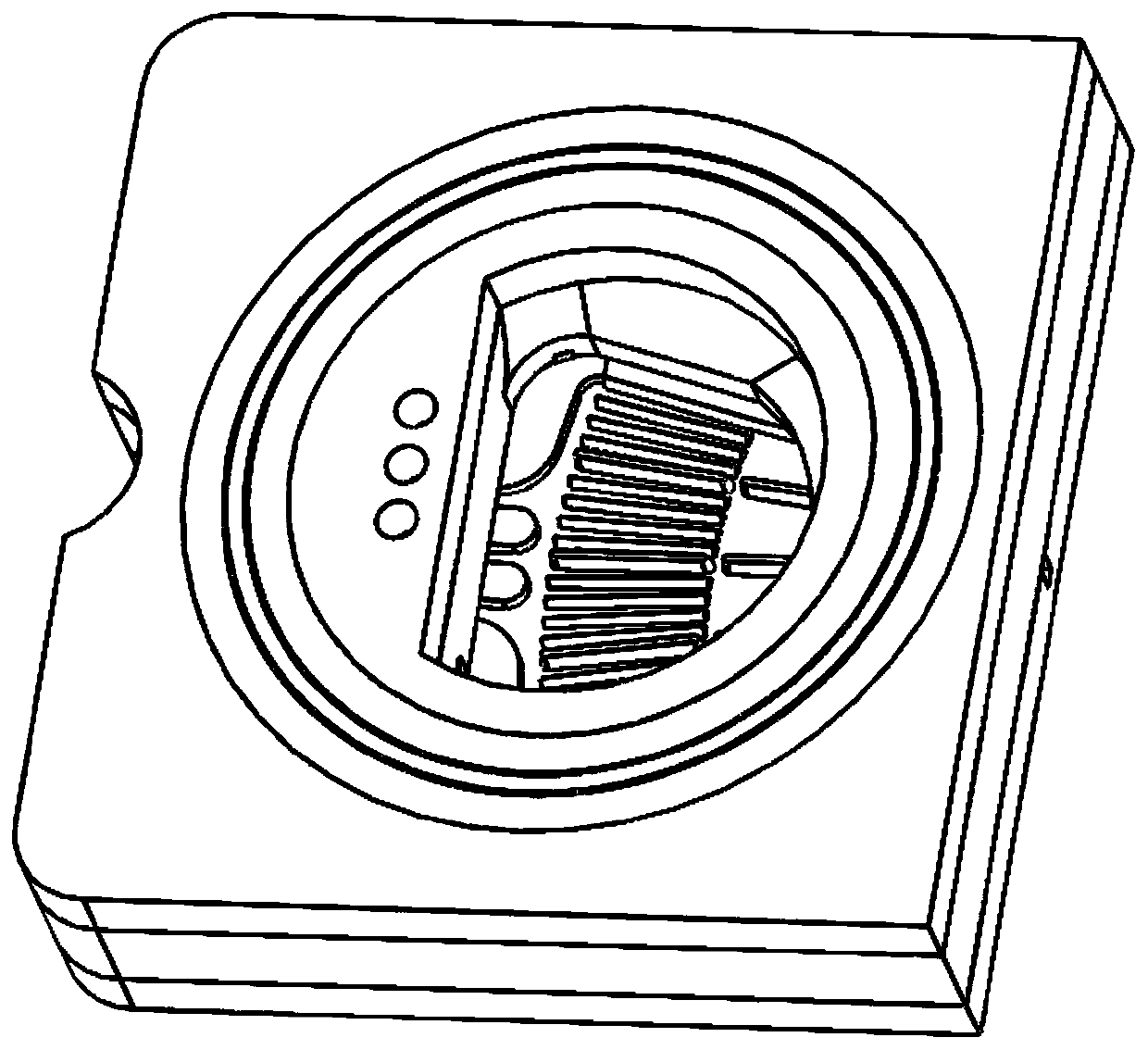

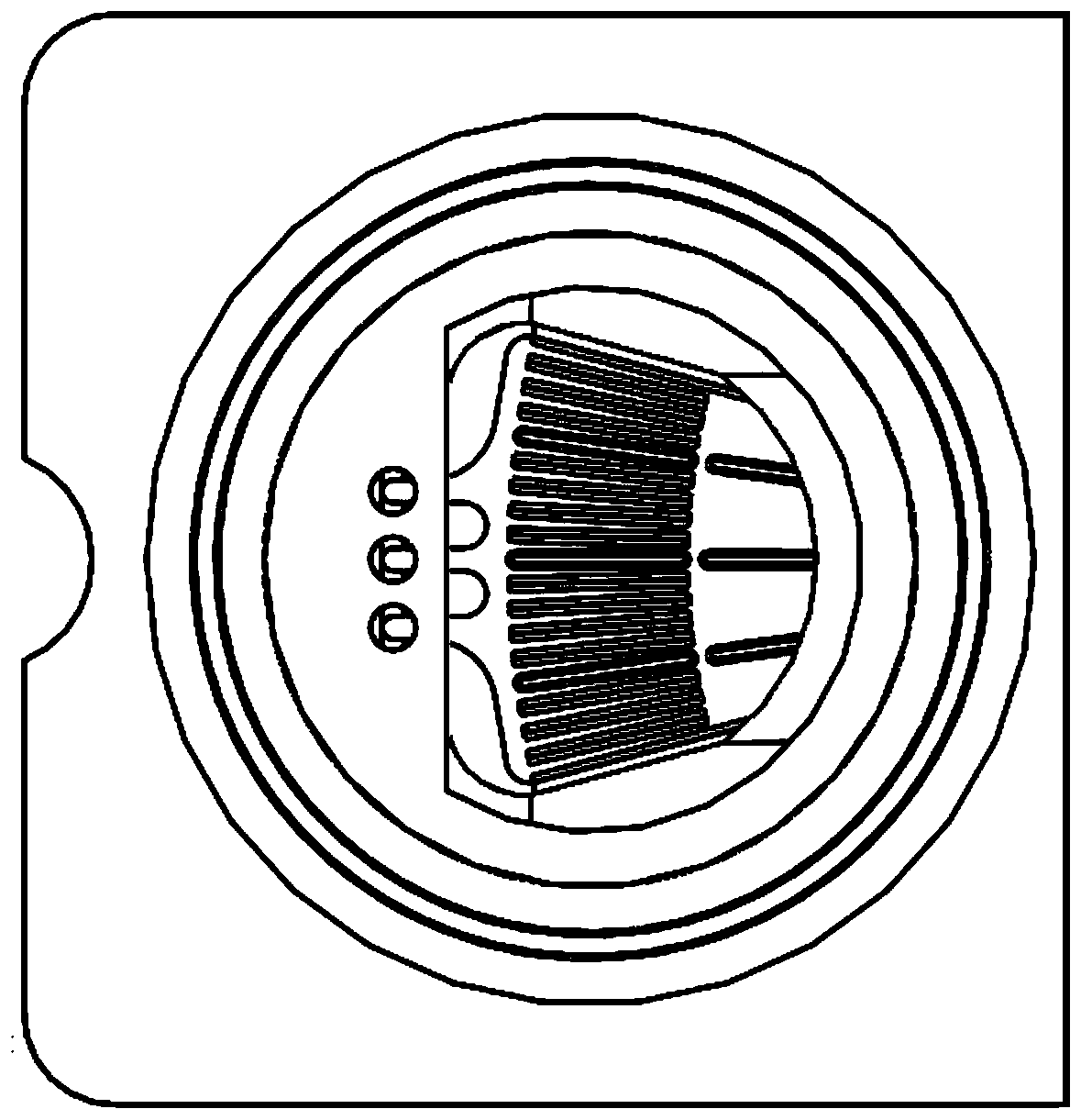

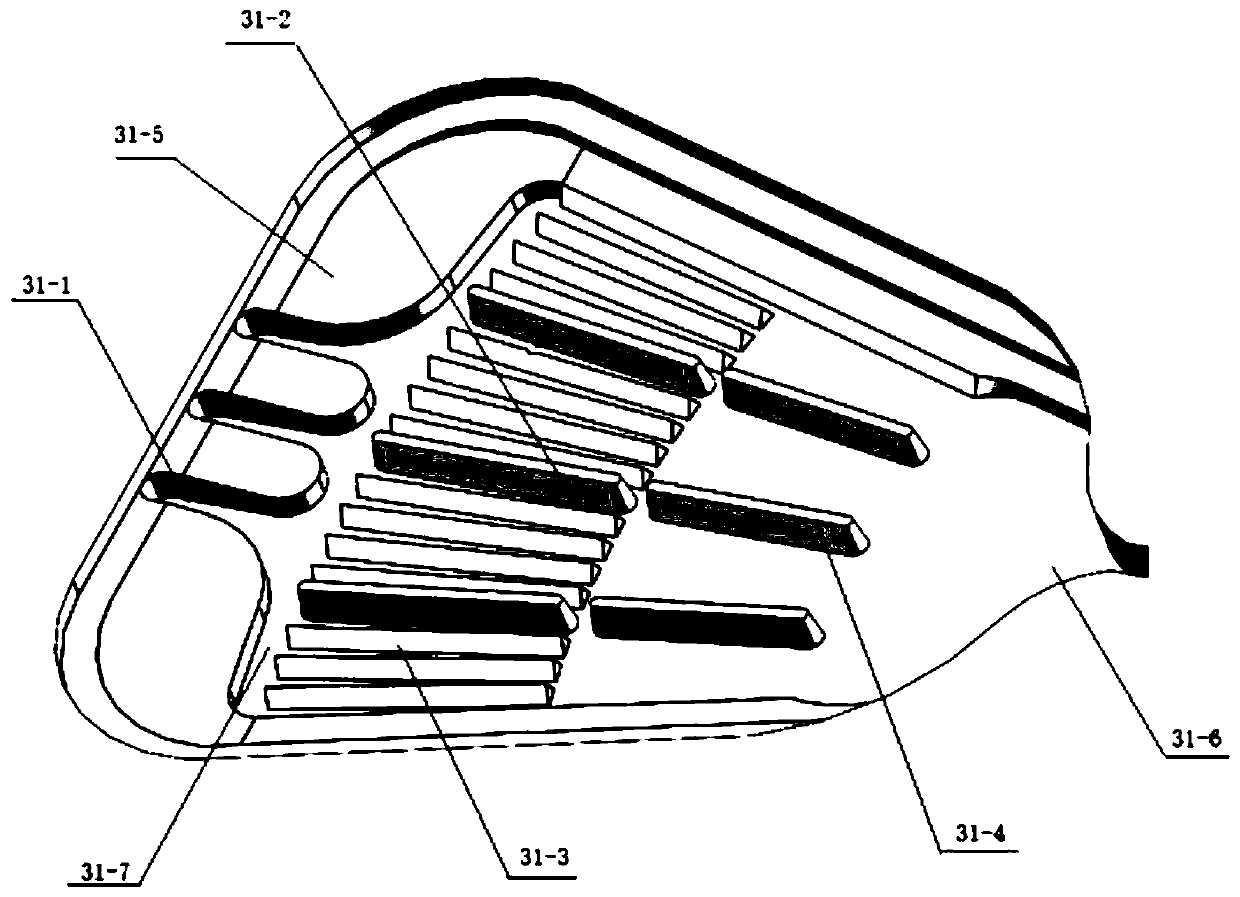

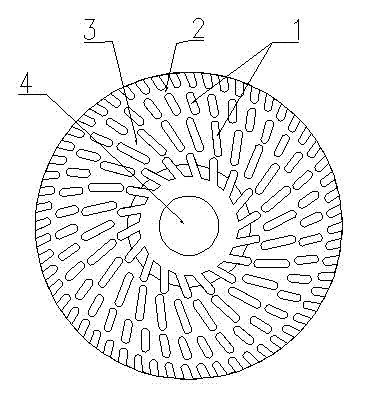

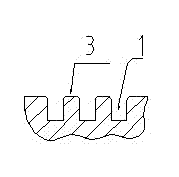

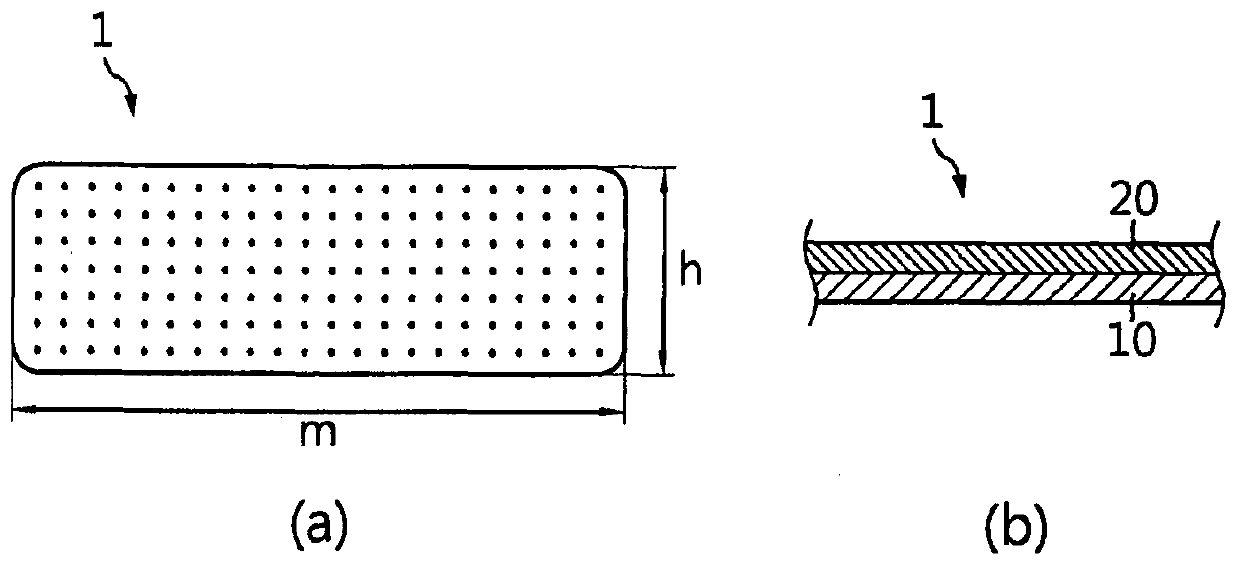

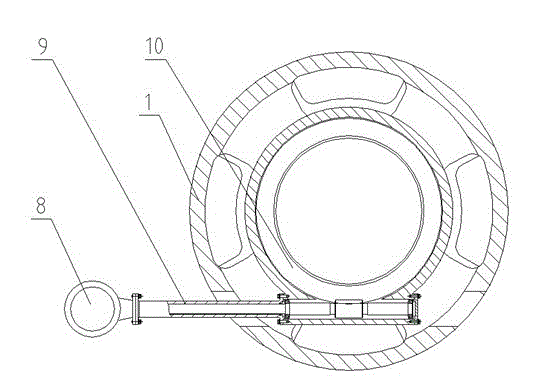

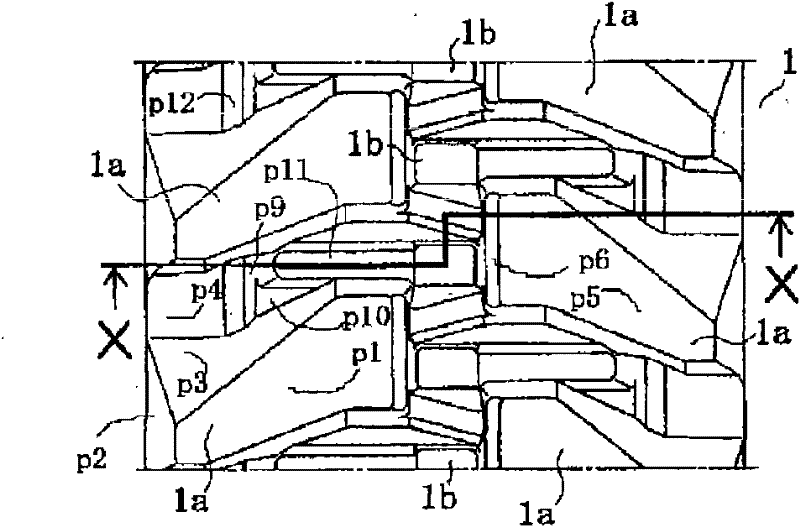

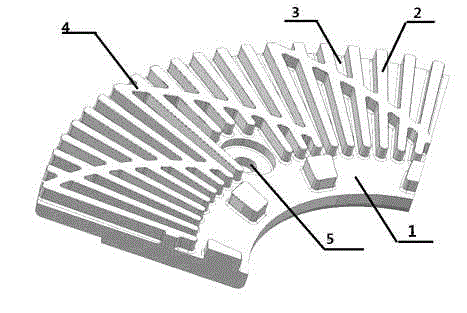

Grinding table of disc grinder for preparing synthetic fiber pulp

ActiveCN102086606AReduce specific edge loadWeaken cut-off functionPulp beating/refining methodsEngineeringResidence time

The invention discloses a grinding table of a disc grinder for preparing synthetic fiber pulp, which comprises a grinding plate, wherein the working surface of the grinding plate is provided with a plurality of grooves; the grooves are distributed in a multiple-layer concentric circle mode around the grinding plate; the grooves are evenly distributed on each layer of the concentric circle; grinding teeth are formed on the grinding plate between every two adjacent grooves on the same circle; and a pulp baffle plate is formed at the gap between any two adjacent layers. The invention can prolongthe the residence time of materials in the disc grinder, weaken the cut-off function of the grinding table, enhance the effects of crushing, kneading and fibrillation on the fibers, and greatly improve the microfibrillation degree of the pulp fibers.

