Patents

Literature

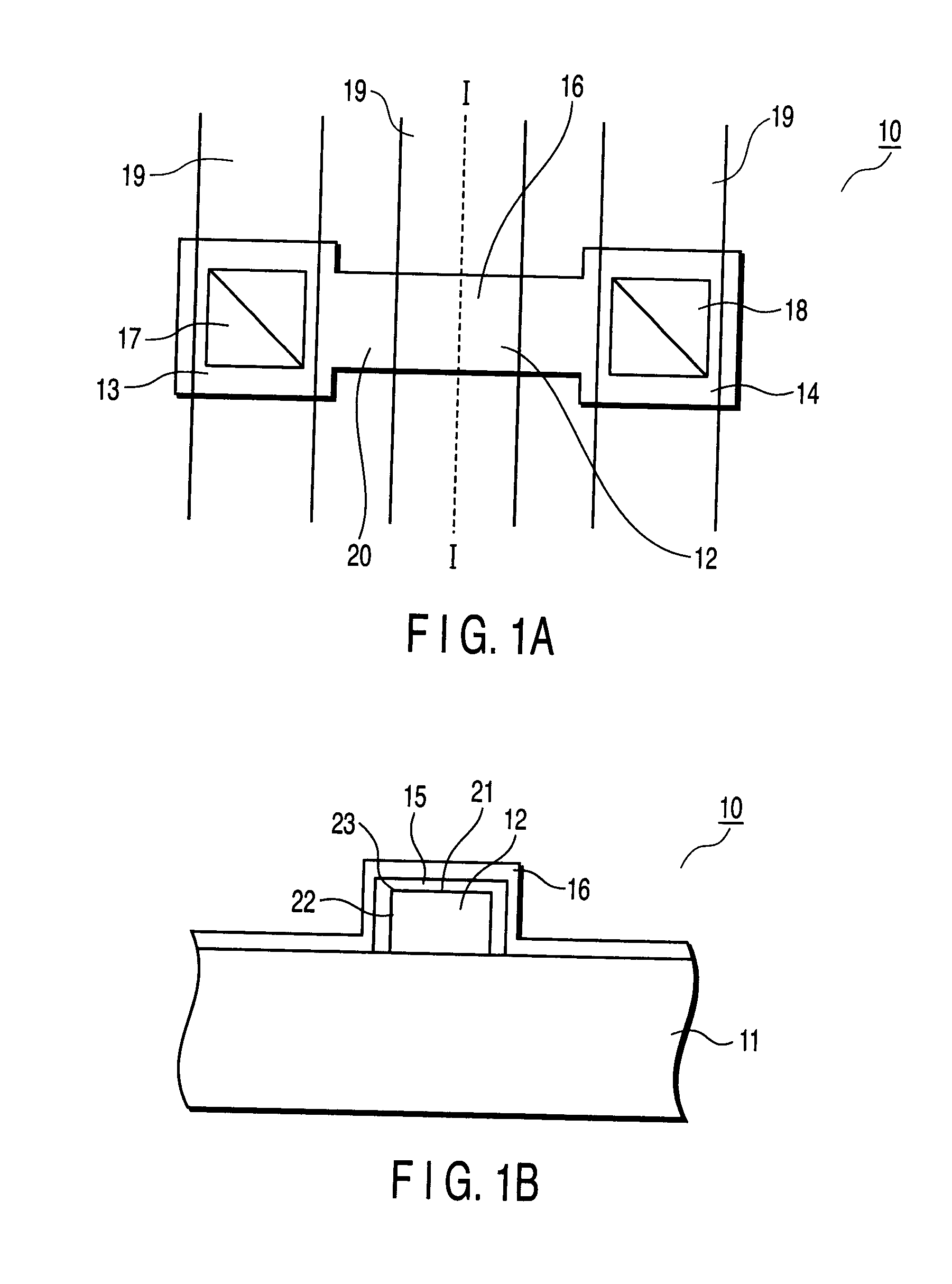

87results about How to "Reduce non-uniformity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

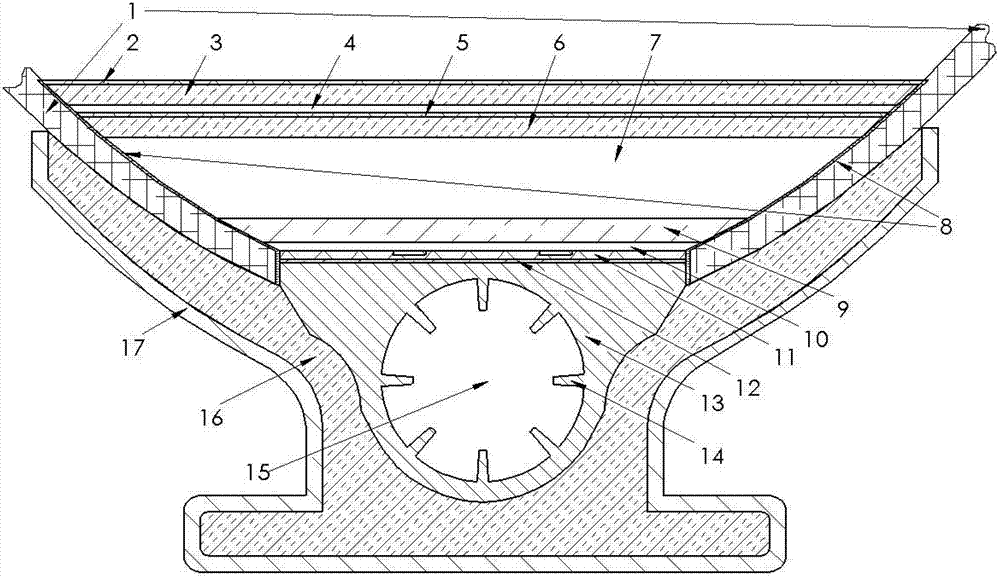

System for actively reducing radial vibrations in a rotating shaft, and method of operating the system to achieve this

InactiveUS6138629AReduce vibrationReduce unevennessRotating vibration suppressionBraking element arrangementsDrive shaftEngineering

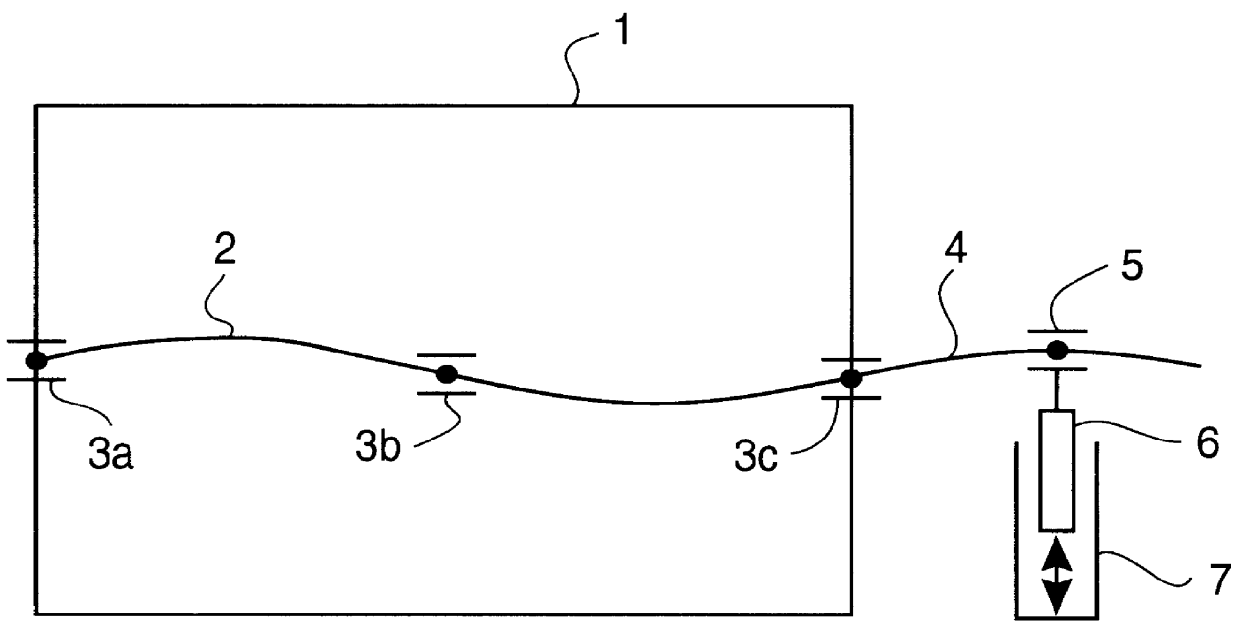

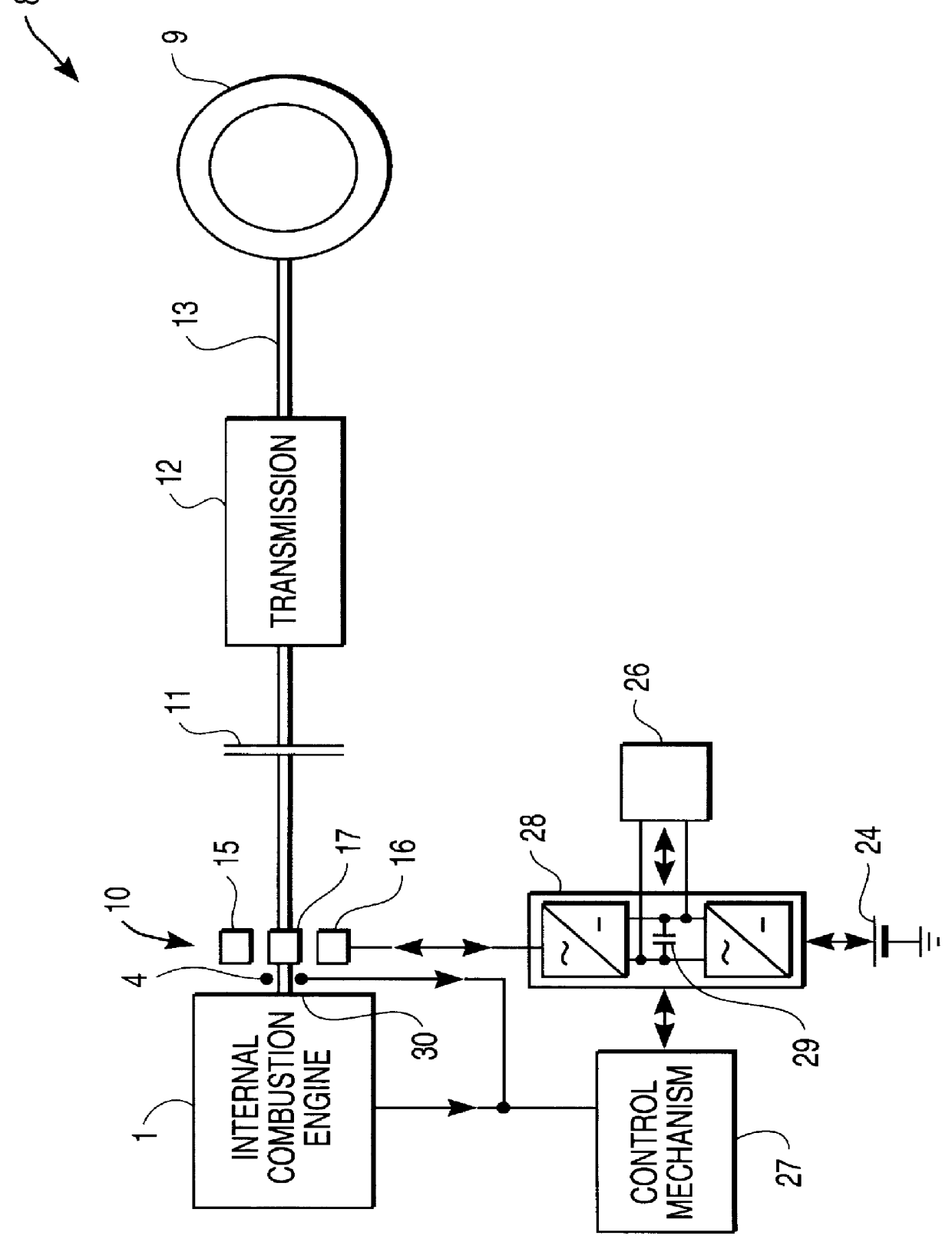

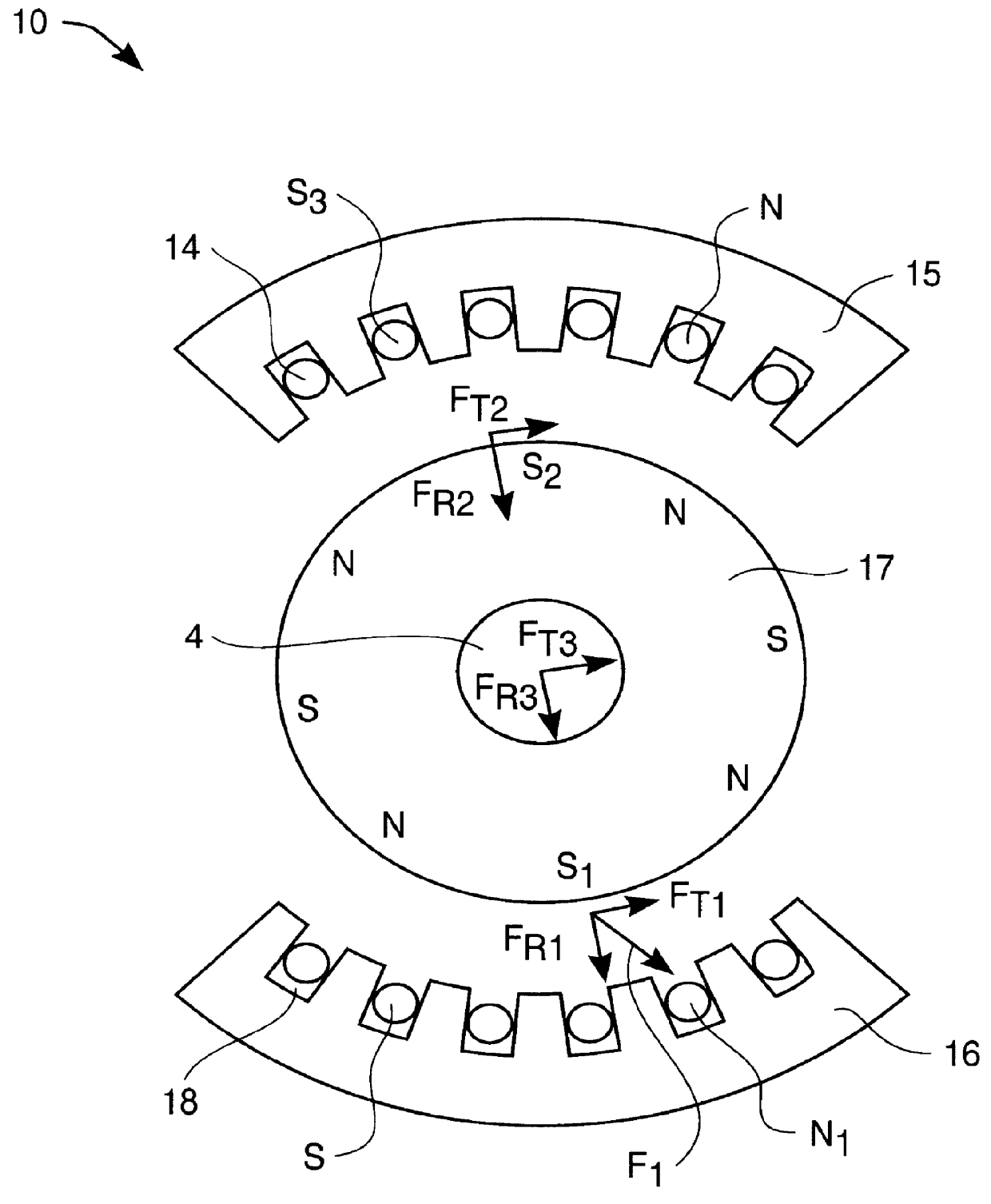

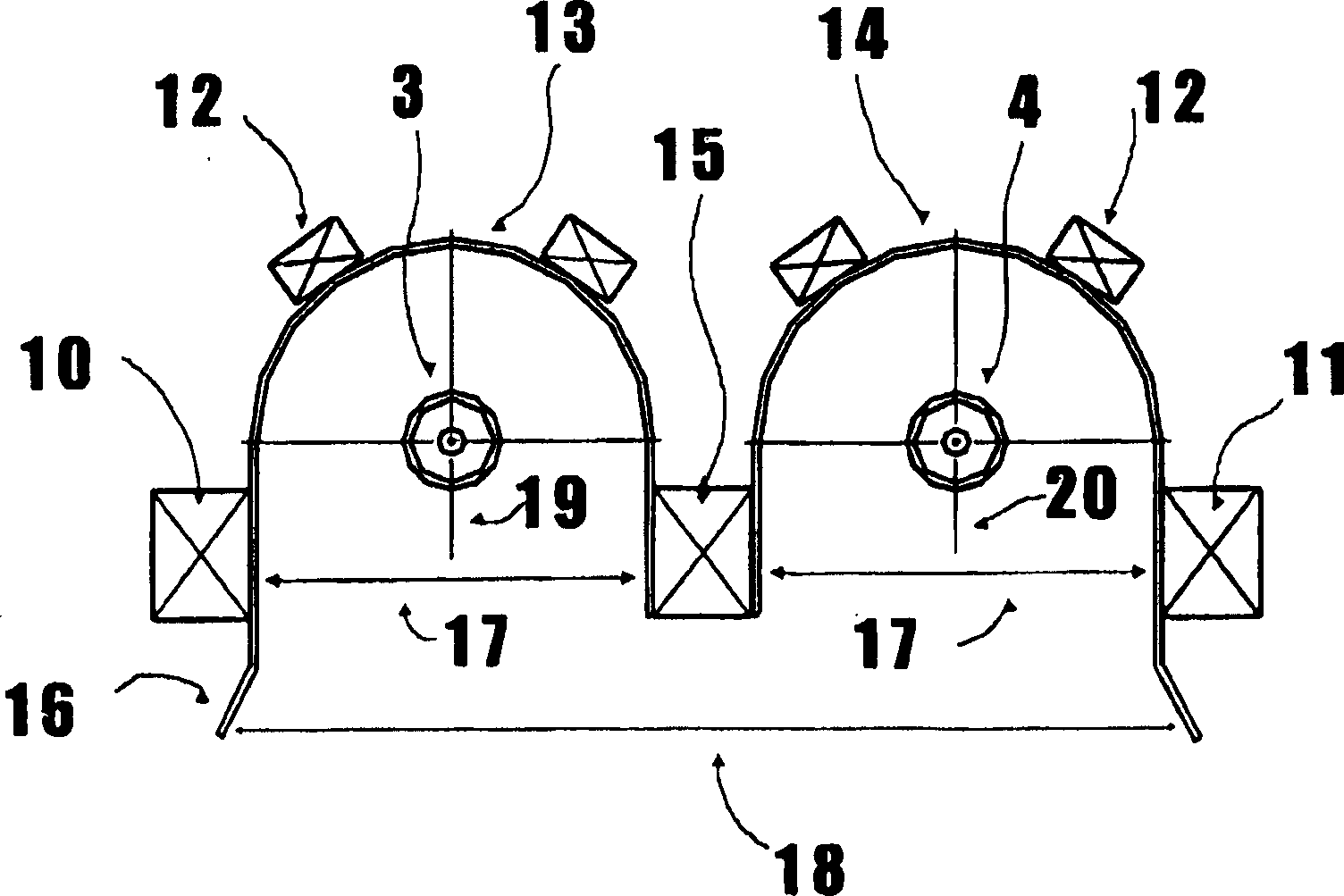

PCT No. PCT / DE96 / 01665 Sec. 371 Date Jul. 23, 1998 Sec. 102(e) Date Jul. 23, 1998 PCT Filed Aug. 31, 1996 PCT Pub. No. WO97 / 08477 PCT Pub. Date Mar. 6, 1997The invention concerns a system for active reduction of radial vibrations of a rotating shaft (4), especially the drive shaft of an internal combustion engine (1), with at least one active electromagnetic device (7; 10; 15, 16), which is configured and controlled such that it applies radial forces to the shaft (4), which counteract the radial vibrations of the shaft (4).

