Grinding table of disc grinder for preparing synthetic fiber pulp

A technology for synthetic fibers and disc refiners, applied in the field of disc refiners, can solve the problems of complex manufacturing process, influence on pulp quality, short service life, etc., to increase grinding time, improve the degree of microfibrillation, and reduce the cutting effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

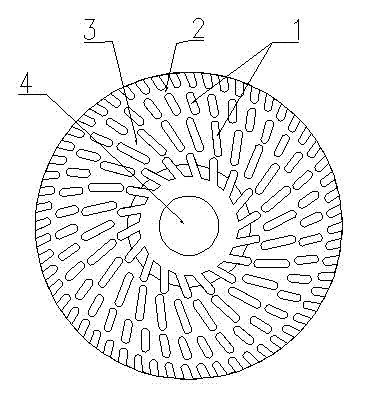

[0036] A disc refiner grinding plate for preparing synthetic fiber pulp, including a grinding disc, with a plurality of grooves on the working surface of the grinding disc, the grooves are distributed in a multi-layer concentric circle around the center of the grinding disc, and each layer of concentric circles The grooves are evenly distributed, the grinding discs between two adjacent grooves on the same circumference form grinding teeth, and the gap between any adjacent two layers forms a baffle.

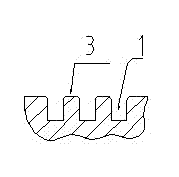

[0037] In the present invention, the grinding tooth includes a plane part formed by the working surface of the grinding disc and an arc-shaped surface part where one side meets the plane part and the other side meets the groove, that is, the groove meets the grinding tooth in an arc shape noodle. The groove forms an angle of 5°C with the diameter of the grinding disc.

[0038] A circular concave feeding channel around the feeding hole is arranged at the feeding hole of the grindi...

Embodiment 2

[0041] A disc refiner grinding plate for preparing synthetic fiber pulp, including a grinding disc, with a plurality of grooves on the working surface of the grinding disc, the grooves are distributed in a multi-layer concentric circle around the center of the grinding disc, and each layer of concentric circles The grooves are evenly distributed, and the grinding discs between two adjacent grooves on the same circumference form grinding teeth, and the gap between any two adjacent layers forms a continuous baffle, that is, a circular baffle .

[0042] In the present invention, the groove and the diameter of the grinding disc form an included angle of 20°C. A circular concave feeding channel around the feeding hole is arranged at the feeding hole of the grinding disc. The inner side of the feeding channel communicates with the feeding hole, and the outer side communicates with the groove on the first layer outside the center of the grinding disc.

[0043] Set the inclination dire...

Embodiment 3

[0045] A disc refiner grinding plate for preparing synthetic fiber pulp, including a grinding disc, with a plurality of grooves on the working surface of the grinding disc, the grooves are distributed in a multi-layer concentric circle around the center of the grinding disc, and each layer of concentric circles The grooves are evenly distributed, the grinding discs between two adjacent grooves on the same circumference form grinding teeth, and the gap between any adjacent two layers forms a baffle.

[0046] In the present invention, the grinding tooth includes a plane part formed by the working surface of the grinding disc and an arc-shaped surface part where one side is connected to the plane part and the other side is connected to the groove, that is, the plane part is connected to the groove. The curved surface and the curvature of the curved surface can be adjusted by those skilled in the art according to the above-mentioned records in actual production.

[0047] Set the g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com