Owner:BLUESTAR CHENGDU NEW MATERIALS

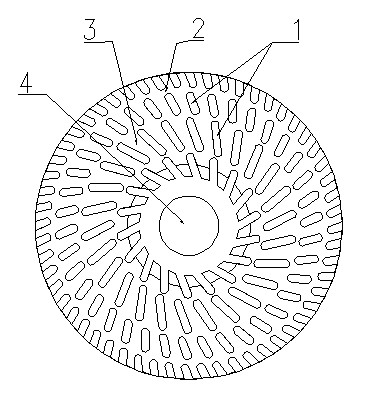

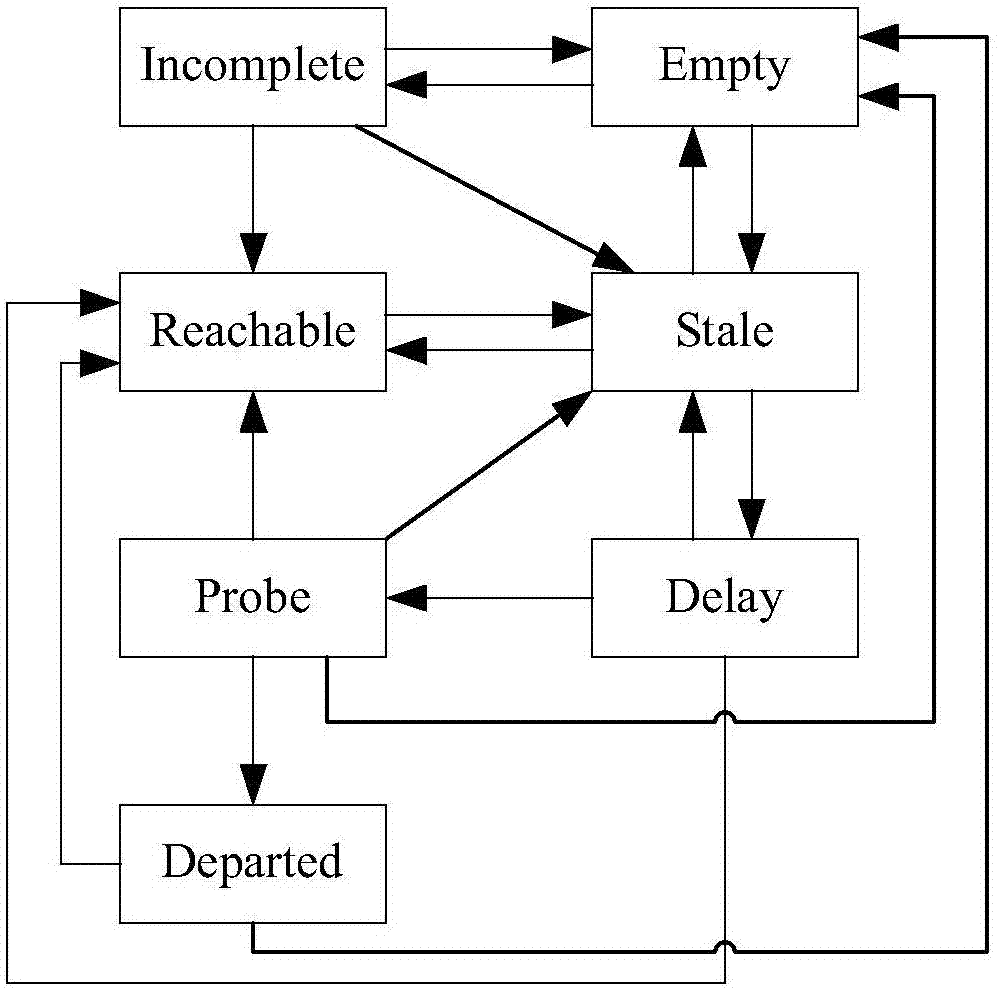

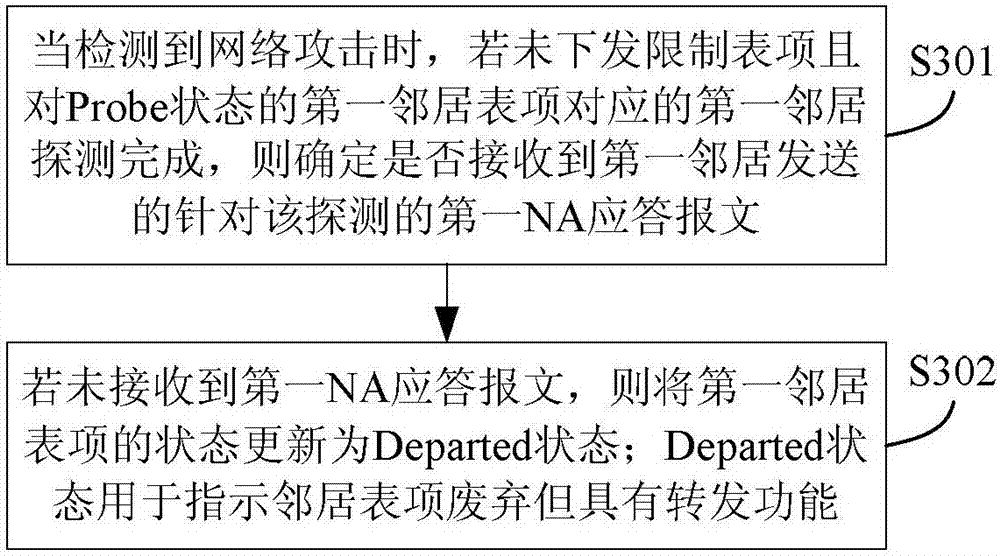

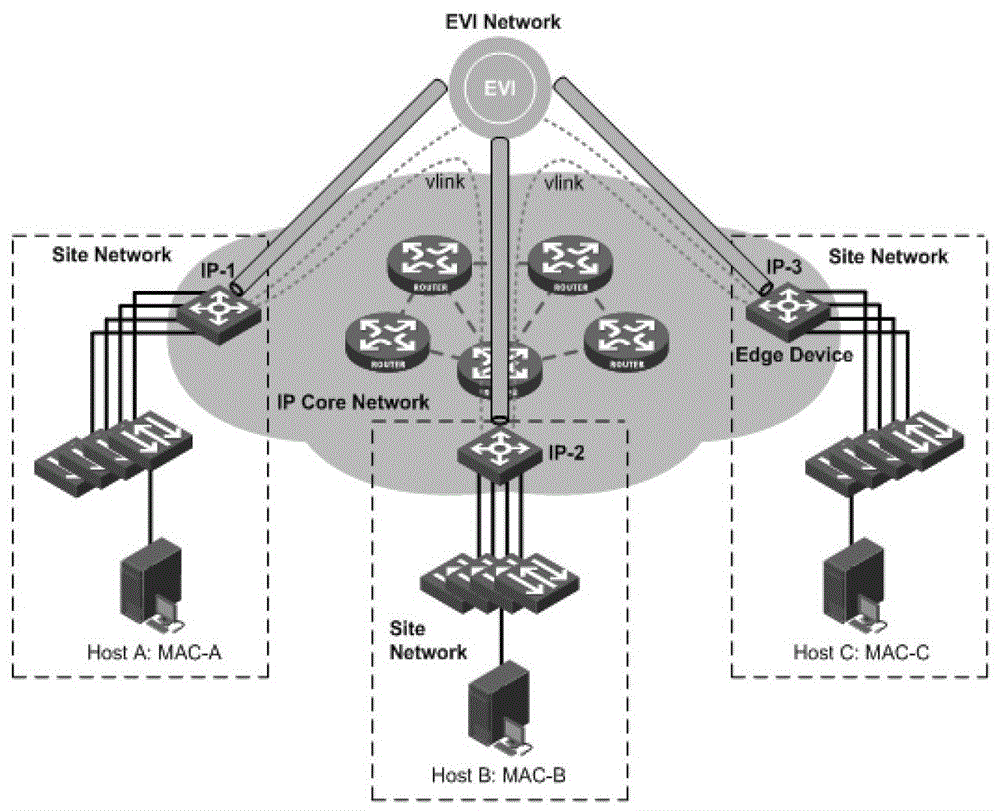

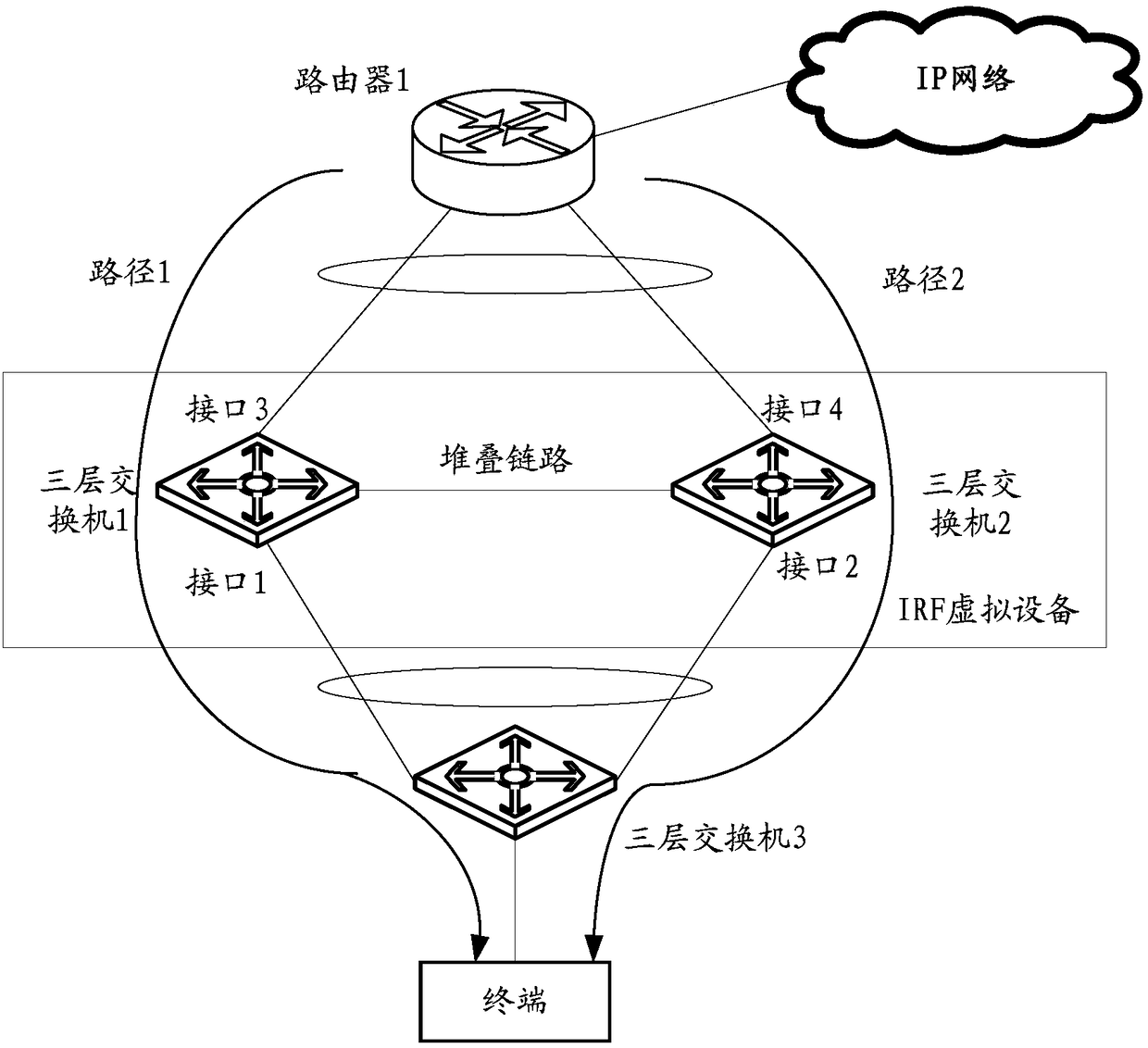

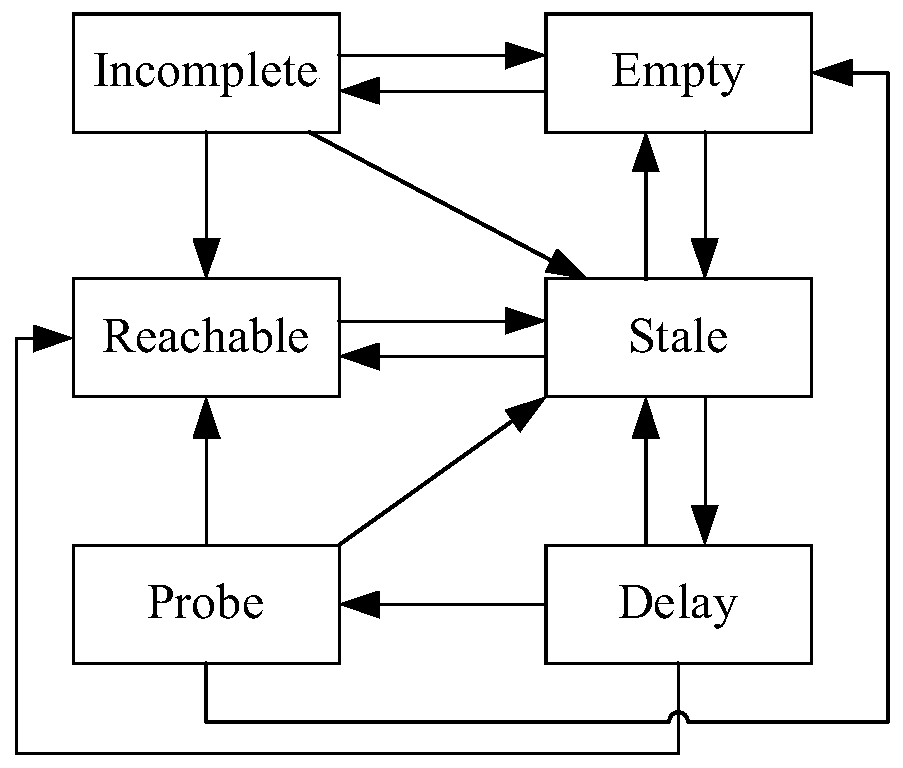

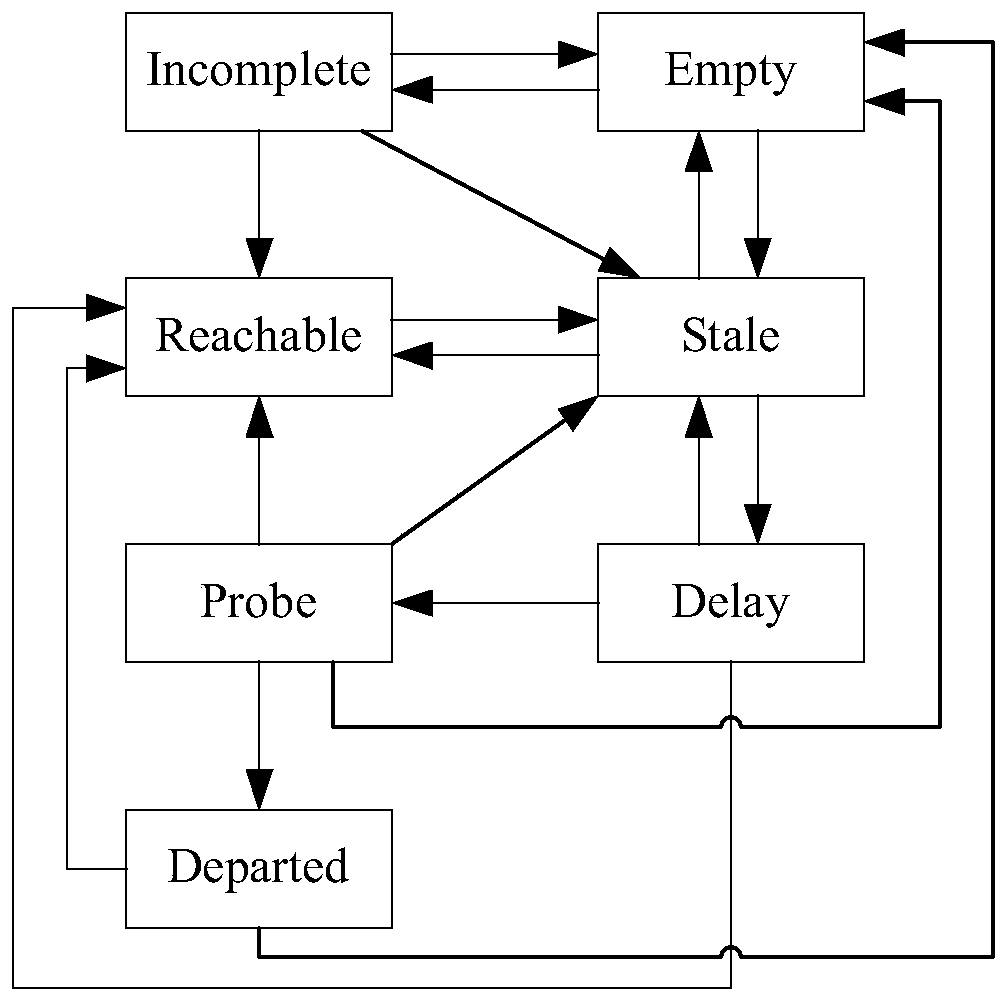

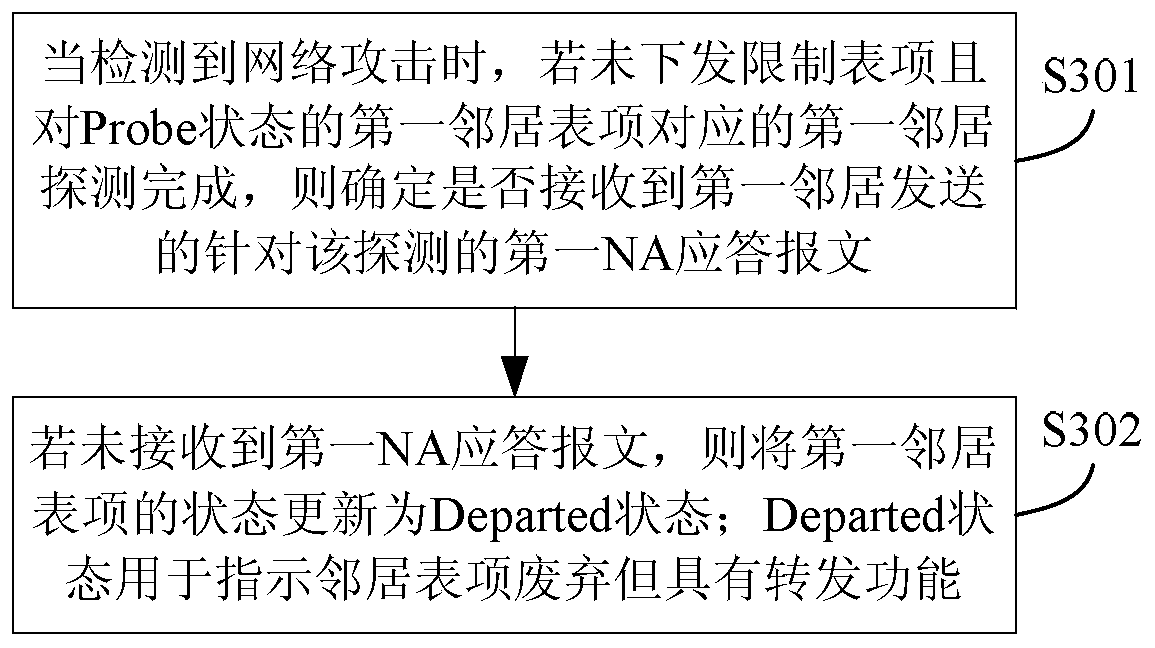

Neighbor table entry processing method and device

The embodiment of the invention provides a neighbor table entry processing method and device. The method comprises the following steps: when network attack is detected, if a limiting table entry is not issued ad first neighbor test corresponding to a first neighbor table entry in a Probe state is accomplished, determining a first NA answer message for the detection sent by a first neighbor is received; and if the first NA answer message is not received, updating the state of the first neighbor table entry as a Departed state, wherein the Departed state is used for indicating that the neighbortable entry is discharged but it has a forwarding function. By application of the neighbor table entry processing method and device in the embodiment of the invention, in the case of the network attack, the device breakdown can be reduced, and the impact of network attack is relieved.