Owner:CONTINENTAL ISAD ELECTRONICS SYST GMBH & CO KG

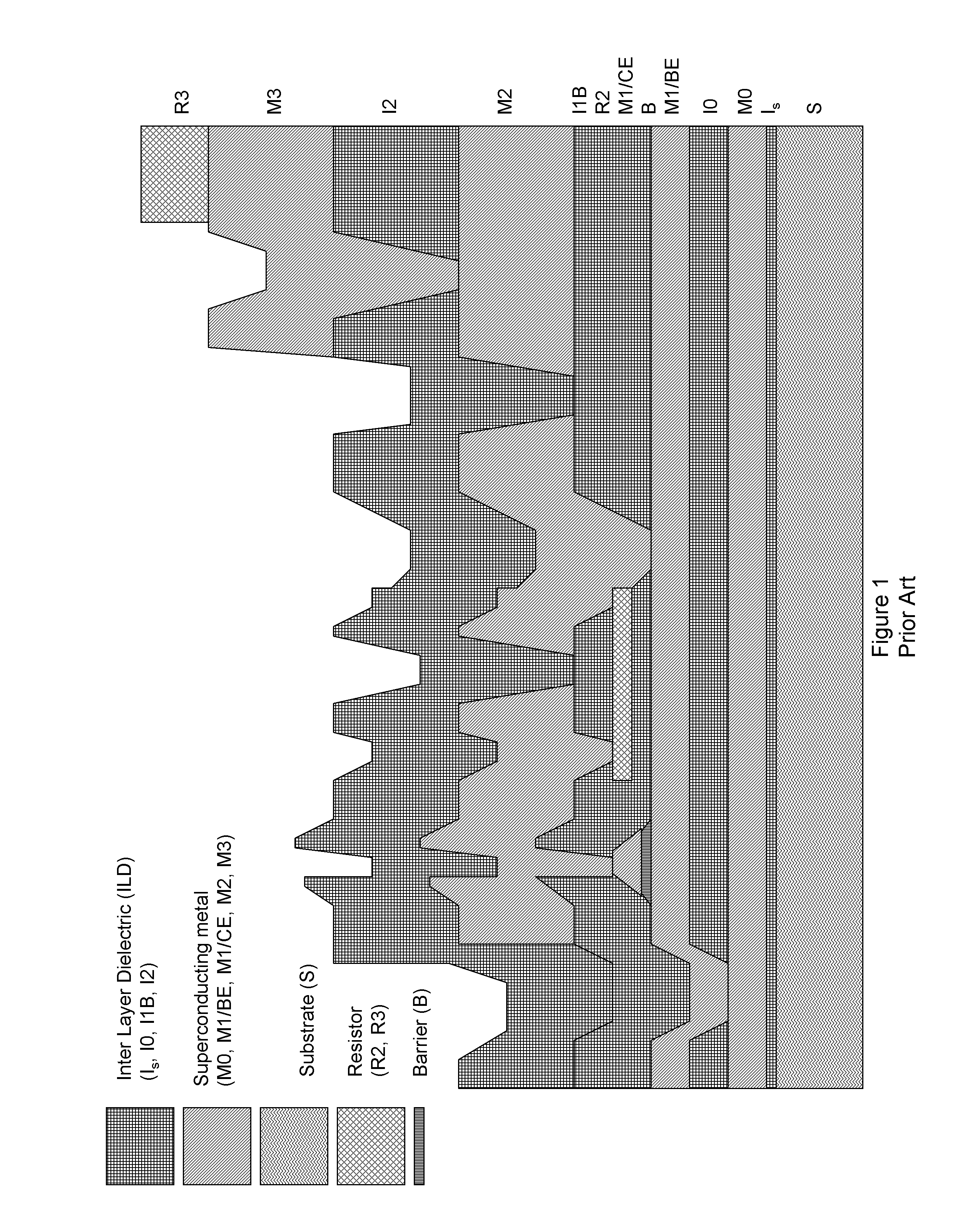

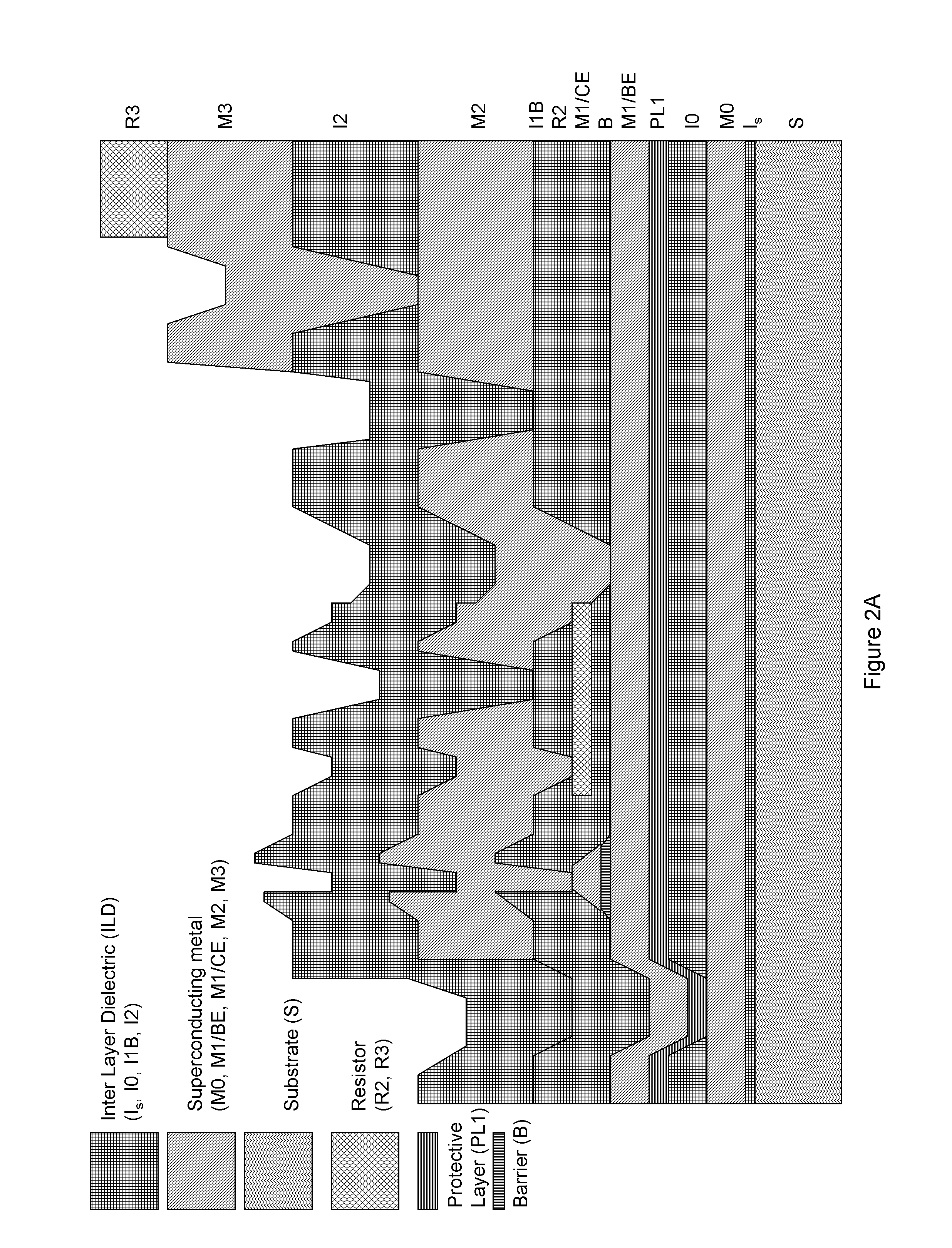

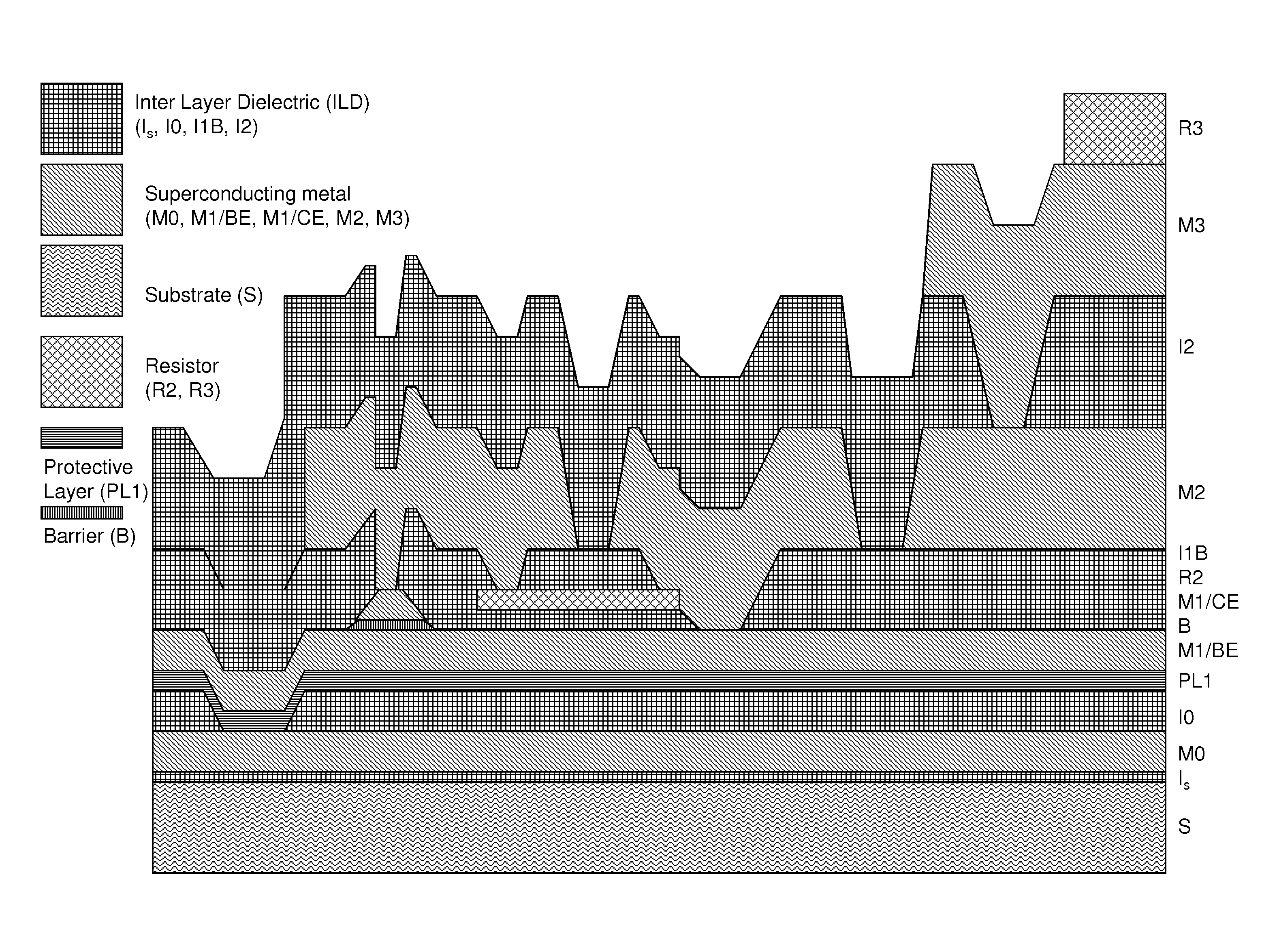

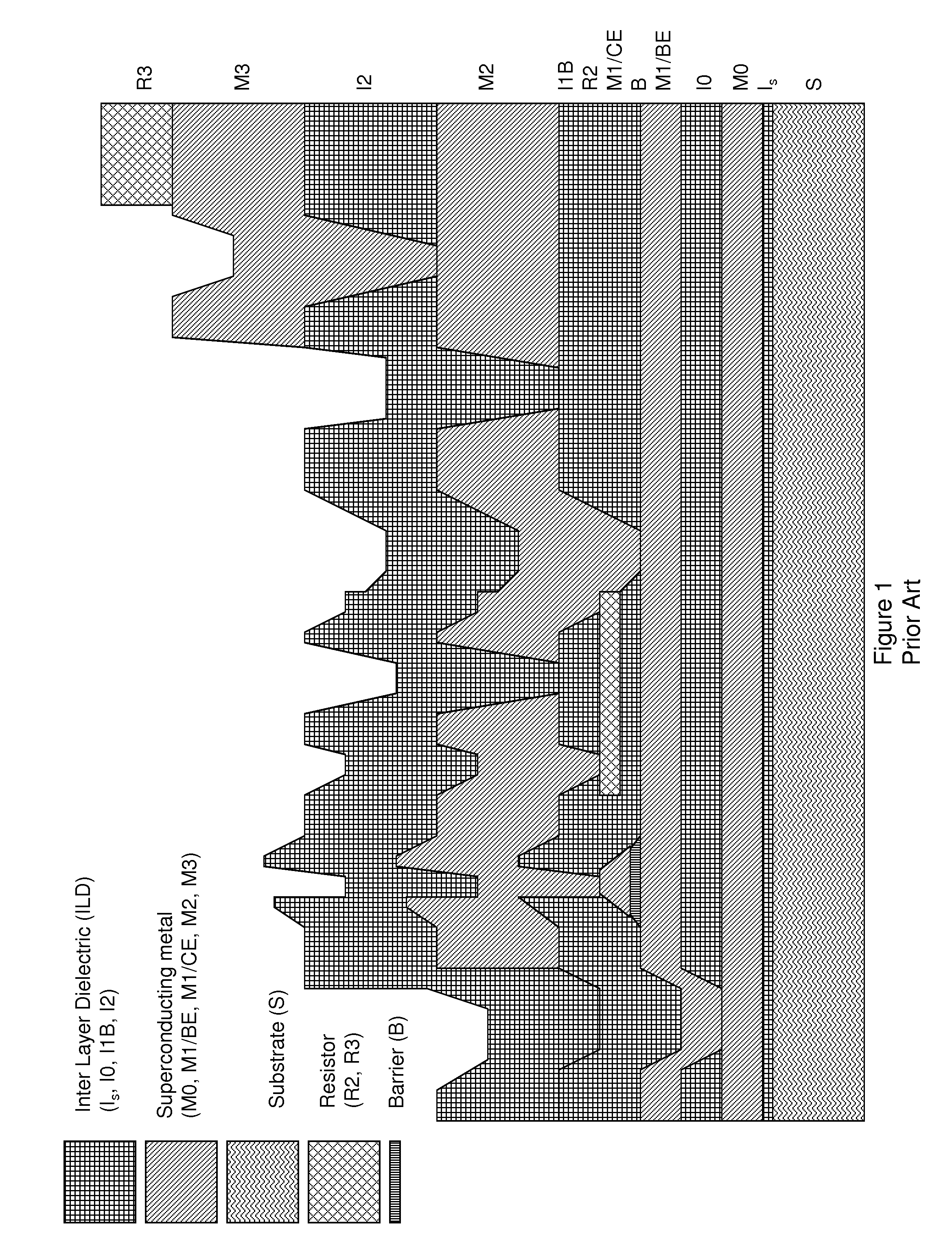

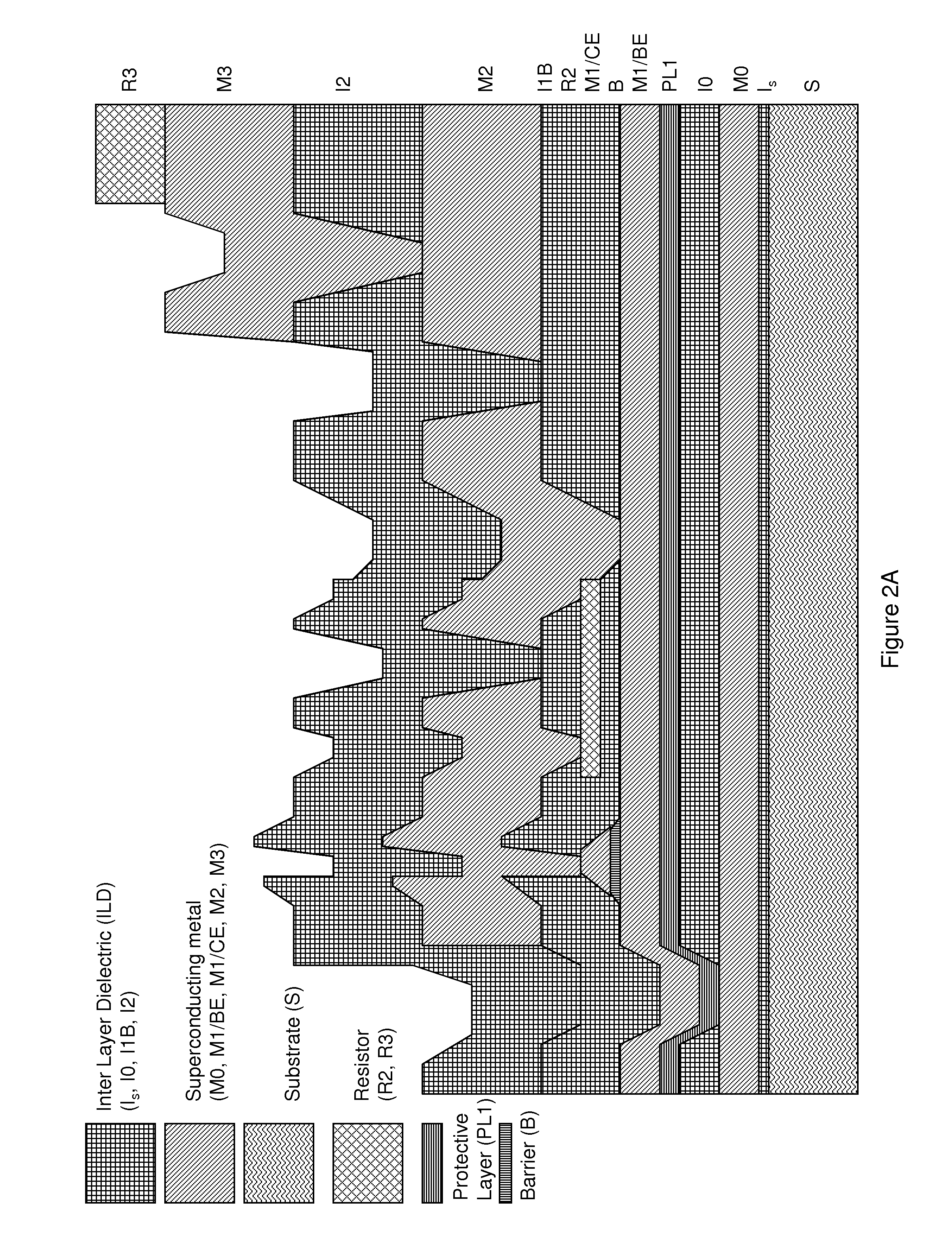

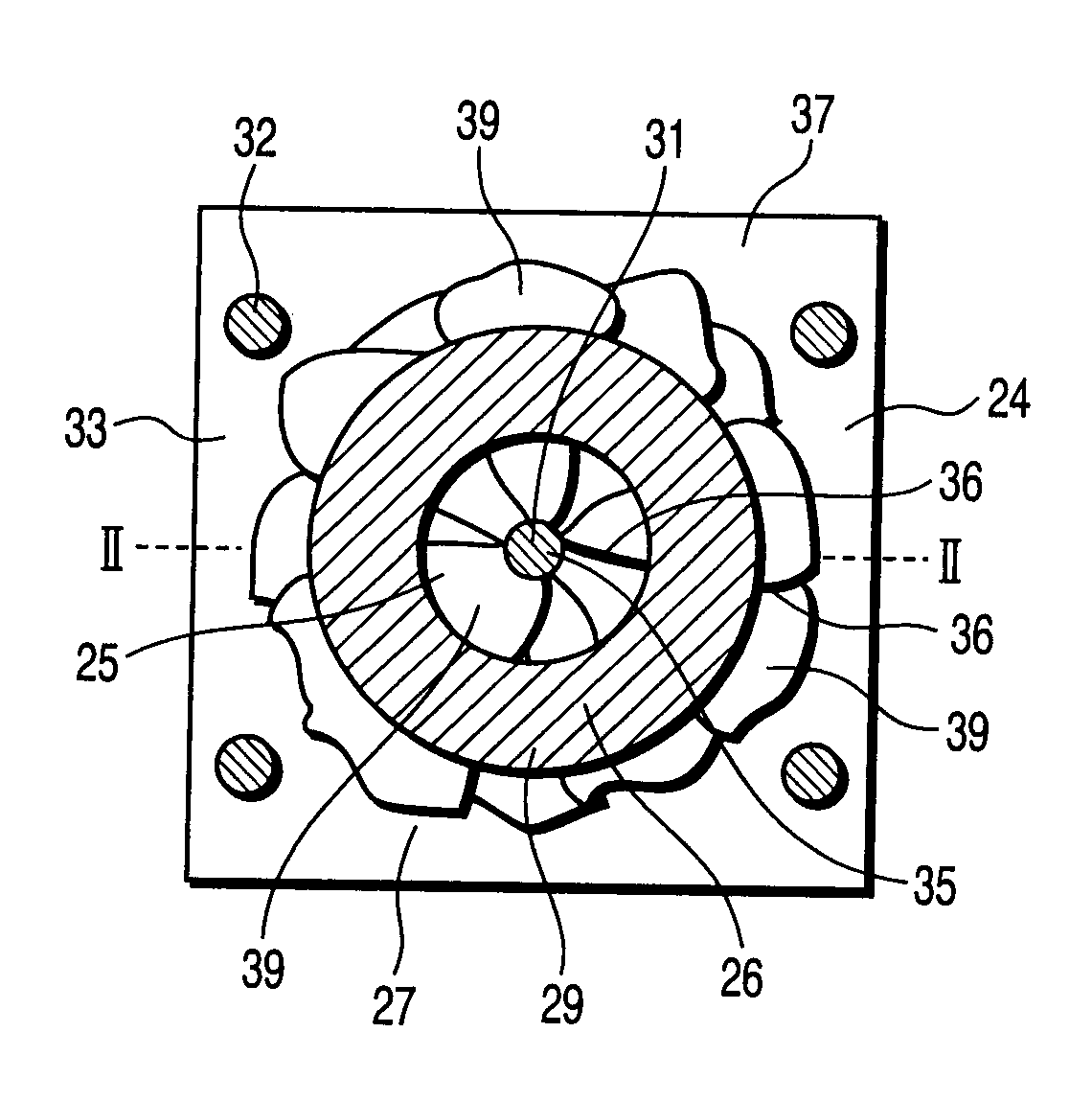

System and method for providing multi-conductive layer metallic interconnects for superconducting integrated circuits

ActiveUS8437818B1Reduce and prevent diffusion of impurityReduce non-uniformitySuperconductors/hyperconductorsSemiconductor/solid-state device detailsImpurity diffusionRapid single flux quantum

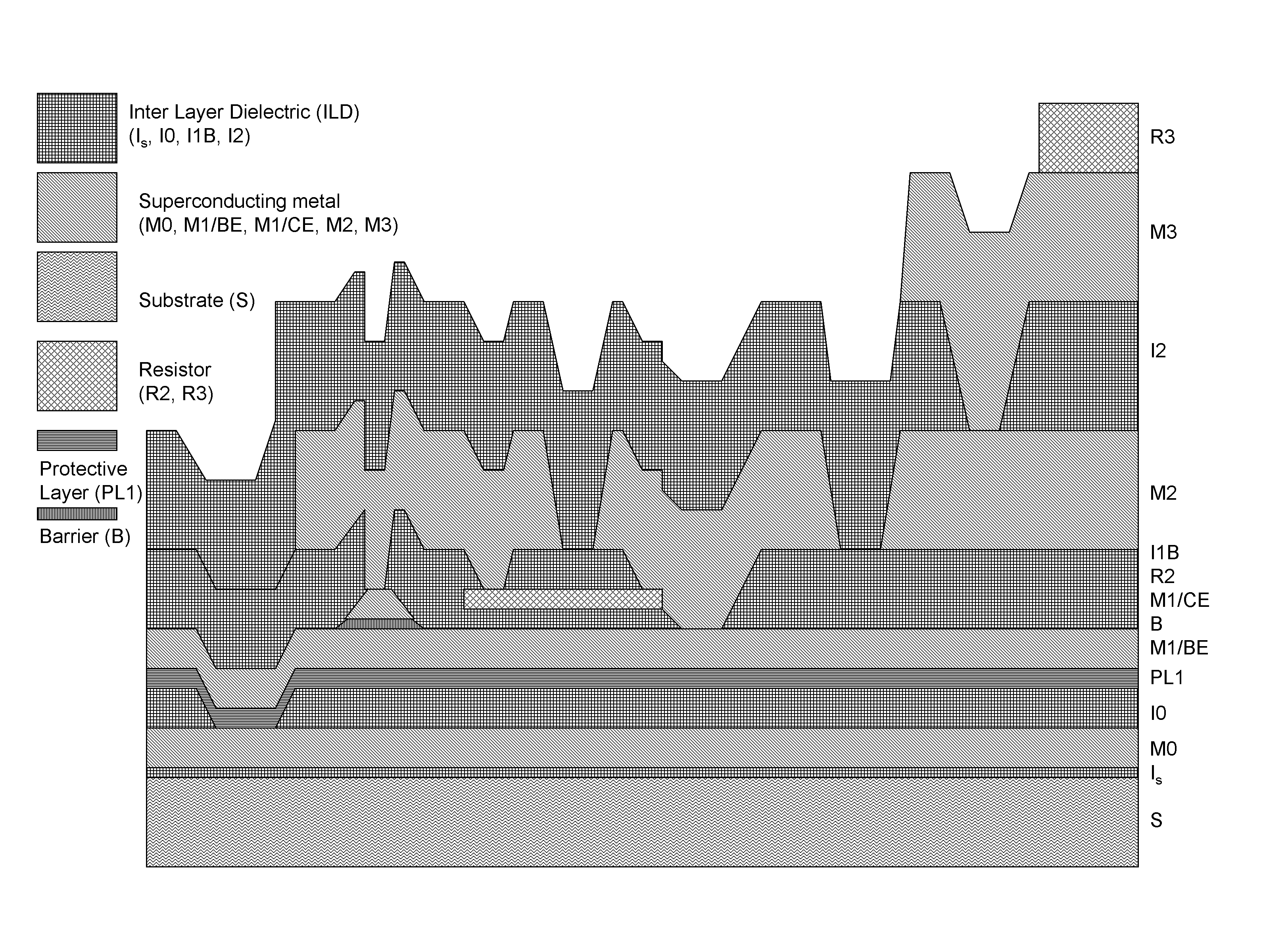

Superconducting integrated circuits require several wiring layers to distribute bias and signals across the circuit, which must cross each other both with and without contacts. All wiring lines and contacts must be fully superconducting, and in the prior art each wiring layer comprises a single metallic thin film. An alternative wiring layer is disclosed that comprises sequential layers of two or more different metals. Such a multi-metallic wiring layer may offer improved resistance to impurity diffusion, better surface passivation, and / or reduction of stress, beyond that which is attainable with a single-metallic wiring layer. The resulting process leads to improved margin and yield in an integrated circuit comprising a plurality of Josephson junctions. Several preferred embodiments are disclosed, for both planarized and non-planarized processes. These preferred and other methods may be applied to digital circuits based on Rapid Single Flux Quantum logic, and to quantum computing using Josephson junction qubits.

Owner:SEEQC INC

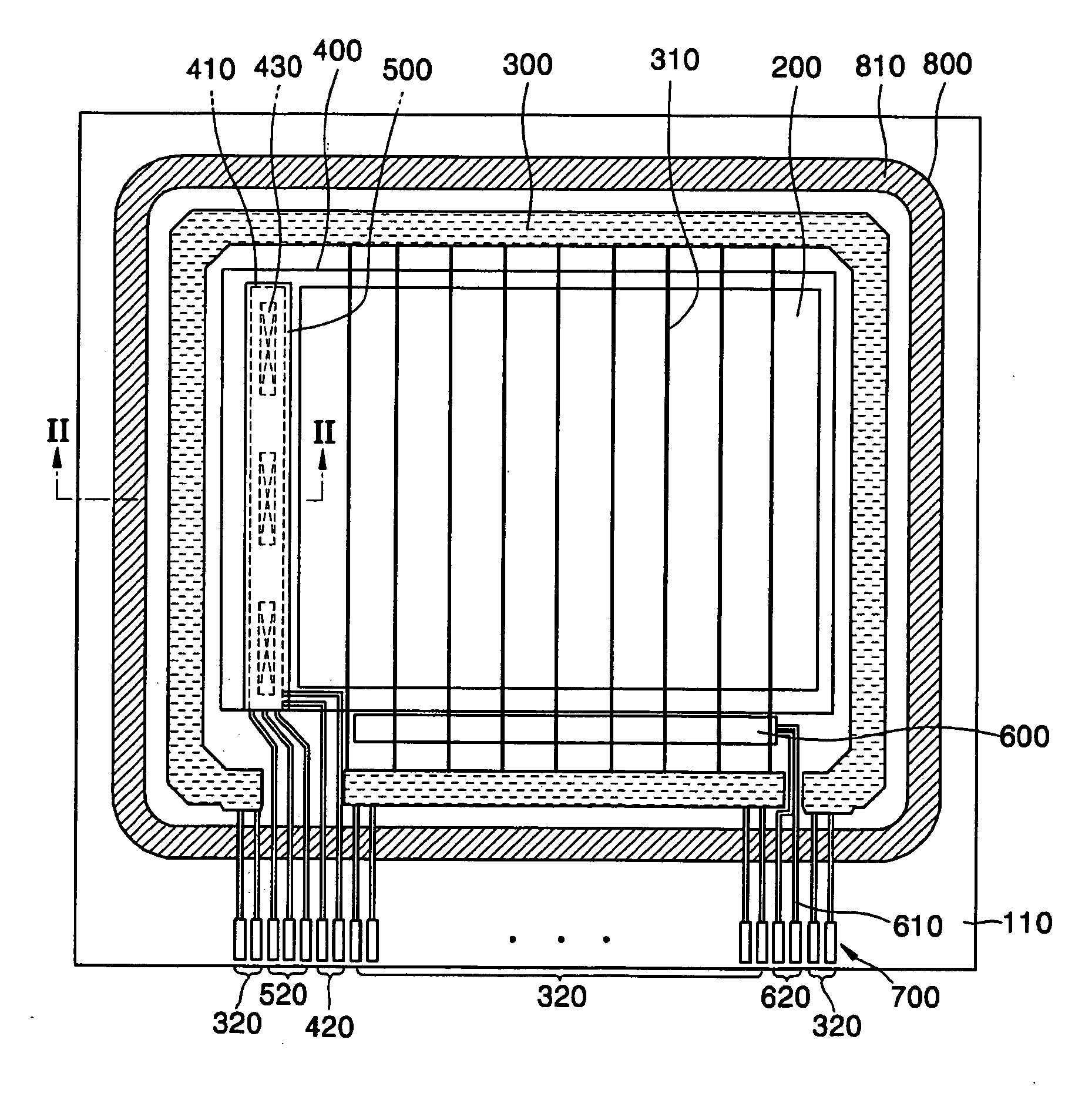

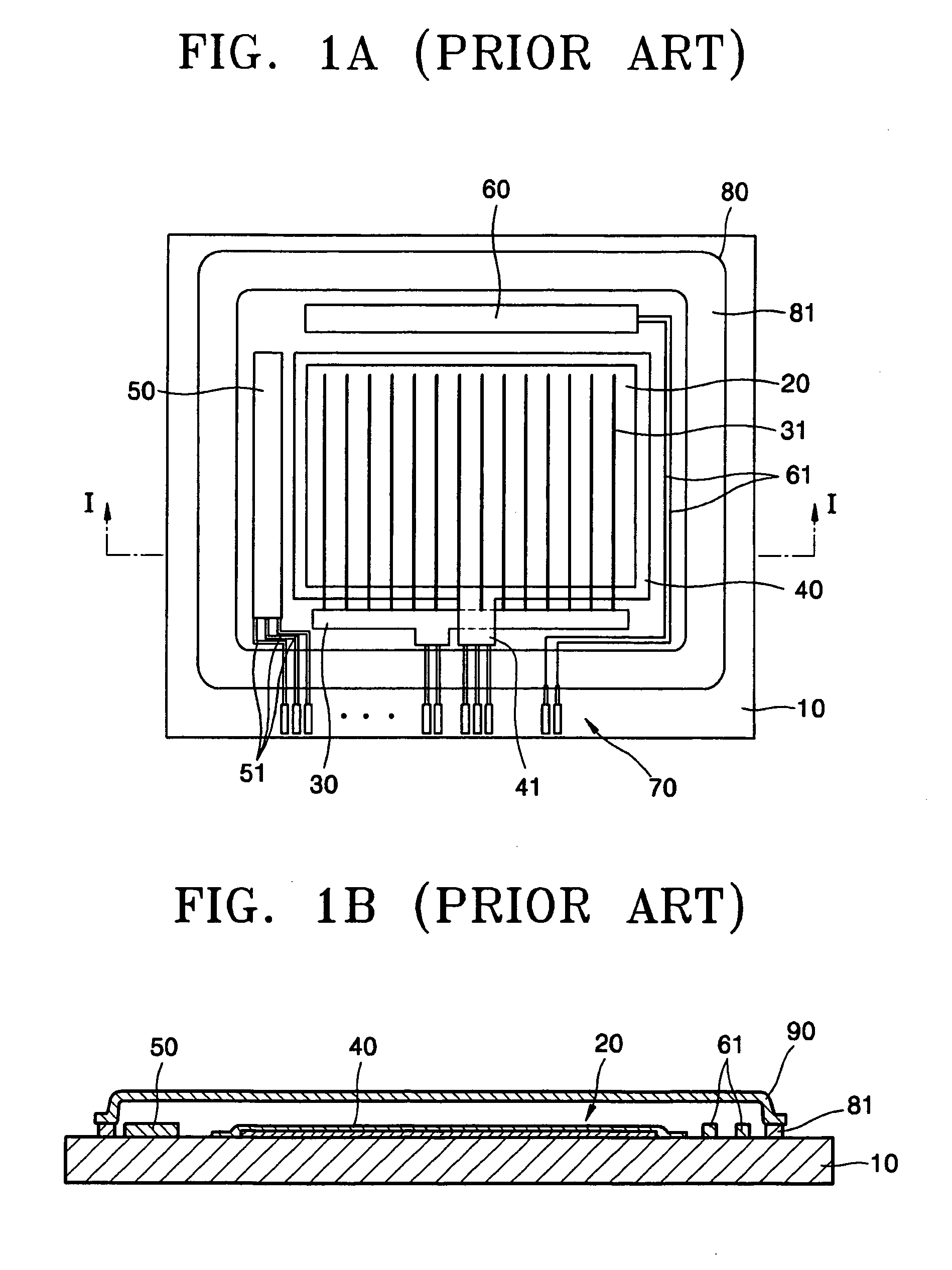

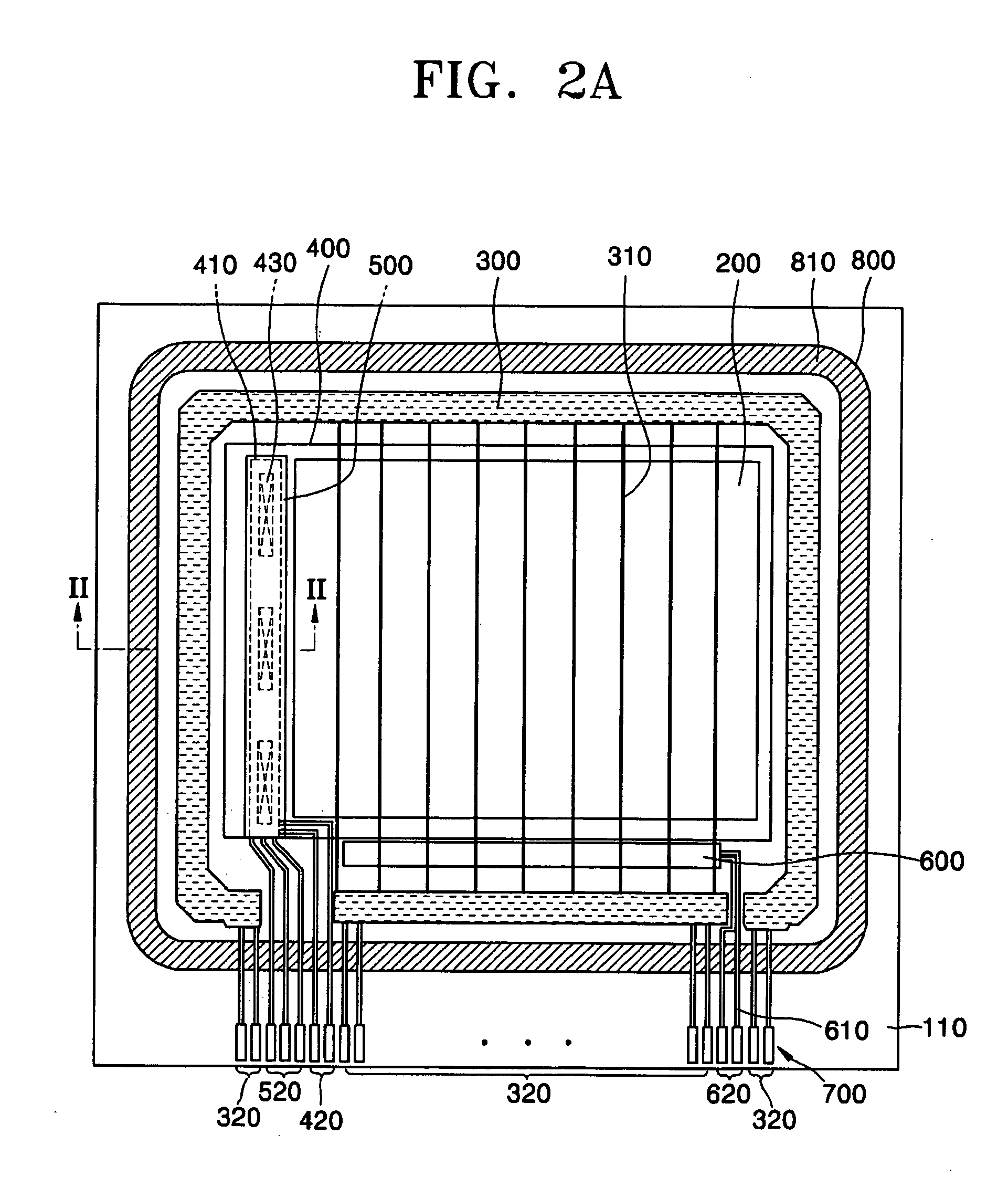

Electroluminescence display device

ActiveUS20050200270A1Raise the ratioReduce non-uniformityDischarge tube luminescnet screensElectroluminescent light sourcesPeripheralEngineering

An electroluminescent display device may include a display area formed on one surface of a substrate. It may further include a first electrode layer, a second electrode layer, and an electroluminescent emission layer between the first and second electrode layers. It may also include an electrode power supply line that supplies electrode power to the display area. The electrode power supply line can be located at least partially on an outer periphery of the display area, and may directly contact the second electrode layer. An electrical component may be arranged under the electrode power supply line, and may have one or more conductive layers.

Owner:SAMSUNG DISPLAY CO LTD

System and method for providing multi-conductive layer metallic interconnects for superconducting integrated circuits

ActiveUS8301214B1Reduce and prevent diffusion of impurityReduce non-uniformitySuperconductors/hyperconductorsSemiconductor/solid-state device detailsImpurity diffusionRapid single flux quantum

Superconducting integrated circuits require several wiring layers to distribute bias and signals across the circuit, which must cross each other both with and without contacts. All wiring lines and contacts must be fully superconducting, and in the prior art each wiring layer comprises a single metallic thin film. An alternative wiring layer is disclosed that comprises sequential layers of two or more different metals. Such a multi-metallic wiring layer may offer improved resistance to impurity diffusion, better surface passivation, and / or reduction of stress, beyond that which is attainable with a single-metallic wiring layer. The resulting process leads to improved margin and yield in an integrated circuit comprising a plurality of Josephson junctions. Several preferred embodiments are disclosed, for both planarized and non-planarized processes. These preferred and other methods may be applied to digital circuits based on Rapid Single Flux Quantum logic, and to quantum computing using Josephson junction qubits.

