Straw and/ or ryegrass raw material semi-chemical pulp preparation method

A semi-chemical pulp and wheat straw technology, applied in pulp beating/refining methods, raw material separation, fiber raw material treatment, etc., can solve the problems of low average length of pulping fibers, high refining energy consumption, and poor paper strength performance. Achieve the effect of improving the strength performance index, reducing the damage of the fiber, and reducing the cutting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

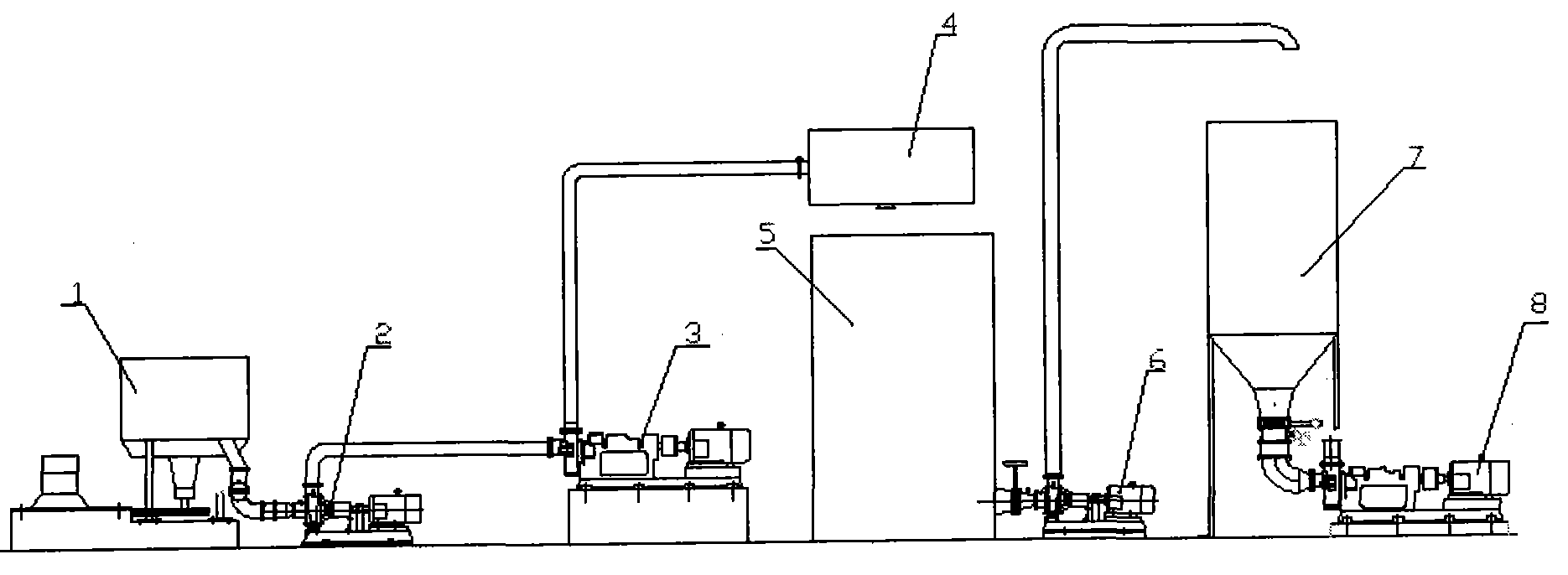

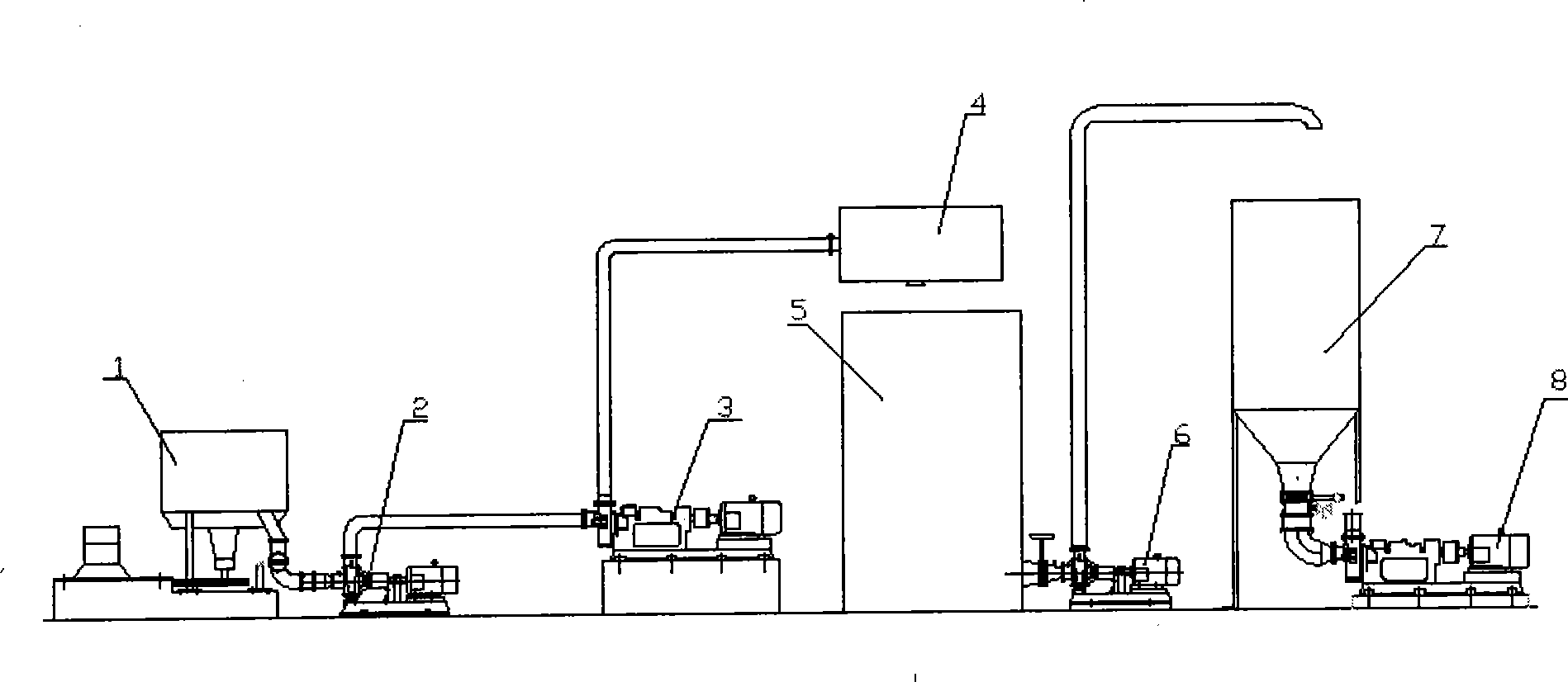

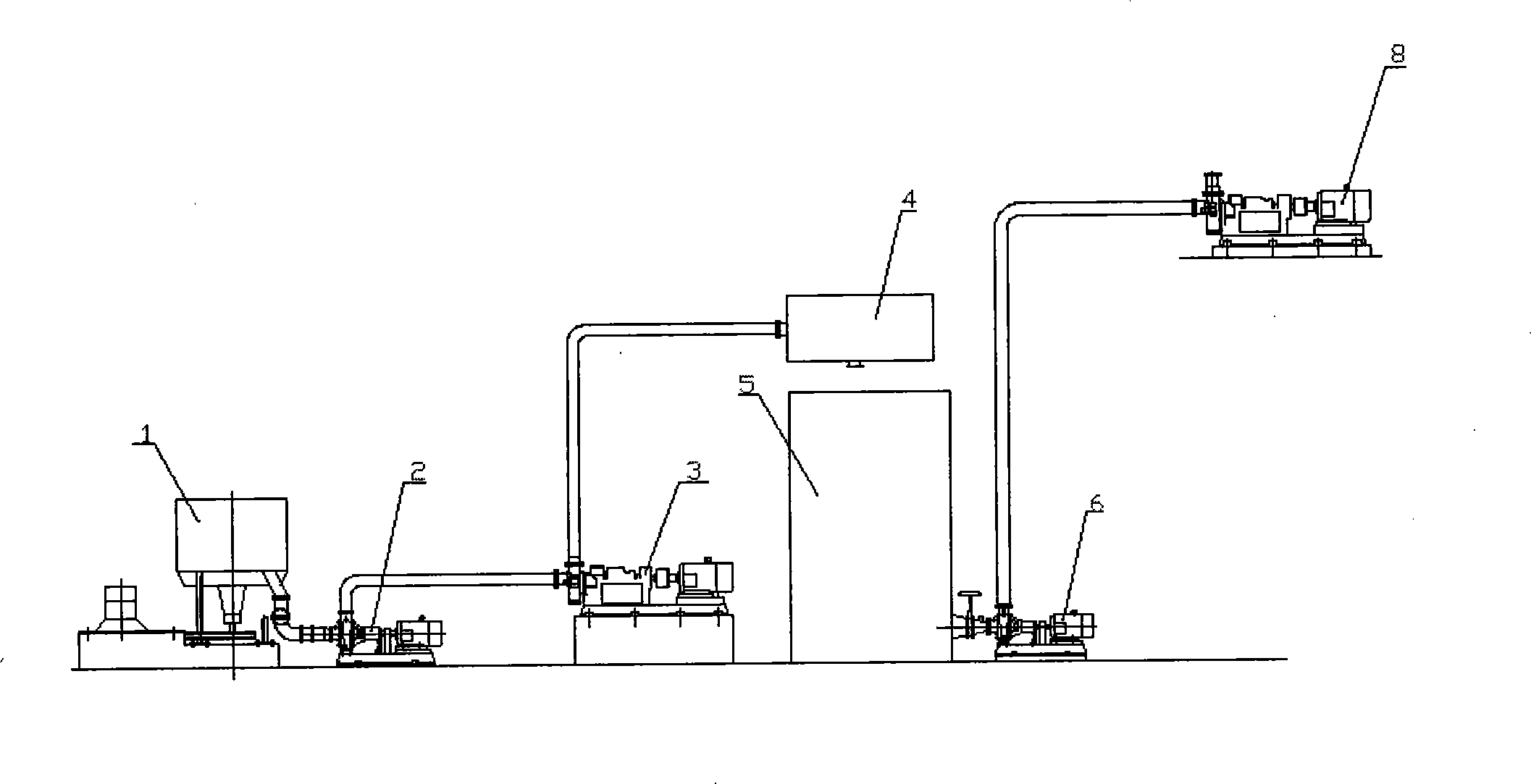

[0020] Embodiment 1 carries out following operations according to the device represented in Fig. 1:

[0021] (1) After chemical pre-impregnation or cooking, the rice straw raw material is sent to the hydropulper 1 for dilution and dispersion. Here, the raw material was diluted with water to a concentration of 3.5% (weight %), and dispersed into a uniform material, and the treatment time was 20 minutes.

