Coated white cardboard made of various fiber raw materials and production process of coated white cardboard

A fiber raw material and production process technology, applied in the field of coated white cardboard and its production process, can solve the problems of poor paper strength, poor water drainage performance, paper opacity and low bulk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

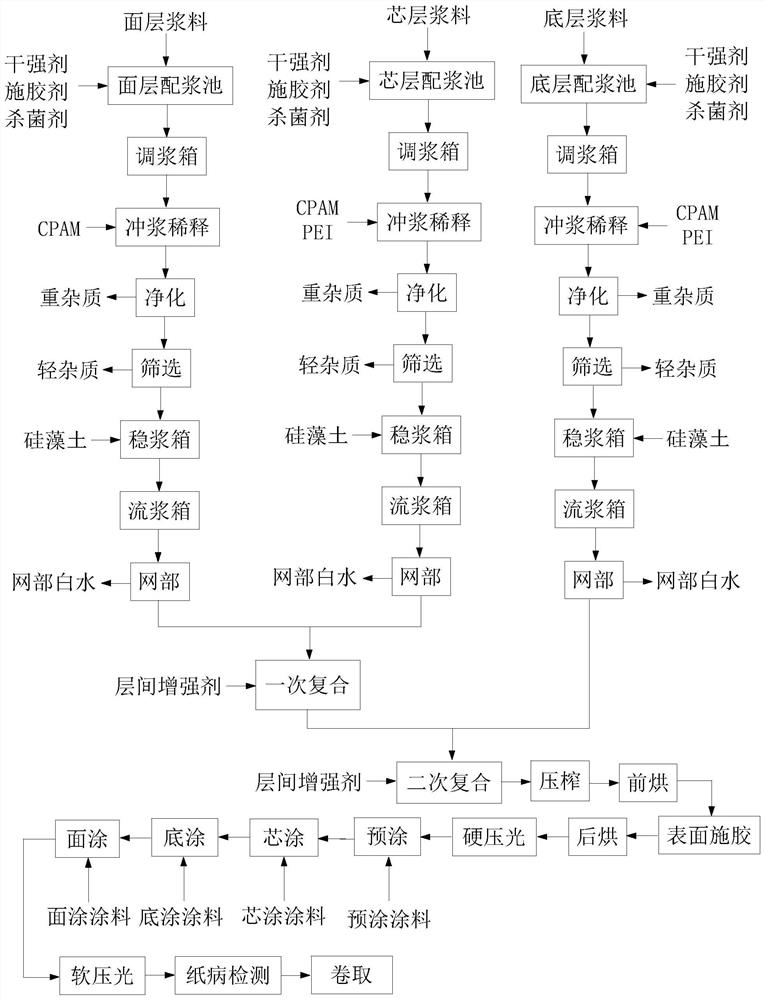

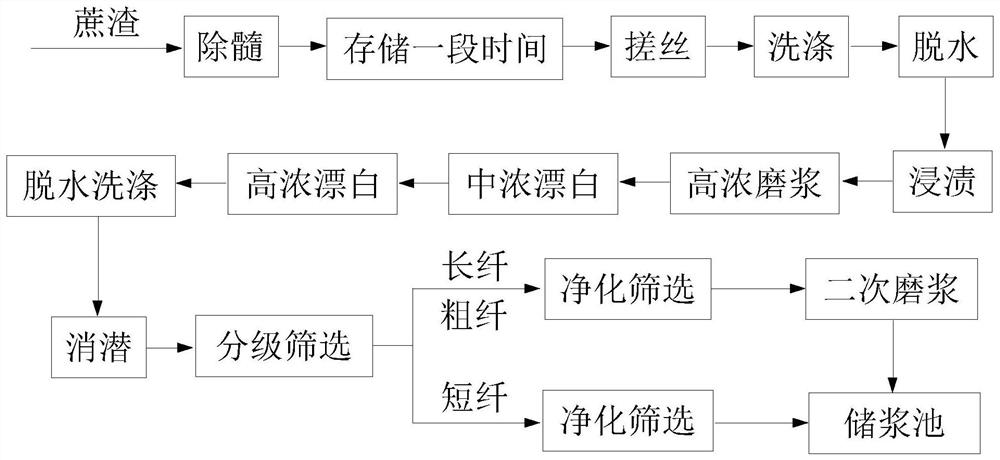

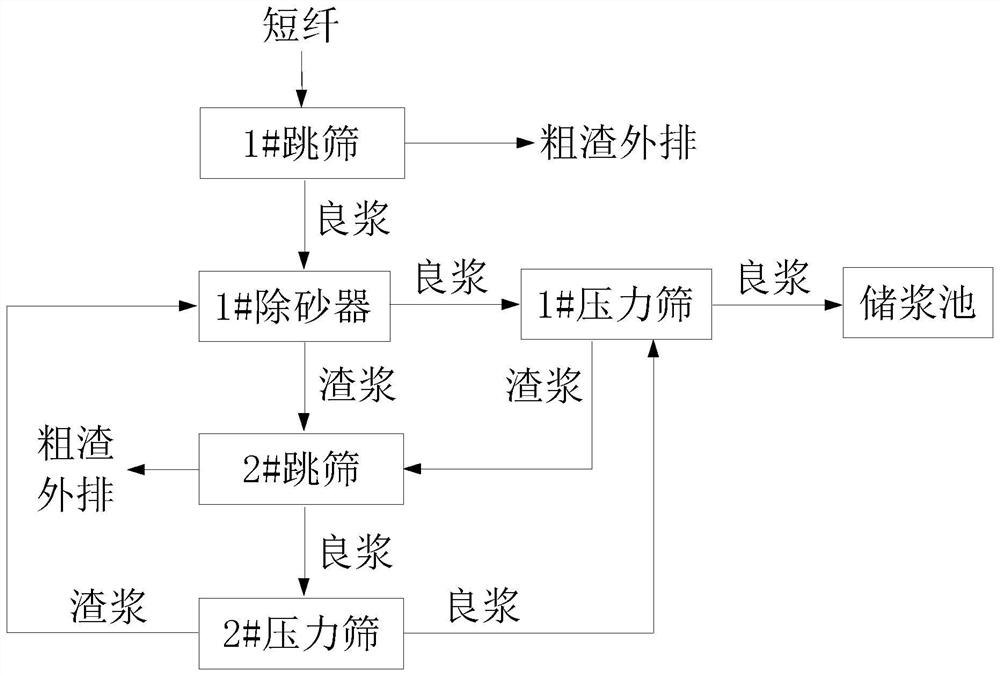

Method used

Image

Examples

Embodiment 1

[0040] A kind of coated white cardboard of various fiber raw materials, its basis weight is 300g / m 2 , including a surface layer, a core layer and a bottom layer, the surface layer is coated with a precoat layer, a core layer layer and a topcoat layer sequentially from the inside to the outside, and the outside of the bottom layer is coated with a primer layer. The weight of the surface layer is 42g / m 2 , the weight of the bottom layer is 54g / m 2 , the coating amount of pre-coating is 11g / m 2 , the coating weight of the core coating is 12g / m 2 , the coating amount of the top coat is 12g / m 2 , the coating amount of the primer layer is 10g / m 2 .