Owner:SEEQC INC

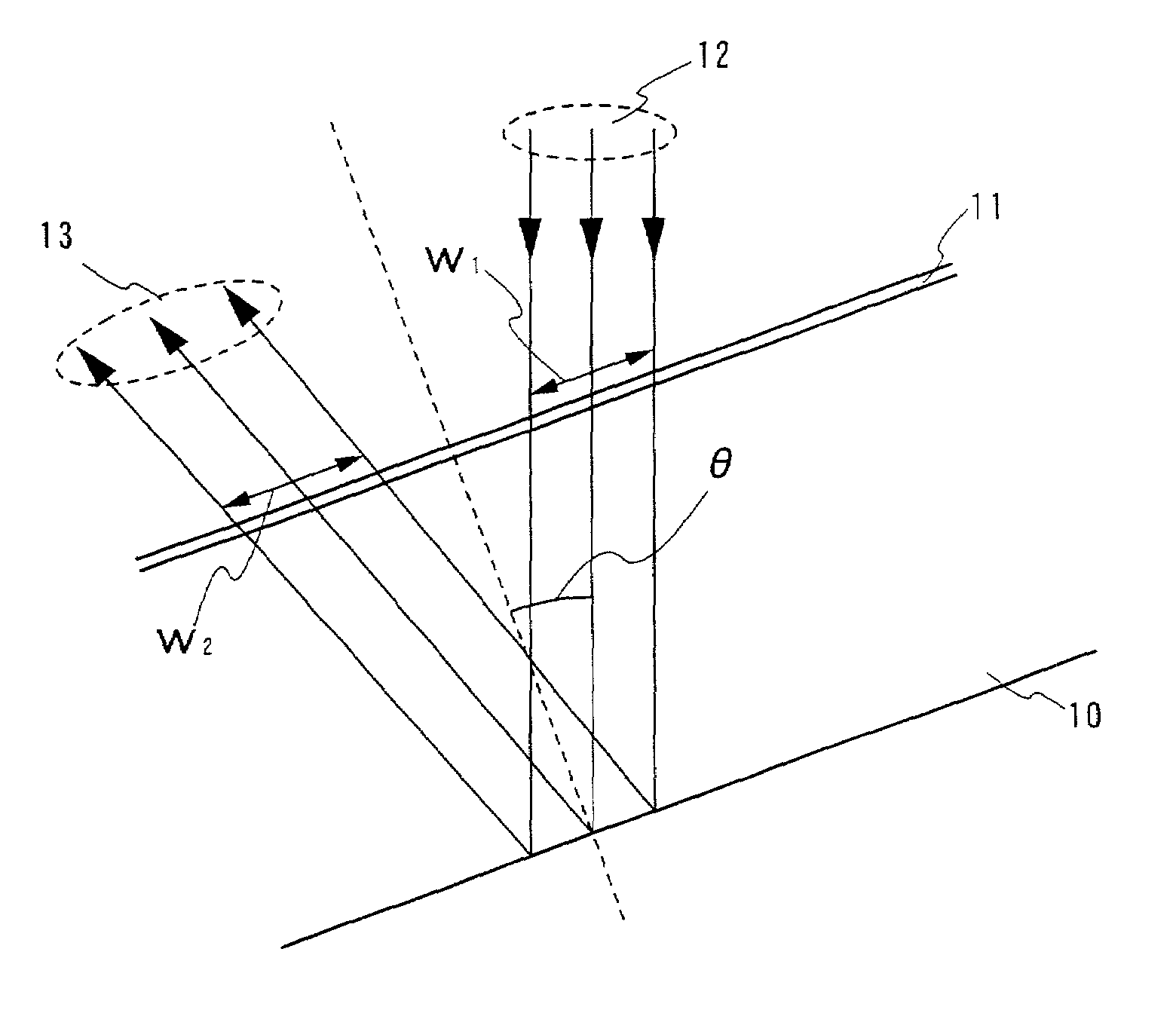

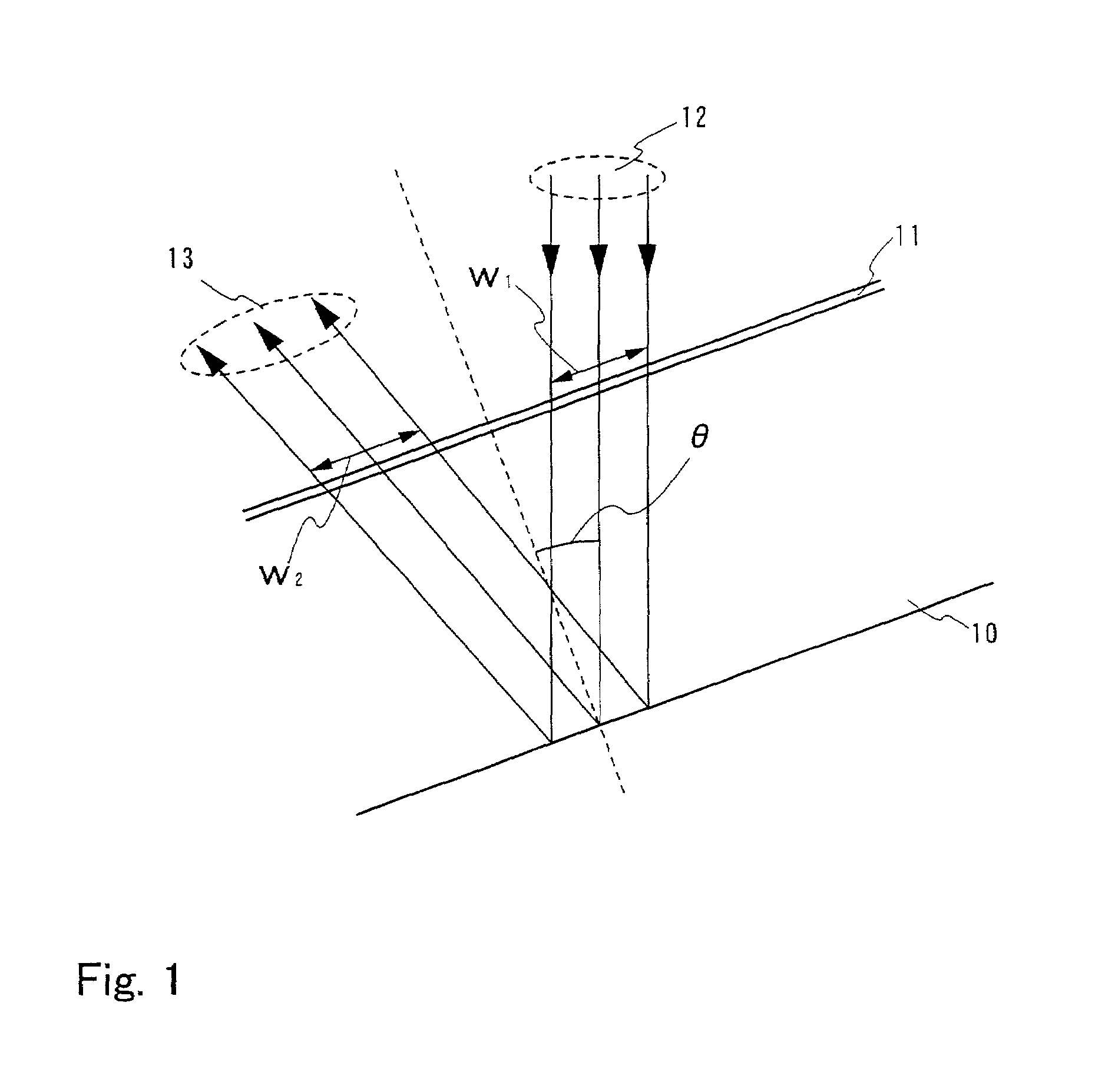

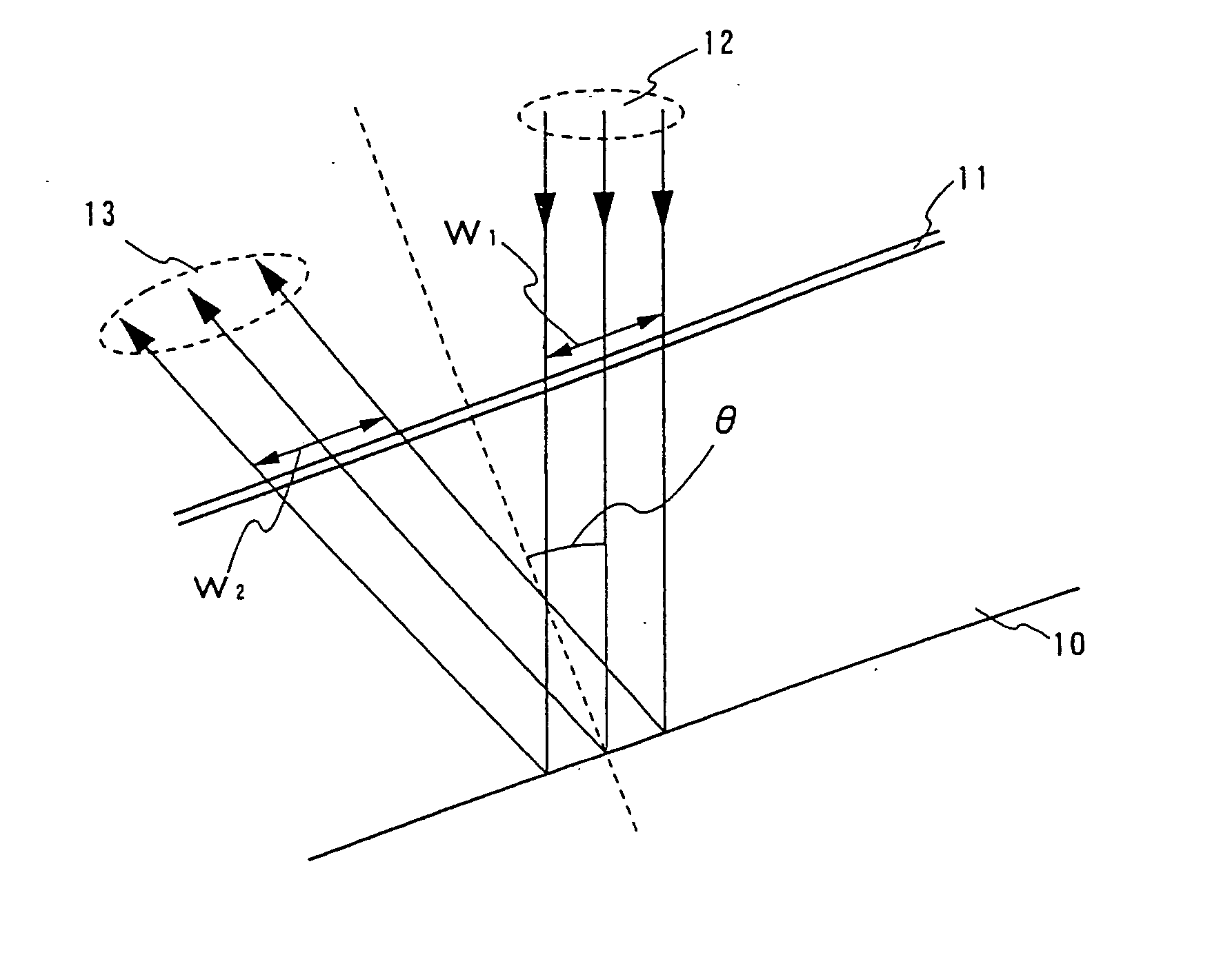

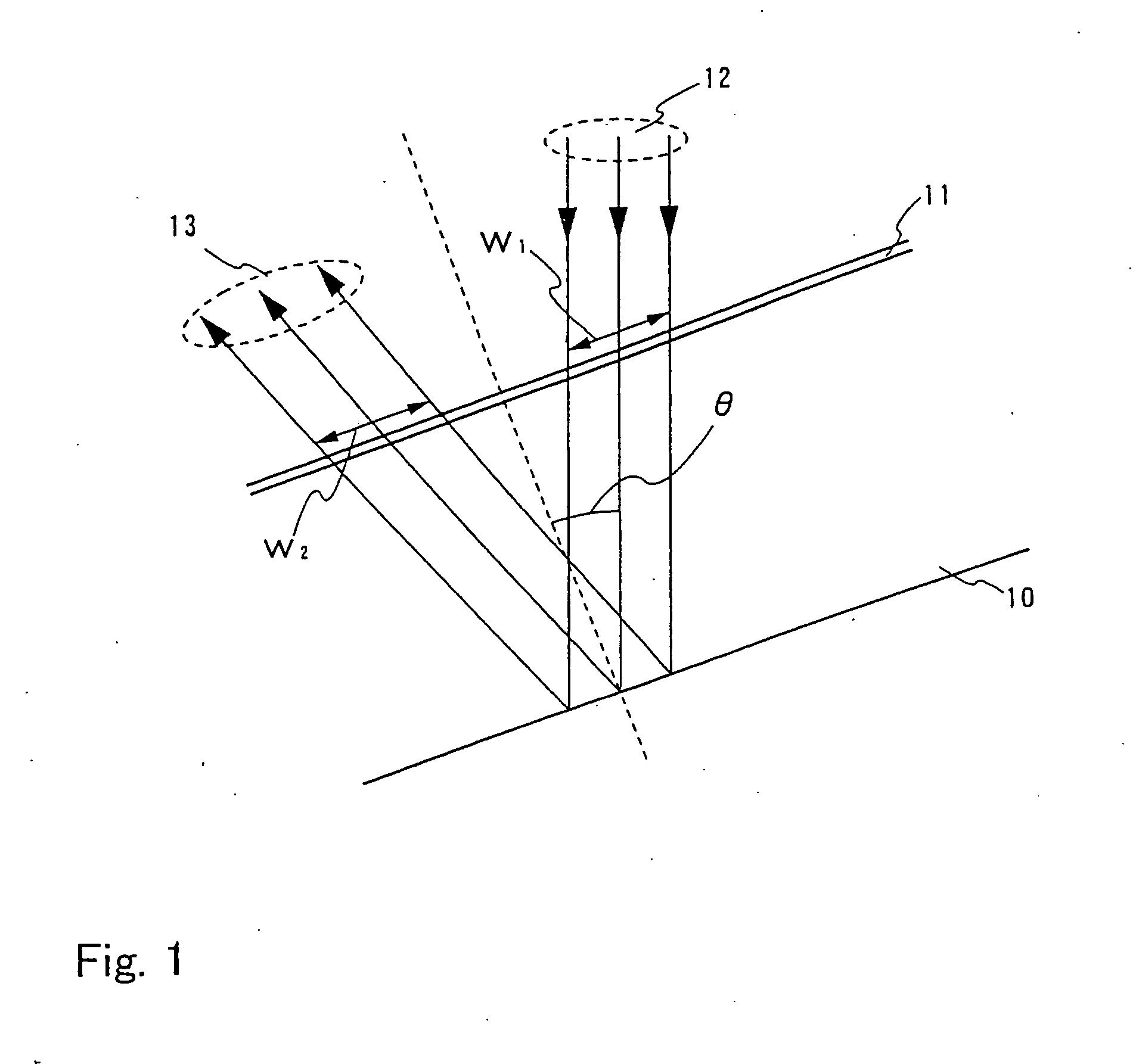

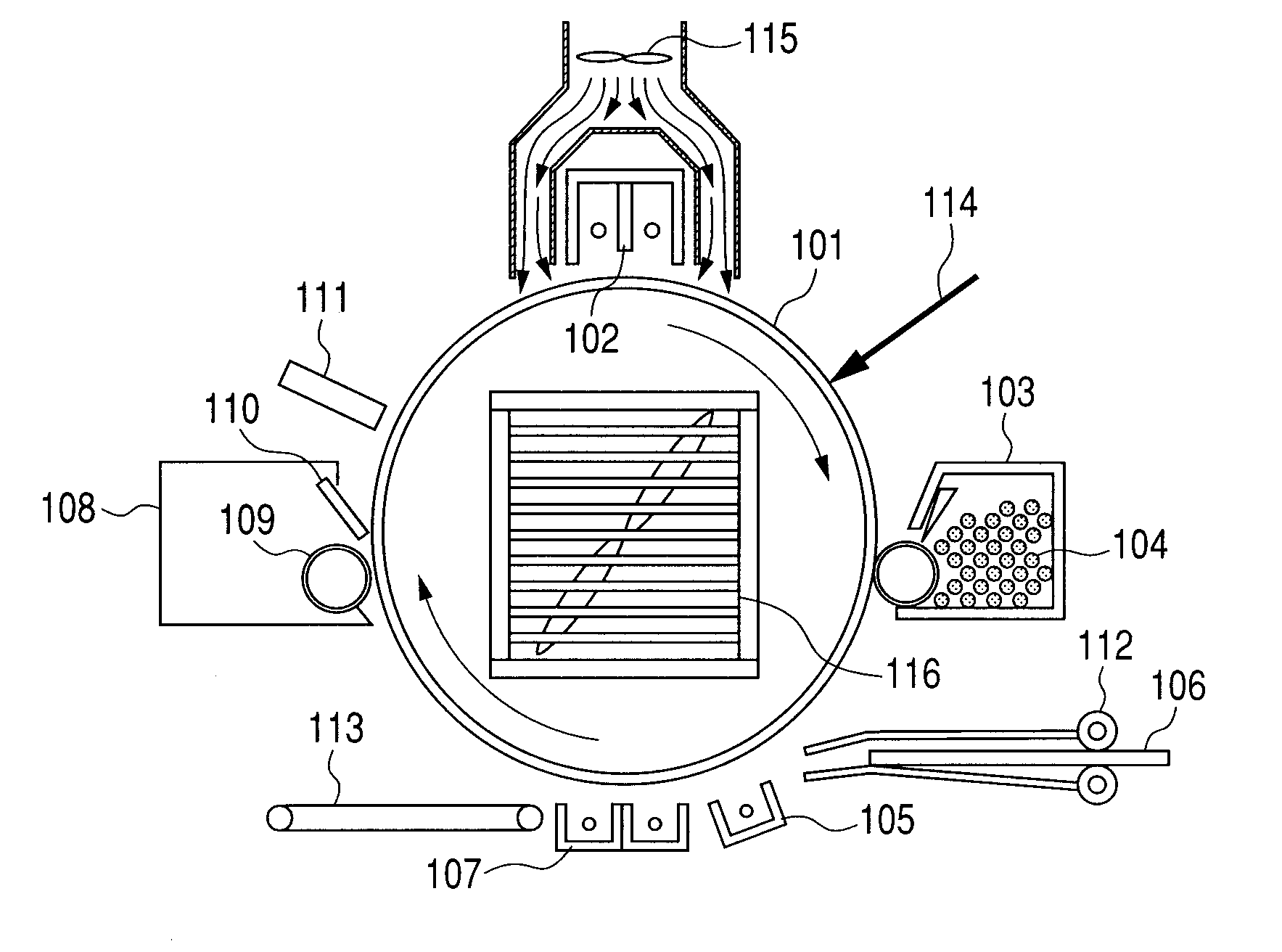

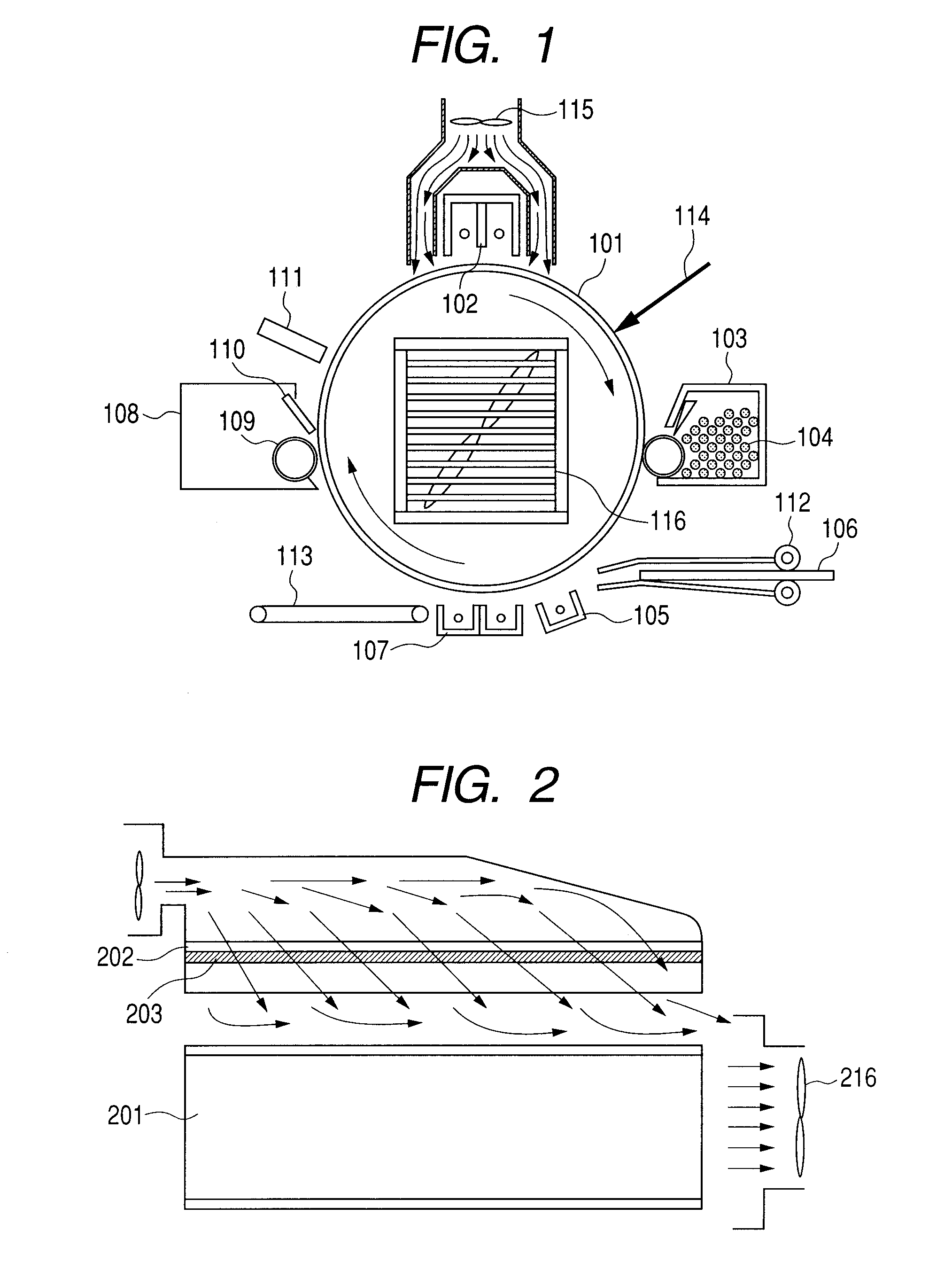

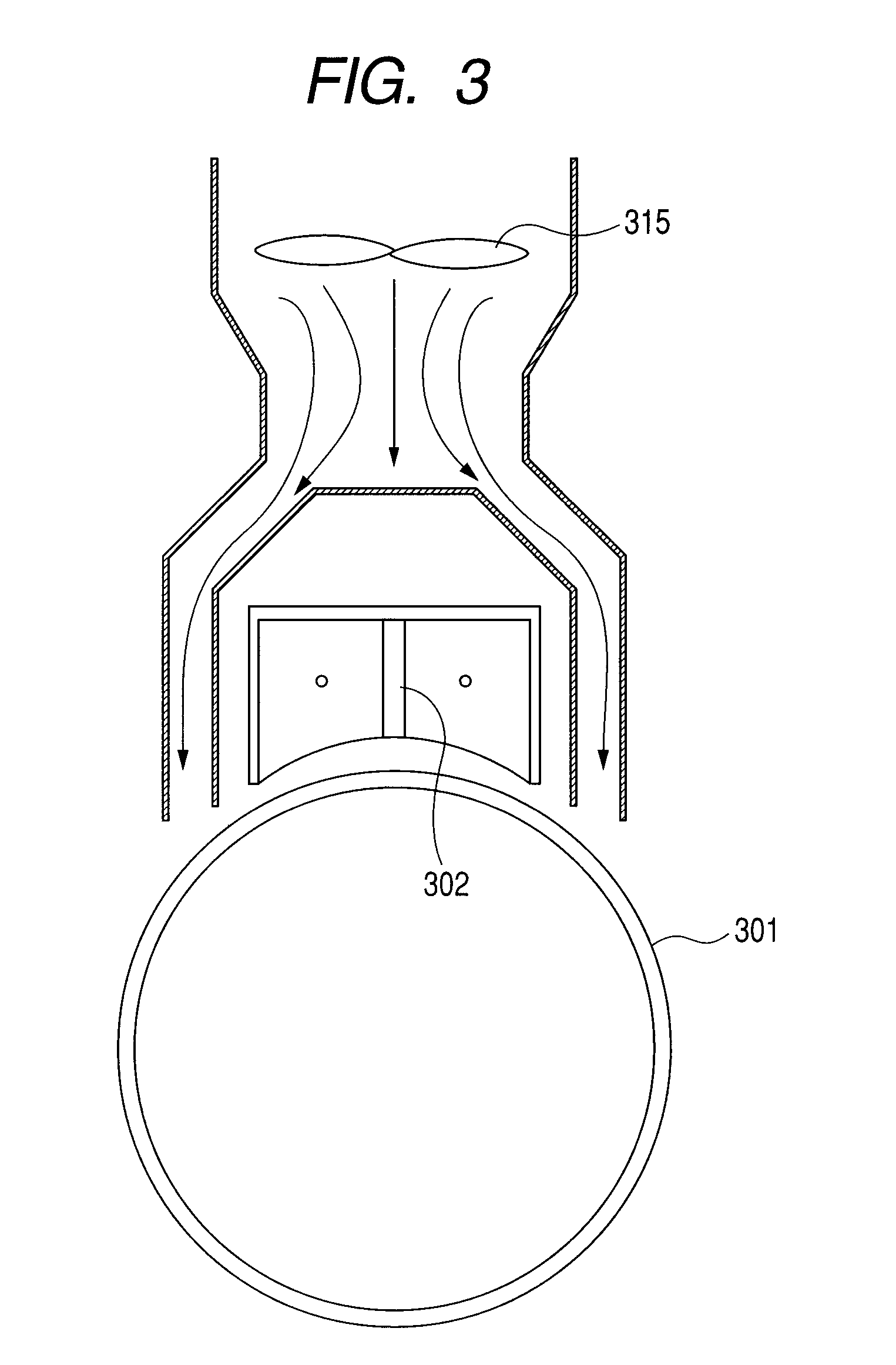

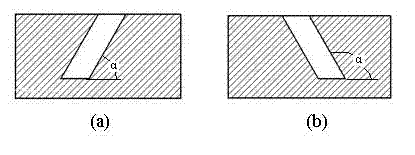

Laser annealing method and semiconductor device fabricating method

ActiveUS7160764B2Low running costReduce non-uniformitySolid-state devicesSemiconductor/solid-state device manufacturingHarmonicLight beam

When the second harmonic of a YAG laser is irradiated onto semiconductor films, concentric-circle patterns are observed on some of the semiconductor films. This phenomenon is due to the non-uniformity of the properties of the semiconductor films. If such semiconductor films are used to fabricate TFTs, the electrical characteristics of the TFTs will be adversely influenced. A concentric-circle pattern is formed by the interference between a reflected beam 1 reflected at a surface of a semiconductor film and a reflected beam 2 reflected at the back surface of a substrate. If the reflected beam 1 and the reflected beam 2 do not overlap each other, such interference does not occur. For this reason, a laser beam is obliquely irradiated onto the semiconductor film to solve the interference. The properties of a crystalline silicon film formed by this method are uniform, and TFTs which are fabricated by using such crystalline silicon film have good electrical characteristics.