[0022] (2) The diluted and dispersed material is transported by the pump 2 to the disintegrating machine 3 for discrete and disintegrating treatment. The rotating speed of the executive element of the deflaker is 1500 rpm. Under the action of the shearing force generated by the high-speed rotation of the actuator of the debonder, the straw raw material is dispersed and decomposed into fiber bundles.

[0023] (3) The slurry dispersed and decomposed by the dehydrator 3 is transported to the dehydration equipment 4 for dehydration, and concentrated to a concentration of 8.4% (w...

Embodiment 2

[0027] Embodiment 2 carries out the following operations according to the device represented in Figure 1:

[0028] (1) After chemical pre-impregnation or cooking, the wheat straw raw material is sent to the hydropulper 1 for dilution and dispersion. Here, the raw material was diluted with water to a concentration of 4.5% (weight %), and dispersed into a uniform material, and the treatment time was 30 minutes.

[0029] (2) The diluted and dispersed material is transported by the pump 2 to the disintegrating machine 3 for discrete and disintegrating treatment. The rotating speed of the executive element of the deflaker is 980 rpm. Under the action of the shearing force generated by the high-speed rotation of the actuator of the deflaker, the wheat straw raw material is dispersed and decomposed into fiber bundles.

[0030] (3) The slurry dispersed and decomposed by the dehydrator 3 is transported to the dehydration equipment 4 for dehydration, and concentrated to a concentratio...

Embodiment 3

[0034] Embodiment 3 carries out following operation according to the device represented in Fig. 1:

[0035] (1) Rice straw and wheat straw each account for half of the weight. After chemical pre-impregnation or cooking, they are sent to the hydropulper 1 for dilution and dispersion. Here, the raw material was diluted with water to a concentration of 2.5% (weight %), and dispersed into a homogeneous material, and the processing time was 25 minutes.

[0036] (2) The diluted and dispersed material is transported by the pump 2 to the disintegrating machine 3 for discrete and disintegrating treatment. The rotating speed of the executive element of the deflaker is 1500 rpm. Under the action of the shear force generated by the high-speed rotation of the actuator of the deflaker, the material is dispersed and decomposed into fiber bundles.

[0037] (3) The slurry separated and decomposed by the dehydrator 3 is transported to the dehydration equipment 4 for dehydration, and concentra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com