Batch refiner and refining process thereof

A refiner, intermittent technology, applied in the field of paper pulping, can solve the problems of redundant equipment, difficulty in adapting to the change of pulp feeding, difficulty in increasing or reducing the grinding area, etc., to save energy, improve efficiency and quality, and high The effect of flow efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

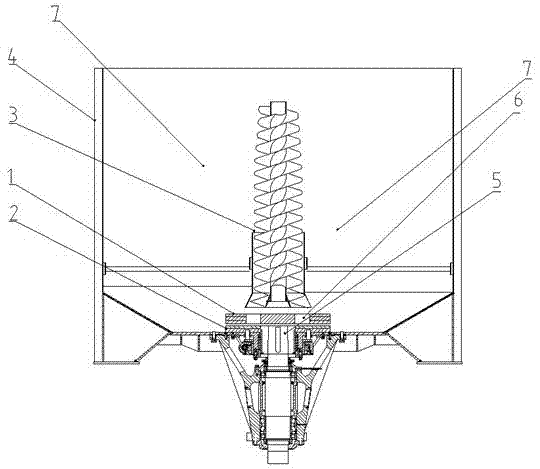

[0057] The batch refiner described in this embodiment, such as figure 1 shown, including:

[0058] A housing 4, on which a pulp inlet and a pulp outlet that can be controlled to be switched on and off are provided;

[0059] The grinding table includes a coaxially arranged moving grinding table 2 and a fixed grinding table 1, the moving grinding table 2 and the fixed grinding table 1 are arranged in the housing 4, and a refining gap is arranged between the moving grinding table 2 and the fixed grinding table 1;

[0060] The transmission shaft 5 is coaxially connected with the moving grinding table 2, and drives the moving grinding table 2 to rotate synchronously;

[0061] Gap adjustment mechanism, used to adjust the gap between the movable grinding disc 2 and the fixed grinding disc 1;

[0062] The pushing flow device 3 is arranged in the housing 4, and the liquid inlet channel 6 is arranged on the fixed grinding plate 1, and the liquid inlet channel is arranged through the t...

Embodiment 2

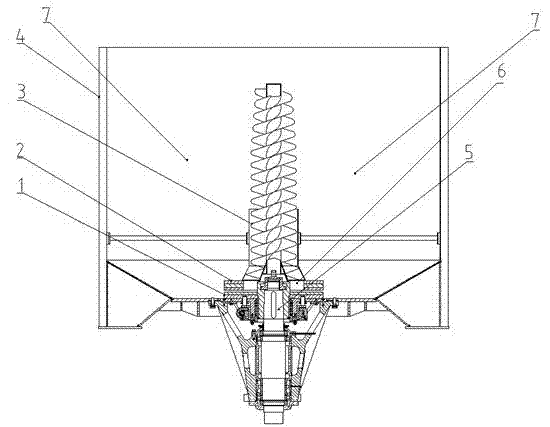

[0072] The batch refiner described in this embodiment, such as figure 2 shown, including:

[0073] A housing 4, on which a pulp inlet and a pulp outlet that can be controlled to be switched on and off are provided;

[0074] The grinding table includes a coaxially arranged moving grinding table 2 and a fixed grinding table 1, the moving grinding table 2 and the fixed grinding table 1 are arranged in the housing 4, and a refining gap is arranged between the moving grinding table 2 and the fixed grinding table 1;

[0075] The transmission shaft 5 is coaxially connected with the movable grinding table 2 and drives the moving grinding table 2 to rotate synchronously;

[0076] Gap adjustment mechanism, used to adjust the gap between the movable grinding disc 2 and the fixed grinding disc 1;

[0077] The pushing flow device 3 is arranged in the housing 4, and the liquid inlet channel 6 is arranged on the moving grinding table 2, and the liquid inlet channel 6 is arranged through t...

Embodiment 3

[0087] A kind of intermittent refiner of the present invention, such as figure 2 shown, including:

[0088] A housing 4, on which a pulp inlet and a pulp outlet that can be controlled to be switched on and off are provided;

[0089] The grinding table includes a coaxially arranged moving grinding table 2 and a fixed grinding table 1, the moving grinding table 2 and the fixed grinding table 1 are arranged in the housing 4, and a refining gap is arranged between the moving grinding table 2 and the fixed grinding table 1;

[0090] The transmission shaft 5 is coaxially connected with the movable grinding table 2 and drives the moving grinding table 2 to rotate synchronously;

[0091] Gap adjustment mechanism, used to adjust the gap between the movable grinding disc 2 and the fixed grinding disc 1;

[0092] The pushing flow device 3 is arranged in the housing 4, and the liquid inlet channel 6 is arranged on the moving millstone 2, and the liquid inlet channel is arranged through t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com