Owner:SEMICON ENERGY LAB CO LTD

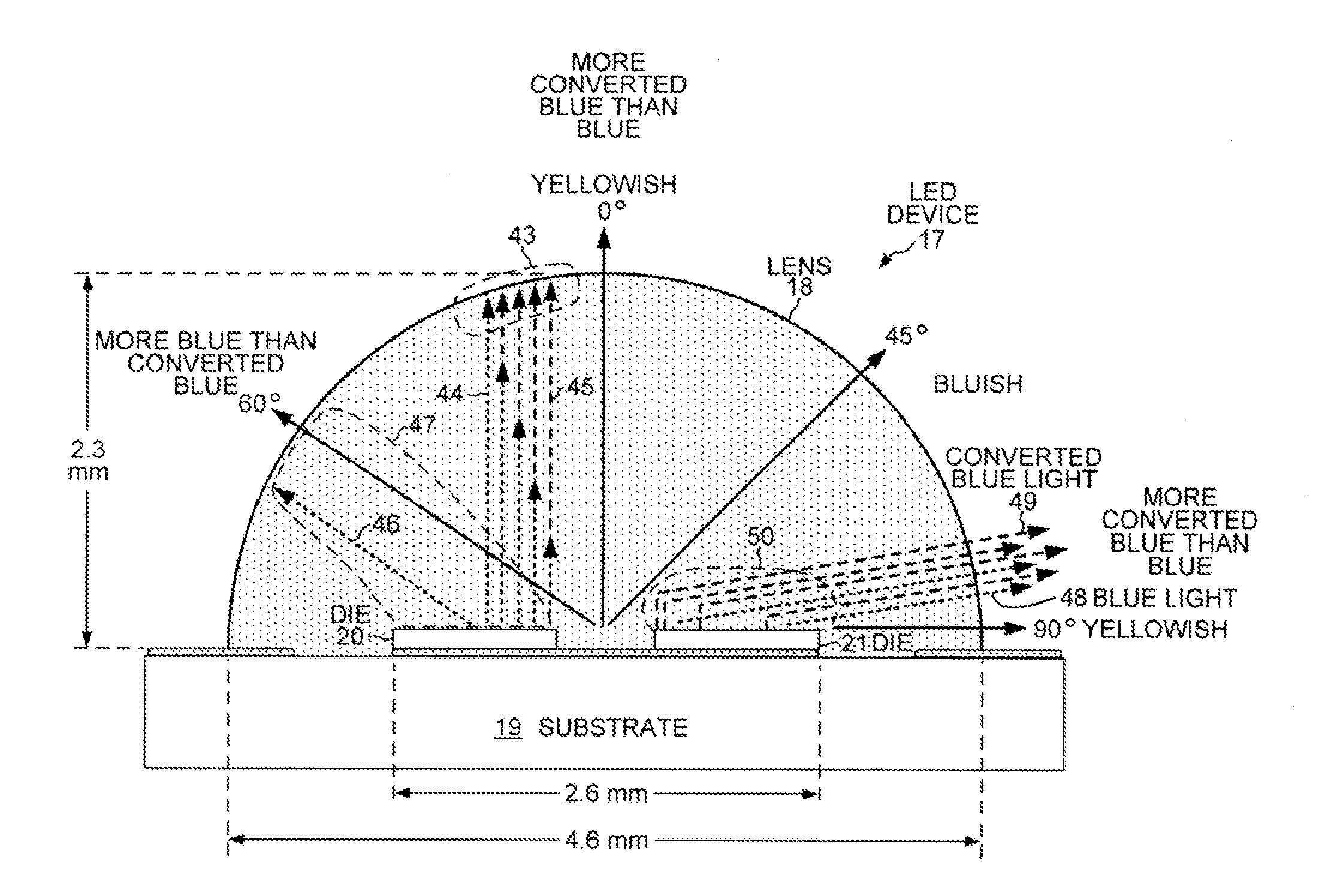

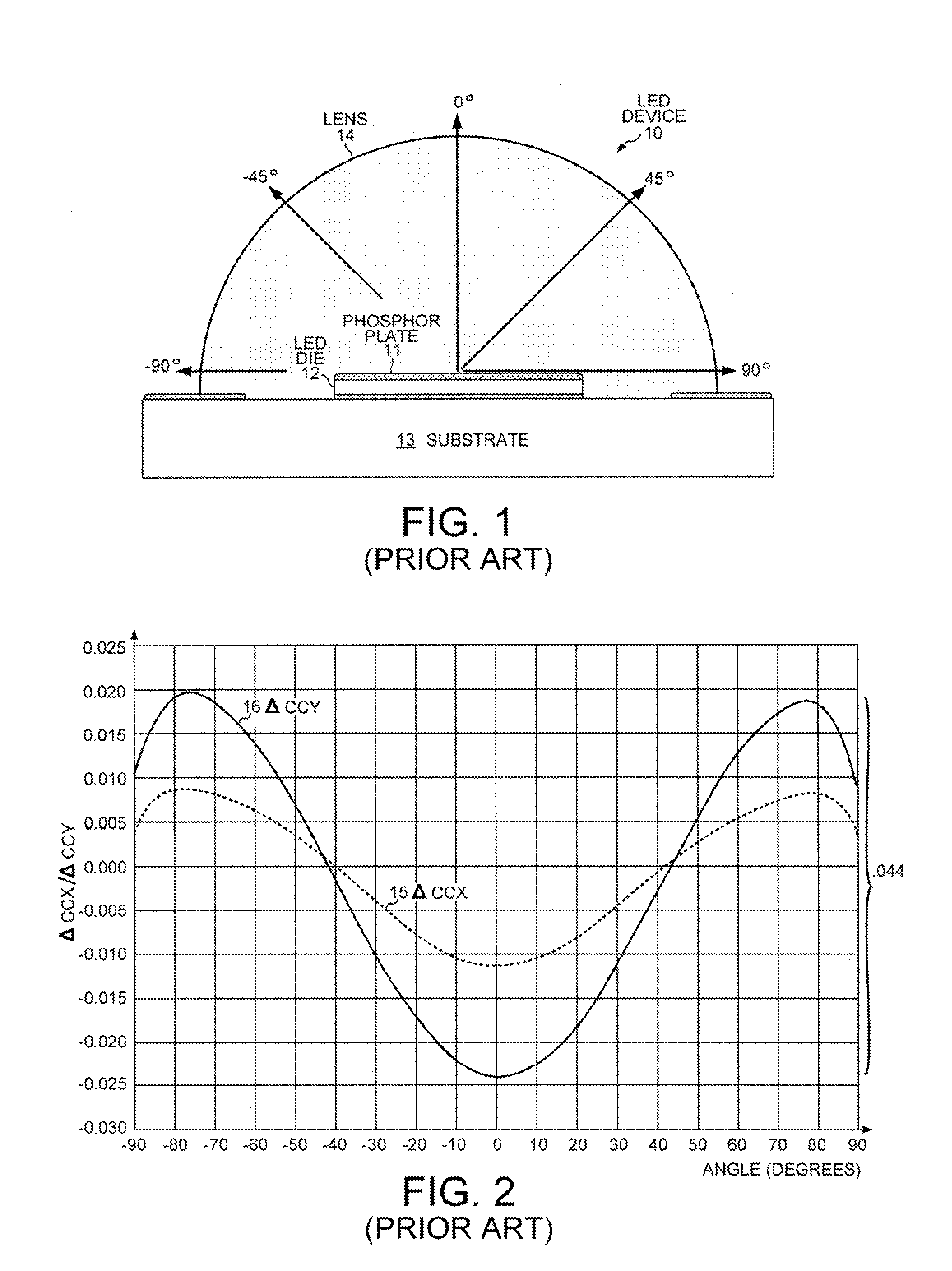

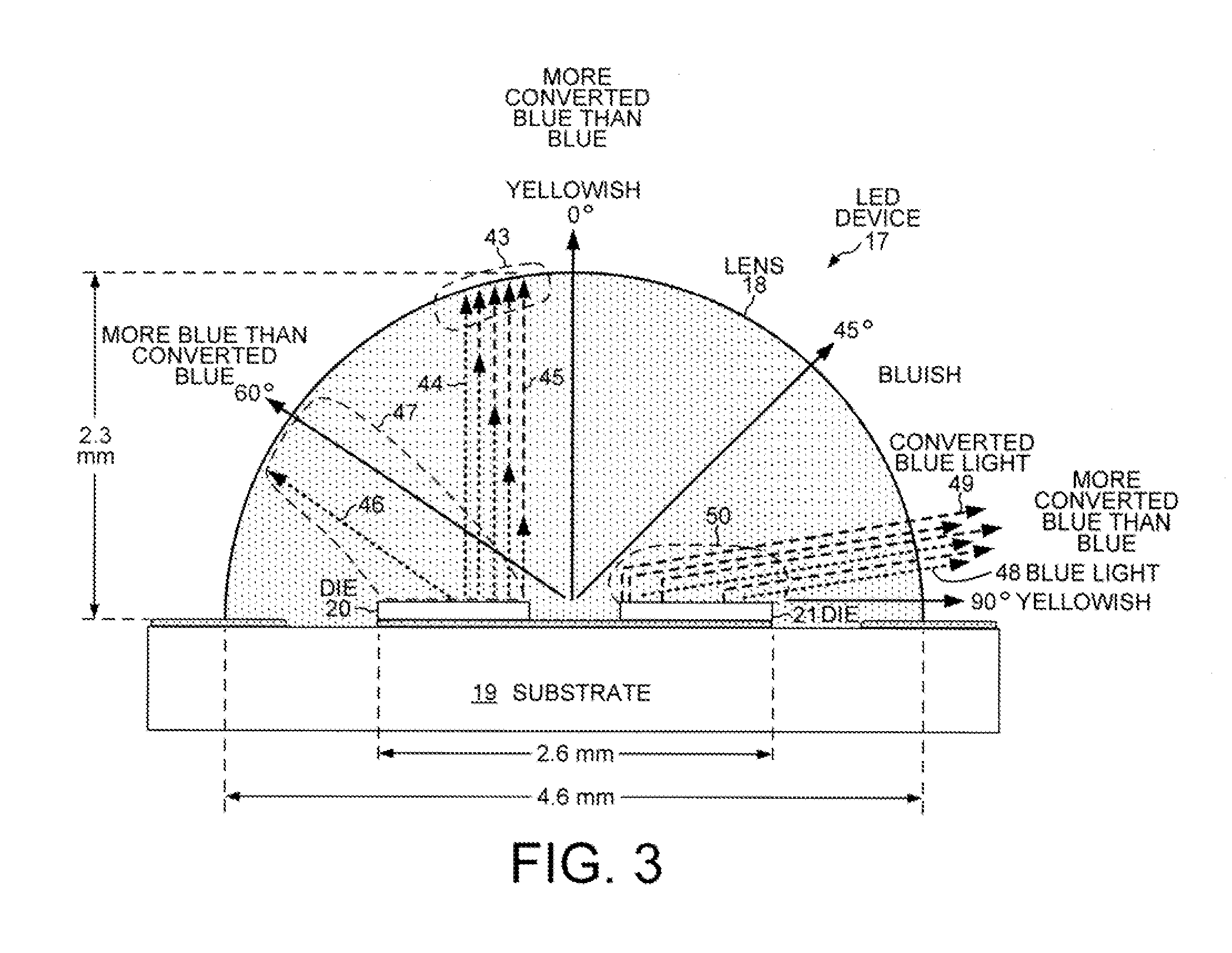

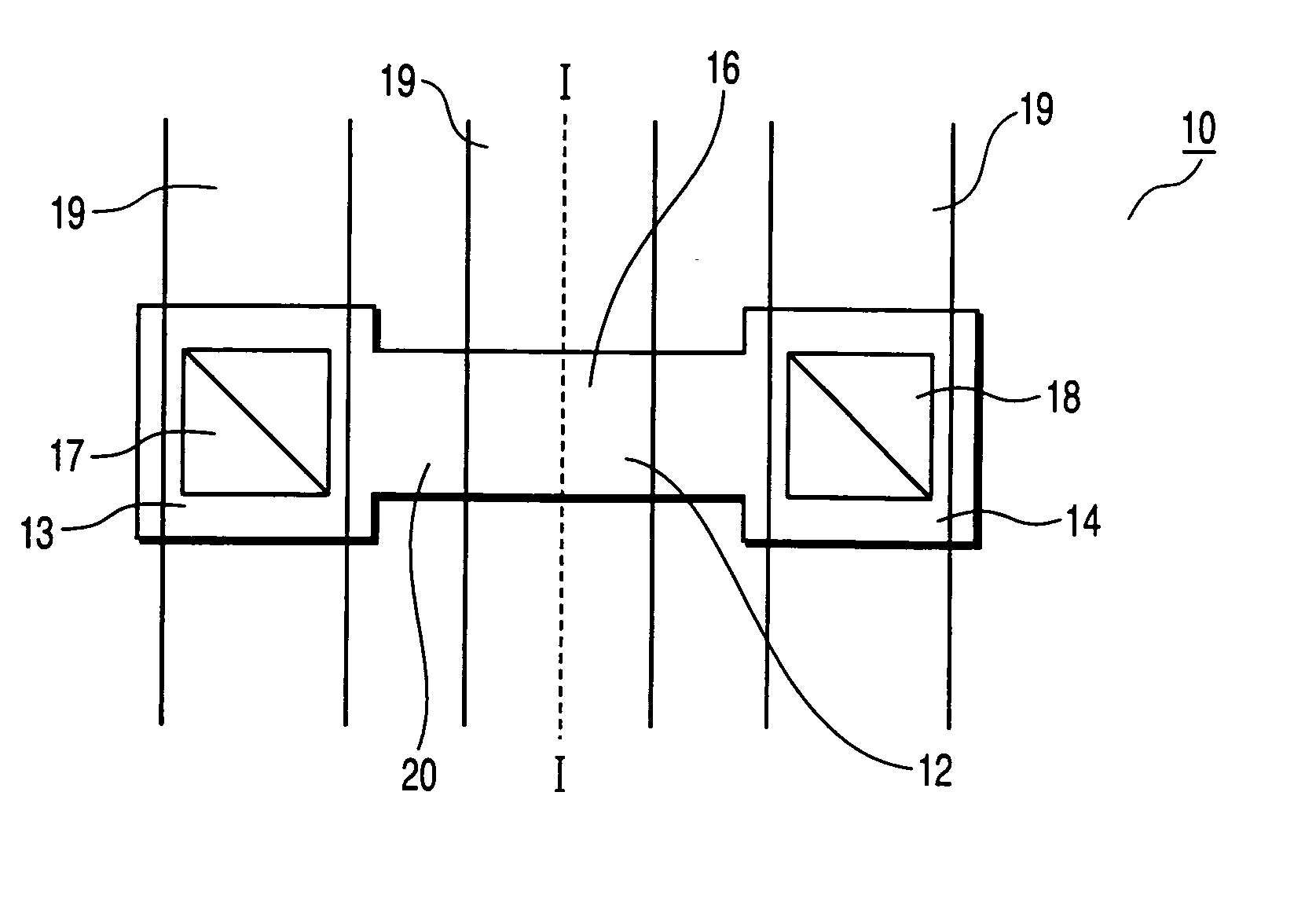

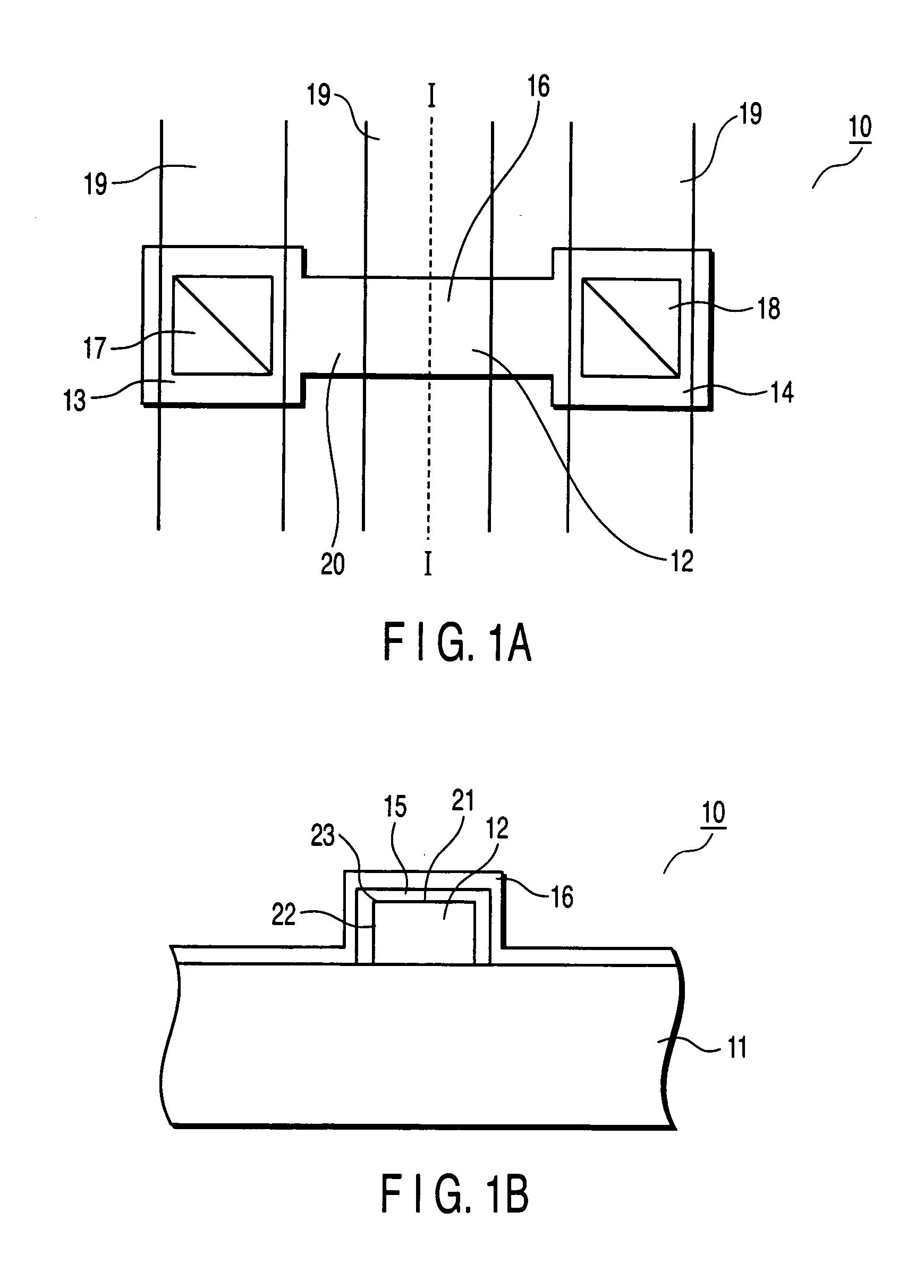

LED Lens Design with More Uniform Color-Over-Angle Emission

ActiveUS20130292709A1Reduce non-uniformityImprove color performanceSolid-state devicesSemiconductor/solid-state device manufacturingPhysicsColor coordinates

An LED device with improved angular color performance has a silicone lens shaped as a portion of a sphere. The lens is molded over an array of LED dies disposed on the upper surface of a substrate. Phosphor particles are disbursed throughout the material used to mold the lens. The distance between farthest apart edges of the LED dies is more than half of the length that the lens extends over the surface of the substrate. The distance from the top of the lens dome to the surface of the substrate is between 57% and 73% of the radius of the sphere. Shaping the lens as the top two thirds of a hemisphere reduces the non-uniformity in the emitted color such that neither of the CIE color coordinates x or y of the color changes more than 0.004 over all emission angles relative to the surface of the substrate.

Owner:BRIDGELUX INC

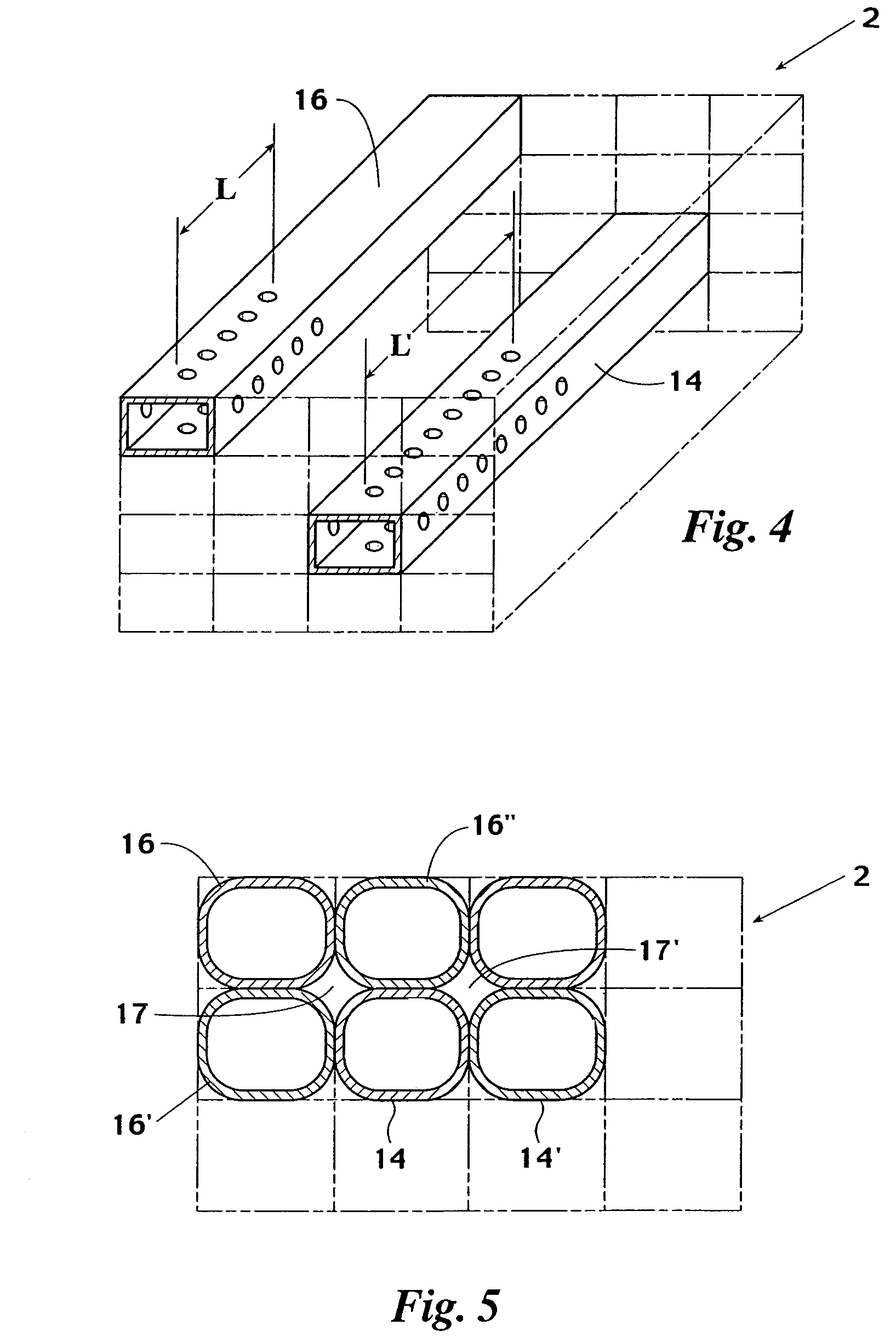

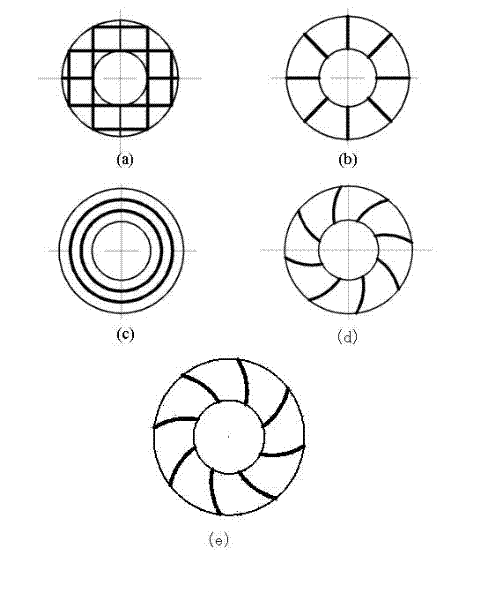

Thin-film transistor formed on insulating substrate

InactiveUS20050212063A1Run at high speedReduce the possibilityTransistorSolid-state devicesHigh concentrationSingle crystal

There is provided a thin-film transistor that is formed on an insulating substrate, is capable of a high-speed operation, has small non-uniformity among devices, is hardly susceptible to device destruction due to high voltage, and is free from the effect of a parasitic transistor that forms at an edge part of an Si island. The thin-film semiconductor device is formed using a thin-film semiconductor provided on the insulating substrate and includes a gate region for formation of a channel region through which a drain current flows. The gate region has a ring shape in plan on the insulating substrate. High concentration impurity-doped regions are dividedly provided on an inside and an outside of the ring-shaped gate region, and the channel region is formed of a plurality of fan-shaped semiconductor single-crystal portions.