Owner:NEW H3C TECH CO LTD

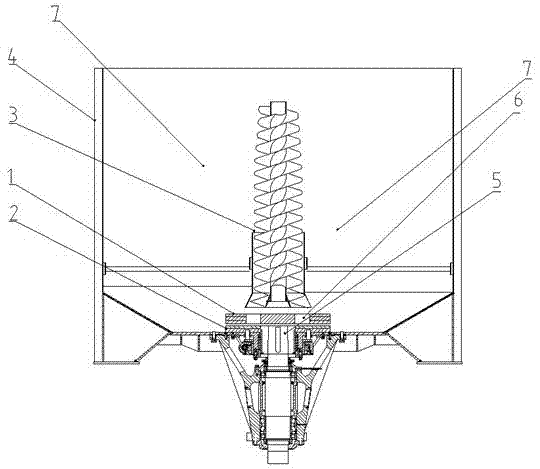

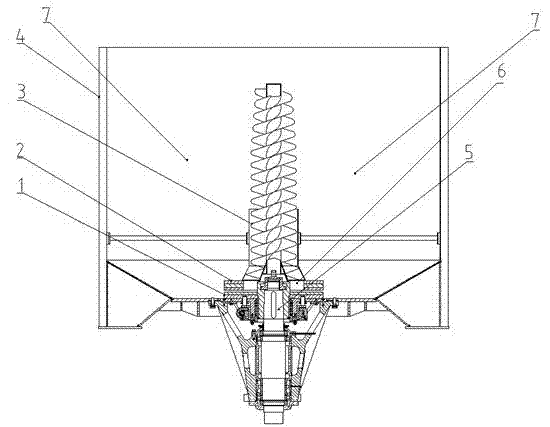

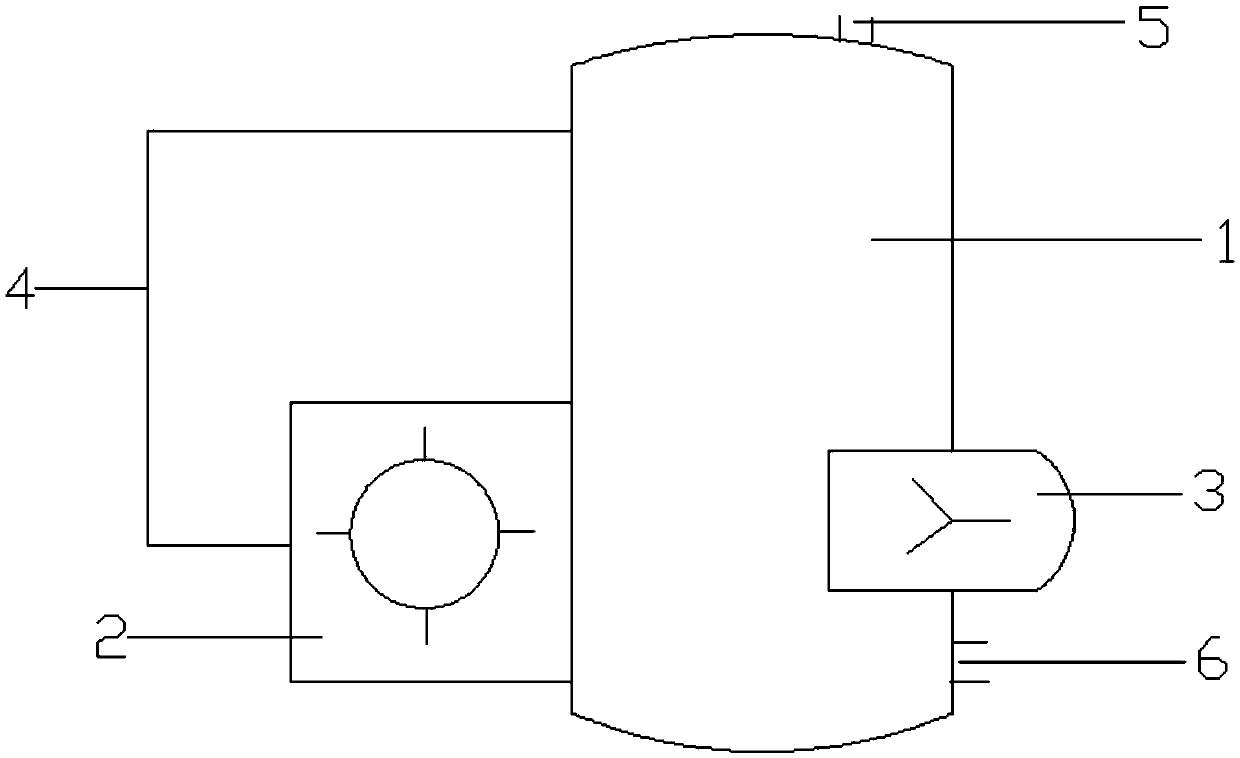

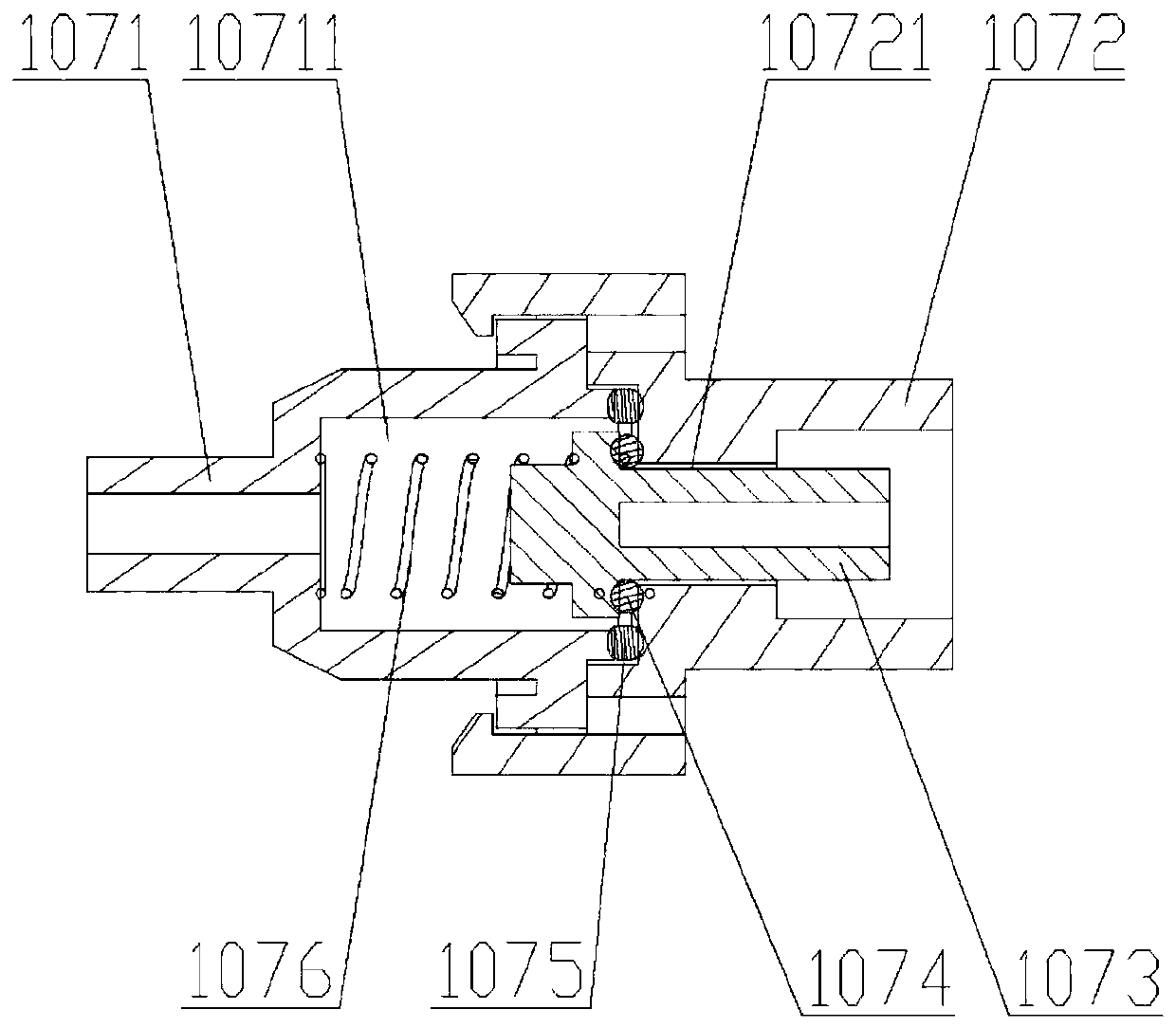

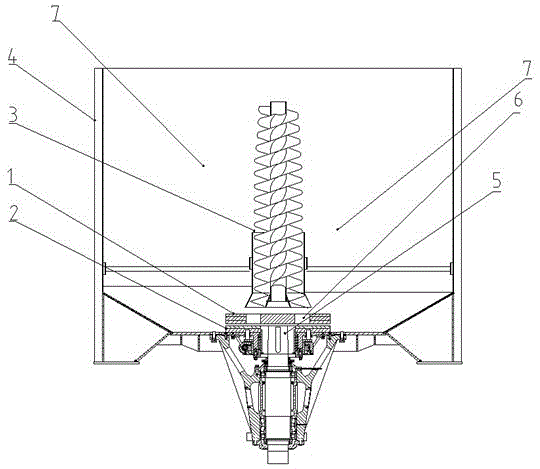

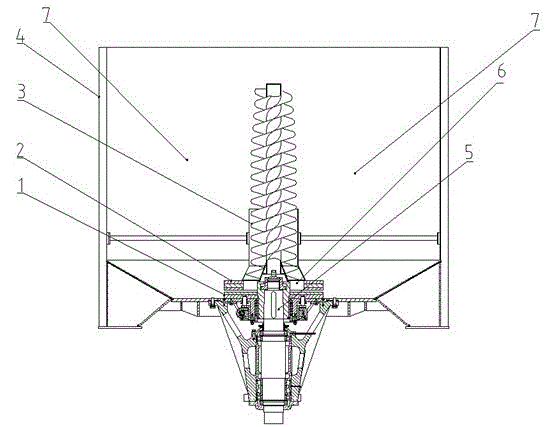

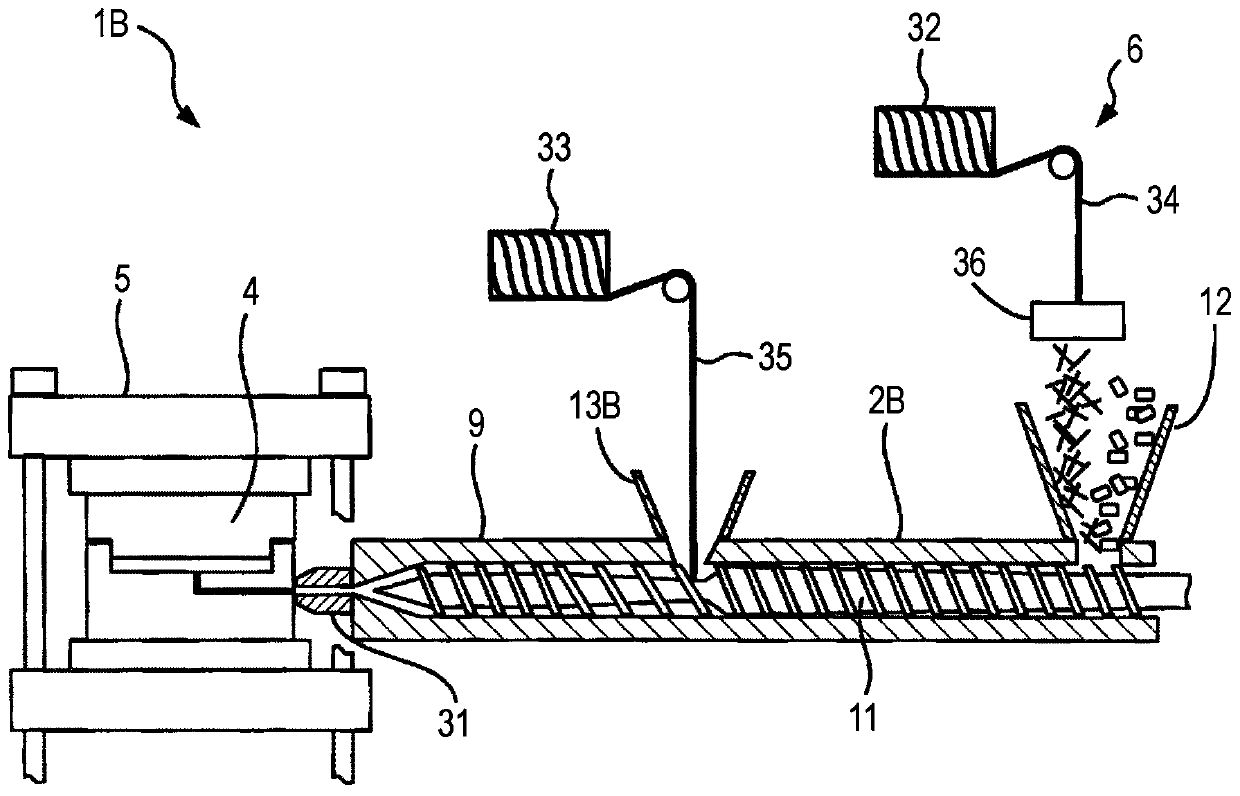

Batch refiner and refining process thereof

ActiveCN102828432AFlexible operationAchieve regulationPulp beating/refining methodsProcess engineeringIndustrial engineering

The invention provides a batch refiner which comprises a shell, a moving refining plate, a fixed refining plate, a transmission shaft and a gap adjusting mechanism, wherein the moving refining plate and the fixed refining plate are coaxially arranged, and the transmission shaft is coaxially connected with the moving refining plate. The batch refiner is further provided with a fluid pushing device, a fluid inlet channel is arranged on the moving refining plate or the fixed refining plate and penetrates through two bottom surfaces of the moving refining plate or the fixed refining plate, a discharge end face of the fluid pushing device faces the fluid inlet channel, and communicated backflow gaps are reserved between the fluid pushing device and the shell as well as between each refining plate and the shell respectively. Multiple refining can be achieved by circulating pulp between the refining plates when the batch refiner is operated, and times of refining are not limited by the batch refiner; and gaps between the refining plates can be adjusted by the gap adjusting mechanism so as to adapt to changes of the pulp. The batch refiner is simple and flexible in operation.

Owner:山东惠祥专利造纸机械有限公司

Polyphenylene sulfide millstone for papermaking pulping

InactiveCN103305002AGood physical propertiesReduce cut-offPulp beating/refining methodsFiberWear resistant

The invention discloses a polyphenylene sulfide millstone for papermaking pulping. The polyphenylene sulfide millstone is used for a papermaking pulping process and is made of a polyphenylene sulfide composite material. Preferably, the polyphenylene sulfide composite material comprises 30-70 weight percent of polyphenylene sulfide, 5-10 weight percent of toughening component, 20-50 weight percent of reinforced fiber and 0-20 weight percent of wear-resistant component. The polyphenylene sulfide millstone for papermaking pulping is high in thermal stability, preferably, the polyphenylene sulfide composite material with the toughening component and the reinforced fiber is adopted, the elasticity modulus is 10-30 GPa and is close to the plant fiber elasticity modulus, the millstone made of the polyphenylene sulfide composite material has a small fiber cutting effect, and the physical performance of the pulp can be effectively improved.

Owner:四川华通特种工程塑料研究中心有限公司 +1

Sample introduction chamber for micro-fluidic chip, and single index micro-fluidic chip

PendingCN110124758AEasy dischargeConducive to centralized filtrationLaboratory glasswaresBlood poolMicro fluidic

The invention discloses a sample introduction chamber for a micro-fluidic chip, and a single index micro-fluidic chip. The sample introduction chamber for the micro-fluidic chip comprises a sample filtering cell and a sample introduction portion arranged at the cell mouth of the sample filtering cell; the sample filtering cell is arranged in a palm-leaf fan shape, the liquid outlet of the sample filtering cell is arranged in the narrow sidewall, and the bottom of the sample filtering cell is provided with flow guiding zones; the sample introduction portion is provided with air holes, air guiding grooves are arranged in the positions, close to the wide sidewall of the bottom of the sample filtering cell and correspond to the air holes, and an air gathering zone is arranged between all the air guiding grooves and the flow guiding zones; and every air guiding groove is communicated with the corresponding air hole, and every air guiding groove is communicated with the flow guiding zones through the air gathering zone. The bottom of the sample filtering cell is provided with the air guiding grooves, and the air gathering zone is arranged between the air guiding grooves and the flow guiding zones, so air can be easily discharged during sample introduction, and bubbles are reduced.

Owner:NANJING LANSION BIOTECH CO LTD

Unbleached tissue packing paper and production method thereof

PendingCN104452465AReduce the degree of beatingVarious performance parameters were prepared from unbleached straw pulp with low beating degreeFlexible coversNatural cellulose pulp/paperPapermakingEngineering

The invention relates to an unbleached tissue packing paper and a production method thereof, and belongs to the field of tissue packing paper in the papermaking industry. The whiteness of the unbleached tissue packing paper is 35-50%, a pulp used in the production of the unbleached tissue packing paper comprises 20-30% of wood pulp and 70-80% of unbleached straw pulp, and the beating degree of the unbleached straw pulp is 42-53DEG SR. The unbleached straw pulp with low beating degree is mainly used by the unbleached tissue packing paper, so a technical prejudice that the production of tissue packing paper needs the straw pulp with high beating degree is overcome; the produced paper has the advantages of high strength, low cost, environmental protection, no toxic substances, wide application range; the production method overcomes the problem of high difficulty of the production of the tissue packing paper from the straw pulp; and the produced tissue packing paper has also has uniform quality, good transparency and high physical strength.