[0041] The fiber raw materials of the surface layer include 20 parts of bleached kraft softwood pulp (NBKP) and 80 parts of bleached kraft hardwood pulp (LBKP). The fiber raw materials of the core layer include 12 parts of bleached kraft softwood pulp (NBKP), 75 parts of bleached hardwood chemithermomechanical pulp (BCTMP), 12 pa...

Embodiment 2

[0072] A kind of coated white cardboard of various fiber raw materials, its basis weight is 350g / m 2, including a surface layer, a core layer and a bottom layer, the surface layer is coated with a precoat layer, a core layer layer and a topcoat layer sequentially from the inside to the outside, and the outside of the bottom layer is coated with a primer layer. The weight of the surface layer is 48g / m 2 , the weight of the bottom layer is 58g / m 2 , the coating amount of pre-coating is 12g / m 2 , the coating weight of the core coating is 13g / m 2 , the coating amount of the top coat is 12g / m 2 , the coating amount of the primer layer is 11g / m 2 .

[0073] The fiber raw materials of the surface layer include 25 parts of bleached kraft softwood pulp (NBKP) and 75 parts of bleached kraft hardwood pulp (LBKP). The fiber raw materials of the core layer include 15 parts of bleached kraft softwood pulp (NBKP), 70 parts of bleached hardwood chemithermomechanical pulp (BCTMP), 15 par...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com