Owner:ADVANCED LCD TECH DEVMENT CENT

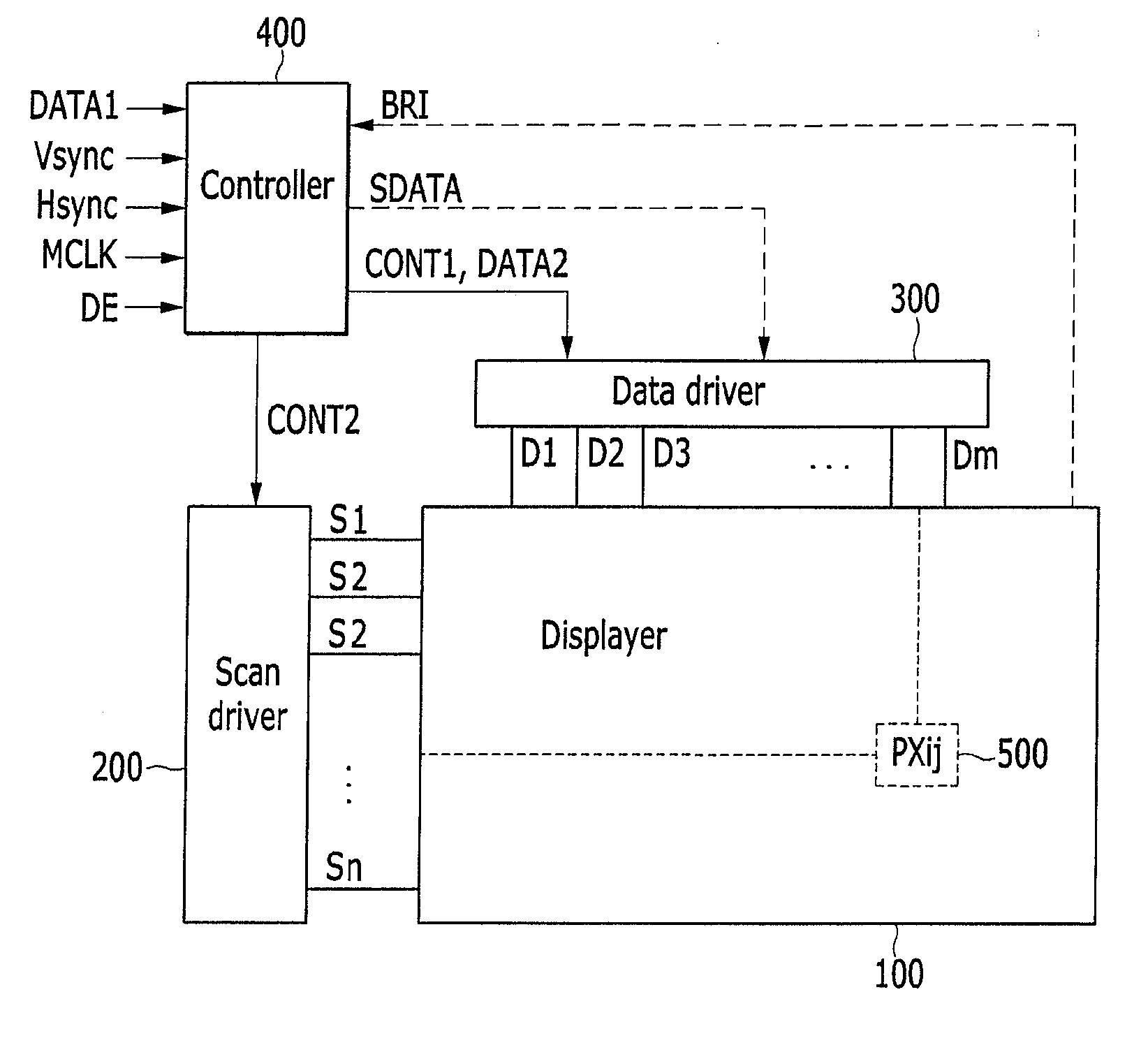

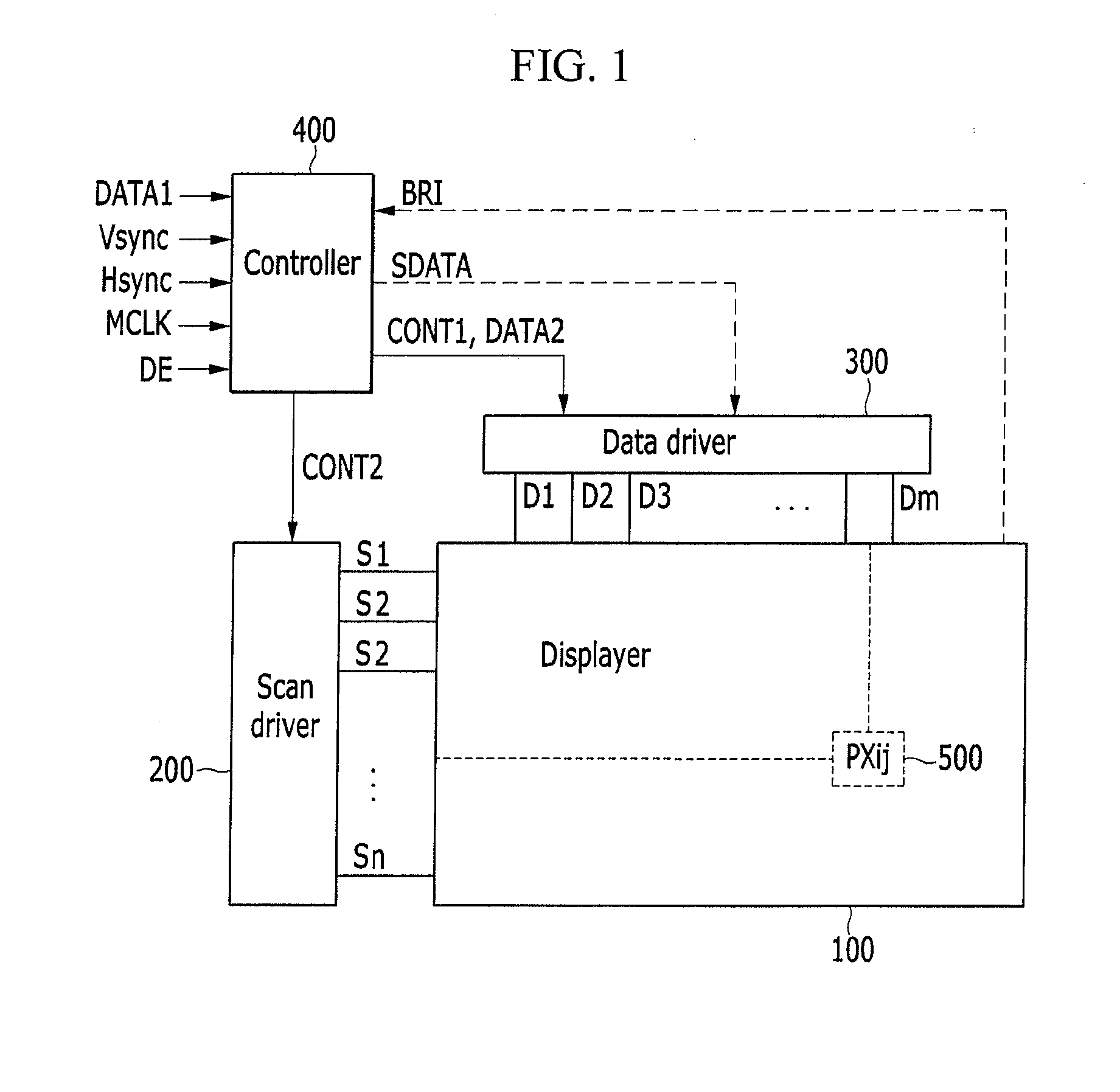

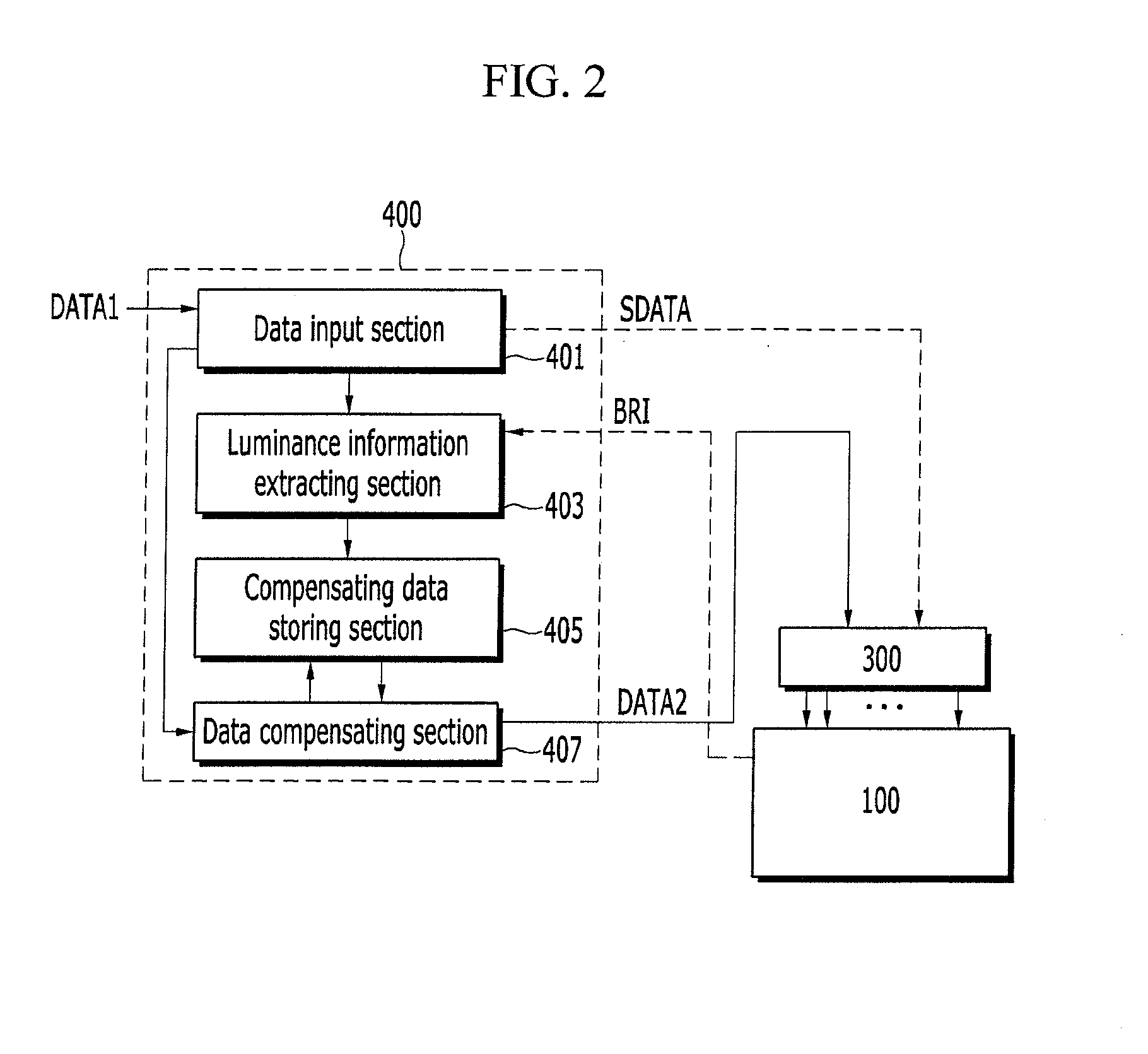

Display device and method for compensation of image data of the same

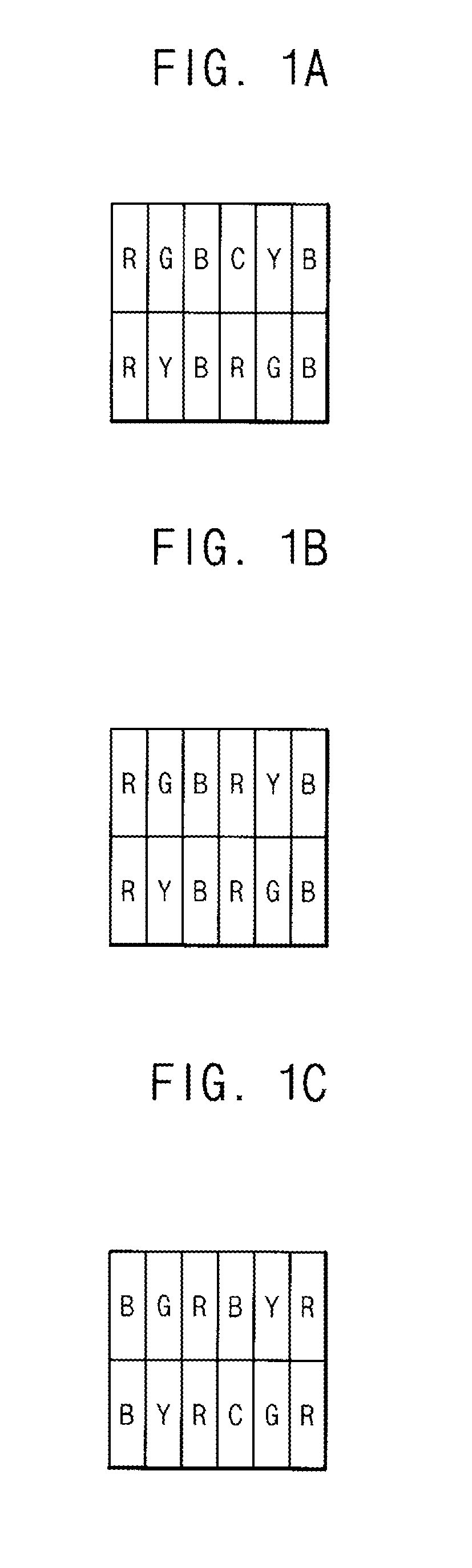

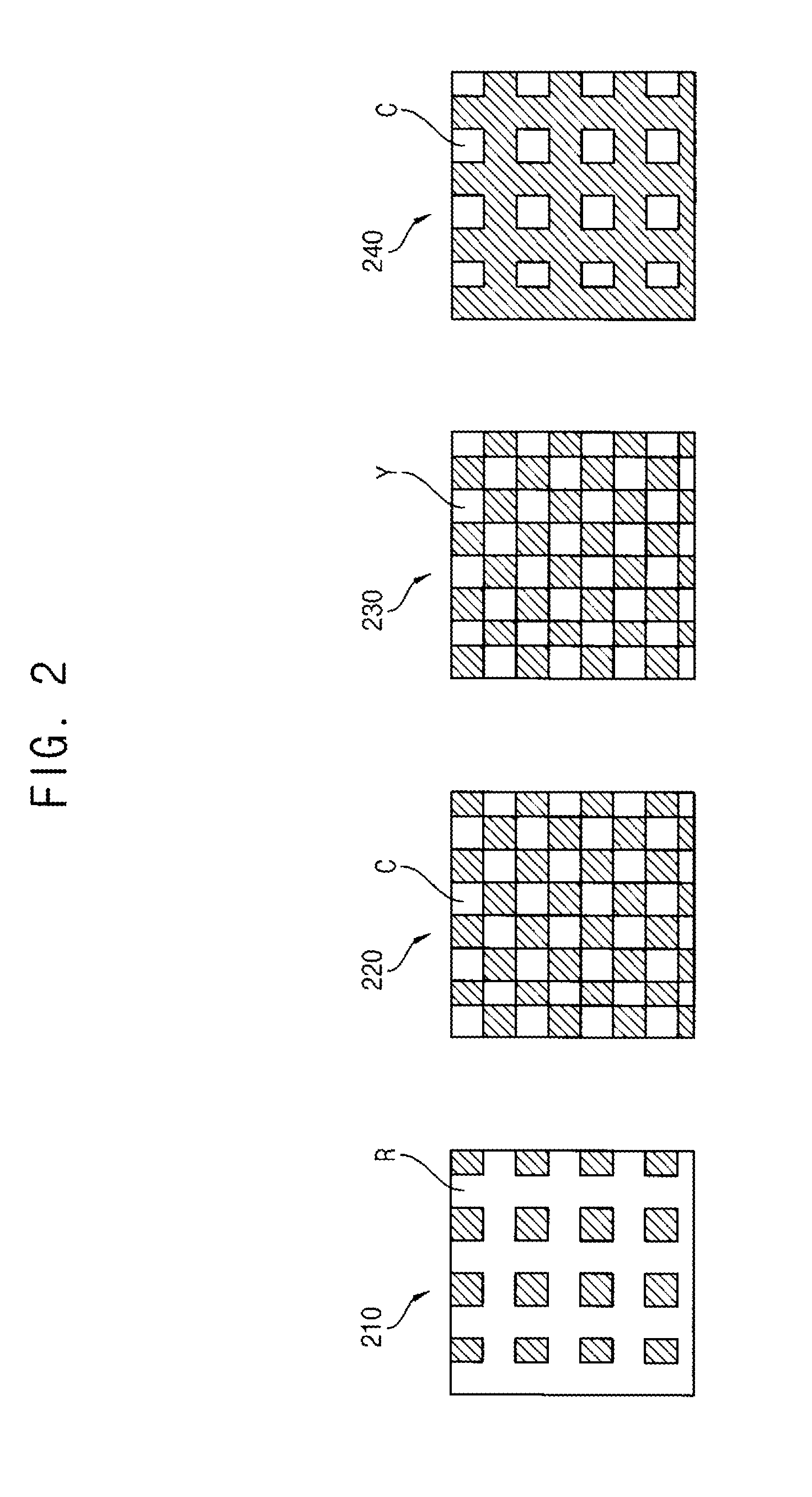

ActiveUS20140253603A1Increased non-uniformitySimply and effectively appliedCathode-ray tube indicatorsInput/output processes for data processingDisplay deviceData signal

A display device includes: a display including a plurality of pixels; and a controller configured to: receive an external input image signal, adjust the external input image signal to compensate for brightness deviations of the pixels, and transmit corresponding image data signals to the pixels, wherein the controller includes: a data input section configured to receive the external input image signal and transmit a test image data signal to the pixels through a data driver, a luminance information extracting section configured to: extract brightness information for the pixels after displaying a test image in accordance with the test image data signal, and calculate first, second, and third parameters, using the brightness information, and a data compensating section configured to generate the image data signals by adjusting the external input image signal based on the first, second, and third parameters.

Owner:SAMSUNG DISPLAY CO LTD

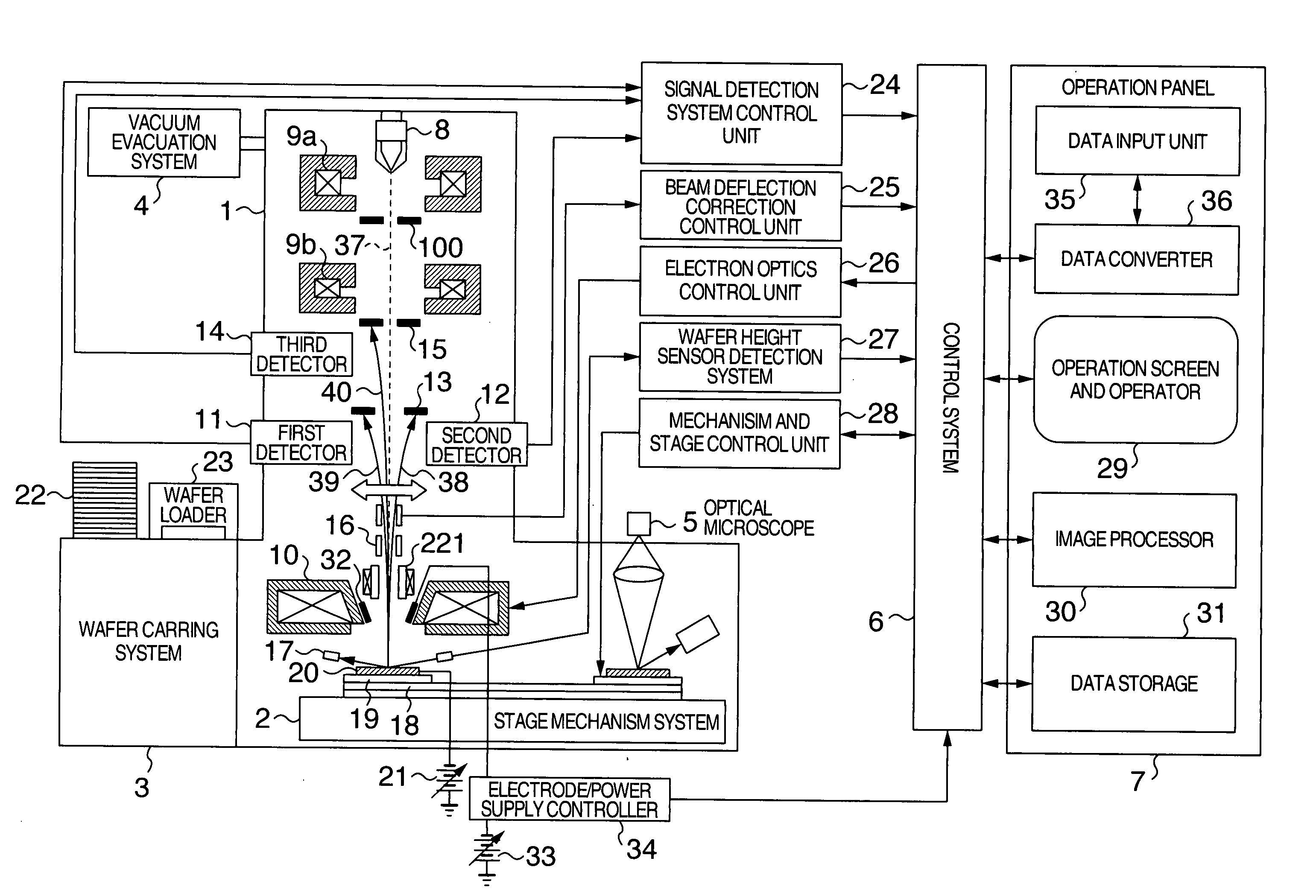

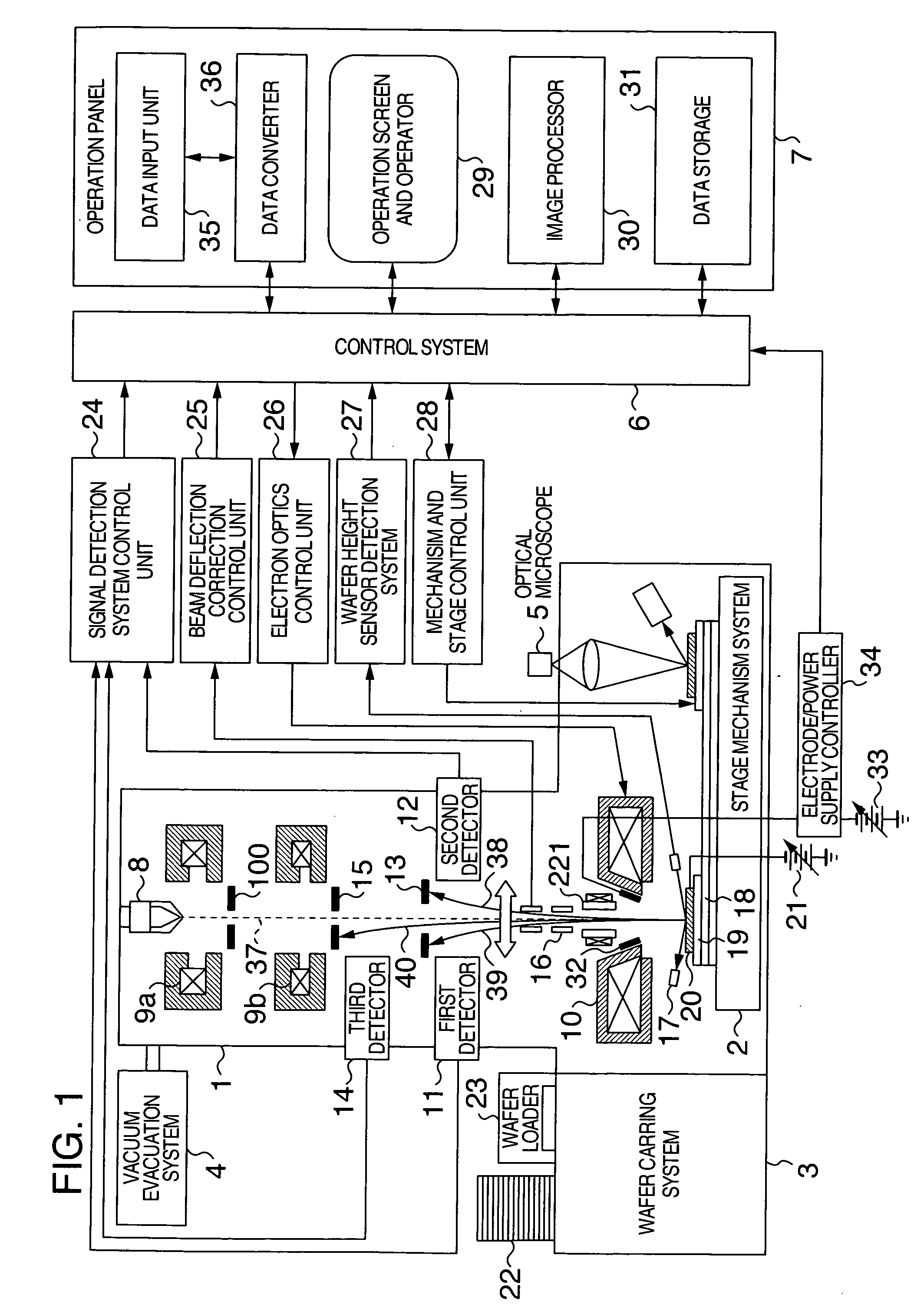

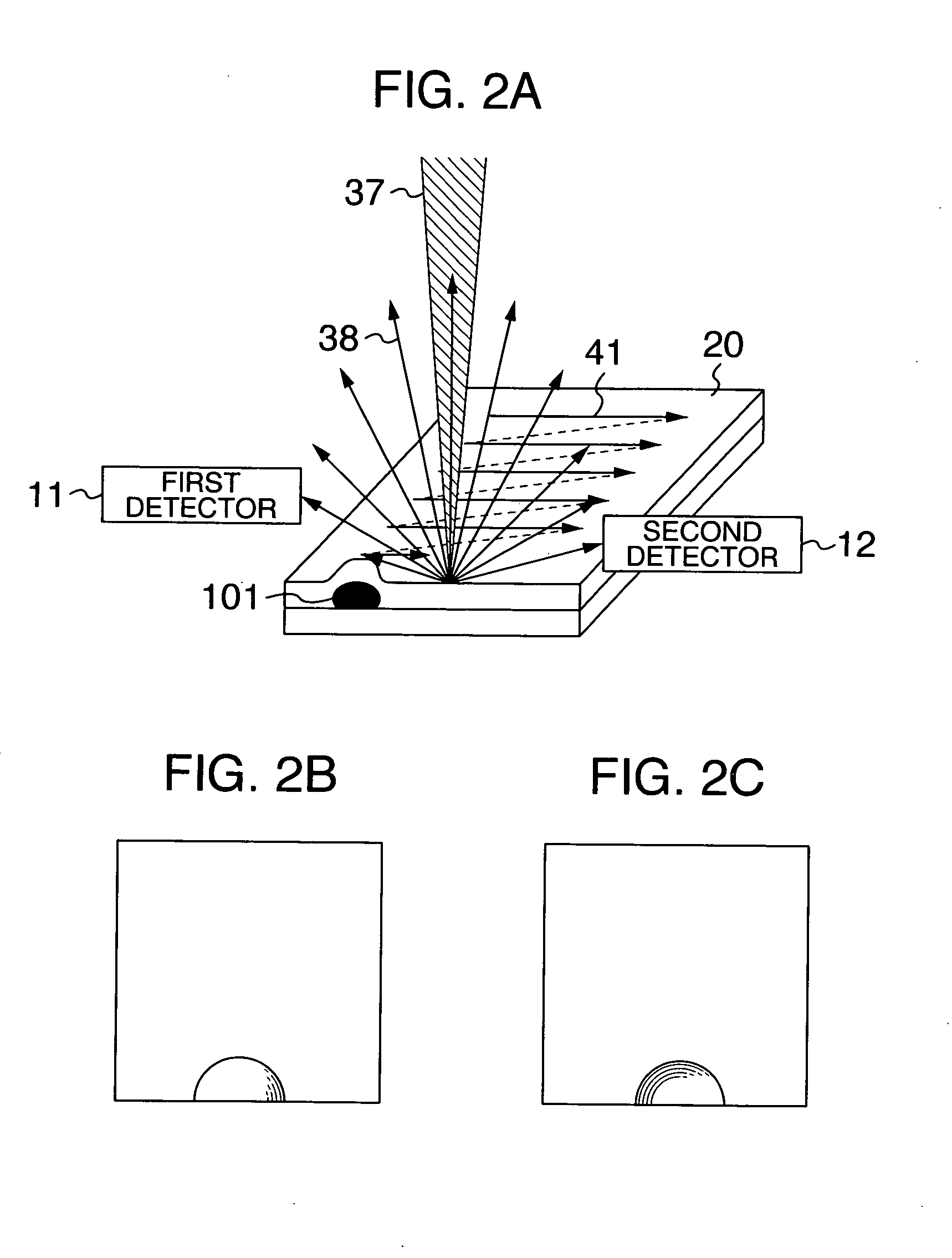

Inspection method and inspection system using charged particle beam

ActiveUS20060243906A1Prevent degradation in shadow contrastStable detectionThermometer detailsMaterial analysis using wave/particle radiationHigh angleSecondary electrons

In an electric immersion lens having high resolution capability, secondary electrons generated from a specimen are accelerated to suppress the dependency of rotational action of the secondary electrons applied thereto by an objective lens upon energy levels of the secondary electrons and when selectively detecting low and high angle components of elevation and azimuth as viewed from a secondary electron generation site by means of an annular detector interposed between an electron source and the objective lens, the secondary electrons are adjusted and deflected by means of an E×B deflector such that the center axis of secondary electrons converged finely under acceleration is made to be coincident with the center axis of a low elevation signal detection system and the secondary electrons are deviated from an aperture of a high elevation signal detection system.

Owner:HITACHI HIGH-TECH CORP

Solar energy concentrating frequency dividing photovoltaic photo-thermal cogeneration device

InactiveCN102779885AIncrease profitReduce non-uniformitySolar heat devicesEnergy industryHeat conductingThermal insulation

The invention discloses a solar energy concentrating frequency dividing photovoltaic photo-thermal cogeneration device which comprises a composite paraboloid concentrator. First ultra clear glass, second ultra clear glass, an upper water channel and solar energy frequency dividing glass are configured in the composite paraboloid concentrator from top to bottom, a photovoltaic cell is configured below the solar energy frequency dividing glass and configured on a heat conducting silica gel, a lower water pipe is arranged below the heat conducting silica gel, and thermal insulation materials of the lower water pipe are configured on a bracket. When sunlight penetrates through the first ultra clear glass, an upper vacuum layer and the second ultra clear glass and near-infrared light in the sunlight irradiates the photovoltaic cell, by means of a sunlight frequency dividing technique, water working media in the upper water channel and the solar energy frequency dividing glass jointly absorb the near-infrared light and convert the near-infrared light to heat energy, the rest visible light irradiates the photovoltaic cell and is converted to electric energy and heat energy, the electric energy is supplied for users to use, and the heat energy is transmitted to the water working media in a lower water channel. According to the solar energy concentrating frequency dividing photovoltaic photo-thermal cogeneration device, photovoltaic photo-thermal cogeneration is achieved, and whole efficiencies of the device are improved.