Owner:SHANDONG TRALIN PAPER

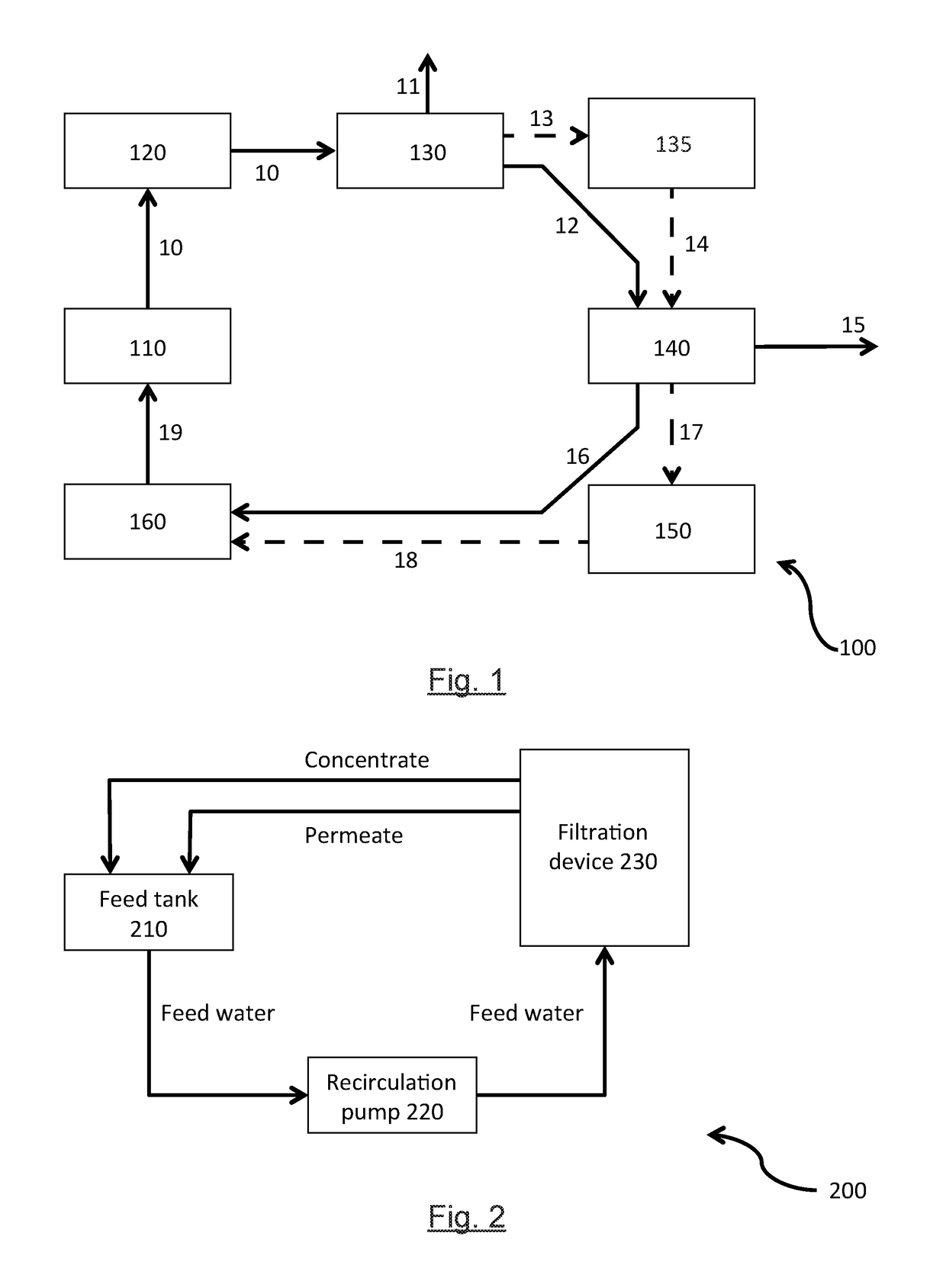

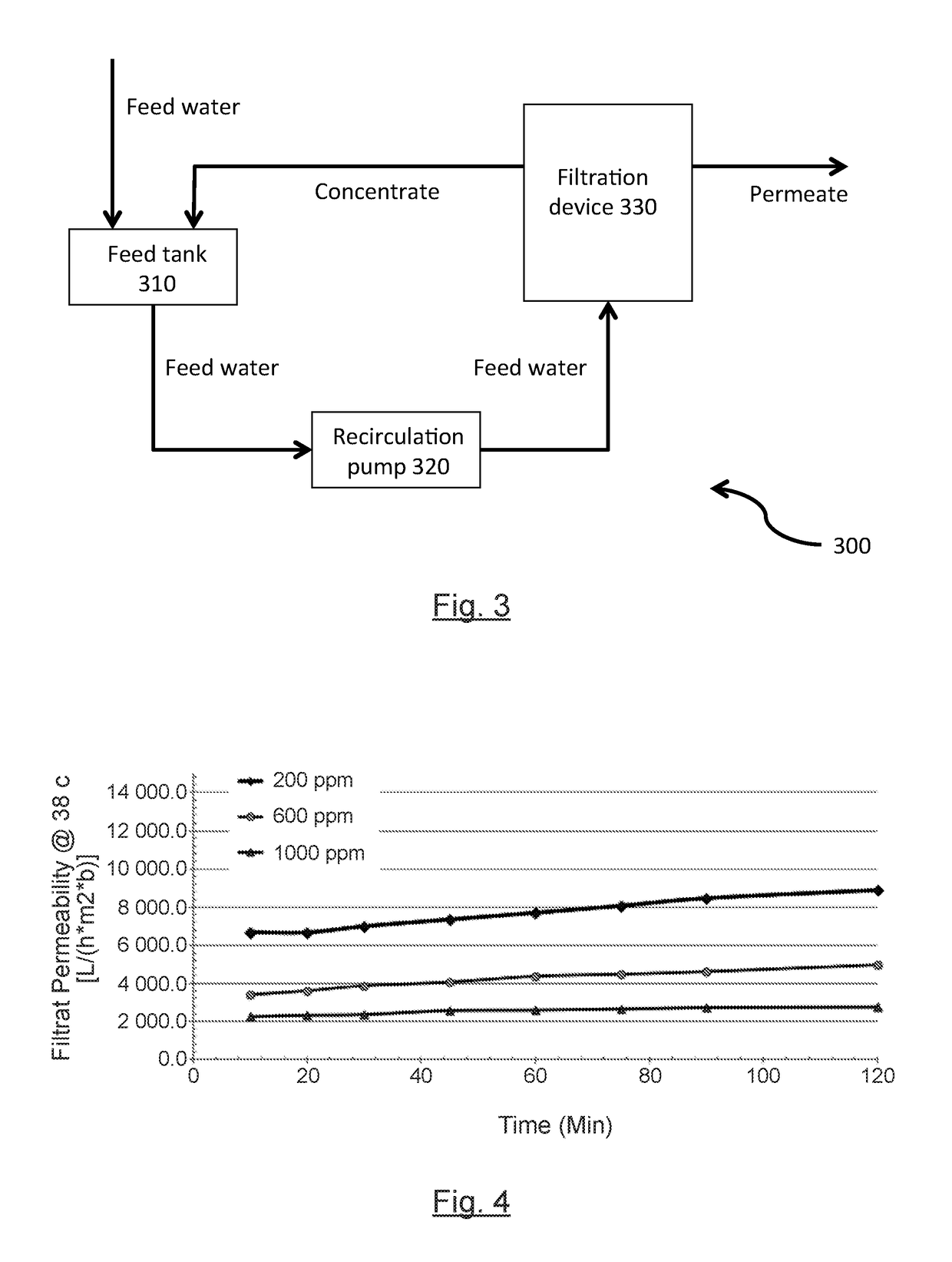

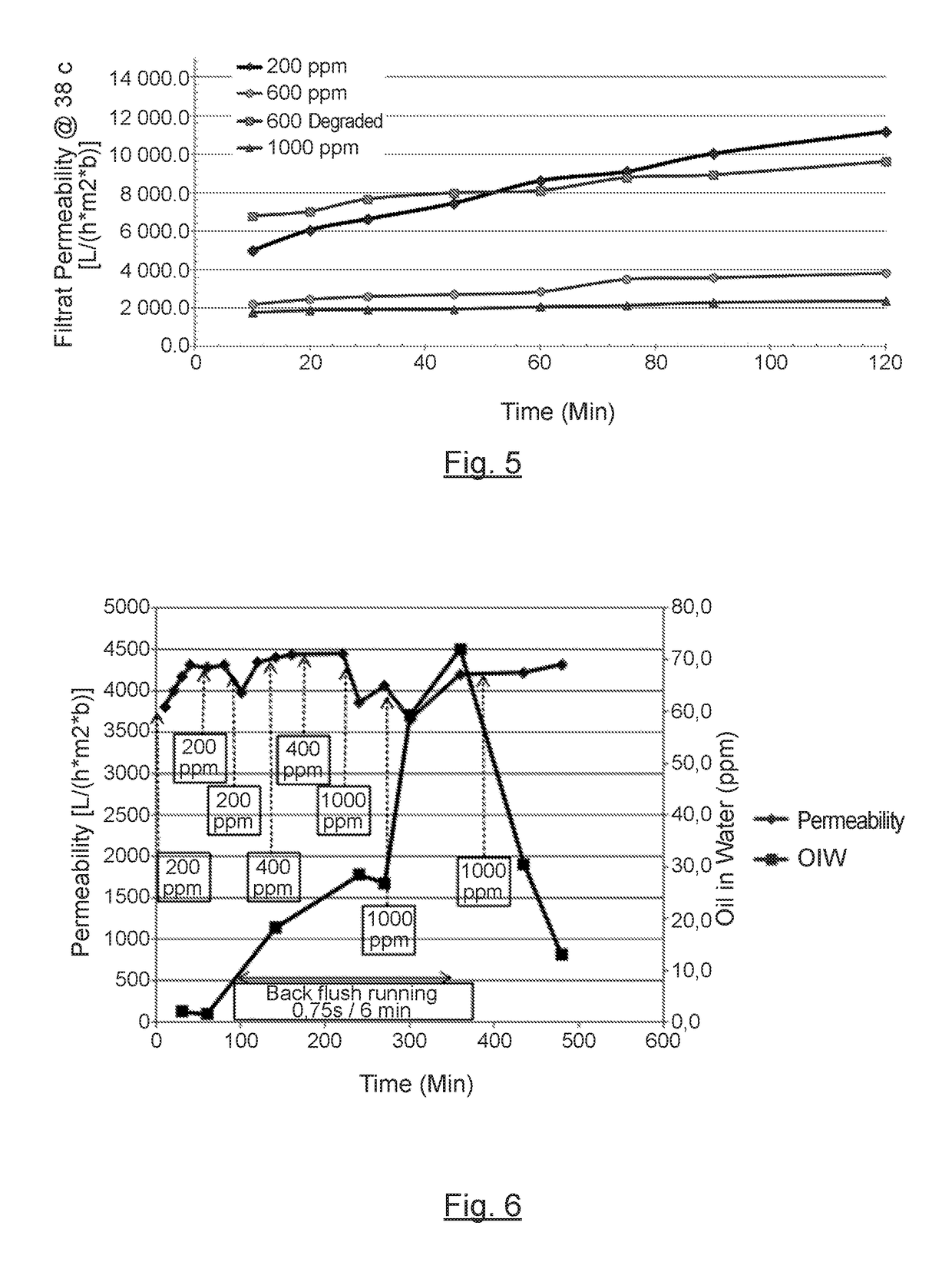

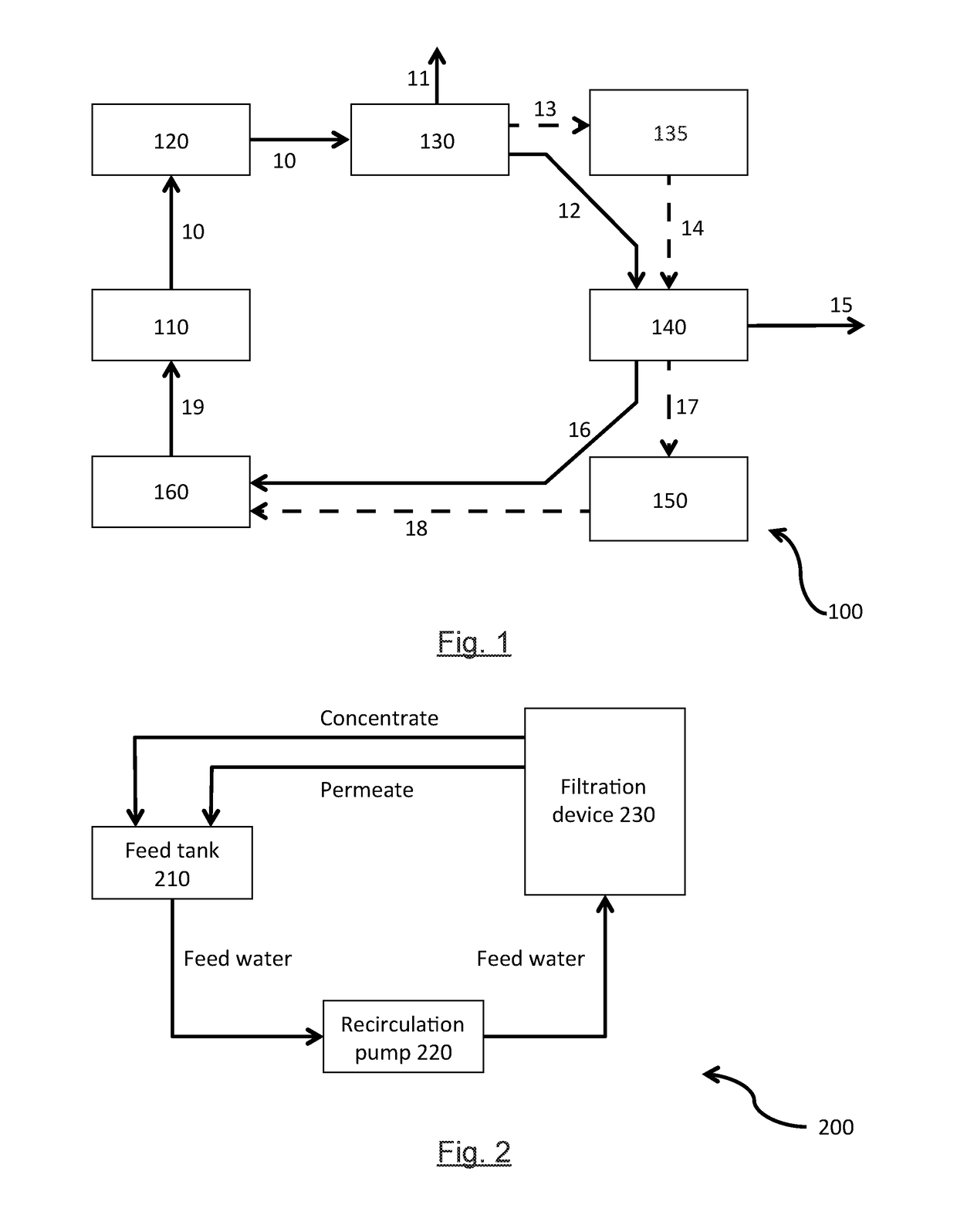

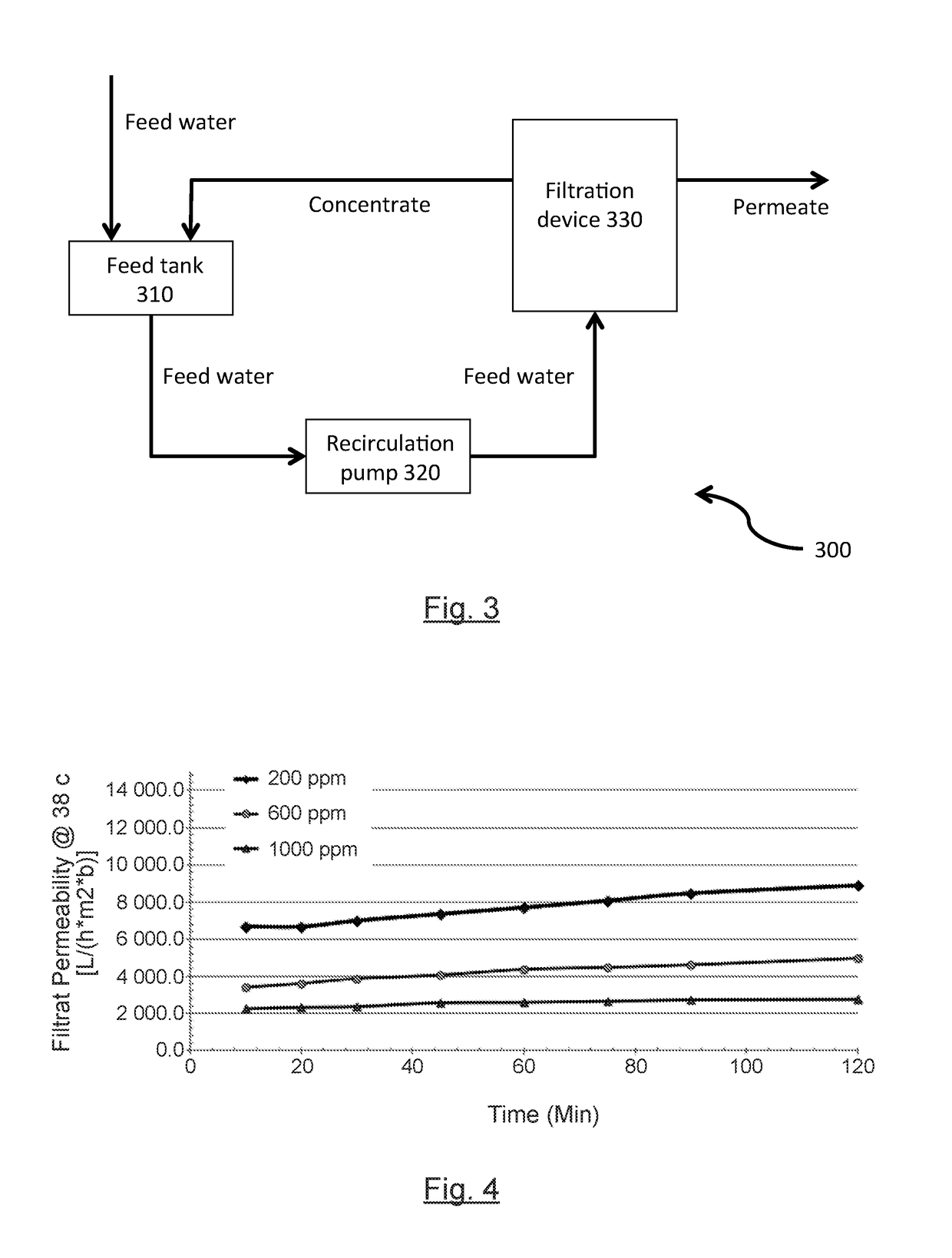

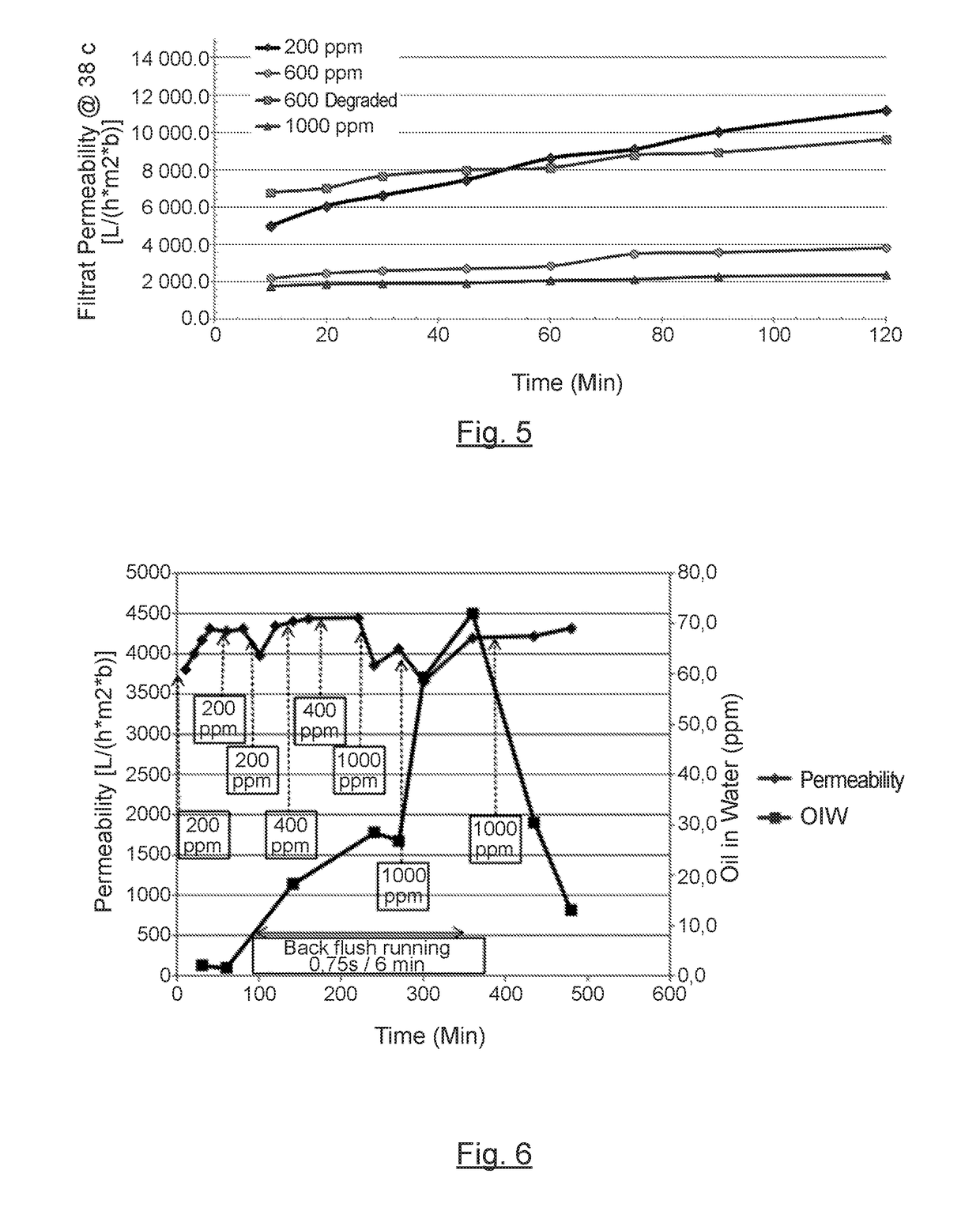

Chemically enhanced oil recovery method using viscosity-increasing polymeric compounds

ActiveUS20170233639A1Reduce the amount requiredAdjustable viscosityWaste water treatment from quariesMembranesChemistryProduced water

The present invention is concerned with the treatment of produced water, obtained from a chemically enhanced oil recovery process using viscosity-increasing polymeric compounds. Said treatment comprises particularly the steps of obtaining a produced water, from an oil-water mixture recovered from an oil-bearing formation, wherein the produced water comprises the viscosity-increasing polymeric compounds; and, of directing the produced water to a specific filtration device, and subjecting the produced water to filtration, for obtaining a retentate stream and a permeate stream. Said process allows particularly obtaining a permeate comprising the viscosity-increasing polymeric compounds, said permeate being substantially free of suspended solids, free oil and emulsified oil.

Owner:SNF SA

Equal cost tree transfer method and device

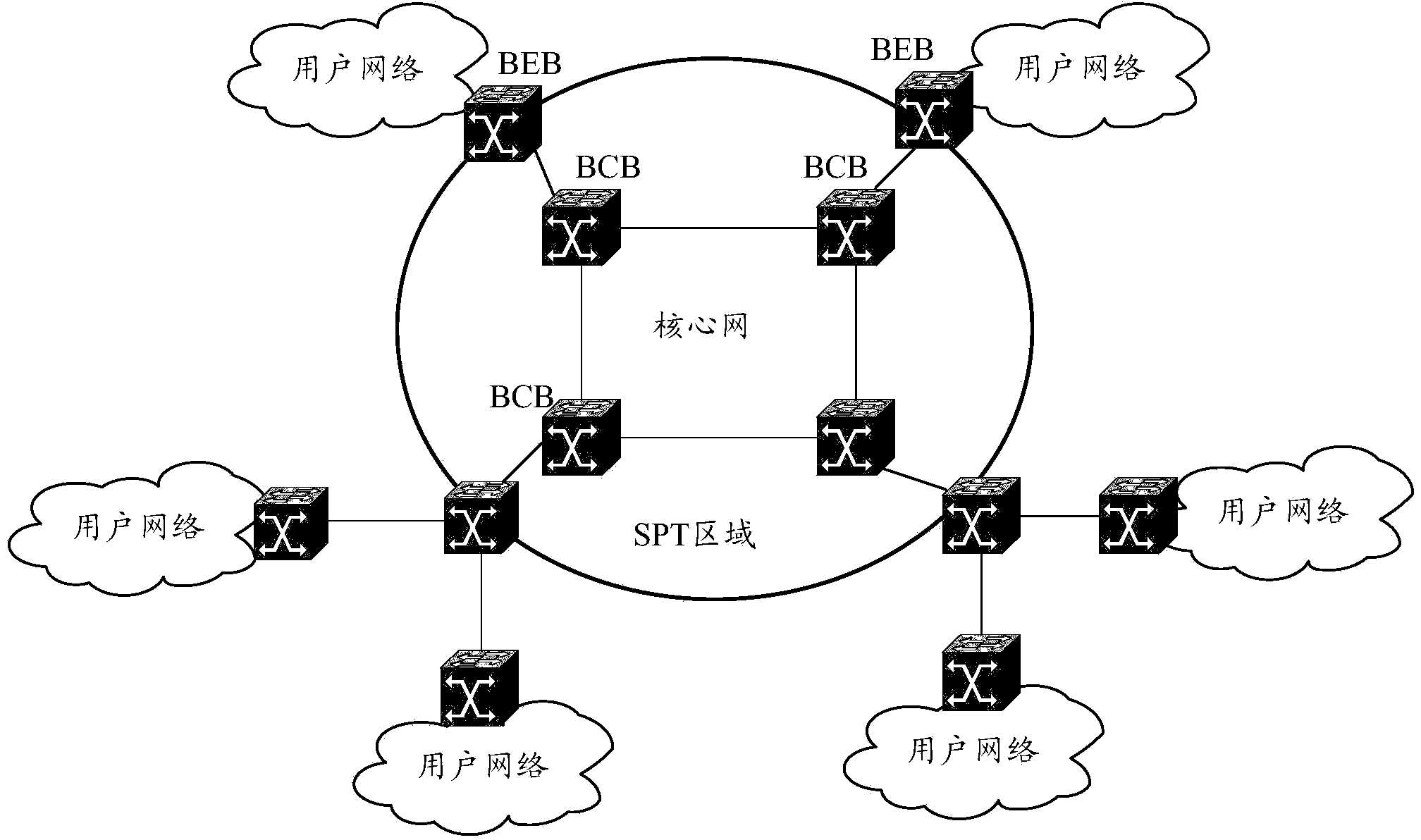

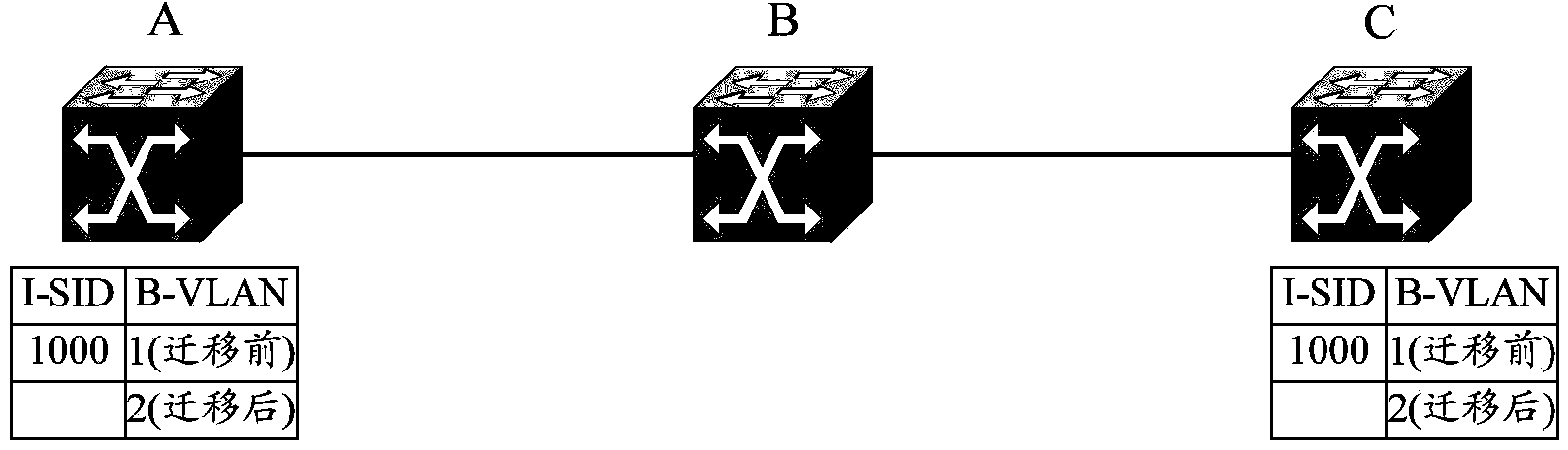

ActiveCN103634191AImprove the migration processReduce cut-offNetworks interconnectionComputer scienceLocal area network

The invention provides an equal cost tree transfer method and equipment. The method comprises the steps of when BCB (backbone core bridge) equipment detects that any one BEB (backbone edge bridge) equipment does not support ECT (equal cost tree) smooth transfer in the ECT transfer process of an I-SID (backbone service instance identifier), judging whether the unicast forwarding table entry of the I-SID in a new B-VLAN (backbone-virtual local area network) taking the BEB equipment as a source is calculated or not, if so, directly deleting the unicast forwarding table entry of the I-SID in the old B-VLAN taking the BEB equipment as the source, if not, after receiving an LSP (link state protocol) message sent by the BEB equipment, calculating a unicast forwarding table entry of the I-SID in the new B-VLAN taking the BEB equipment as the source, sending the calculated table entry to a data plane, and deleting the unicast forwarding table entry of the I-SID in the old B-VLAN taking the BEB equipment as the source at the same time. The cutoff phenomenon during ECT transfer is reduced.

Owner:NEW H3C TECH CO LTD

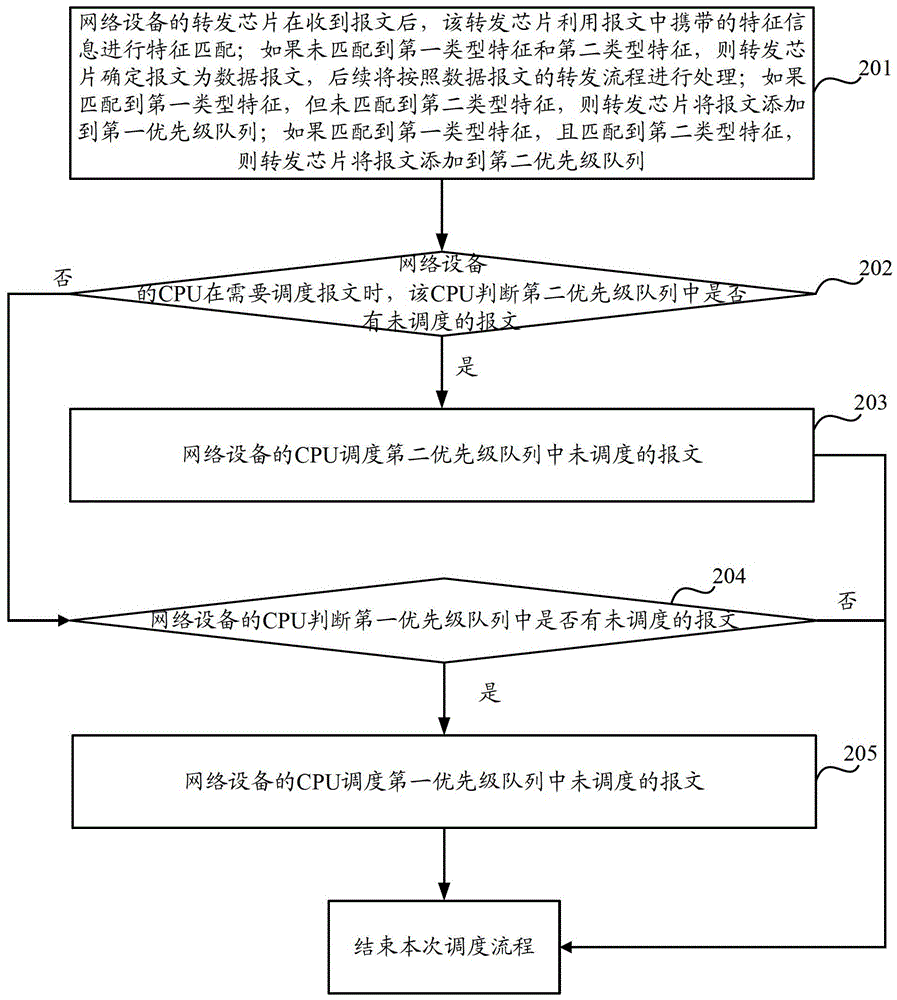

A message scheduling method and device

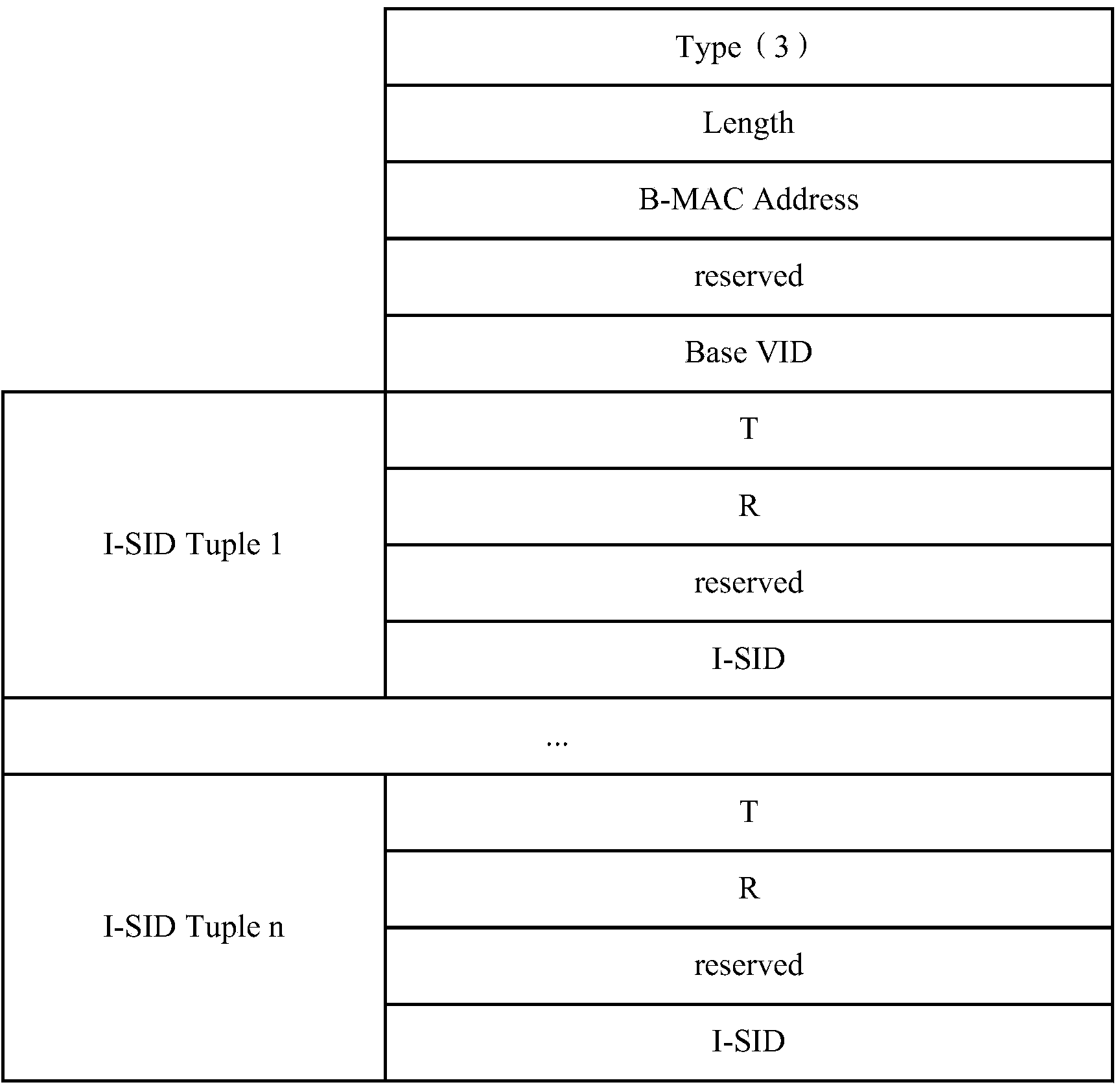

ActiveCN103188171BTimely processingReduce cut-offData switching networksNeighbor relationProtocol for Carrying Authentication for Network Access

The invention discloses a message scheduling method and equipment. The method comprises: after a forwarding chip of a network device receives a message, the forwarding chip uses the feature information carried in the message to perform feature matching; One type of feature, but not matched to the second type of feature, then add the message to the first priority queue; if the first type of feature is matched, and the second type of feature is matched, the message is added to the second priority queue; when the CPU of the network device is dispatching messages, the CPU judges whether there is a message in the second priority queue; if yes, then dispatches the messages in the second priority queue If not, judge whether there is a message in the first priority queue; if yes, schedule the message in the first priority queue. In the embodiment of the present invention, the network device can process the protocol message for maintaining the neighbor relationship in time.

