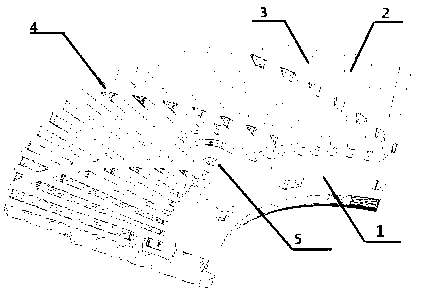

Polyphenylene sulfide millstone for papermaking pulping

A technology of polyphenylene sulfide and polyphenylene sulfide resin, which is applied in pulp beating/refining method, papermaking, textiles and papermaking, etc., can solve the problem of small splitting effect, low paper strength, and cutting of papermaking plant fibers. Large effect, etc., to achieve the effect of small cutting effect, improved performance, and improved physical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] 30wt% polyphenylene sulfide resin, 5wt% toughening component, 50wt% reinforcing fiber, 15wt% wear-resistant component. The elastic modulus of the obtained polyphenylene sulfide composite material is 14.75 to 15.68 GPa.

Embodiment 2

[0033] 40wt% polyphenylene sulfide resin, 7.5wt% toughening component, 32.5wt% reinforcing fiber, 20wt% wear-resistant component. The elastic modulus of the obtained polyphenylene sulfide composite material is 16.07 to 21.65 GPa.

Embodiment 3

[0035] 50wt% polyphenylene sulfide resin, 8wt% toughening component, 28wt% reinforcing fiber, 14wt% wear-resistant component, the obtained polyphenylene sulfide composite material has a modulus of elasticity: 11.54 to 20.84GPa

PUM

| Property | Measurement | Unit |

|---|---|---|

| heat deflection temperature | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com