Owner:XI AN JIAOTONG UNIV

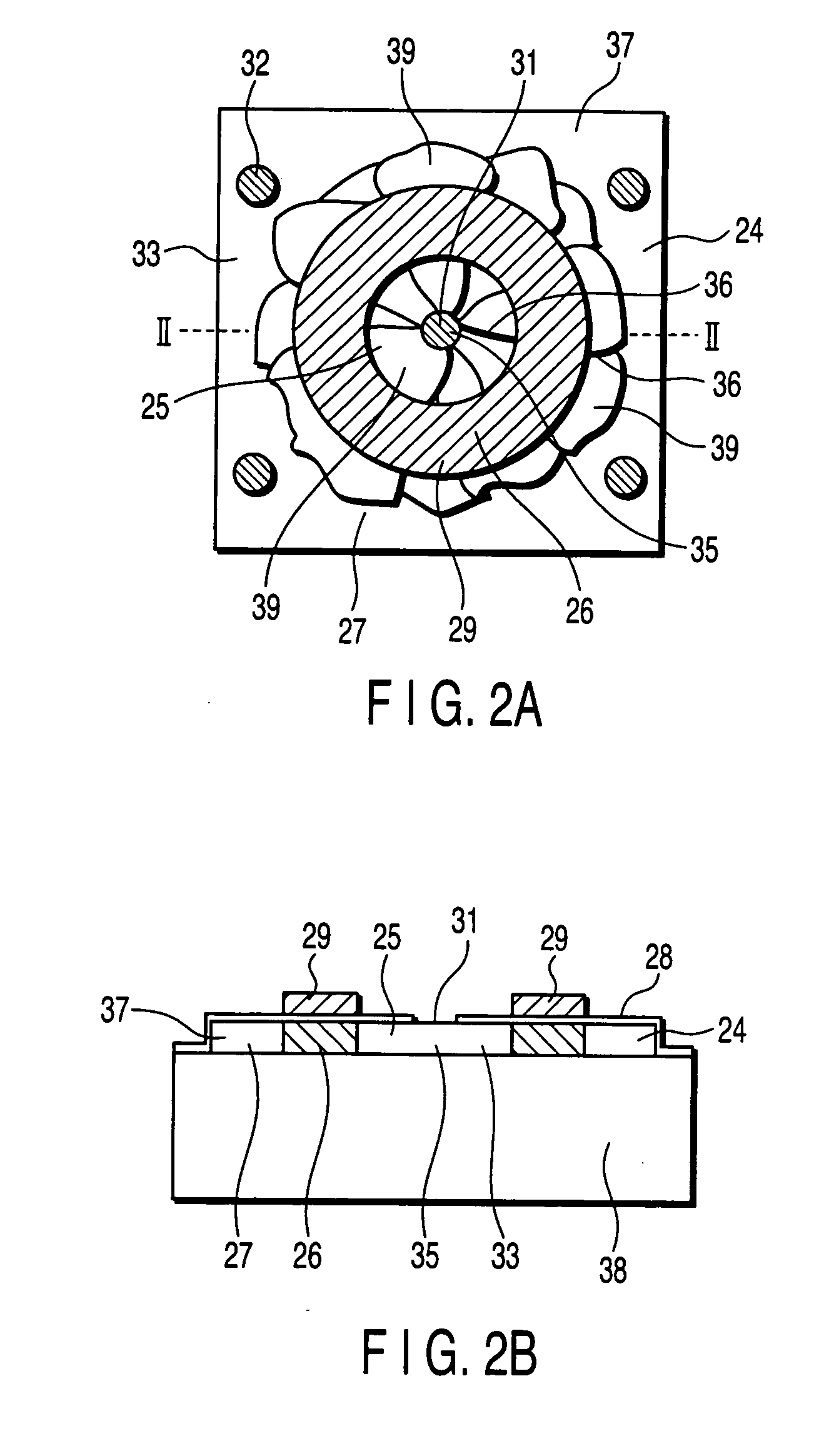

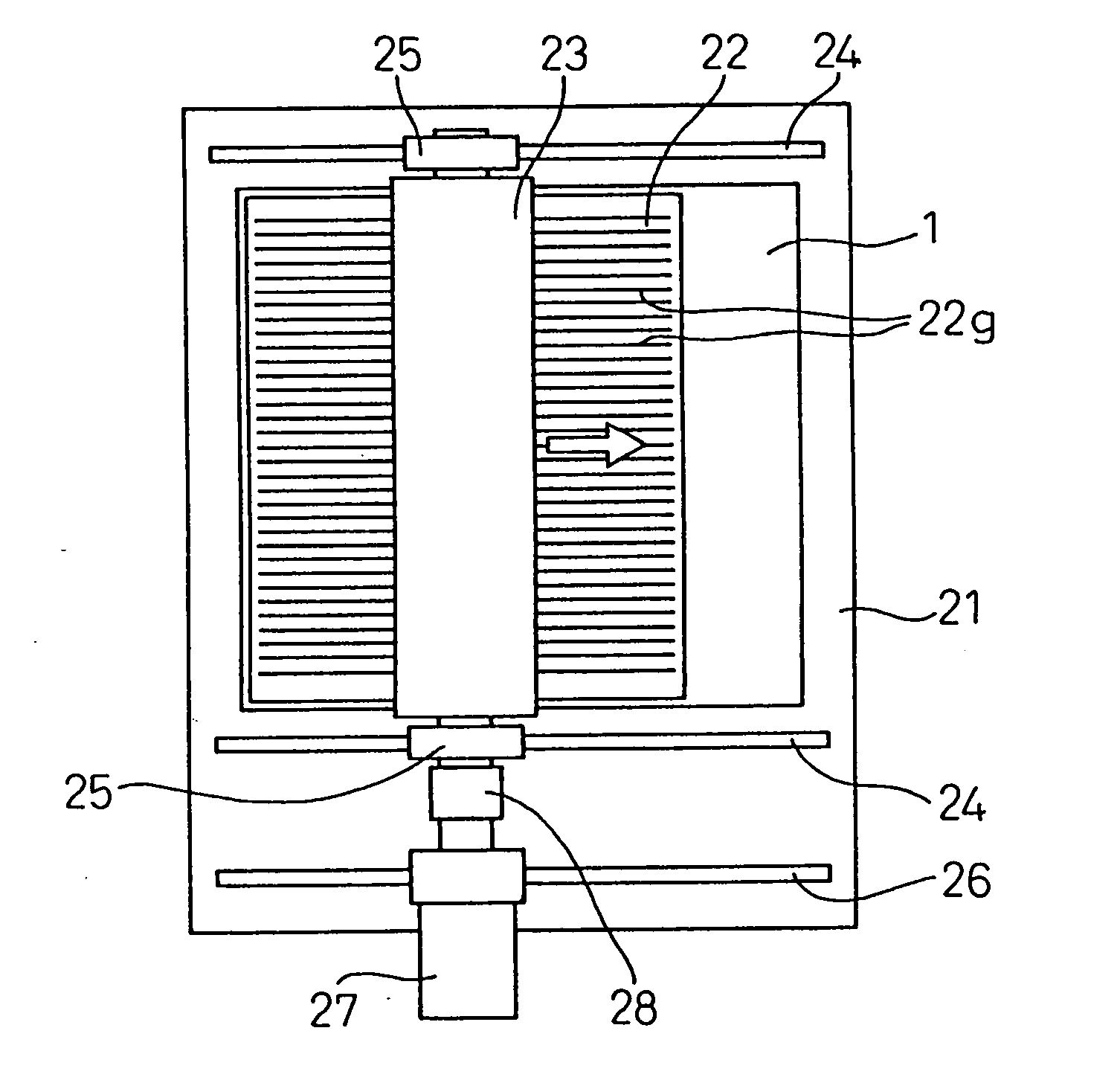

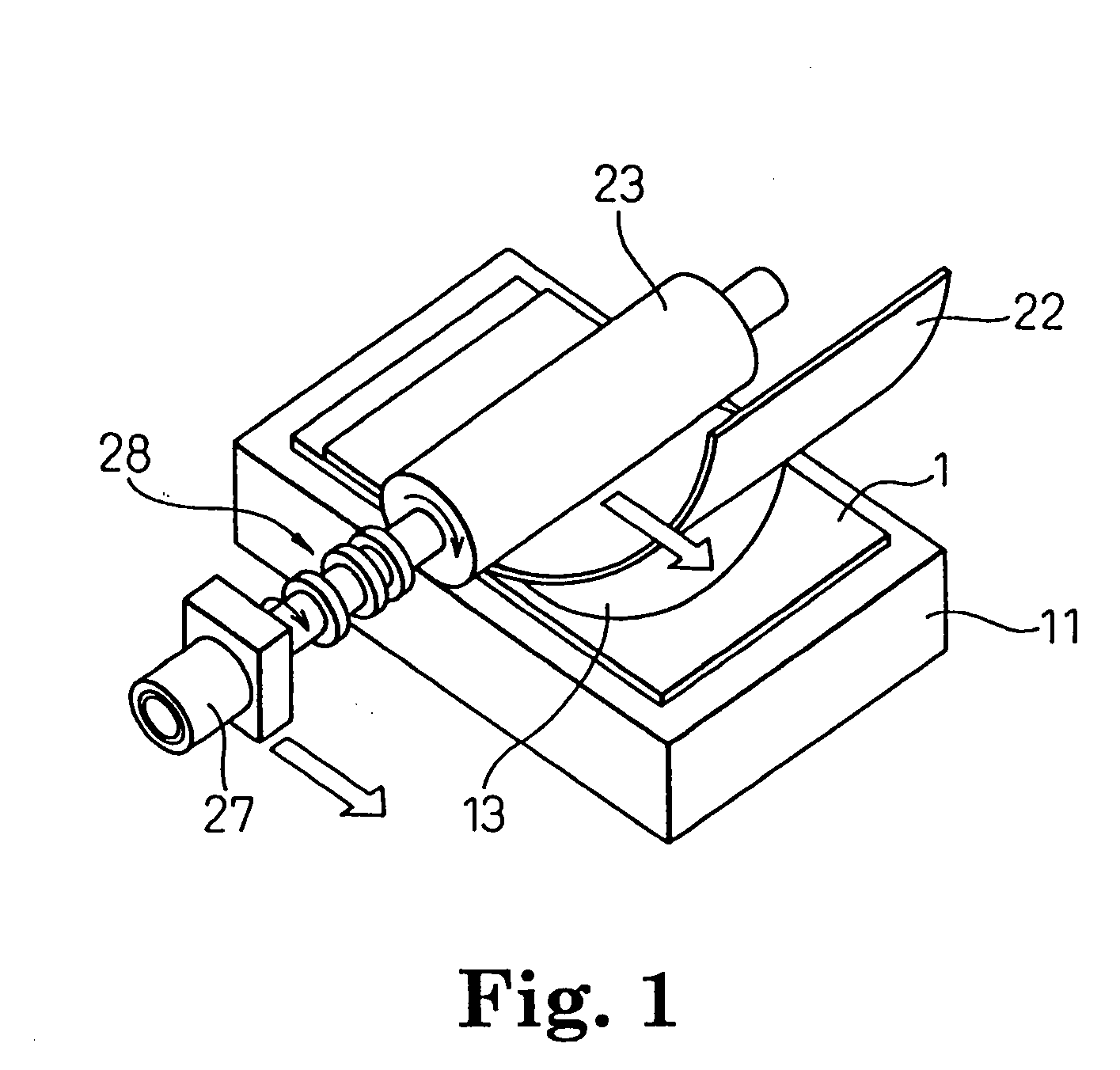

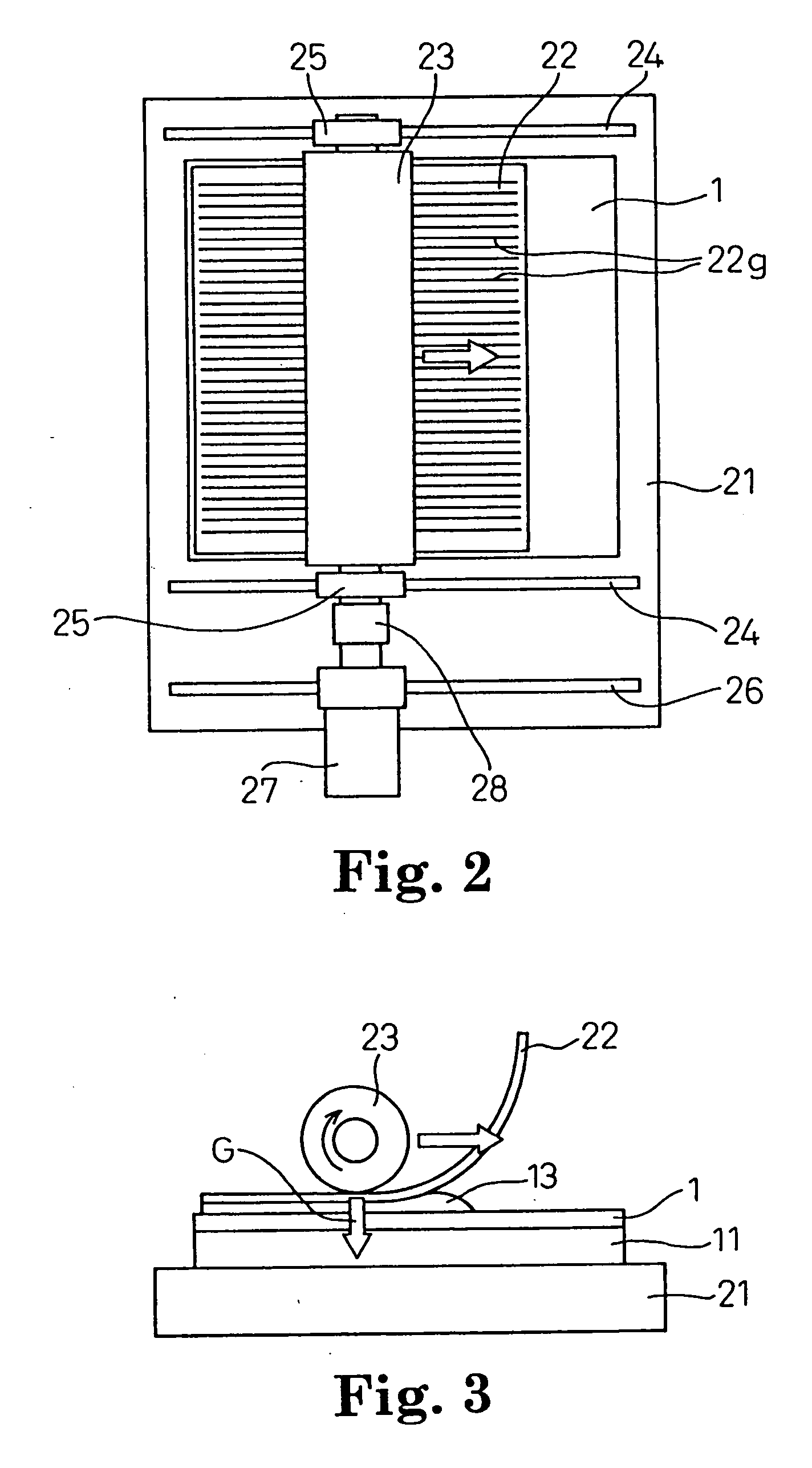

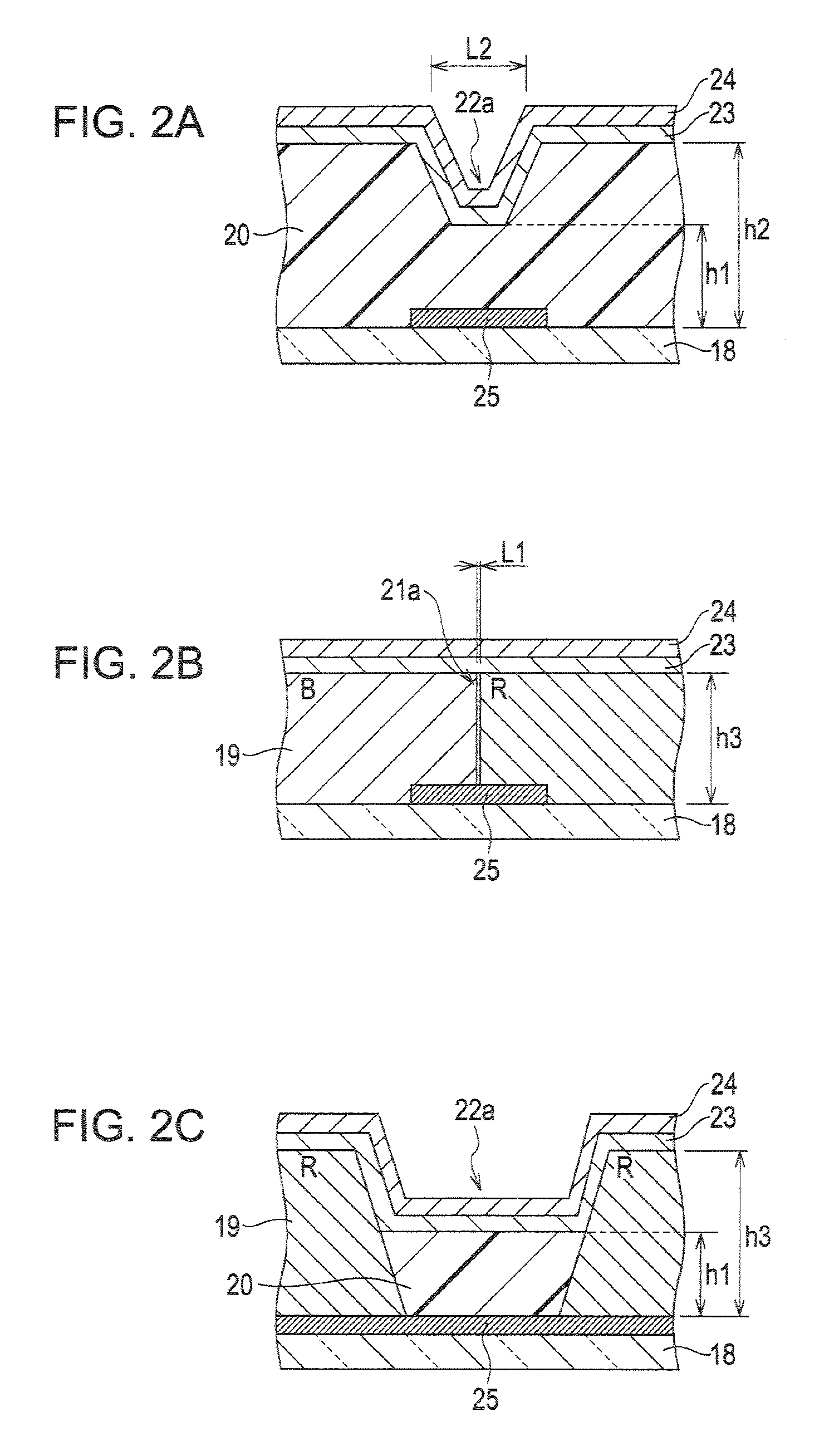

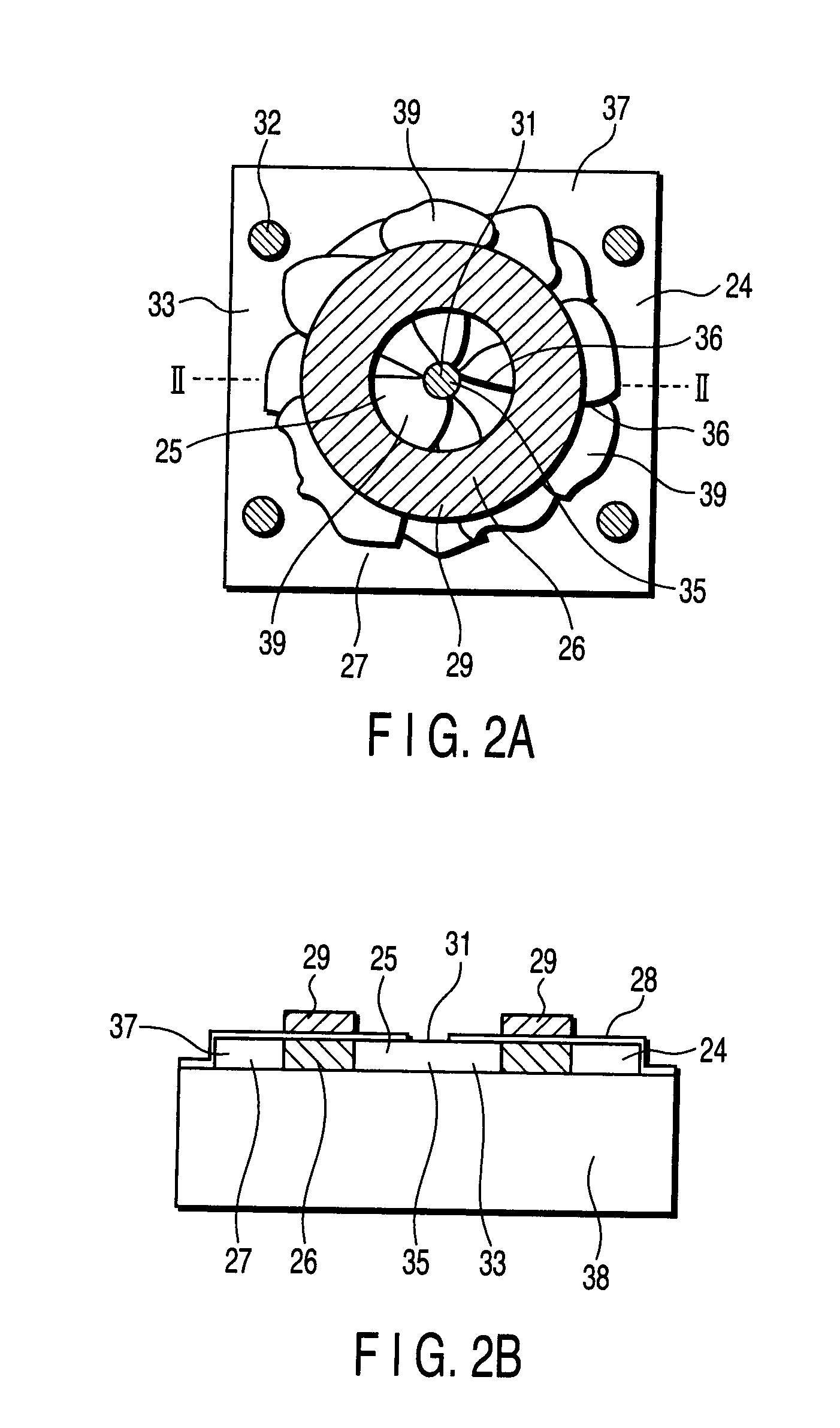

Apparatus, mold and method for producing substrate for plasma display panel

InactiveUS20040166760A1Reduce non-uniformityArtificial flowers and garlandsConfectioneryDielectric layerPlasma display

An apparatus is provided for producing a substrate for PDP, which can easily reduce ununiformity of a dielectric layer and defects of ribs. The apparatus is so constituted that it comprises: a table for the plate, a rib precursor supplying portion for providing a precursor of the ribs on the plate, a pliable mold having at least groove portions provided in parallel with each other at a fixed distance, which is disposed on the precursor of the ribs provided on the plate, a mold pressing portion for applying a pressure to the mold, thereby to contact the mold closely with the plate via the precursor of the ribs, and a driving portion for moving the mold pressing portion along the groove portions of the mold.

Owner:3M INNOVATIVE PROPERTIES CO

Laser annealing method and semiconductor device fabricating method

InactiveUS20070254392A1Low running costReduce non-uniformitySolid-state devicesSemiconductor/solid-state device manufacturingDevice materialHarmonic

When the second harmonic of a YAG laser is irradiated onto semiconductor films, concentric-circle patterns are observed on some of the semiconductor films. This phenomenon is due to the non-uniformity of the properties of the semiconductor films. If such semiconductor films are used to fabricate TFTs, the electrical characteristics of the TFTs will be adversely influenced. A concentric-circle pattern is formed by the interference between a reflected beam 1 reflected at a surface of a semiconductor film and a reflected beam 2 reflected at the back surface of a substrate. If the reflected beam 1 and the reflected beam 2 do not overlap each other, such interference does not occur. For this reason, a laser beam is obliquely irradiated onto the semiconductor film to solve the interference. The properties of a crystalline silicon film formed by this method are uniform, and TFTs which are fabricated by using such crystalline silicon film have good electrical characteristics.

Owner:SEMICON ENERGY LAB CO LTD

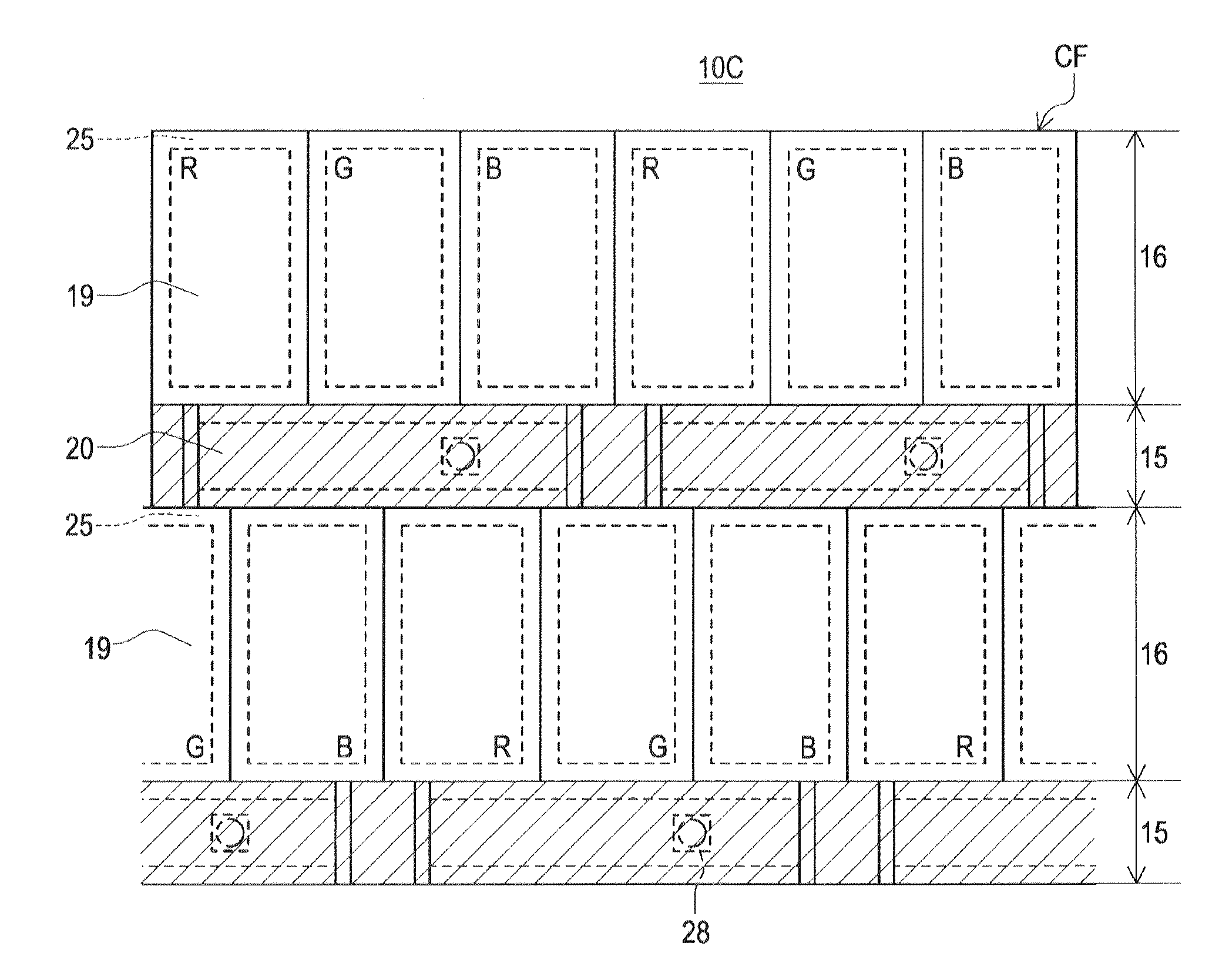

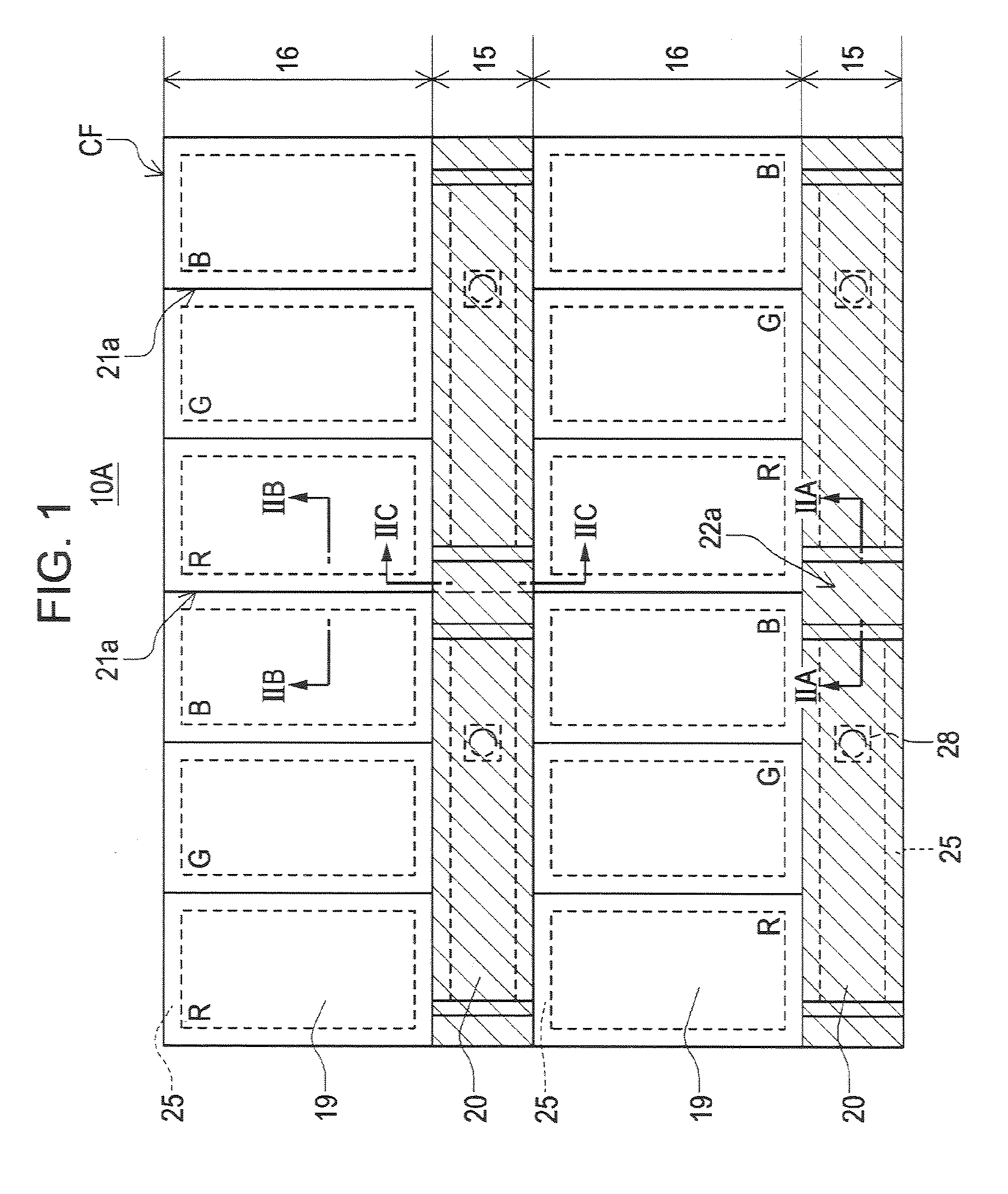

Liquid crystal display device

InactiveUS20090273746A1Easily perceiveSuppress disorderNon-linear opticsPhysicsLiquid-crystal display

A liquid crystal display device is provided which includes a substrate having a pixel electrode; and a color filter substrate having a color filter layer on a transparent substrate while having an alignment film formed on an uppermost layer thereof, the substrate and the color filter substrate each having a display region having a plurality of sub-pixels formed thereon, in which the color filter substrate has a liquid crystal layer thickness-adjustment layer formed of a transparent resin layer being partially formed on an inner side of the alignment film; and the liquid crystal layer thickness-adjustment layer has a trench being formed along and between adjacent ones of the sub-pixels, the bottom position of the trench of the liquid crystal layer thickness-adjustment layer being lower than a height of the color filter layer from a surface of the transparent substrate, and the transparent resin layer existing on the bottom of the trench.