Owner:XINHUASAN INFORMATION TECH CO LTD

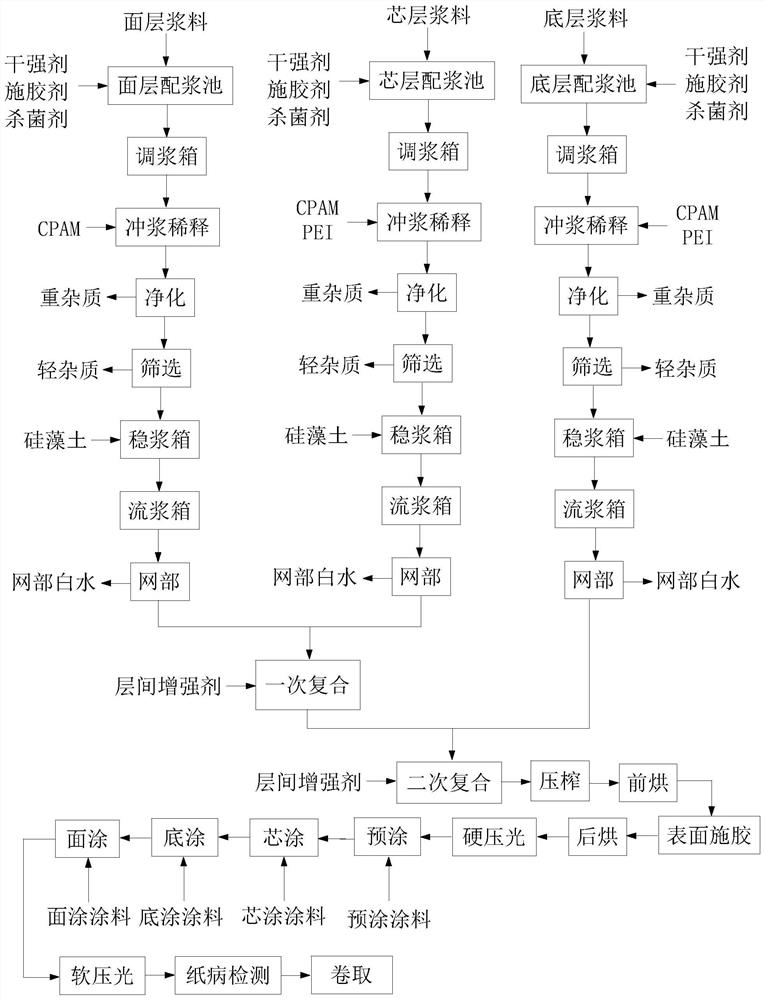

Coated white cardboard made of various fiber raw materials and production process of coated white cardboard

PendingCN114507999AAlleviate shortagesIncrease bulkSpecial paperWater-repelling agents additionBagasse pulpCardboard

The invention relates to a coating white cardboard made of various fiber raw materials and a production process thereof, the fiber raw materials of a core layer comprise bleached sulfate softwood pulp, bleached hardwood chemical thermo-mechanical pulp, white cardboard waste pulp and bagasse pulp, and the fiber raw materials of a bottom layer comprise bleached sulfate softwood pulp, bleached sulfate hardwood pulp and high-grade deinked pulp. An interlayer reinforcing agent is sprayed between the layers; the bagasse pulp can be chemically bleached mechanical pulp, and the interlayer enhancer comprises 40-75 parts of spraying starch, 10-20 parts of water-based novolac epoxy resin emulsion and 8-15 parts of styrene-acrylic emulsion; the retention and drainage aid in the slurry of the core layer and the bottom layer comprises PEI, CPAM and bentonite. According to the method, the problem of shortage of wood raw materials can be relieved, the cost is reduced, the defects of the strength, water resistance and the like of fiber pulp are overcome by spraying the interlayer reinforcing agent between layers, the finished pulp can have better water filtering performance and papermaking performance by chemically bleaching the mechanical bagasse pulp, and meanwhile, the strength performance of the finished paper is improved.

Owner:湛江晨鸣浆纸有限公司

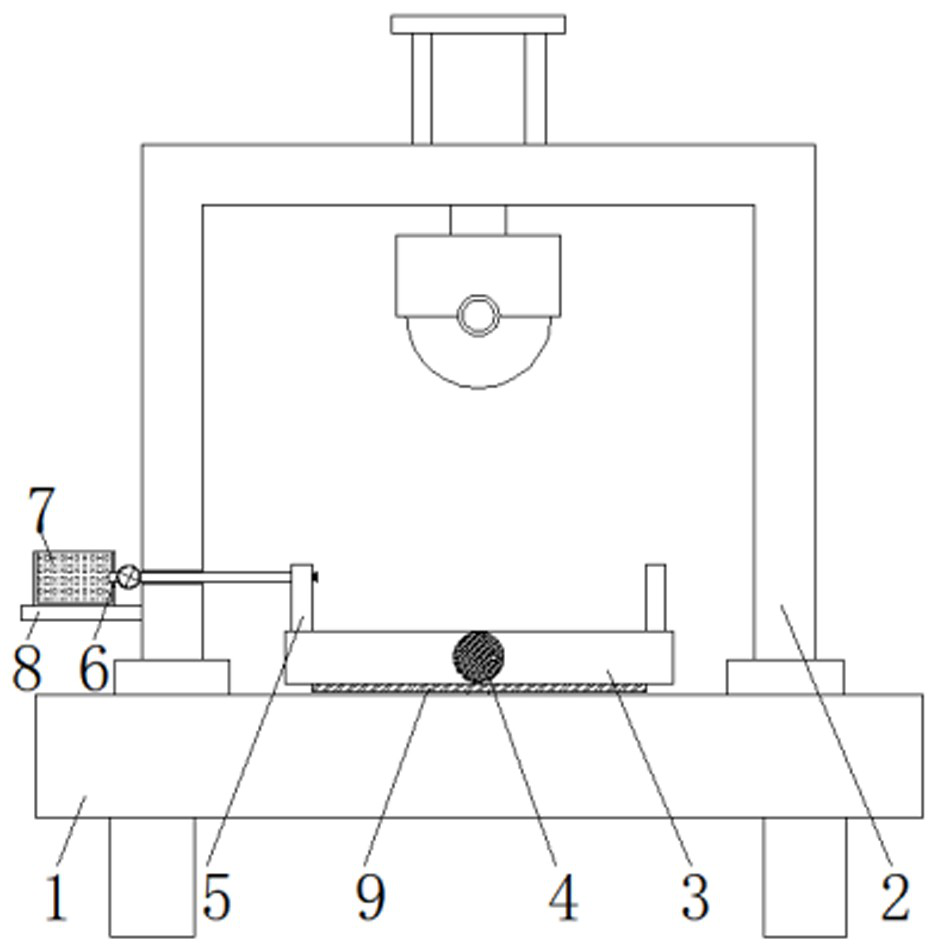

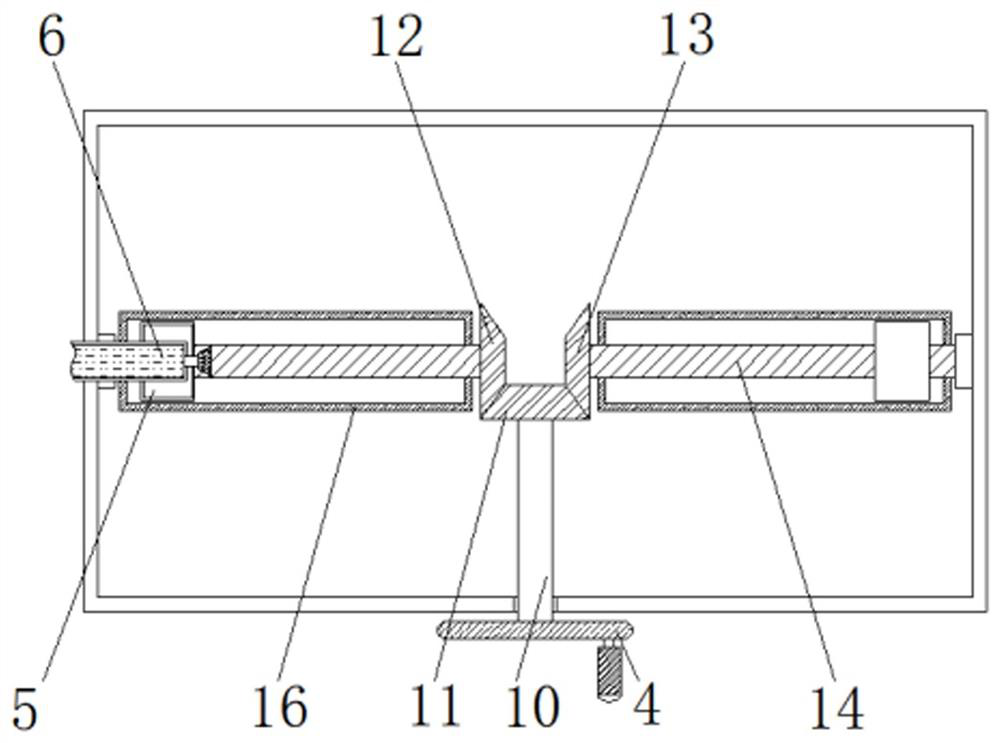

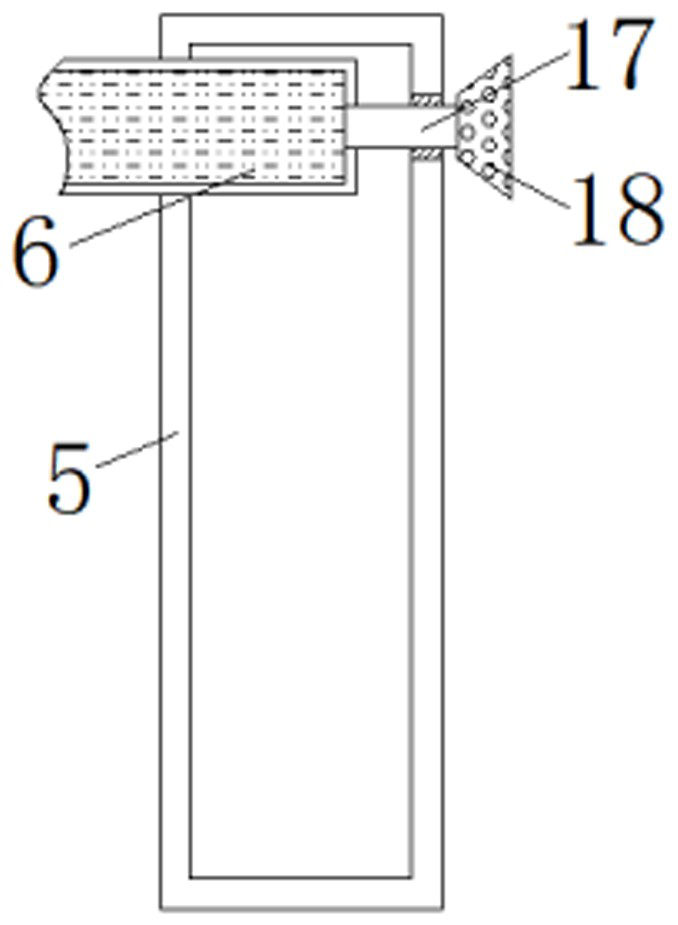

Full-automatic cut-off machine for stainless steel profile

InactiveCN112122702ACut off accuratelyProtect your healthPositioning apparatusMaintainance and safety accessoriesStructural engineeringSS - Stainless steel

The invention discloses a full-automatic cut-off machine for stainless steel profile. The full-automatic cut-off machine comprises a base, wherein an inverted rack is fixed to the top end of the base;a placing table is fixed to the top end of the base, a first rotating shaft is arranged on the outer wall of the front side of the placing table in a penetrating manner and through a bearing, the first rotating shaft extends to a cavity of the placing table and is rotationally provided with a first bevel gear in a sleeve manner at the tail end, and the two sides of the first bevel gear are in engaged connection to a second bevel gear and a third bevel gear correspondingly; first lead screws rotationally penetrate through the inner walls of the second bevel gear and the third bevel gear, the outer walls of the first lead screws are rotationally sleeved with clamping plates, and sliding grooves allowing the clamping plates to slide are formed in the top end of the placing table; water injection pipes are fixed in cavities of the set of clamping plates, penetrate through the inner wall of one sides of the clamping plates, extends to the outer wall of one side of the rack and are connected to a water tank in an inserted mode at the tail end, and a fixing plate is fixed to the bottom end of the water tank; and connecting pipes are fixed to the surfaces of the sides, located in the cavities of the clamping plates, of the water injection pipes and extend to the outer walls of one sides of the clamping plates, and are fixedly provided with atomizing nozzles at the tail ends of the connecting pipes.

Owner:昆山佳欣成精密机械有限公司

Grinding table of disc grinder for preparing synthetic fiber pulp

ActiveCN102086606BReduce specific edge loadWeaken cut-off functionPulp beating/refining methodsEngineeringResidence time

Owner:BLUESTAR CHENGDU NEW MATERIALS

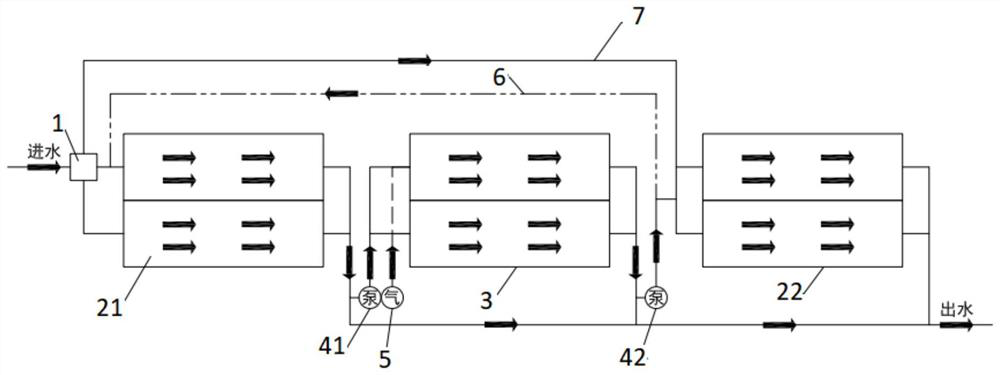

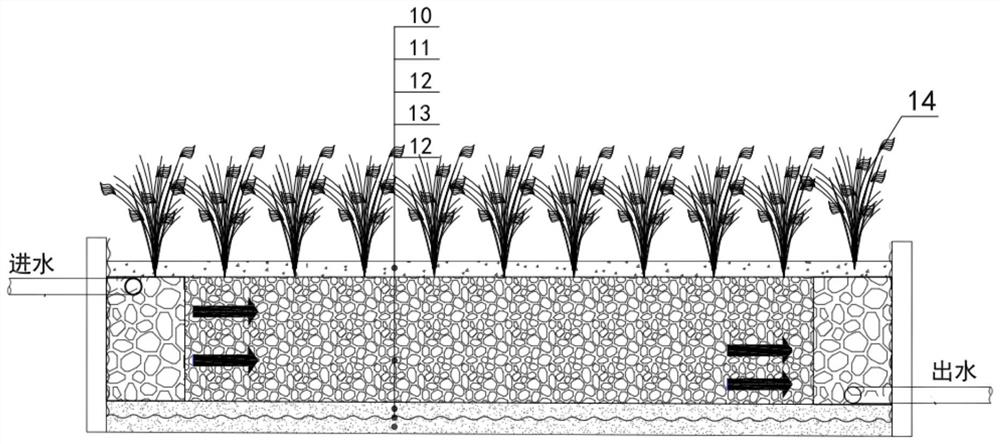

Combined controllable type efficient purification constructed wetland system

InactiveCN113003728AEfficient implementationEasy to operate and controlBiological treatment apparatusWater treatment fluid flow conditionsConstructed wetlandEnvironmental engineering

The invention discloses a combined controllable type efficient purification constructed wetland system. The system comprises a water distribution well, a first water pump, a second water pump, an aeration device, and a first-stage horizontal subsurface flow wetland unit, a second-stage vertical subsurface flow wetland unit and a third-stage horizontal subsurface flow wetland unit which are connected in series through pipelines, wherein the water distribution well is communicated with a water inlet of the first-stage horizontal subsurface flow wetland unit through a water inlet pipe; the first water pump is used for lifting effluent of the first-stage horizontal subsurface flow wetland unit to the second-stage vertical subsurface flow wetland unit, and the aeration device is used for carrying out aeration treatment on inflow water of the second-stage vertical subsurface flow wetland unit; and the second water pump is used for lifting effluent of the second-stage vertical subsurface flow wetland unit to the third-stage horizontal subsurface flow wetland unit. The operation mode is controllable, operation is easy and convenient, main factors influencing the wetland can be effectively controlled, implementation is effective, application is wide, and secondary pollution cannot be caused.