Owner:JAPAN DISPLAY WEST

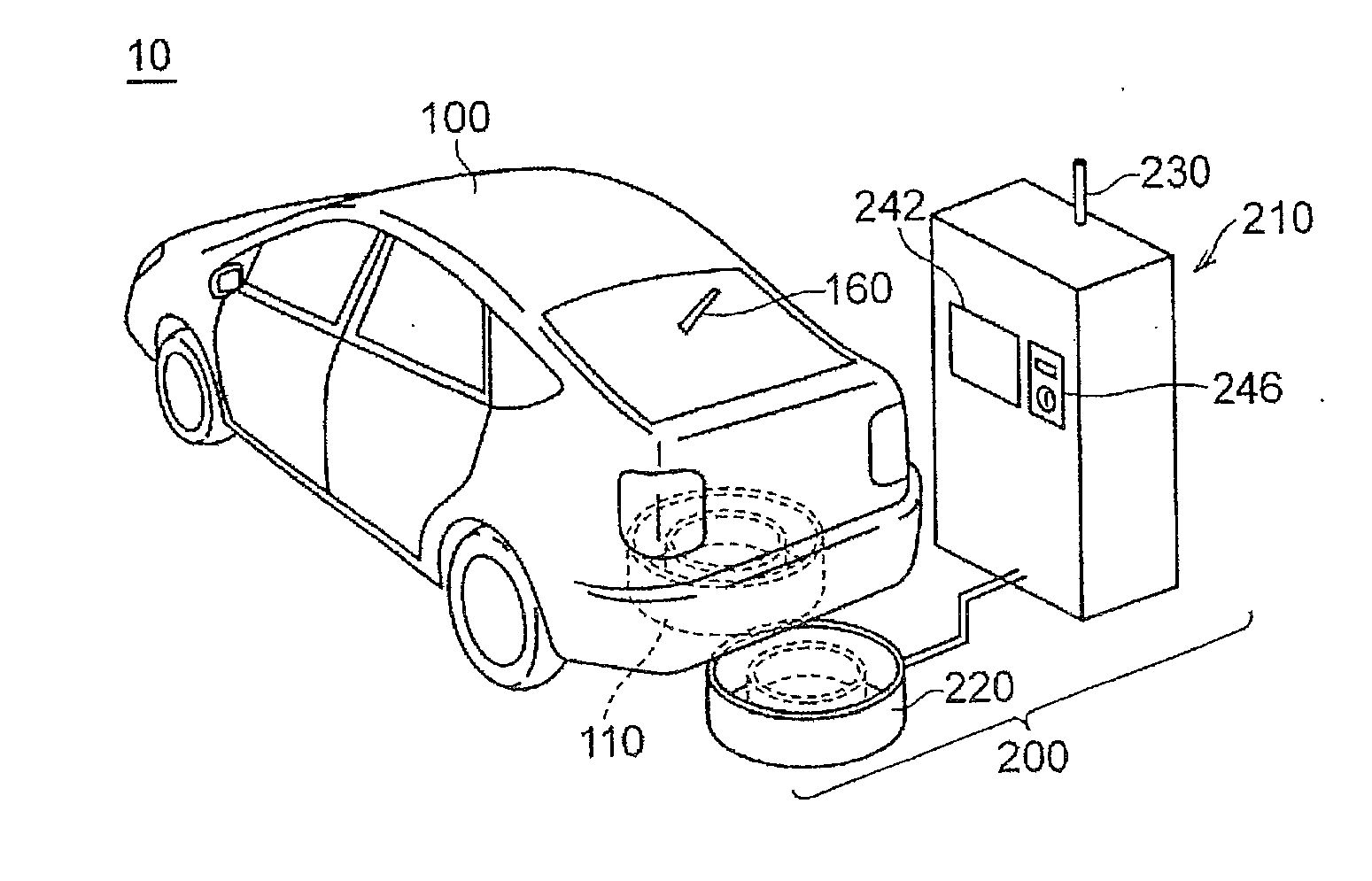

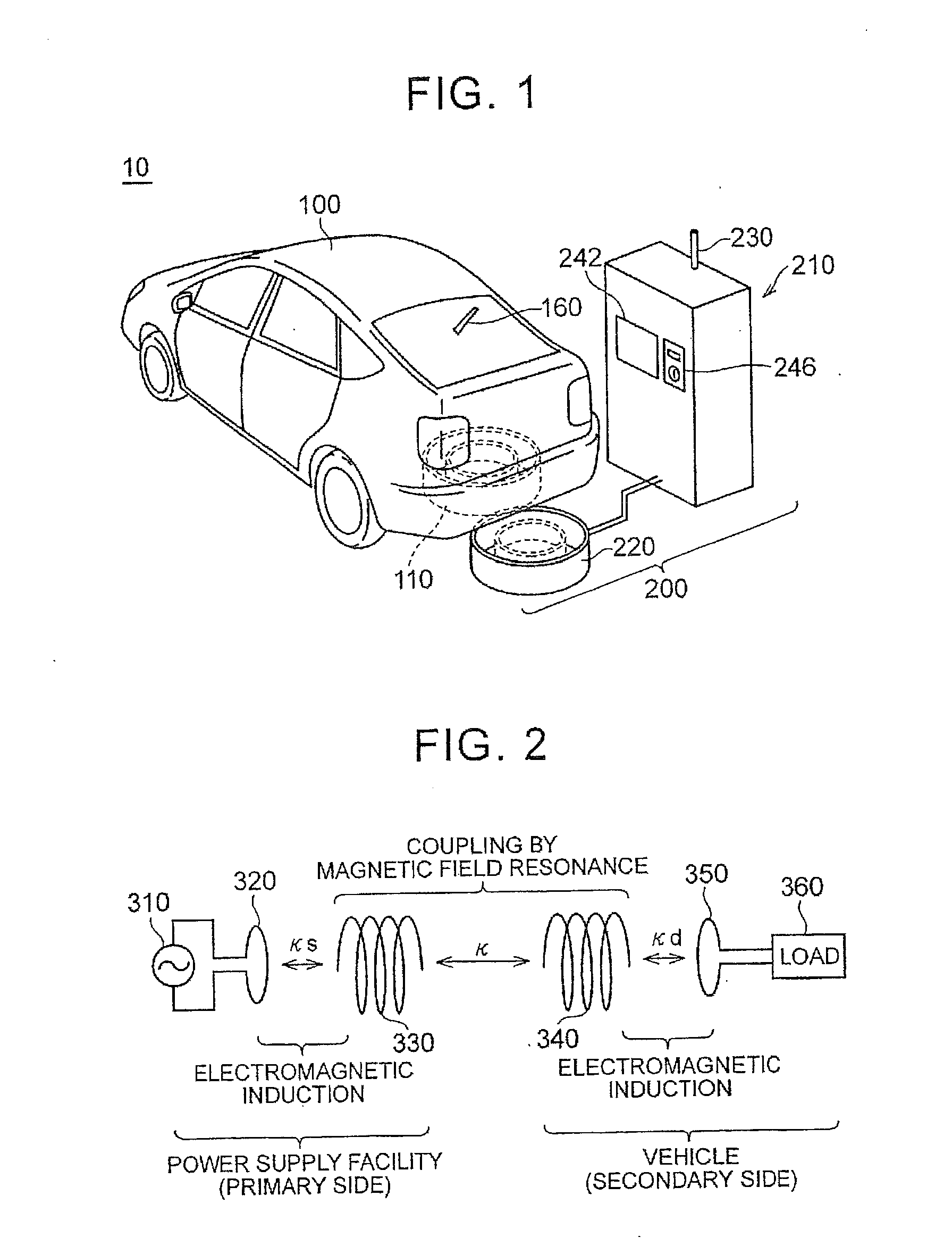

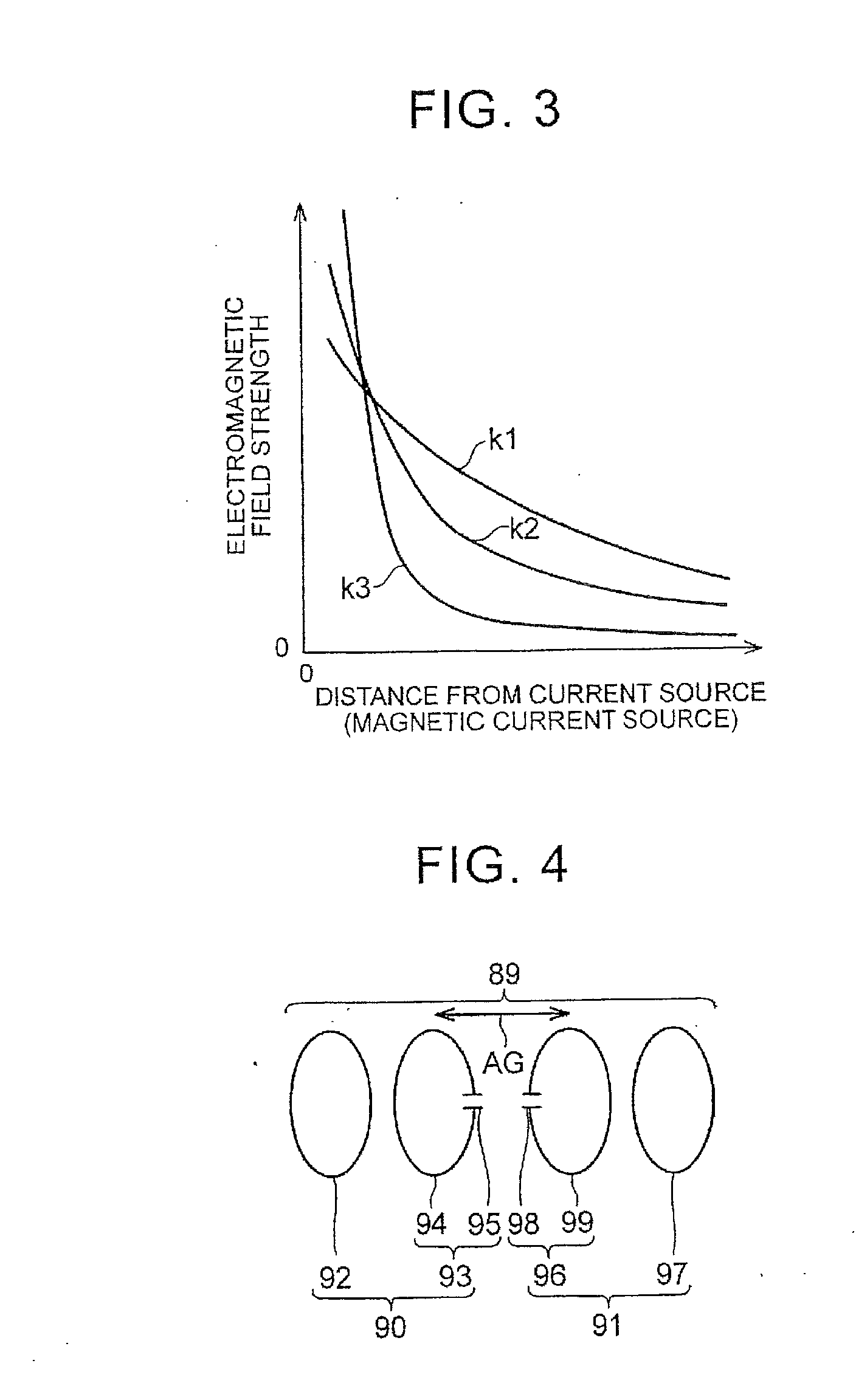

Power supply device and power supply method

ActiveUS20140300316A1Facilitating understanding of userReduce non-uniformityBatteries circuit arrangementsCharging stationsElectric power transmissionEngineering

A power supply device which performs power supply from an outside to a vehicle includes: a power source section for performing the power supply to the vehicle; and a control device that performs control of the power source section. The control device obtains information about power reception efficiency of the vehicle as an object of the power supply and determines a power reception efficiency range and a fee that correspond to the obtained information from a plurality of power reception efficiency ranges and plurality of fees that are set corresponding to the plurality of power reception efficiency ranges. The power supply device preferably further includes a power transmission section for receiving the power from the power source section and contactlessly performing power transmission to the vehicle.

Owner:TOYOTA JIDOSHA KK

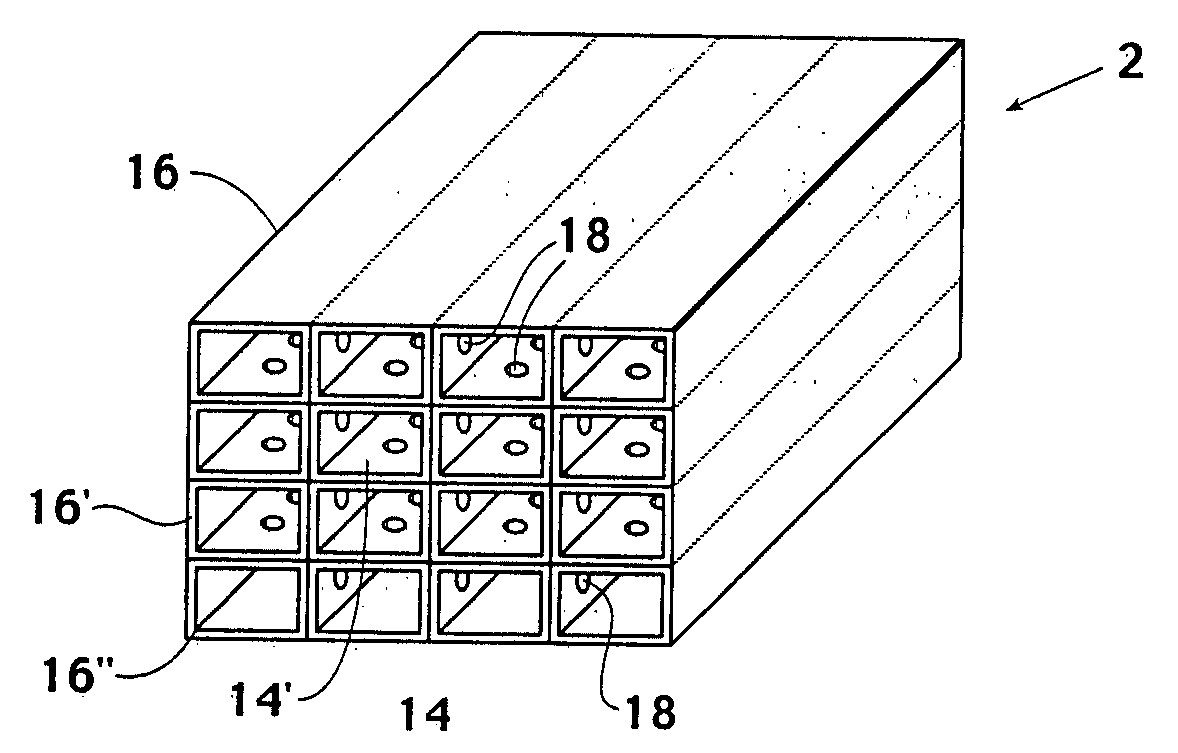

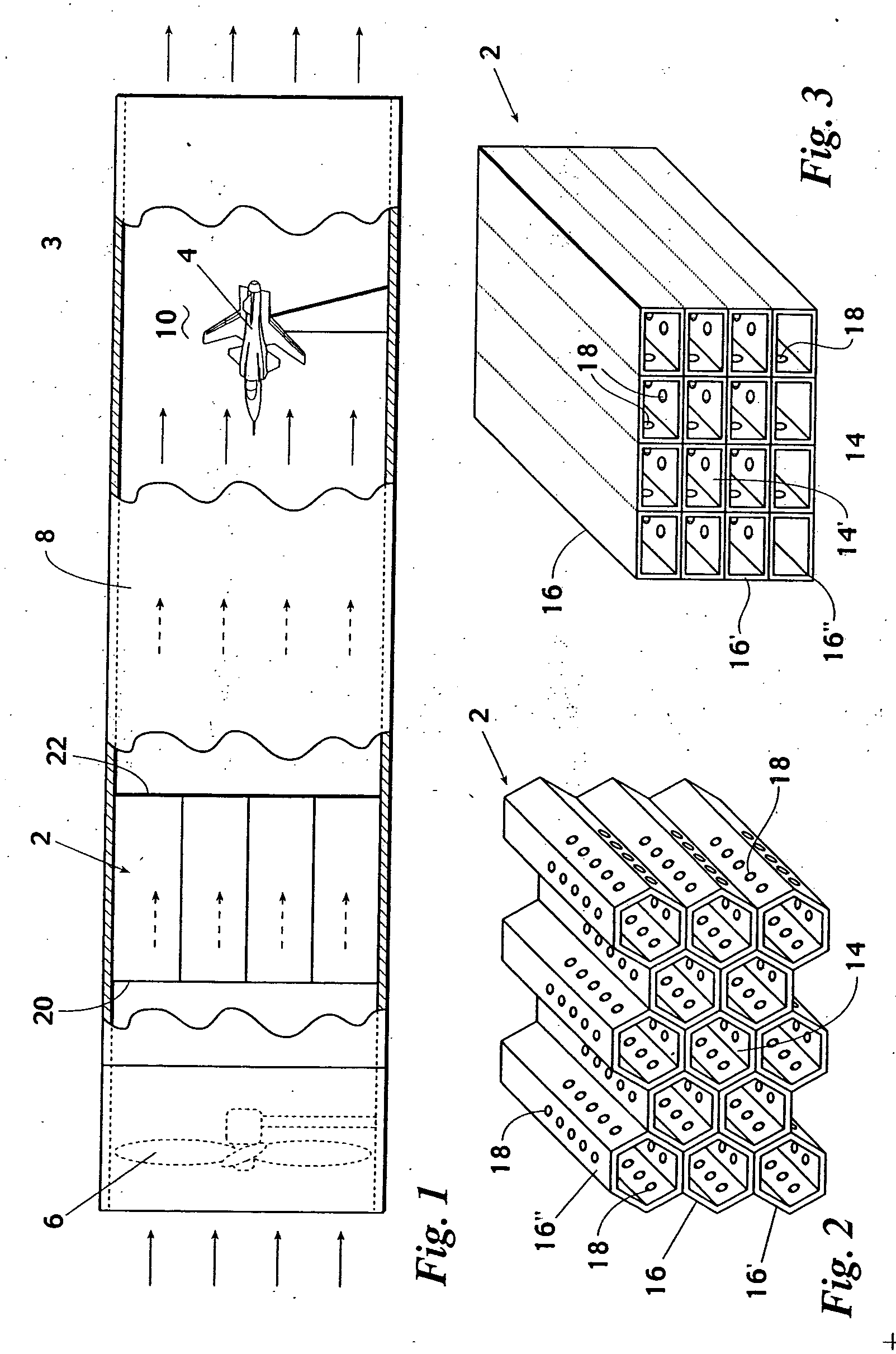

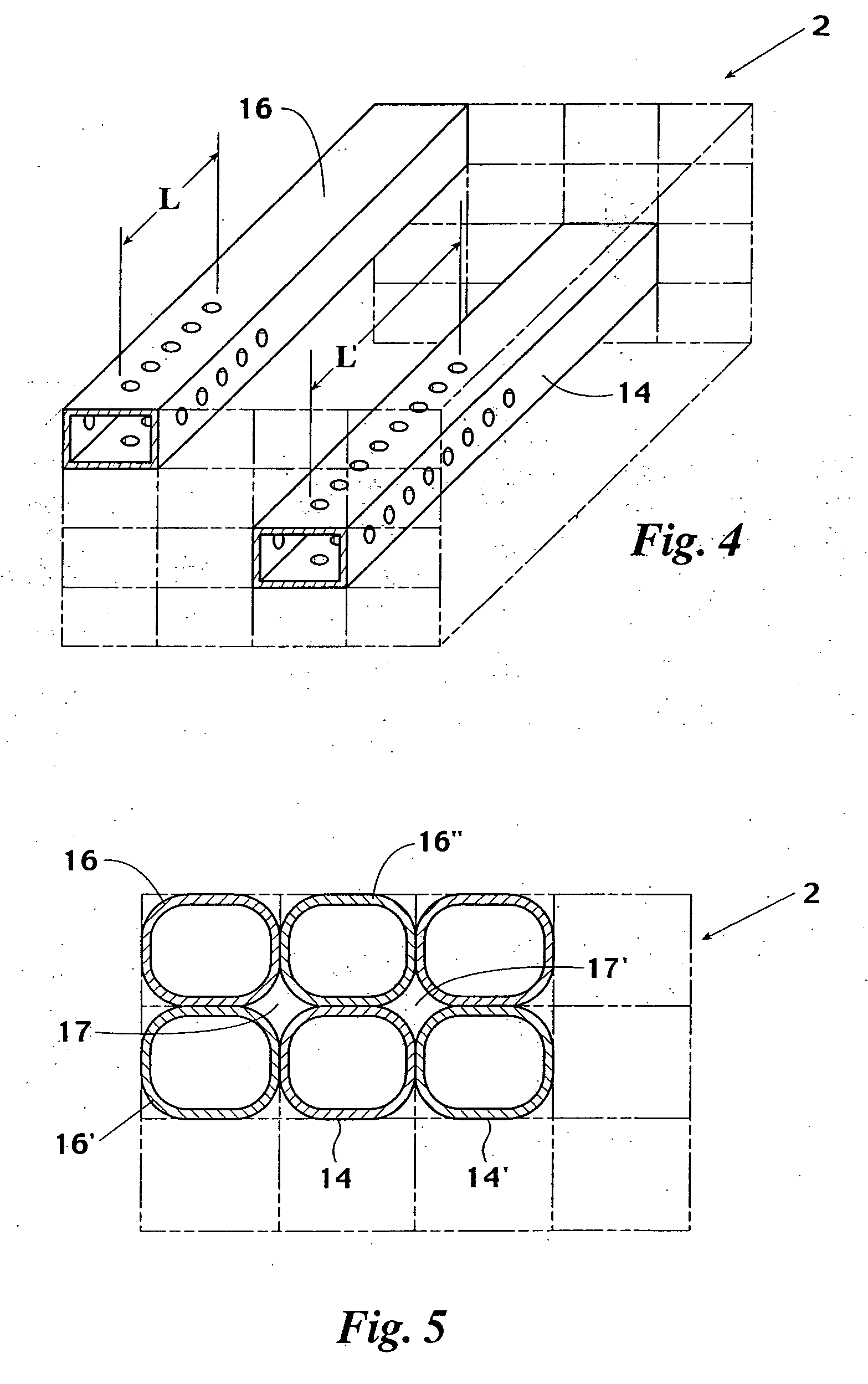

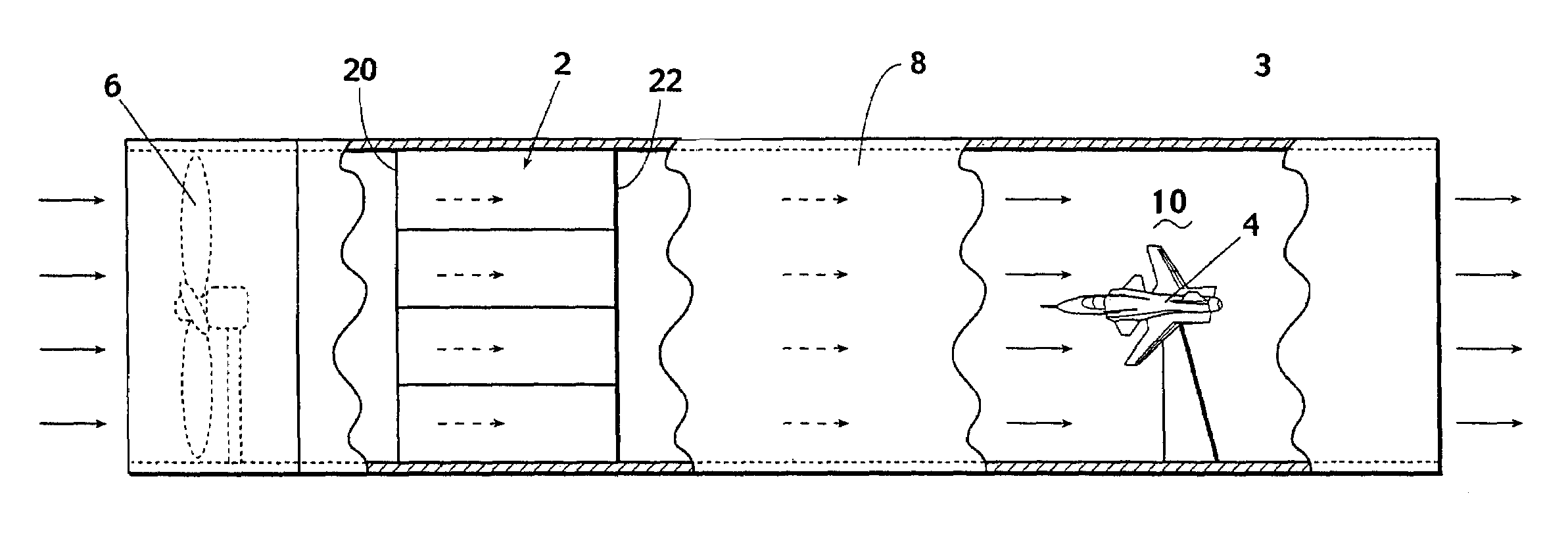

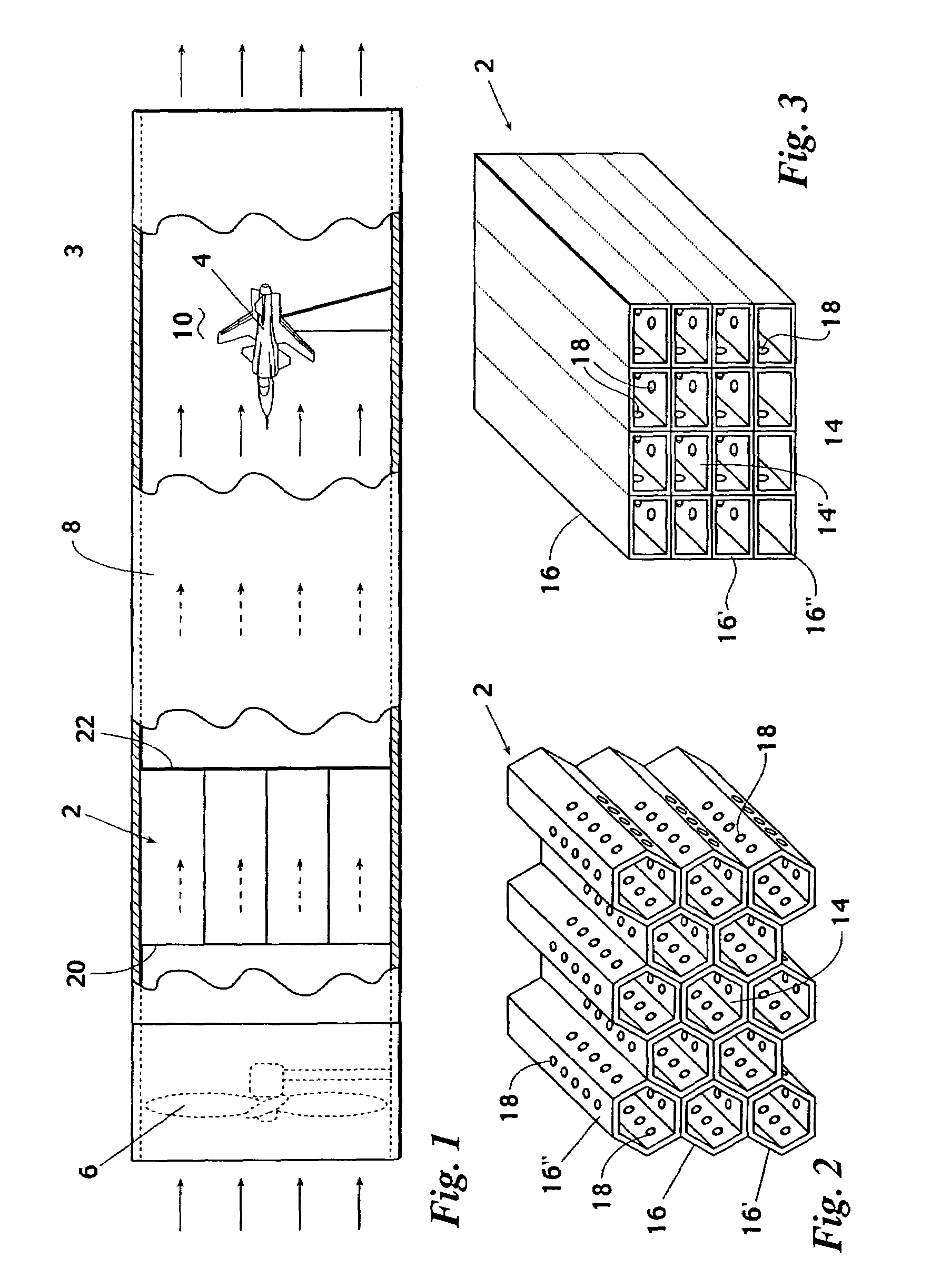

Structure and method for improving flow uniformity and reducing turbulence

InactiveUS20070137717A1Reducing lateral turbulenceReduce trafficAerodynamic testingFluid dynamicsEngineeringGuide tube

A structure for reducing turbulence and increasing flow uniformity in a flowing fluid in a wind tunnel, or a fluid channel, has a plurality of conduits or channels arranged into a conduit bundle. The conduit bundle has a number of parallel conduits with plurality of perforations on the inner side walls of the conduit. As the fluid flows through the conduit bundle the sides of the conduits reduce lateral turbulence while the perforations minimize pressure gradients in the flowing fluid in adjacent conduits, resulting in isotropic turbulence. The invention is particularly useful in testing aircraft, improving engine performance, and fluid mechanics applications.

Owner:VAKILI AHMAD D

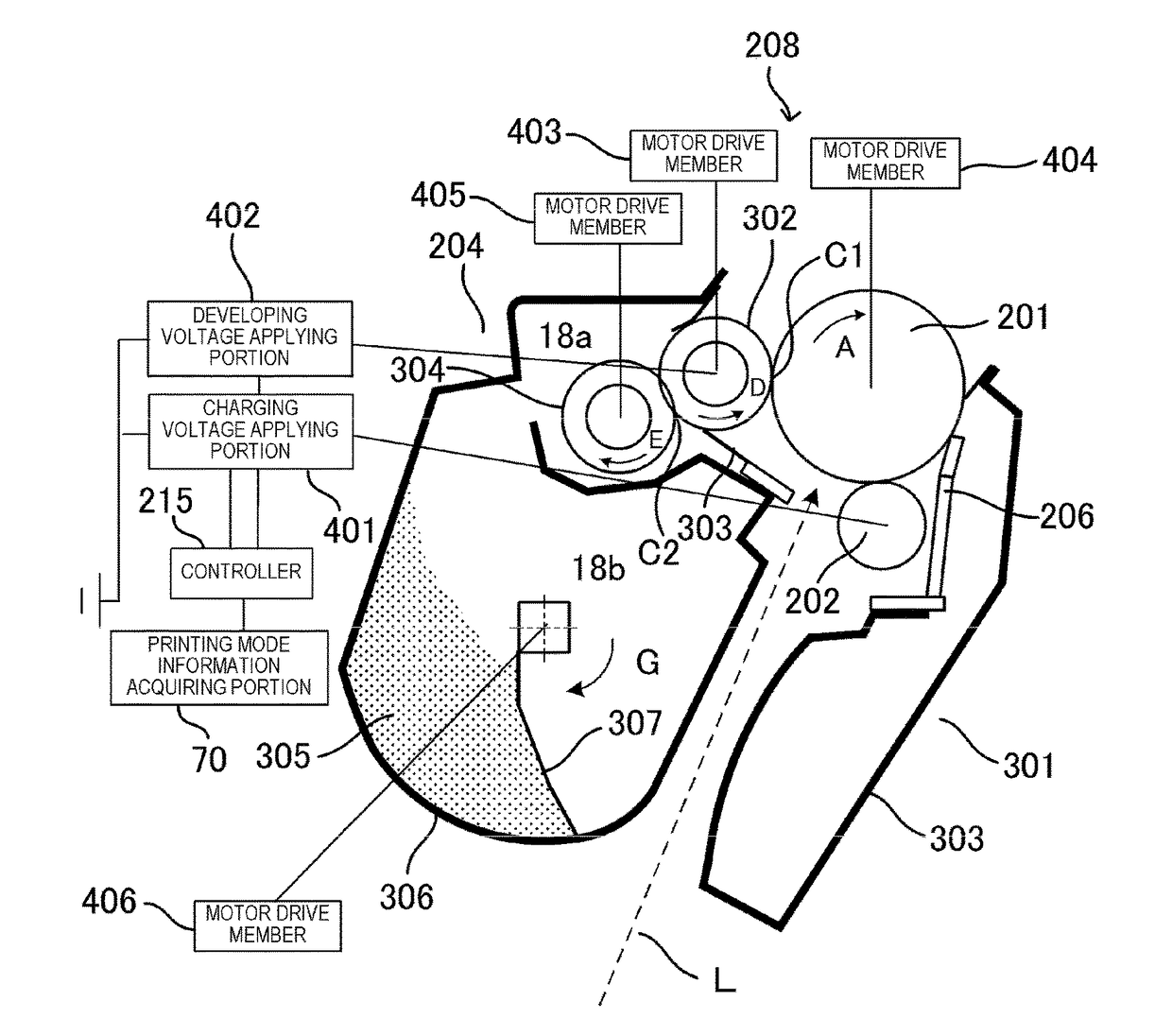

Image forming apparatus

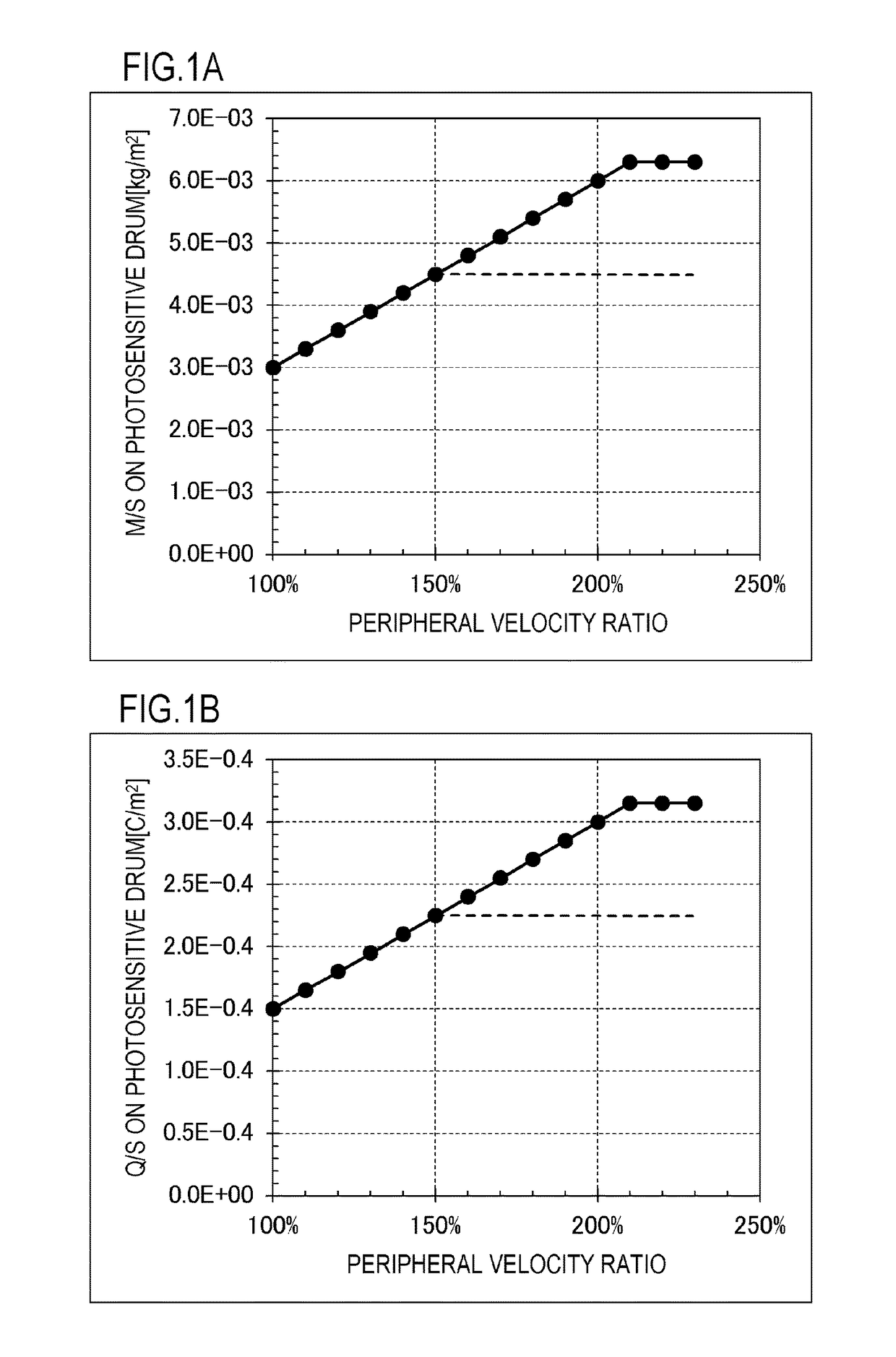

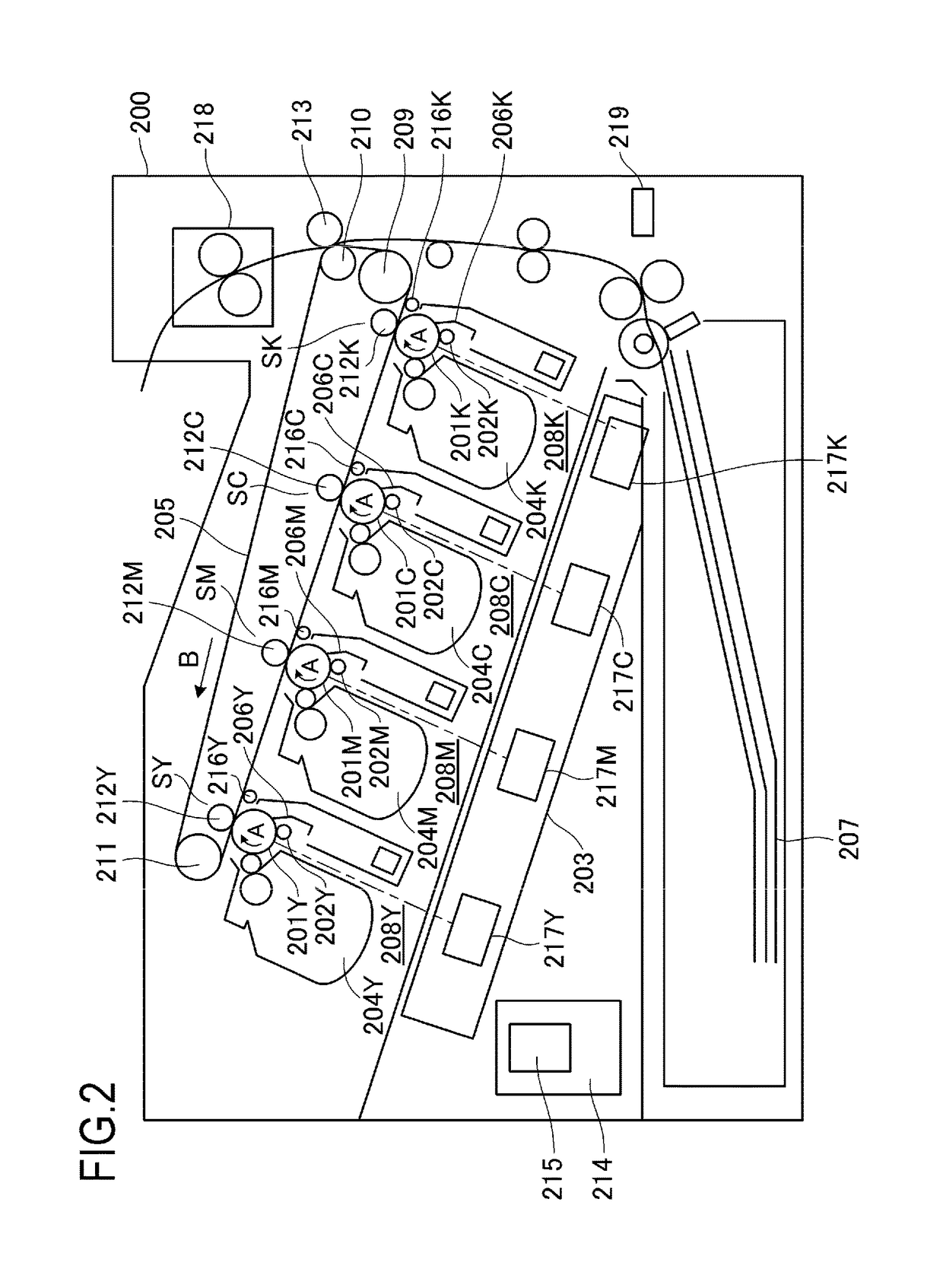

ActiveUS20170277068A1Tinge selection range be increasedSupply amount is increasedElectrographic process apparatusCapacitanceImage formation

When, in a state where a developer borne by a developer bearing member is sandwiched by an opposing portion of an image bearing member and the developer bearing member, C denotes capacitance between the image bearing member and the developer bearing member, ΔV denotes a development contrast, Q / S denotes a charge amount per unit area of the developer borne by the developer bearing member, and Δv denotes a peripheral velocity ratio which is a ratio of a peripheral velocity of the developer bearing member to a peripheral velocity of the image bearing member, a first peripheral velocity ratio is set so that |Q / S×Δv|≦|C×ΔV| is satisfied, and a second peripheral velocity ratio which is larger than the first peripheral velocity ratio is set so that |Q / S×Δv|>|C×ΔV| is satisfied.