Owner:CHINA ENFI ENGINEERING CORPORATION

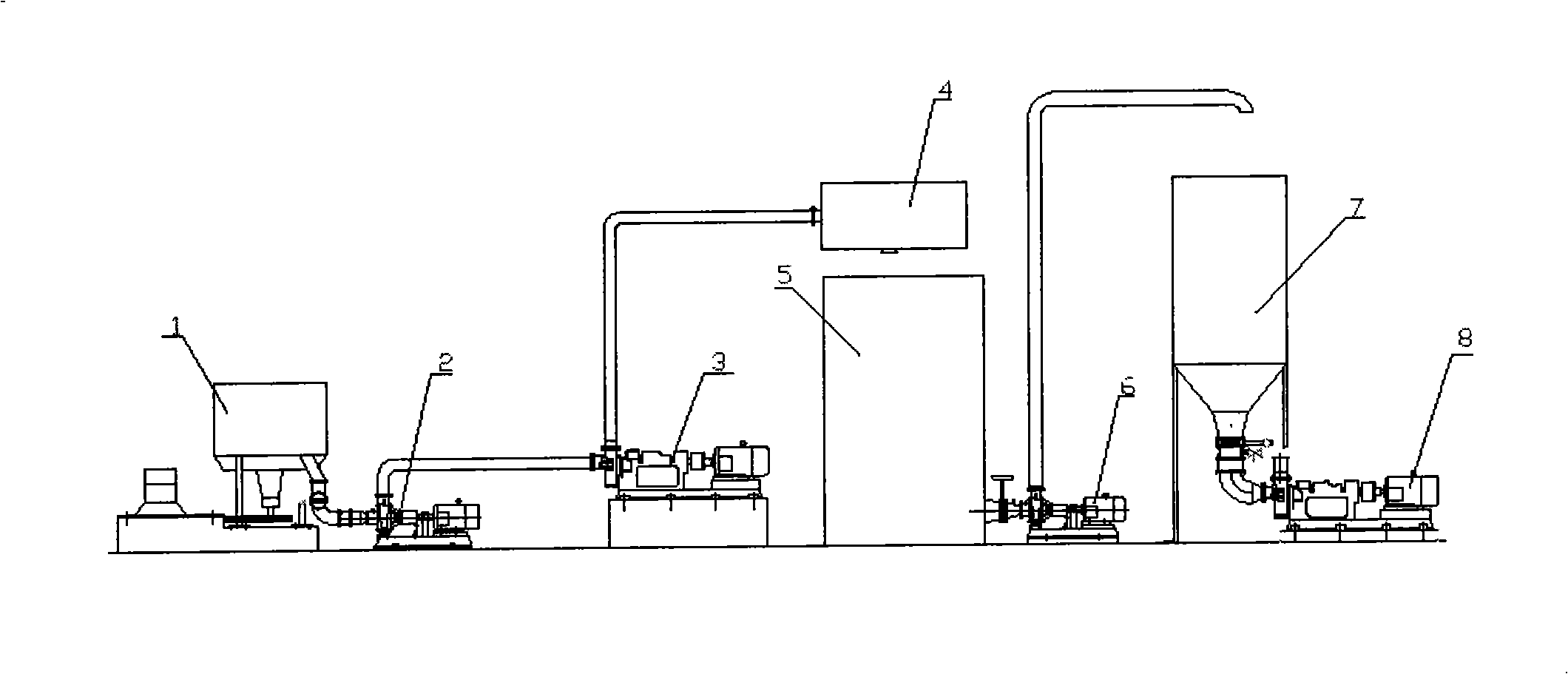

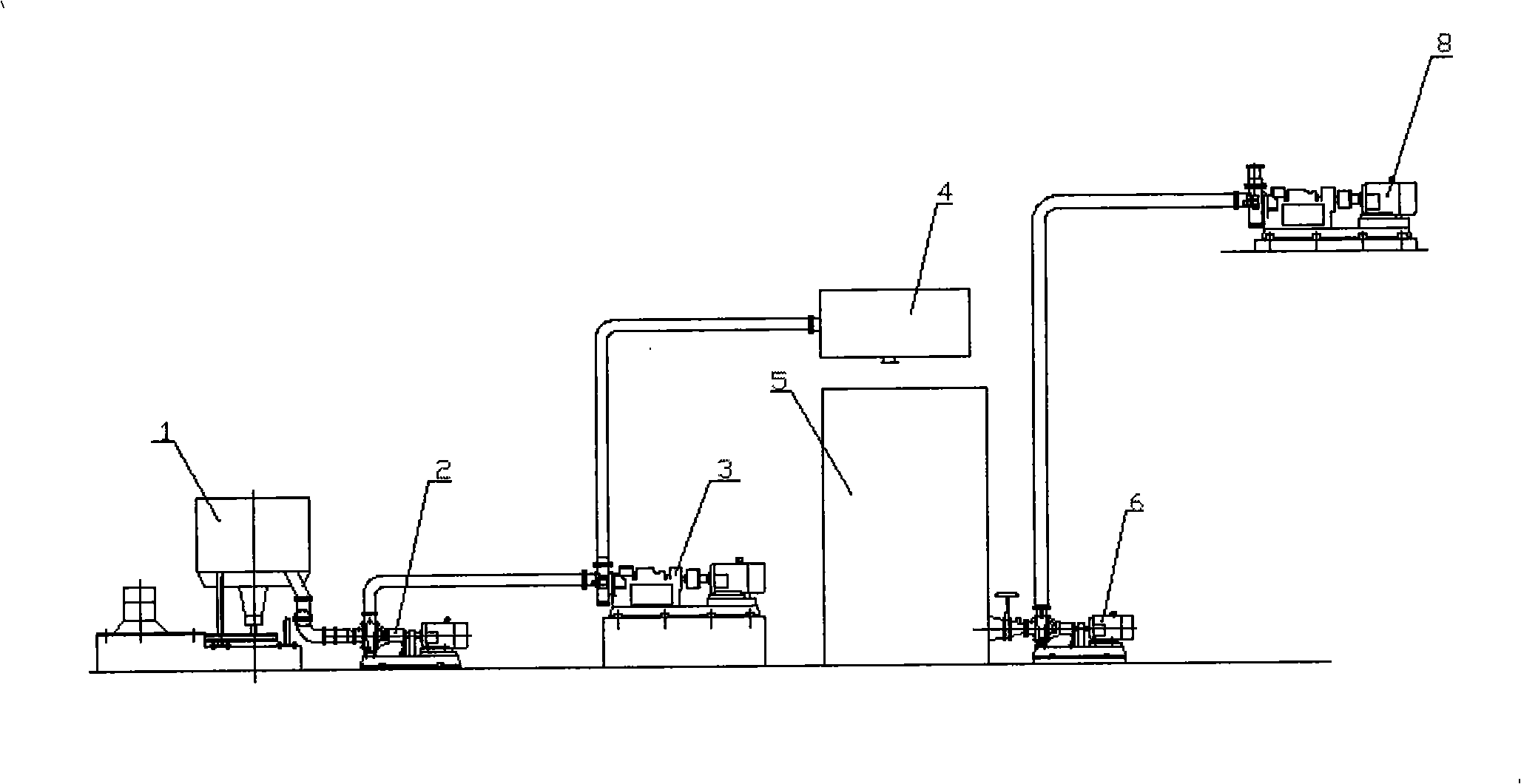

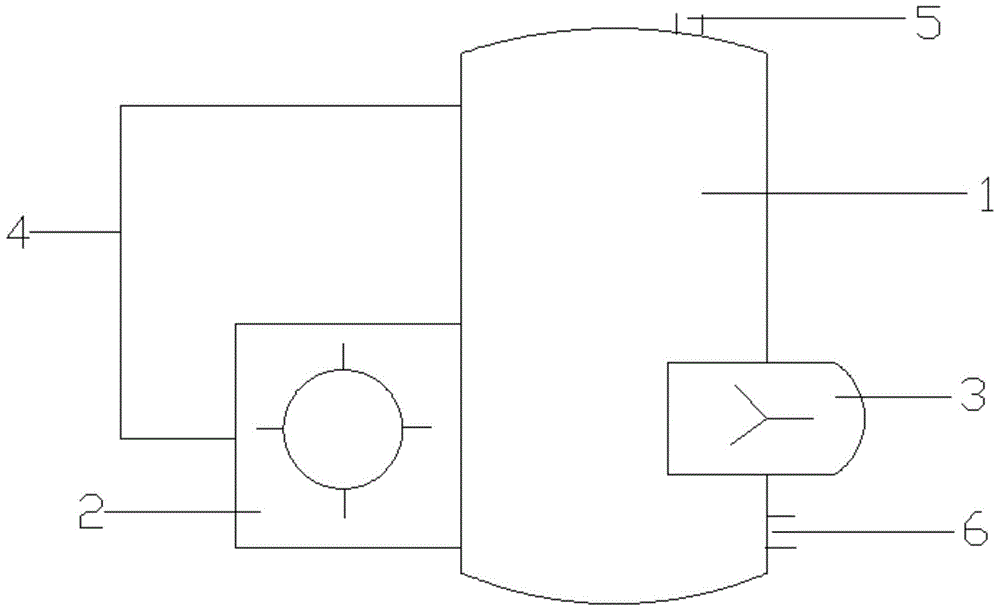

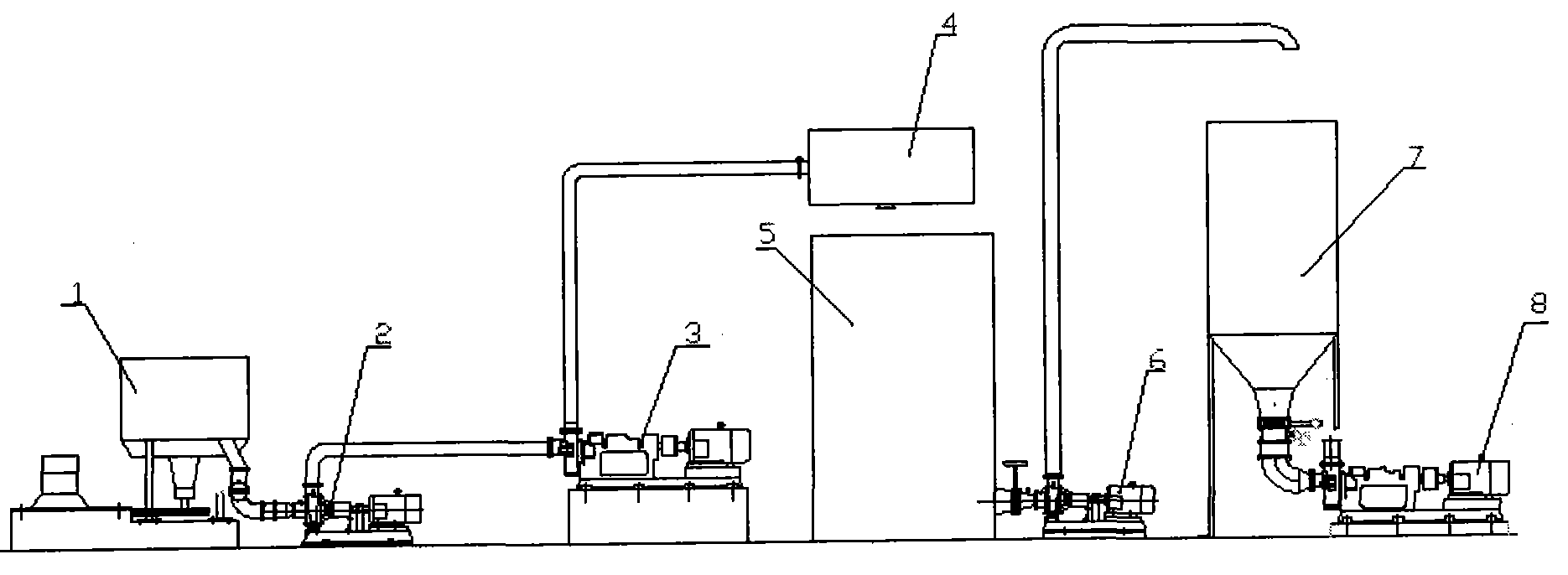

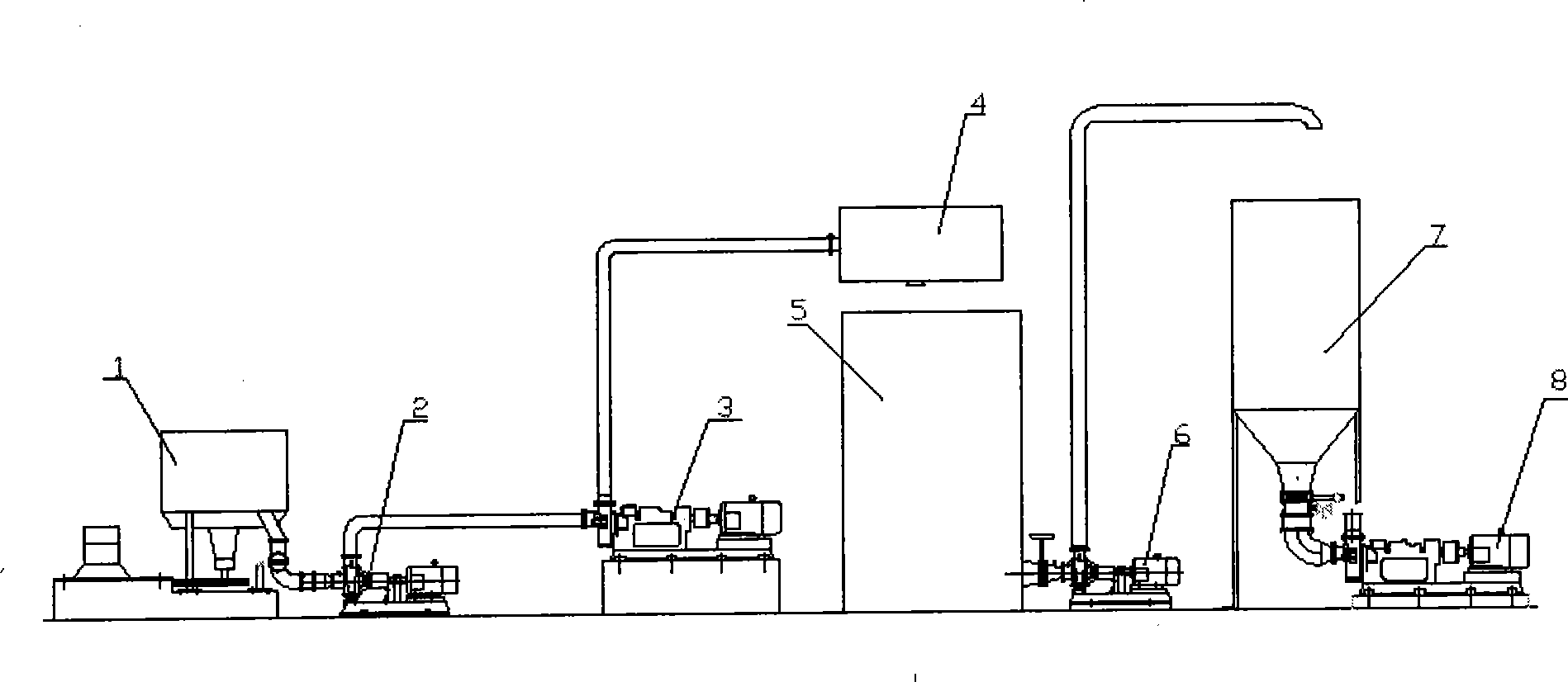

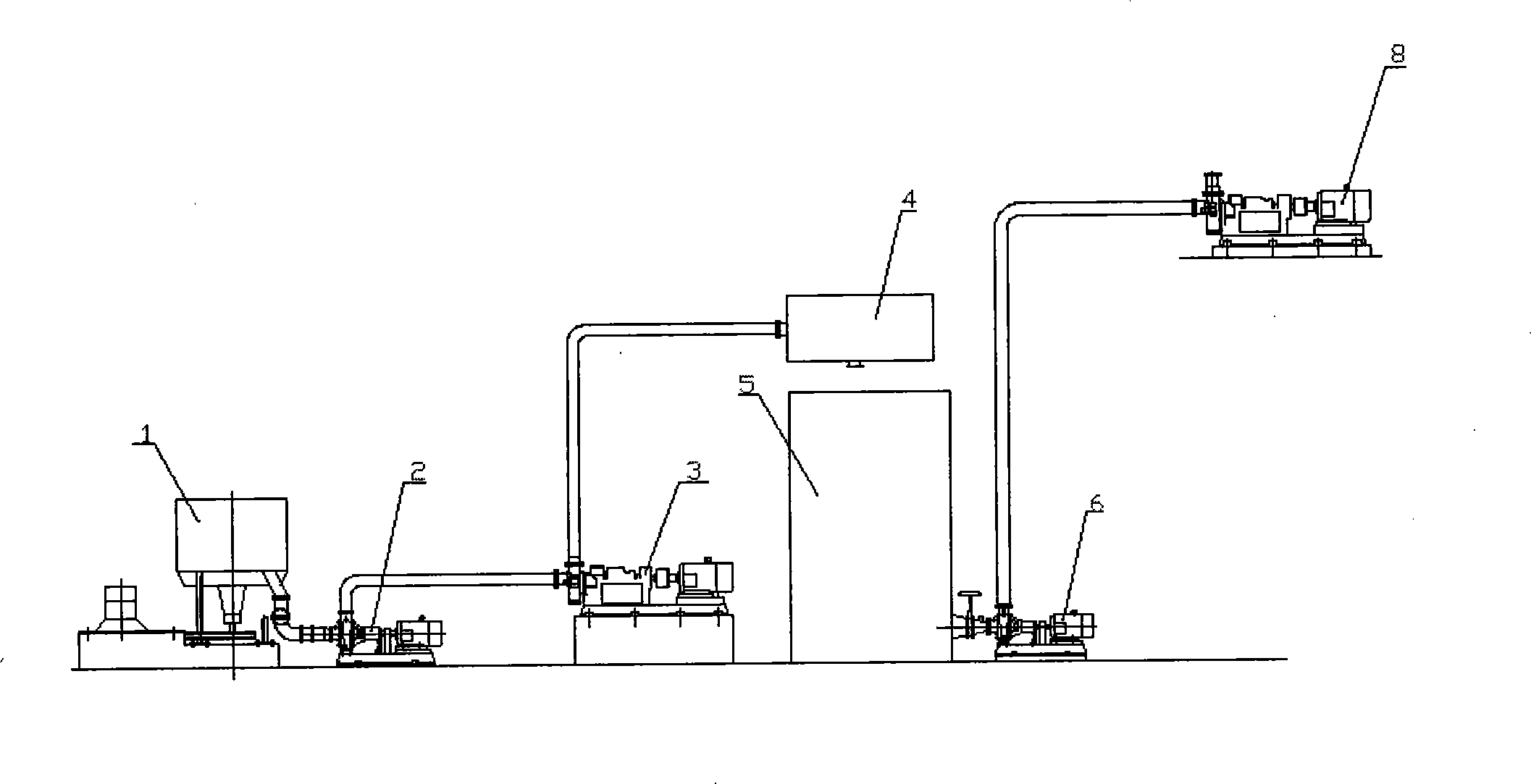

Method and device for extracting and scattering tobacco stems synchronously

ActiveCN105495675AReduce power consumptionSimple structureTobacco preparationPulp and paper industrySolvent

The invention discloses a method and device for extracting and scattering tobacco stems synchronously. The method comprises the step one of carrying out feeding, wherein the tobacco stems and solvent are fed into a storage tank according to the set proportion; the step two of carrying out stirring, wherein a push type paddle stirrer is started, and the materials in the step one are stirred and mixed uniformly to obtain a tobacco stem mixture; the step three of carrying out scattering while carrying out extracting, wherein a scattering machine is started, the tobacco stem mixture in the storage tank enters the scattering machine under action of stirring and driving force of the push type paddle stirrer, and then flows back to the storage tank through a circulating pulp pipe by utilizing the centrifugal pumping action generated by a rotor and pulp separating blades, so that the materials are extracted and scattered in a circulating mode; the step four of carrying out secondary extracting, wherein the scattering machine is closed for carrying out secondary extraction. While extracting and scattering are completed, the purposes of high extracting efficiency, good scattering quality and low energy consumption are achieved.

Owner:山东瑞博斯烟草有限公司

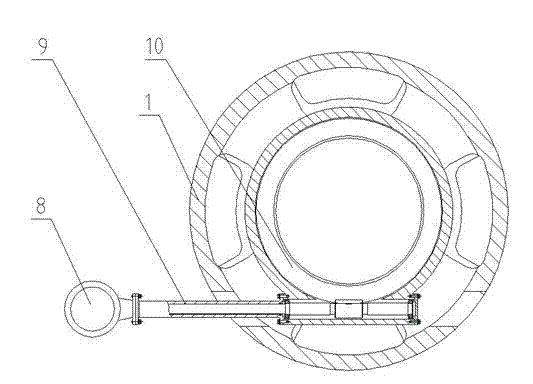

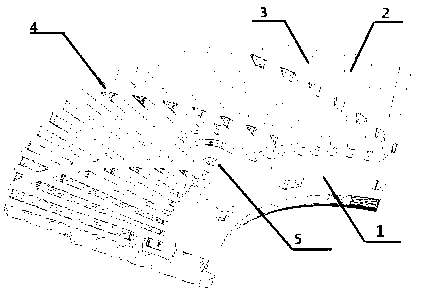

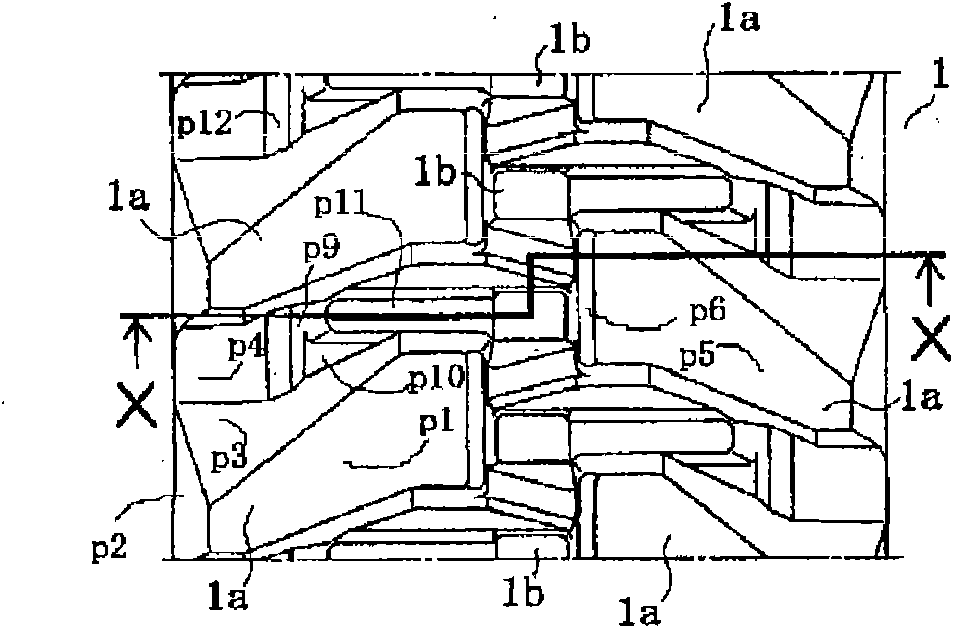

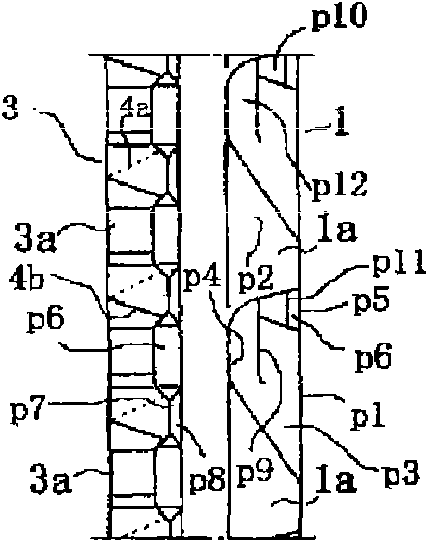

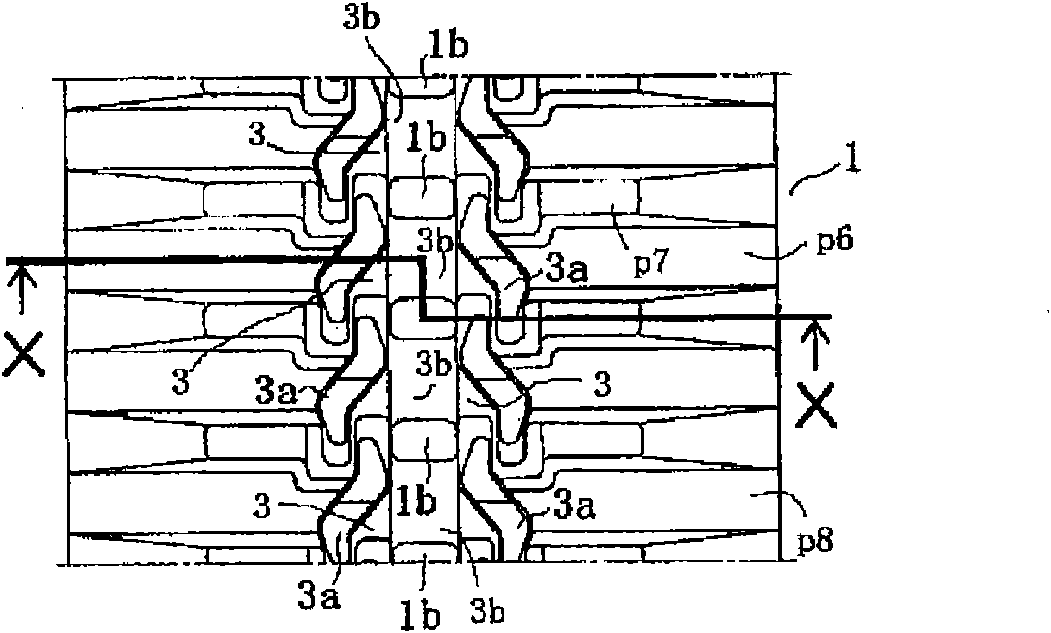

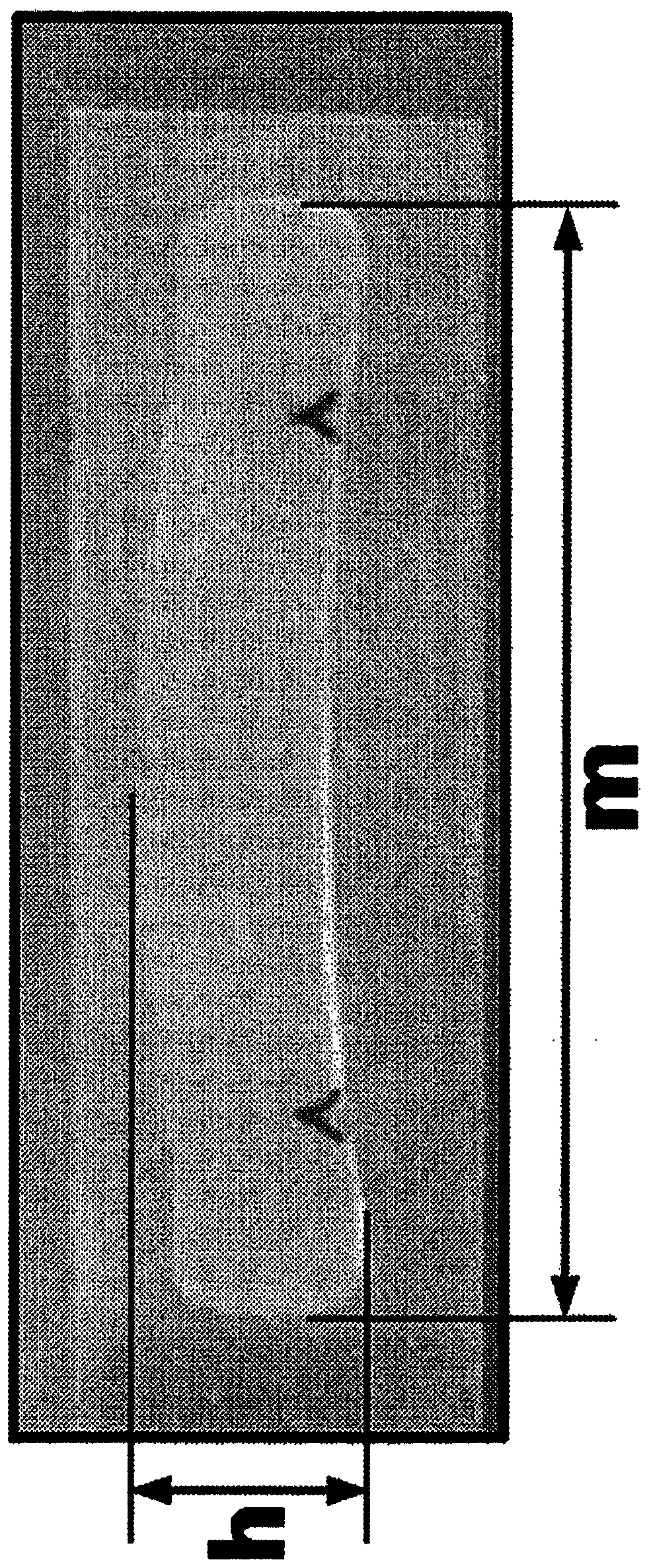

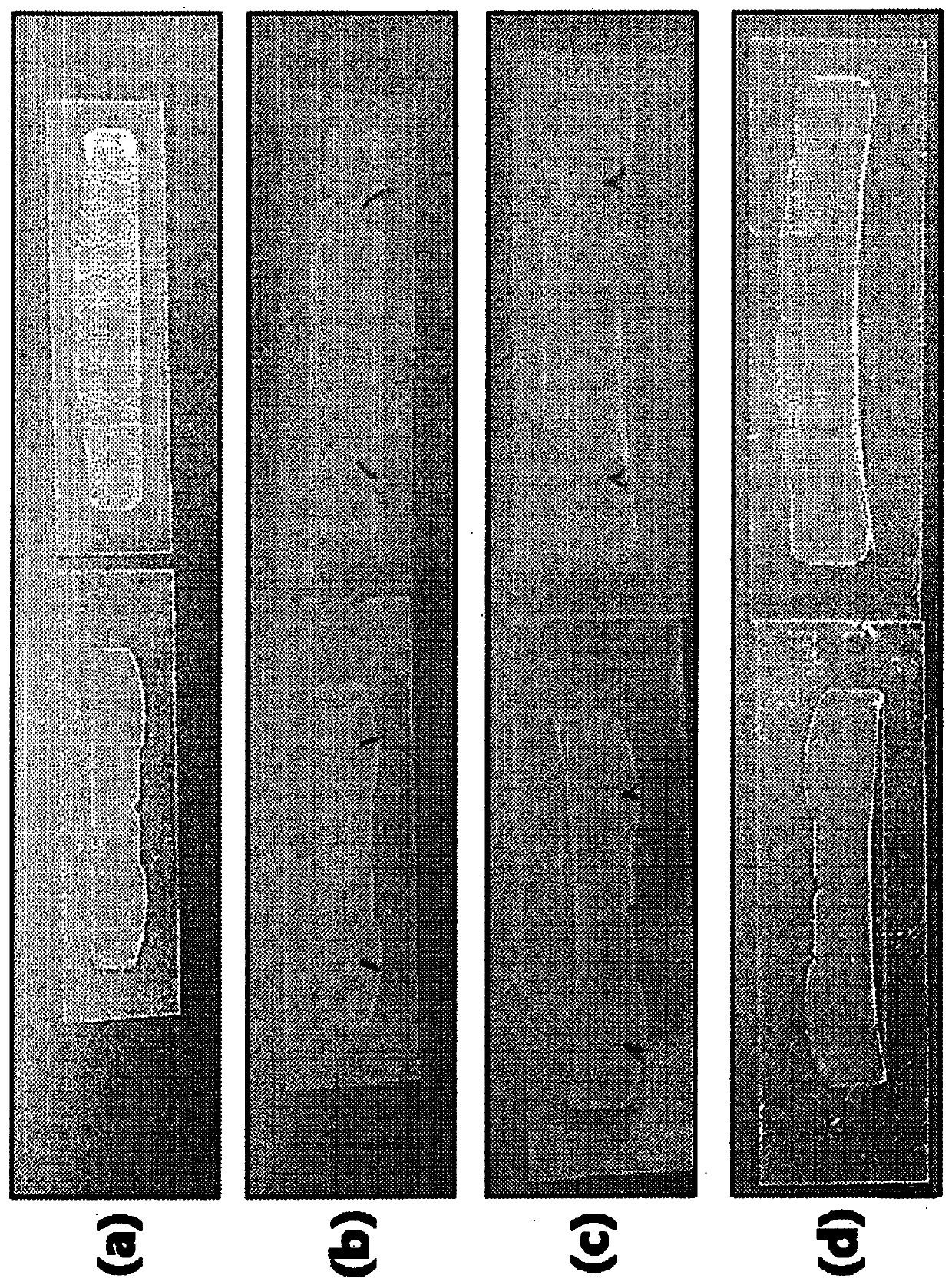

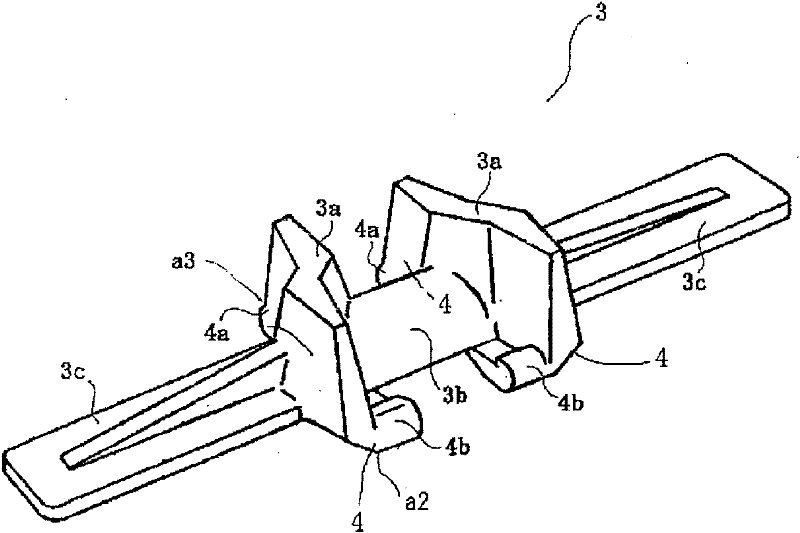

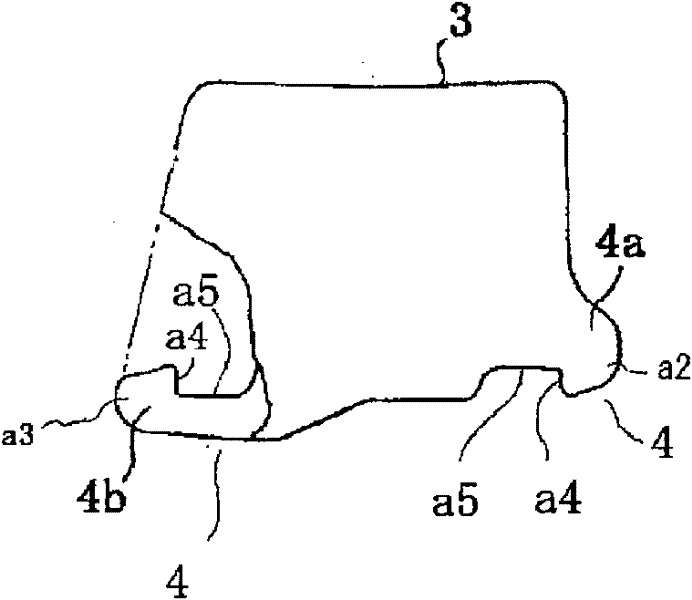

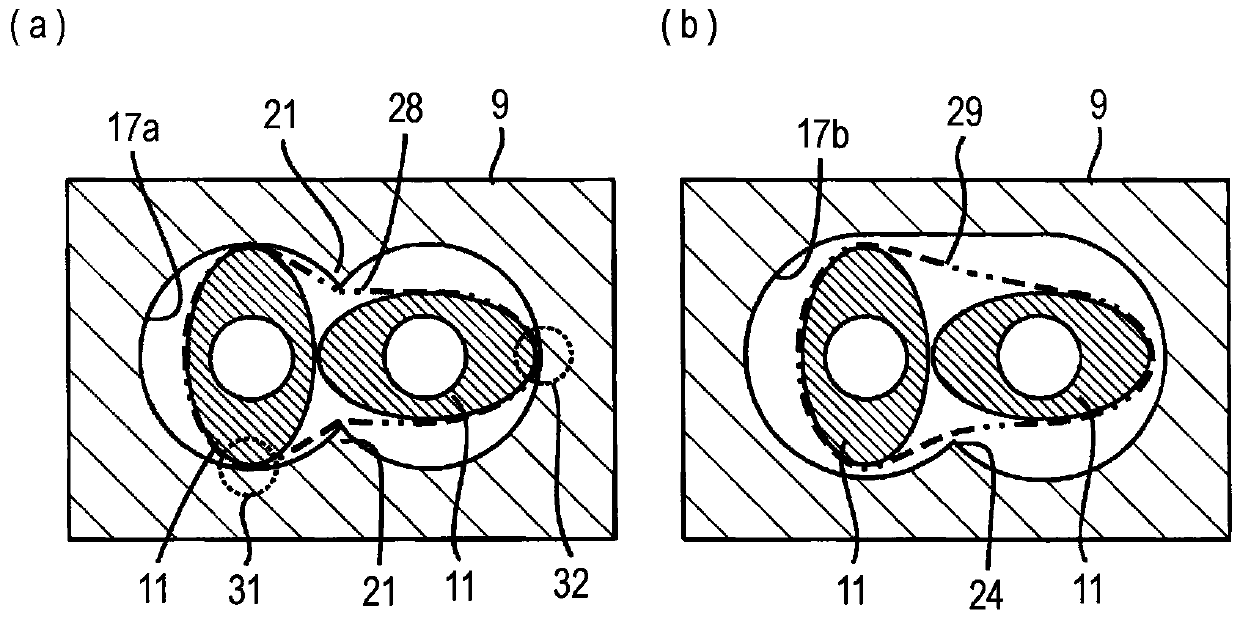

Core for rubber track and rubber track

ActiveCN101687524ABending stabilityAvoid cutsEndless track vehiclesEngineeringMechanical engineering

A rubber track (1) has formed in it simple means that can carry a part of abnormal tensile force acting on substantially the entire length in the circumferential direction of the rubber track (1). Theconstruction secures smooth operation of the rubber track and reliably prevents cutting of a steel cord (s1) due to such abnormal tensile force. A core (3) has an engagement section (3b) located in the center region in the longitudinal direction of the core, guide projections (3a) on the outer sides of opposite ends in the longitudinal direction of the engagement section, and wing sections (3c) provided on the outer sides of the guide projections (3a). The core (3) further has tensile force carrying sections (4a, 4b) arranged at positions that are located in the thickness direction of the core and are closer to the outer periphery of the rubber track than the outer peripheral-side surfaces of the wing sections (3c). The tensile force carrying sections (4a, 4b) carry tensile force acting in the lateral direction of the core and also carry pressing force acting in the thickness direction of the core. Corresponding tensile force carrying sections (4a, 4b) of cores adjacent to each otherin the circumferential direction of the rubber track are engaged with each other. Further, a fixation belt layer in the circumferential direction of the rubber track is provided in a rubber track body(1a) at positions related to tensile force carrying sections (4a, 4b).

Owner:FUKUYAMA GOMU KOGYO

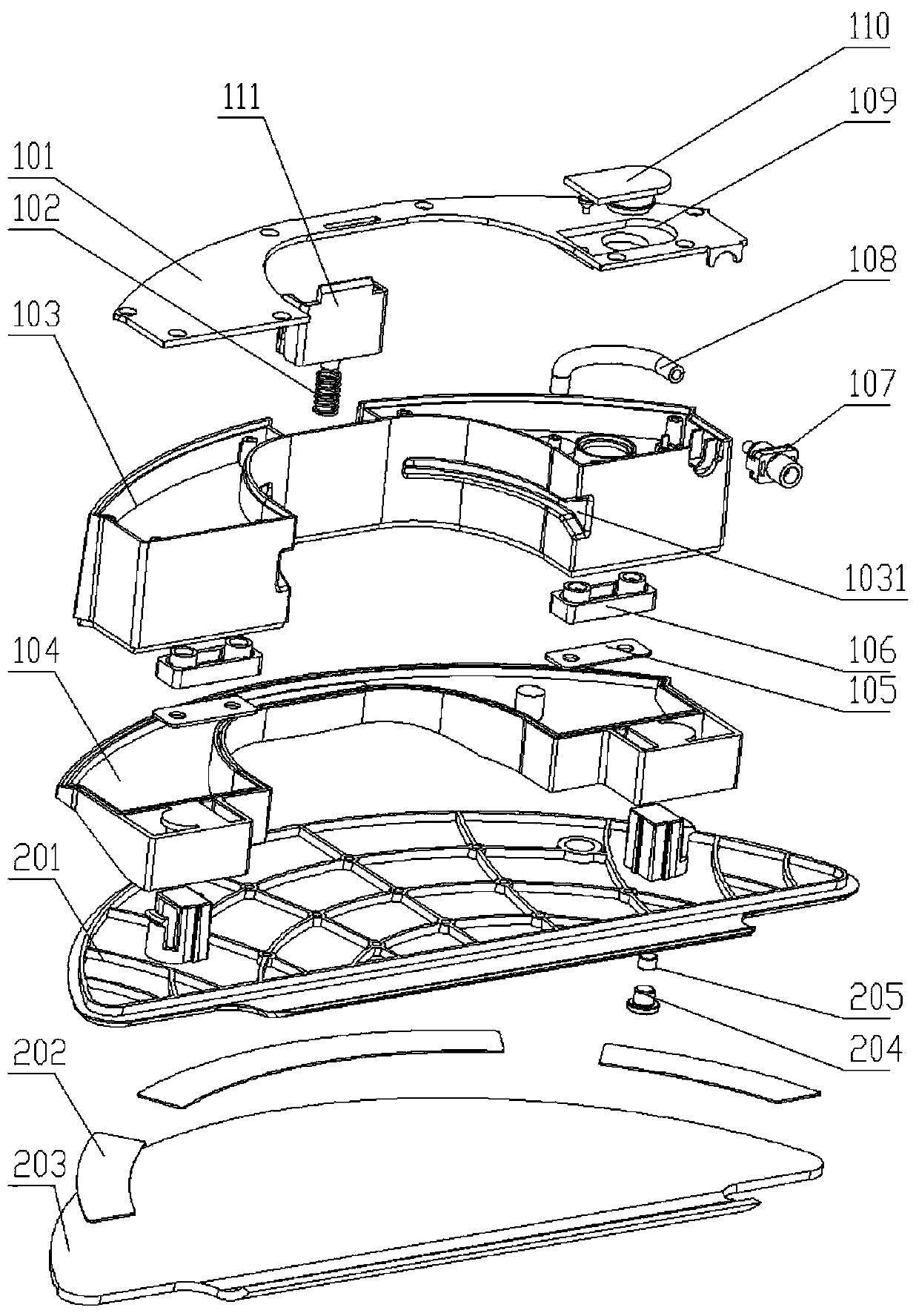

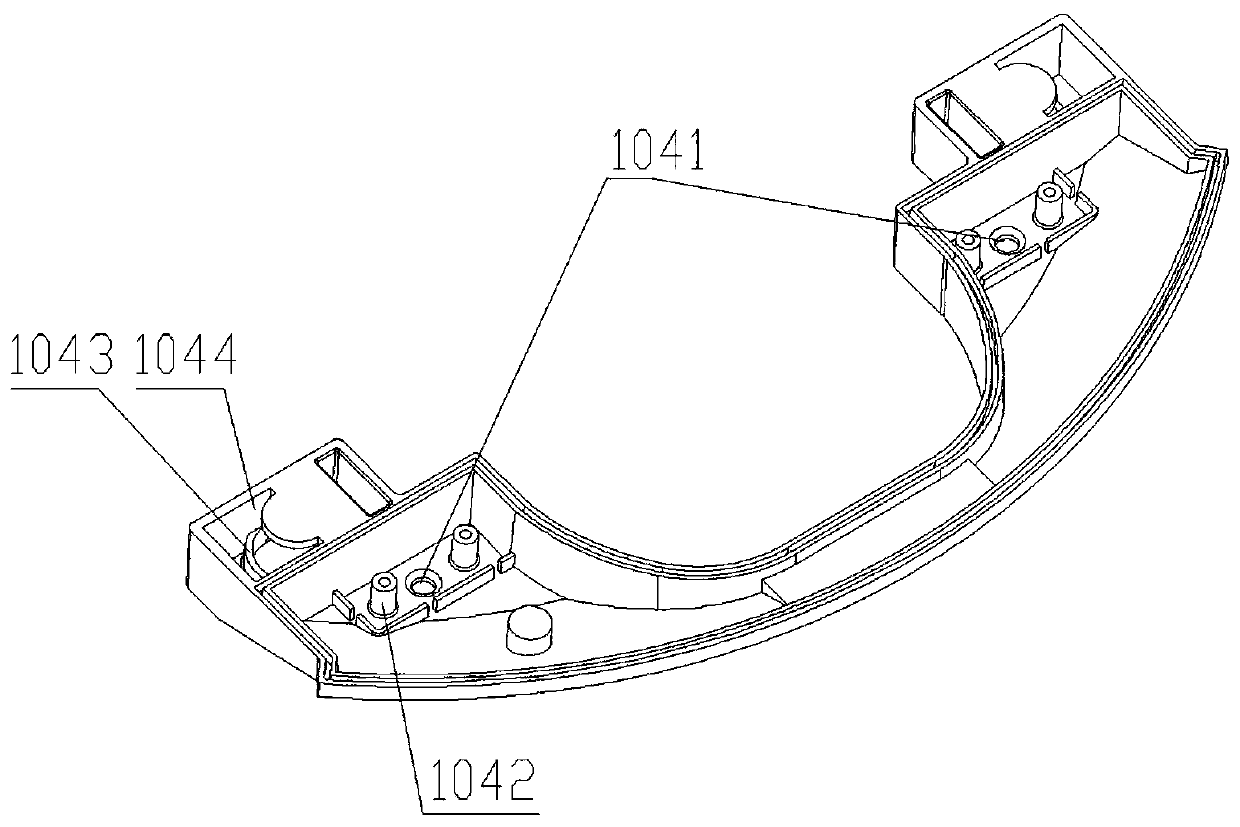

Water tank, mopping assembly and robot sweeper

PendingCN110680251AUniform water flowReduce cut-offCarpet cleanersFloor cleanersWater flowEnvironmental engineering

The invention discloses a water tank. The upper end of a water tank middle shell is connected with a water tank upper cover, the lower end of the water tank middle shell is connected with a water tanklower cover, and water seepage holes are formed in the water tank lower cover and used for allowing water to seep out of the water tank slowly; water guide cloth is arranged at the water seepage holes, and water seeps out of the water seepage holes through the water guide cloth. The invention further discloses a mopping assembly which is applied to a robot sweeper. The mopping assembly comprisesthe water tank in the embodiment, and the lower surface of the water tank lower cover is connected with a cleaning cloth assembly. The invention further discloses the robot sweeper. The robot sweepercan use the water tank or the mopping assembly described in the two embodiments. When the water tank is used, water is not affected by gravity under the action of air pressure, and water can be discharged uniformly. The phenomenon of water flow stopping can be reduced in a slope using process; water seepage is avoided in an out-of-service condition due to zero air pressure difference between internal air pressure of the water tank and atmospheric pressure; and because of the action of the water guide cloth, water cannot leak even though the water tank is shaken.

Owner:微思机器人(深圳)有限公司

Treatment of produced water, particularly obtained from a chemically enhanced oil recovery process using viscosity-increasing polymers

ActiveUS20170247999A1High cut-offEfficient separationWaste water treatment from quariesMembranesFiltrationOil water

Owner:VEOLIA WATER SOLUTIONS & TECH SUPPORT

Brush-off type tooth-attachable patch

InactiveCN111031998AIncreased durabilitySolve the durability problemCosmetic preparationsToilet preparationsMaxilla/MaxillaryCrown length

The present invention provides a pair of tooth-attachable patches for the upper and lower teeth, each of the patches comprising: a drug layer to be attached to teeth; and a support layer laminated onthe drug layer, wherein the heights of the patches for the upper and lower teeth are less than the crown lengths of maxillary and mandibular central incisors, respectively. The tooth-attachable patches of the present invention are prevented from coming in contact with the incisal tips of teeth, thereby reducing a user's feeling of heterogeneity while the patches are attached to the teeth of the user.

Owner:LG HOUSEHOLD & HEALTH CARE LTD

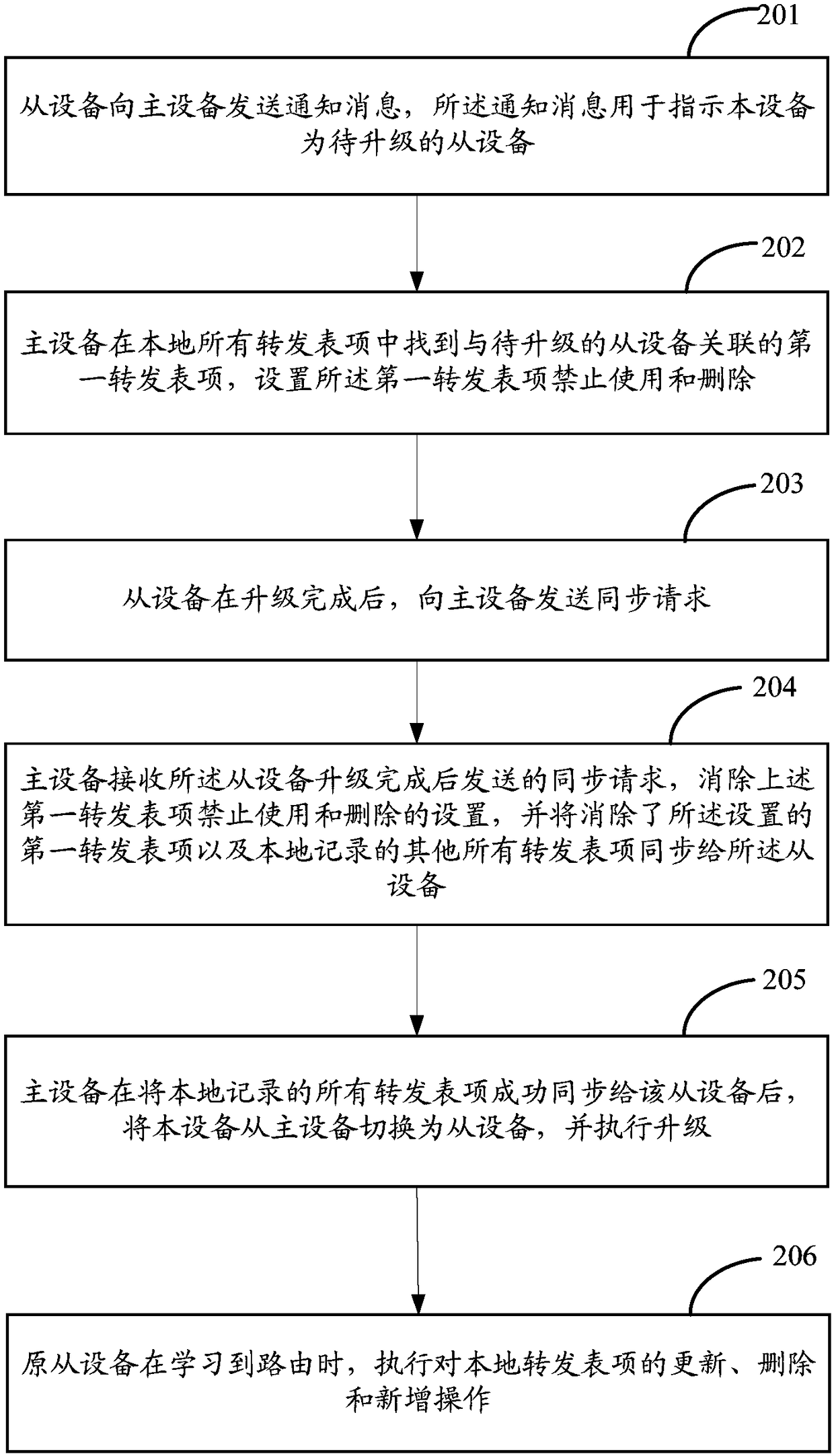

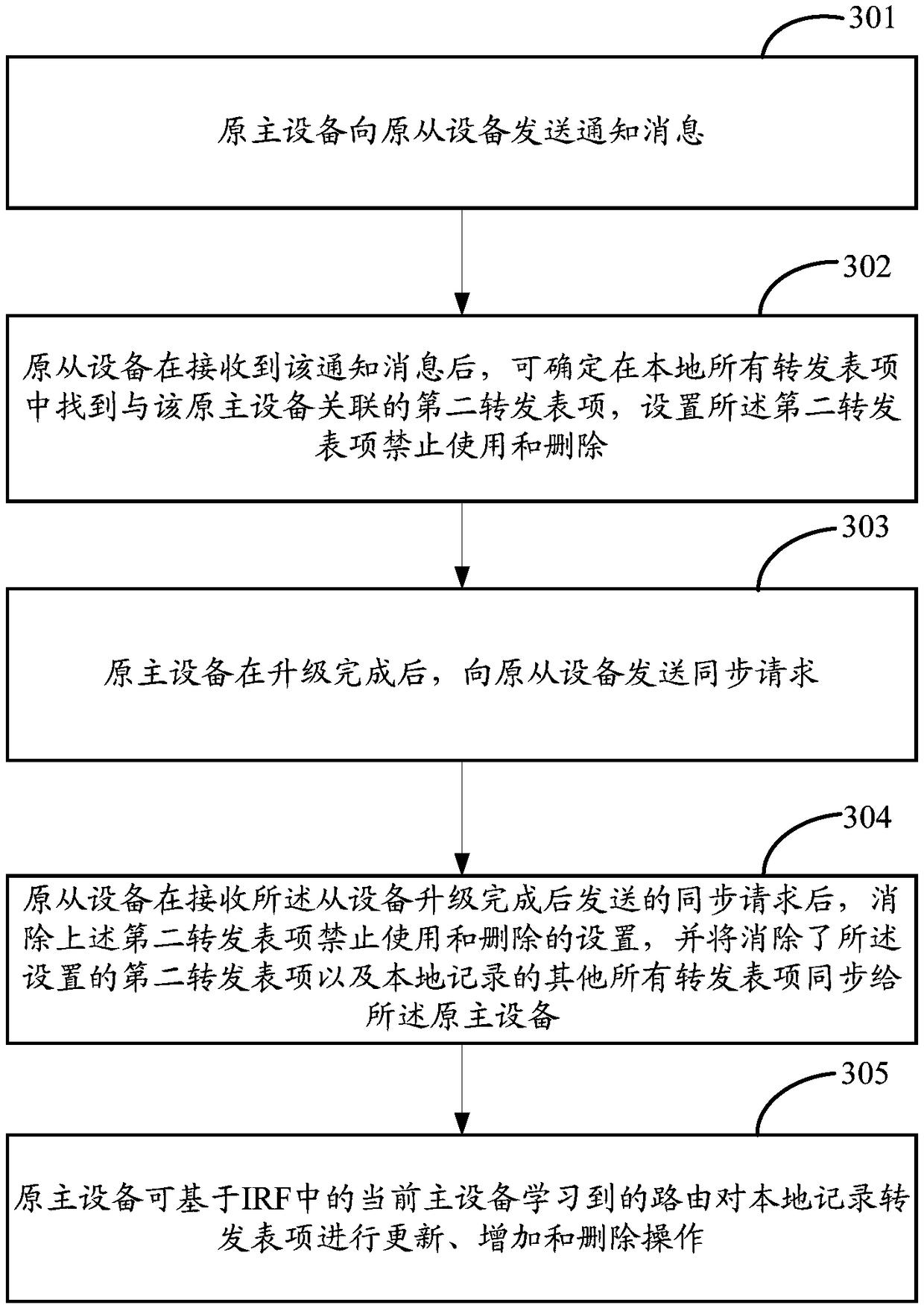

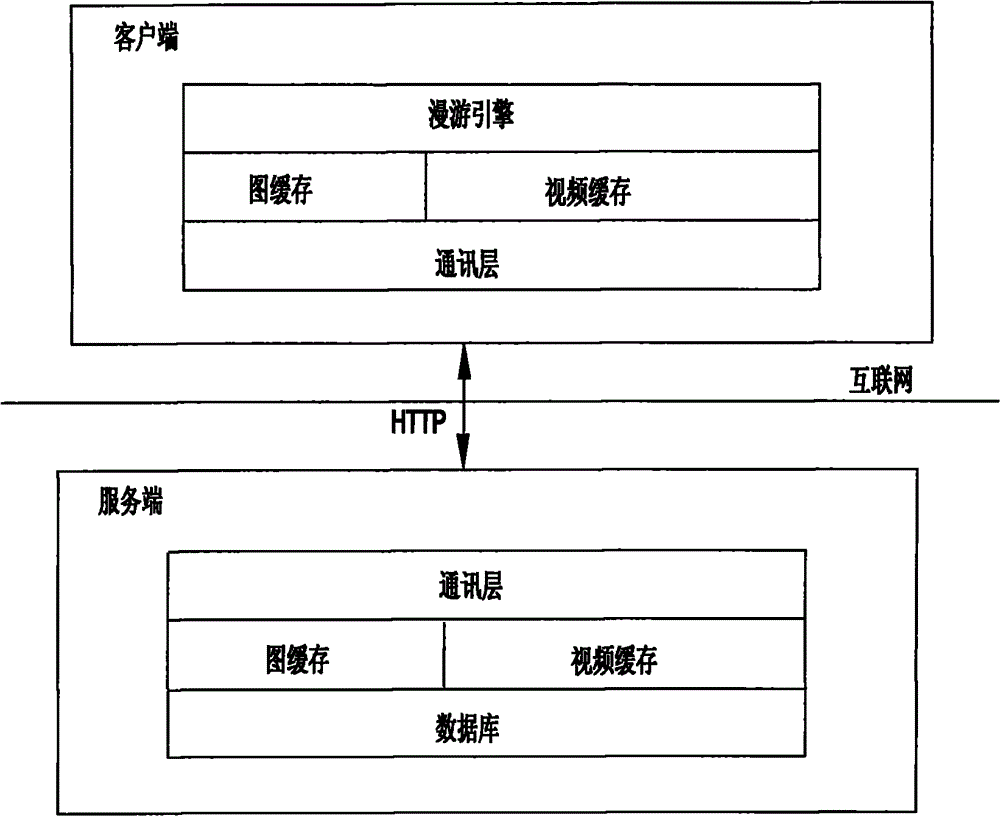

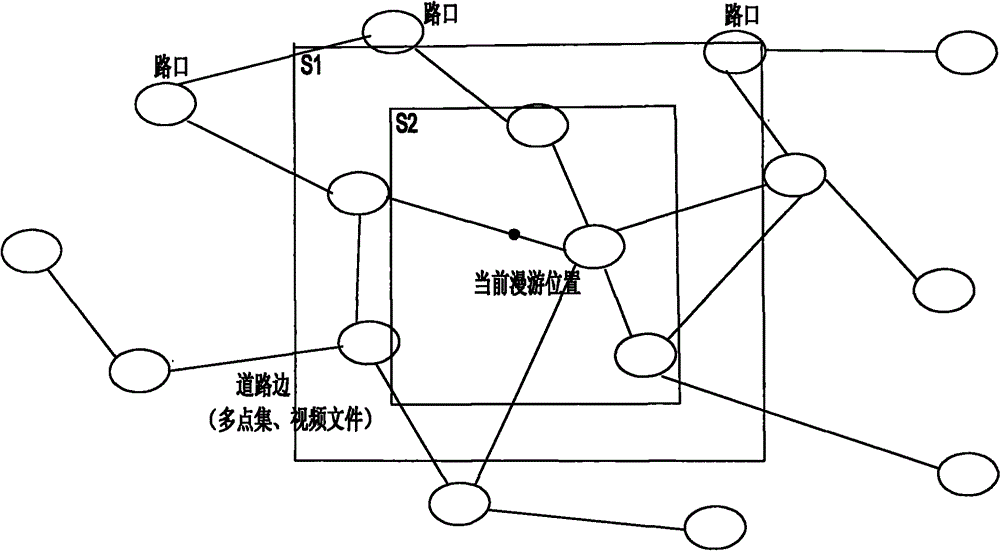

Equipment upgrading method and device

The application provides an equipment upgrading method and device. The method may include the following steps: when member equipment is primary equipment, finding a first forwarding entry associated with slave equipment to be upgraded in all local forwarding entries, and configuring the first forwarding entry to be forbidden from being used and deleted; receiving a synchronization request sent bythe slave equipment after the upgrade is completed, eliminating the configuration that the first forwarding entry is forbidden from being used and deleted, and synchronizing the first forwarding entrythat eliminates the configuration and all other forwarding entries that are recorded locally to the slave equipment; and after all the forwarding entries that are recorded locally are successfully synchronized to the slave equipment, switching the local equipment from the primary equipment to the slave equipment, and carrying out upgrading. By adopting the method provided by the application, theupgrade time for upgrading the equipment in an IRF cannot be increased, and the time of traffic interruption can also be reduced.

Owner:NEW H3C TECH CO LTD

Batch refiner and refining process thereof

ActiveCN102828432BLow tensile strengthHigh component contentPulp beating/refining methodsProcess engineeringIndustrial engineering

Owner:山东惠祥专利造纸机械有限公司

Method and device for processing neighbor entries

Embodiments of the present invention provide a method and device for processing neighbor entries. The method includes: when a network attack is detected, if no restriction entry is issued and the first neighbor corresponding to the first neighbor entry in the Probe state is detected Complete, then determine whether to receive the first NA response message sent by the first neighbor for detection; if the first NA response message is not received, then update the state of the first neighbor entry to the Departed state; wherein, Departed The state is used to indicate that the neighbor entry is discarded but has the forwarding function. By applying the embodiments of the present invention, in the case of a network attack, device outages can be reduced, and the impact of the network attack can be alleviated.

Owner:NEW H3C TECH CO LTD

A method and device for simultaneously extracting and deflecting tobacco stems

The invention discloses a method and device for extracting and scattering tobacco stems synchronously. The method comprises the step one of carrying out feeding, wherein the tobacco stems and solvent are fed into a storage tank according to the set proportion; the step two of carrying out stirring, wherein a push type paddle stirrer is started, and the materials in the step one are stirred and mixed uniformly to obtain a tobacco stem mixture; the step three of carrying out scattering while carrying out extracting, wherein a scattering machine is started, the tobacco stem mixture in the storage tank enters the scattering machine under action of stirring and driving force of the push type paddle stirrer, and then flows back to the storage tank through a circulating pulp pipe by utilizing the centrifugal pumping action generated by a rotor and pulp separating blades, so that the materials are extracted and scattered in a circulating mode; the step four of carrying out secondary extracting, wherein the scattering machine is closed for carrying out secondary extraction. While extracting and scattering are completed, the purposes of high extracting efficiency, good scattering quality and low energy consumption are achieved.

Owner:山东瑞博斯烟草有限公司

Core for rubber track and rubber track

A rubber track (1) has formed in it simple means that can carry a part of abnormal tensile force acting on substantially the entire length in the circumferential direction of the rubber track (1). The construction secures smooth operation of the rubber track and reliably prevents cutting of a steel cord (s1) due to such abnormal tensile force. A core (3) has an engagement section (3b) located in the center region in the longitudinal direction of the core, guide projections (3a) on the outer sides of opposite ends in the longitudinal direction of the engagement section, and wing sections (3c) provided on the outer sides of the guide projections (3a). The core (3) further has tensile force carrying sections (4a, 4b) arranged at positions that are located in the thickness direction of the core and are closer to the outer periphery of the rubber track than the outer peripheral-side surfaces of the wing sections (3c). The tensile force carrying sections (4a, 4b) carry tensile force acting in the lateral direction of the core and also carry pressing force acting in the thickness direction of the core. Corresponding tensile force carrying sections (4a, 4b) of cores adjacent to each otherin the circumferential direction of the rubber track are engaged with each other. Further, a fixation belt layer in the circumferential direction of the rubber track is provided in a rubber track body (1a) at positions related to tensile force carrying sections (4a, 4b).

Owner:FUKUYAMA GOMU KOGYO

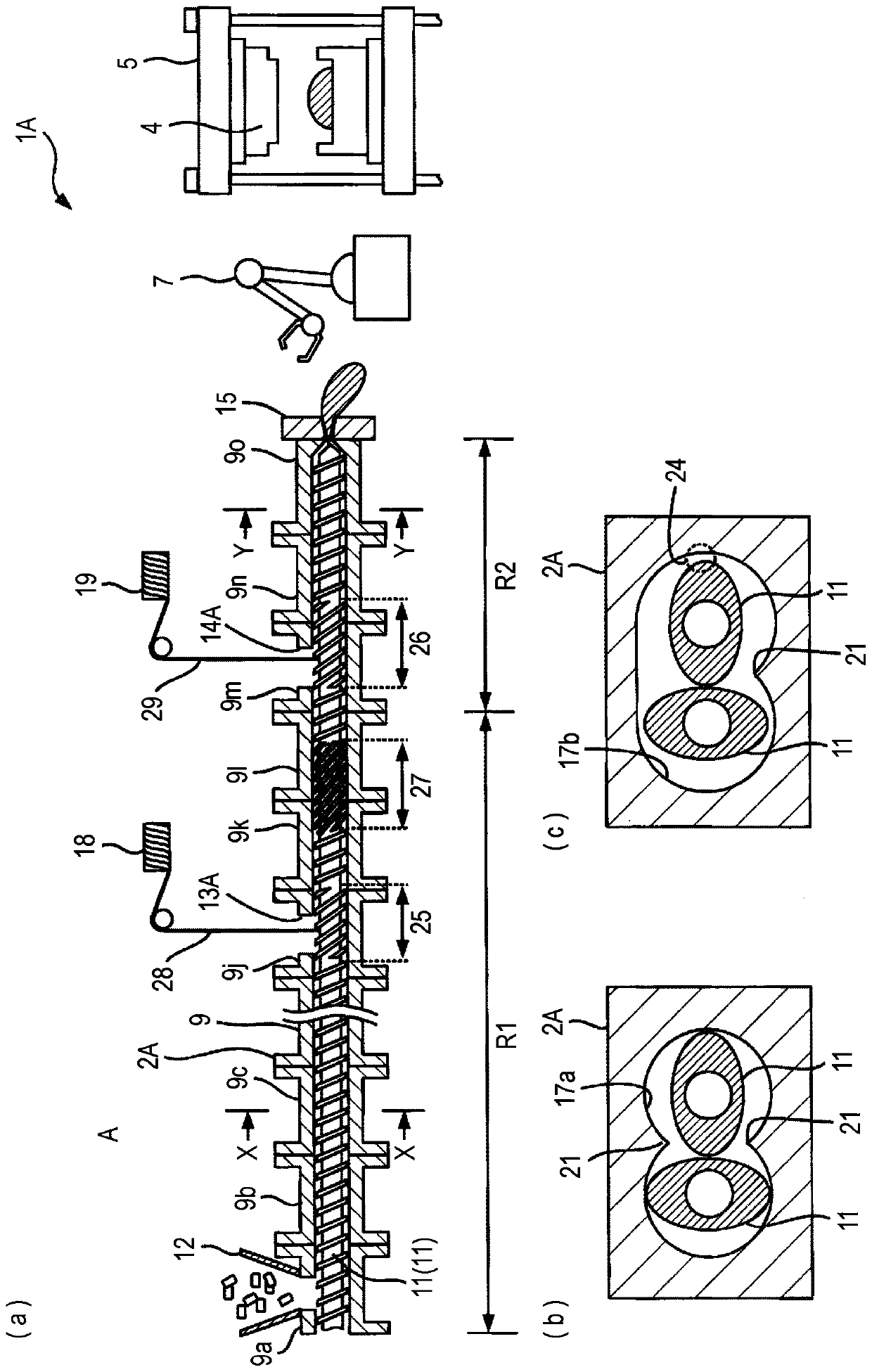

Kneading method for fiber-reinforced thermoplastic resin, plasticizing device, and extruding machine

The present invention provides a kneading method for a fiber-reinforced thermoplastic resin with which dispersibility of reinforcement fibers is enhanced and sufficient reinforcement fibers having a proper fiber length remain, and a fiber-reinforced thermoplastic resin plasticizing device and an extruding machine for carrying out the method. The kneading method comprises supplying a thermoplasticresin and reinforcement fibers into a cylinder of a plasticizing device, and rotating a screw to obtain a fiber-reinforced thermoplastic resin, wherein the size of a clearance between the bore of thecylinder and the screw is made different between an upstream side in the vicinity of a reinforcement fiber loading port and a downstream side, so that the clearance becomes larger from the vicinity ofthe reinforcement fiber loading port toward the downstream side compared with the upstream side.

Owner:JAPAN STEEL WORKS LTD

Straw and/ or ryegrass raw material semi-chemical pulp preparation method

InactiveCN101260630BImprove plasticityReduce cut-offPulp de-wateringPulp beating/refining methodsFiberEnergy consumption

The invention discloses a semi-chemical pulp preparation method of a straw and / or wheat straw hood raw material, comprising the following steps that: (1) after the straw and / or wheat straw hood raw material is processed by the chemical pre-dipping treatment or is boiled, the straw and / or wheat straw hood raw material is sent to a hydrabrusher to dilute and disperse, the concentration is added with water to adjusted within the range of 2.5 to 4.5 percent, and the straw and / or wheat straw hood raw material is dispersed into even materials; (2) the diluted and dispersed material is sent to a fluffer by a pump to process, the straw and / or wheat straw hood raw material is dispersed and disintegrated to become a fasciculus; (3) the dewatering and concentrating are performed: the paste after dispersed and disintegrated by the fluffer is transported to a dewatering device to dewater and is concentrated to a solution with a concentration ranging from 6 to 10 percent; (4) the pulping is performed: the dewaterd and concentrated pulp is pumped up to a disk grinder to perform the pulping in order to obtain the pulp for papermaking. The preparation method effectively keeps the fiber length, improves the intensity performance of the paper and has low energy consumption.

Owner:SOUTH CHINA UNIV OF TECH

A kind of polyphenylene sulfide grinding disc for papermaking beating

InactiveCN103305002BGood physical propertiesReduce cut-offPulp beating/refining methodsFiberWear resistant

The invention discloses a polyphenylene sulfide millstone for papermaking pulping. The polyphenylene sulfide millstone is used for a papermaking pulping process and is made of a polyphenylene sulfide composite material. Preferably, the polyphenylene sulfide composite material comprises 30-70 weight percent of polyphenylene sulfide, 5-10 weight percent of toughening component, 20-50 weight percent of reinforced fiber and 0-20 weight percent of wear-resistant component. The polyphenylene sulfide millstone for papermaking pulping is high in thermal stability, preferably, the polyphenylene sulfide composite material with the toughening component and the reinforced fiber is adopted, the elasticity modulus is 10-30 GPa and is close to the plant fiber elasticity modulus, the millstone made of the polyphenylene sulfide composite material has a small fiber cutting effect, and the physical performance of the pulp can be effectively improved.

Owner:四川华通特种工程塑料研究中心有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com