Owner:CANON KK

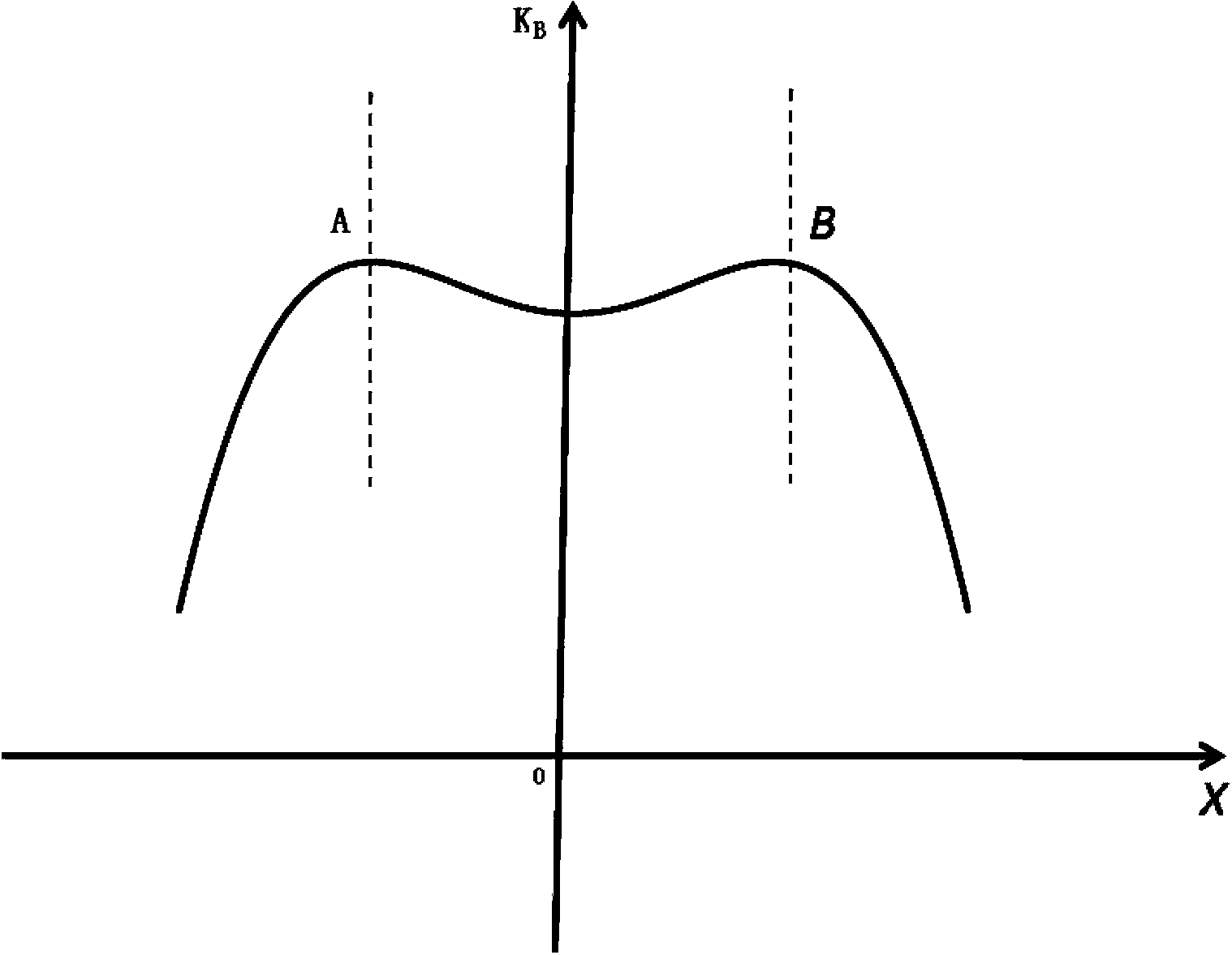

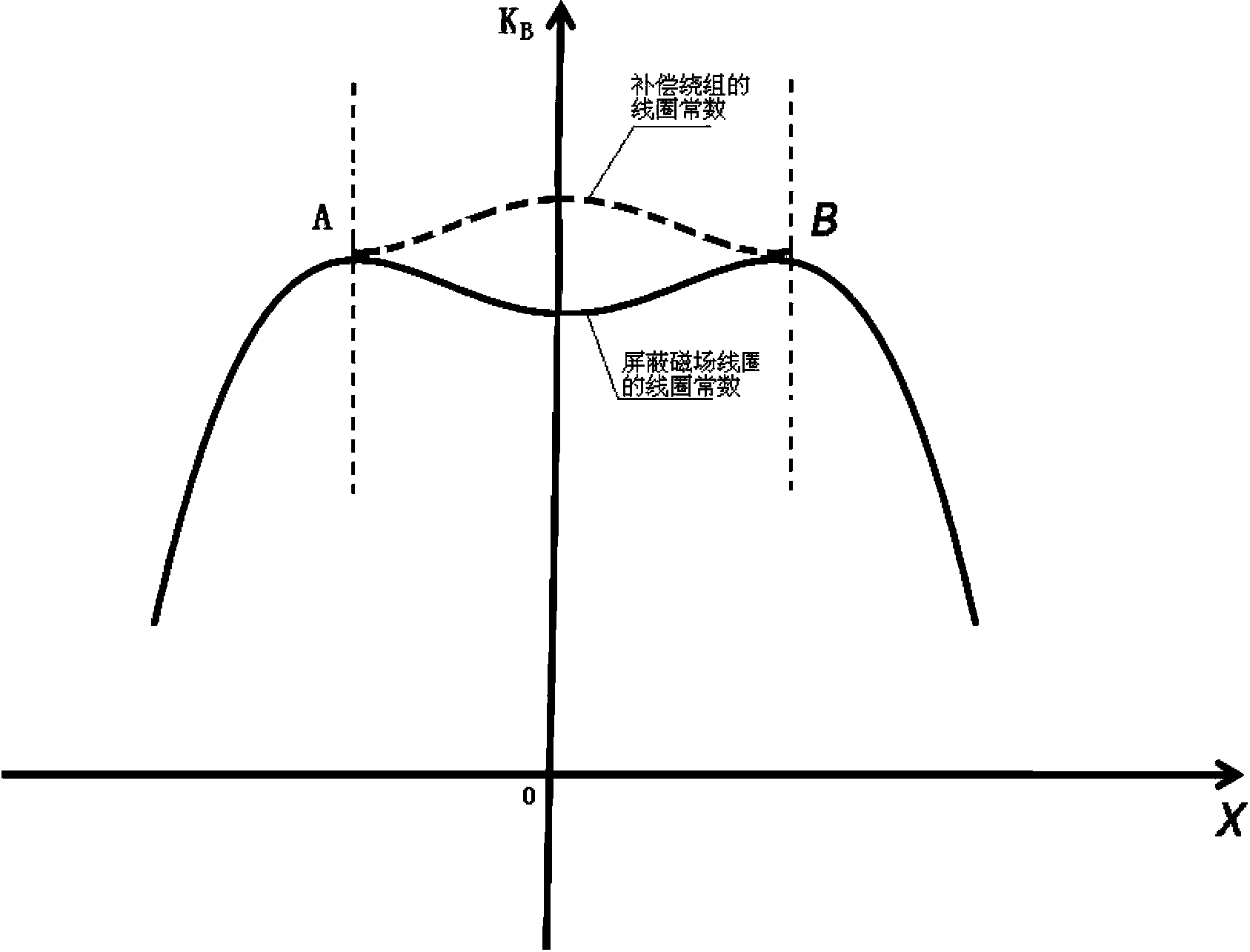

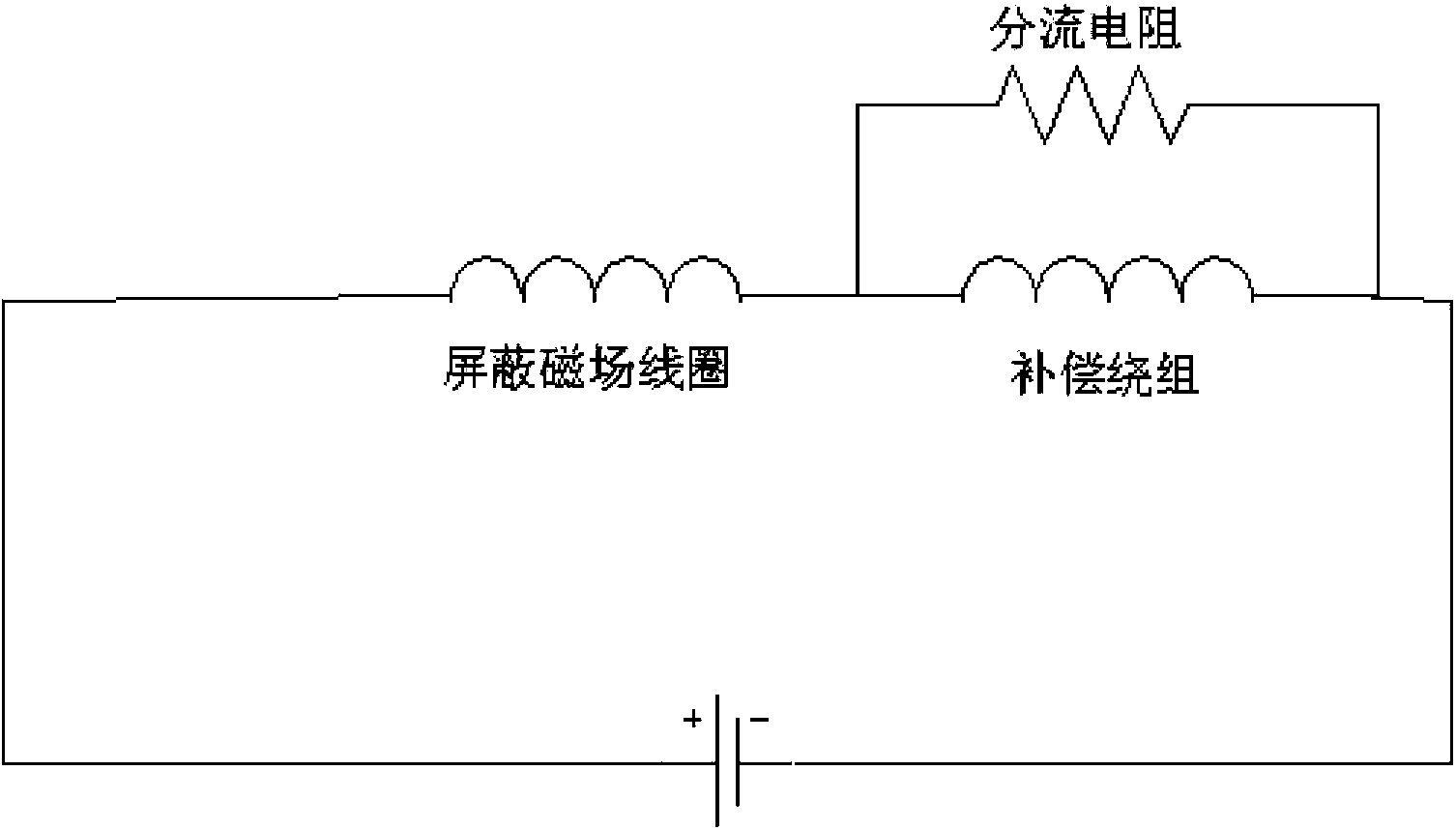

Method for compensating heterogeneity of shield magnetic field coil through winding

InactiveCN103454461AReduce non-uniformityMeeting Calibration Testing NeedsInstrument screening arrangementsMagnetic shieldConductor Coil

The invention provides a method for compensating heterogeneity of a shield magnetic field coil through a winding. The shield magnetic field coil is wound by the compensating winding with the particular specification, and distribution of magnetic lines of force of an original magnetic field coil is changed through the compensating winding, so that the heterogeneity of the shield magnetic field coil is increased in a magnitude mode. The magnetic field generated by the compensating winding has equal magnetic force and the opposite direction with the heterogeneous field additionally produced because a magnetic shield layer changes distribution of the magnetic lines of force in the magnetic field coil, and therefore the purpose of compensating the heterogeneity of the shield magnetic field is achieved.

Owner:710TH RES INST OF CHINA SHIPBUILDING IND CORP

Electrophotographic apparatus

InactiveUS20110123215A1Uniform wearReduce the differenceElectrographic process apparatusRotational axisSurface layer

An electrophotographic apparatus which has an electrophotographic photosensitive member having a surface layer constituted of an amorphous silicon carbide, wherein the ratio of the atom density (C) of carbon atoms to the sum of the atom density (Si) of silicon atoms and the atom density (C) of carbon atoms, C / (Si+C), in the surface layer is set larger from one end portion toward the other end portion of the electrophotographic photosensitive member in the direction of rotational axis thereof, and is from 0.61 or more to 0.75 or less in the whole region of the electrophotographic photosensitive member in the direction of rotational axis thereof and the electrophotographic apparatus has an air current generation means which draws out air from the side of the above one end portion toward the side of the above other end portion.

Owner:CANON KK

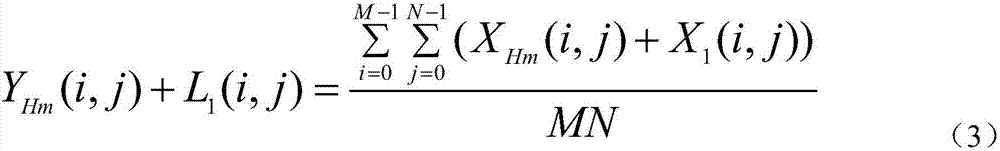

Infrared image preprocessing correction method

ActiveCN107341780AAccurate pre-processing correction effectReduce non-uniformityImage enhancementImage analysisCamera lensMarket potential

The invention discloses an infrared image preprocessing correction method. The method is characterized by comprising the following steps of: 1, acquiring infrared image overall data X of a target by adoption of an infrared detector with a camera lens; and 2, acquiring high-temperature infrared image overall data XH1 of a black target at high temperature and low-temperature infrared image overall data XL1 of the black target at low temperature by adoption of the infrared detector with the camera lens, and calculating correction parameters al and b1 between the high-temperature infrared image overall data XH1 and the low-temperature infrared image overall data XL1. According to the method, the infrared detector with the camera lens and an infrared detector without the camera lens are imported to acquire data and carry out two-point correction processing, so that the image heterogeneity caused by catch noises of the infrared detectors is reduced and then the infrared image preprocessing correction effect is more accurate. Meanwhile, the method is simple in operation, high in processing efficiency and good in instantaneity, has good market potential and is capable of carrying out preprocessing heterogeneous correction on various infrared scenes.

Owner:成都中昊英孚科技有限公司

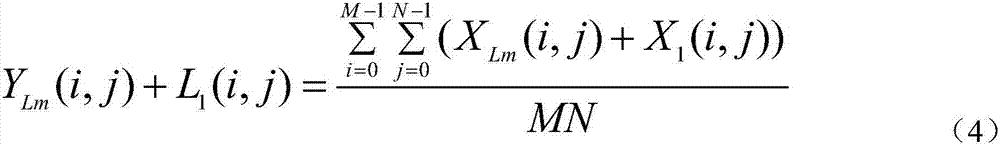

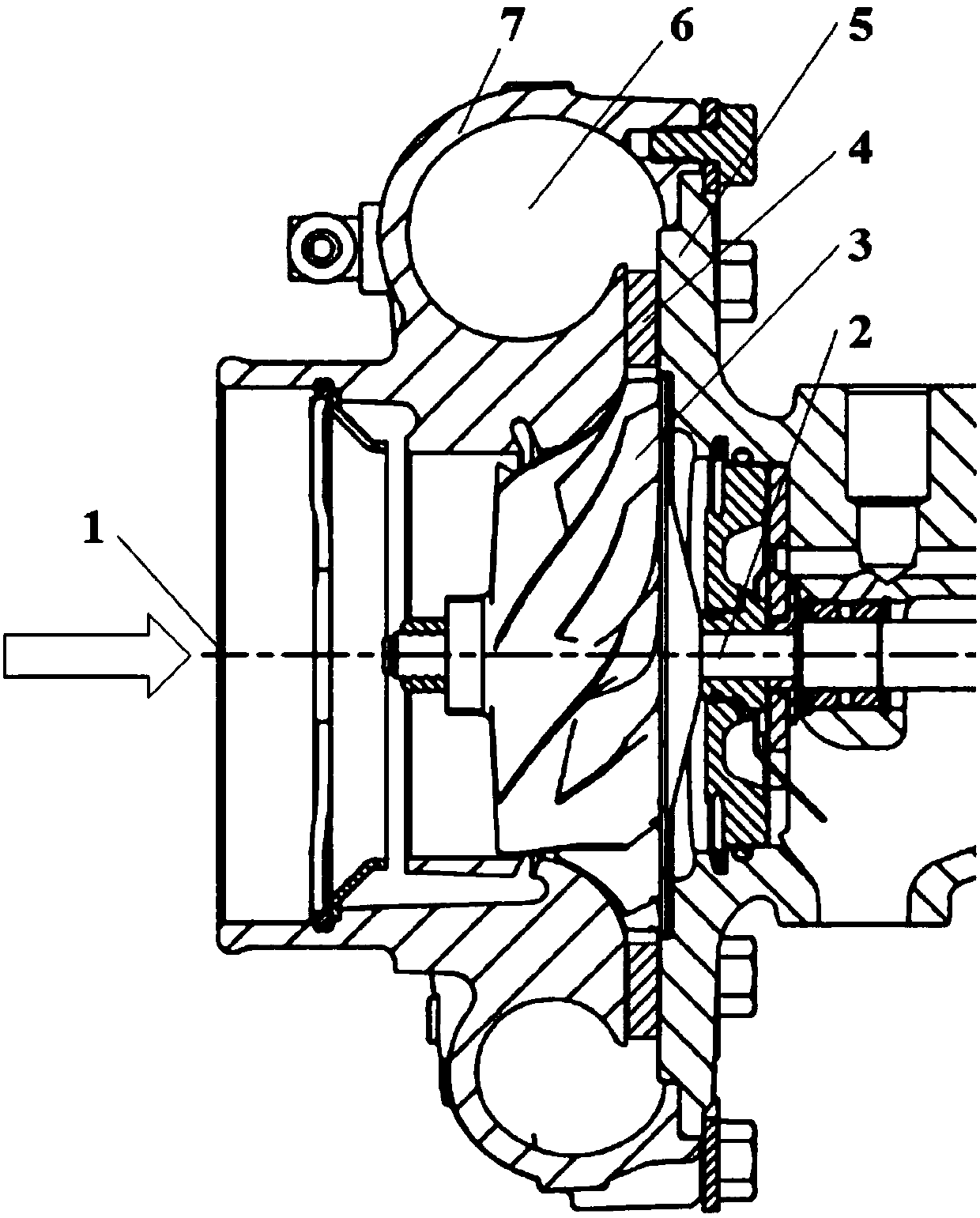

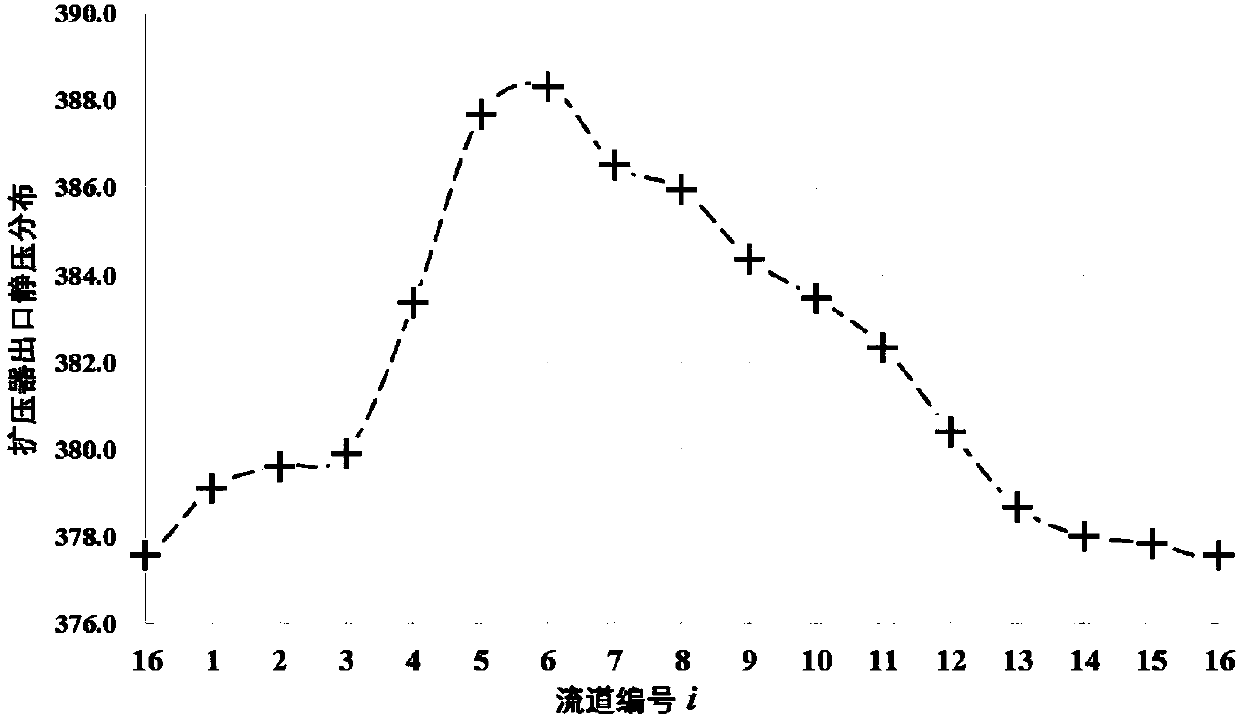

Centrifugal compressor using asymmetrical bladed diffuser with variable blade consistencies in circumferential direction

ActiveCN107061368AImprove flow field structureImprove performancePump componentsPumpsEngineeringFront edge

The invention relates to a centrifugal compressor using an asymmetrical bladed diffuser with variable blade consistencies in the circumferential direction, and belongs to the technical field of turbomachinery. The centrifugal compressor comprises a volute, a centrifugal impeller and the bladed diffuser. The inlet front edge positions and the bladed mounting angles are evenly distributed in the circumferential direction, the blade consistencies are asymmetrically distributed in the circumferential direction, and the consistencies are unequal in different circumferential positions. The blade consistencies are changed by changing the central angles (namely the front edge interval between every two adjacent blades) corresponding to flow channels. The compressor can effectively adapt to the downstream circumferential pressure distortion of the bladed diffuser, the nonuniformity of a flow field in the bladed diffuser is reduced, the flowing stability of the centrifugal compressor is effectively improved, and the stable working range of the centrifugal compressor is enlarged.

Owner:TSINGHUA UNIV +1

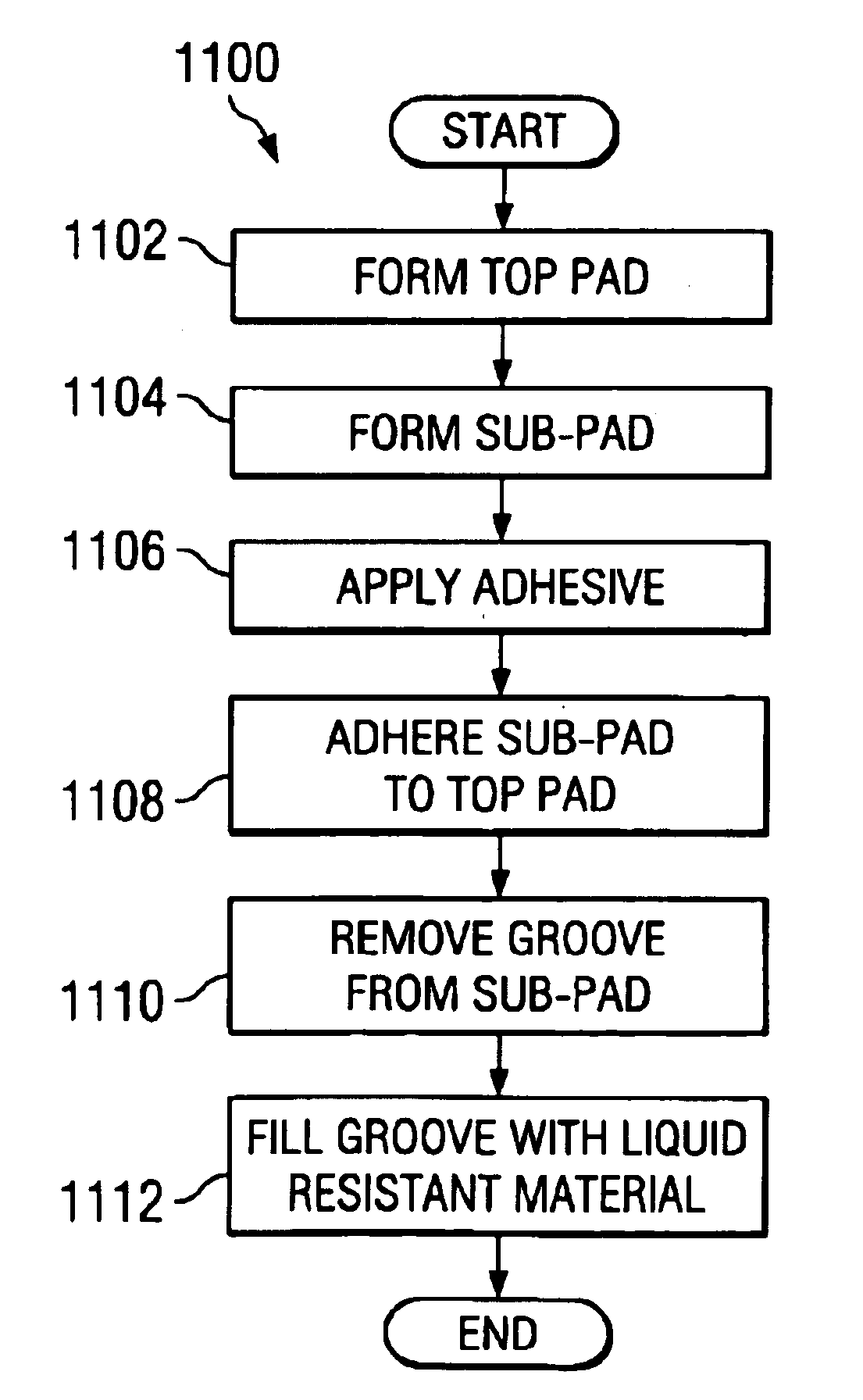

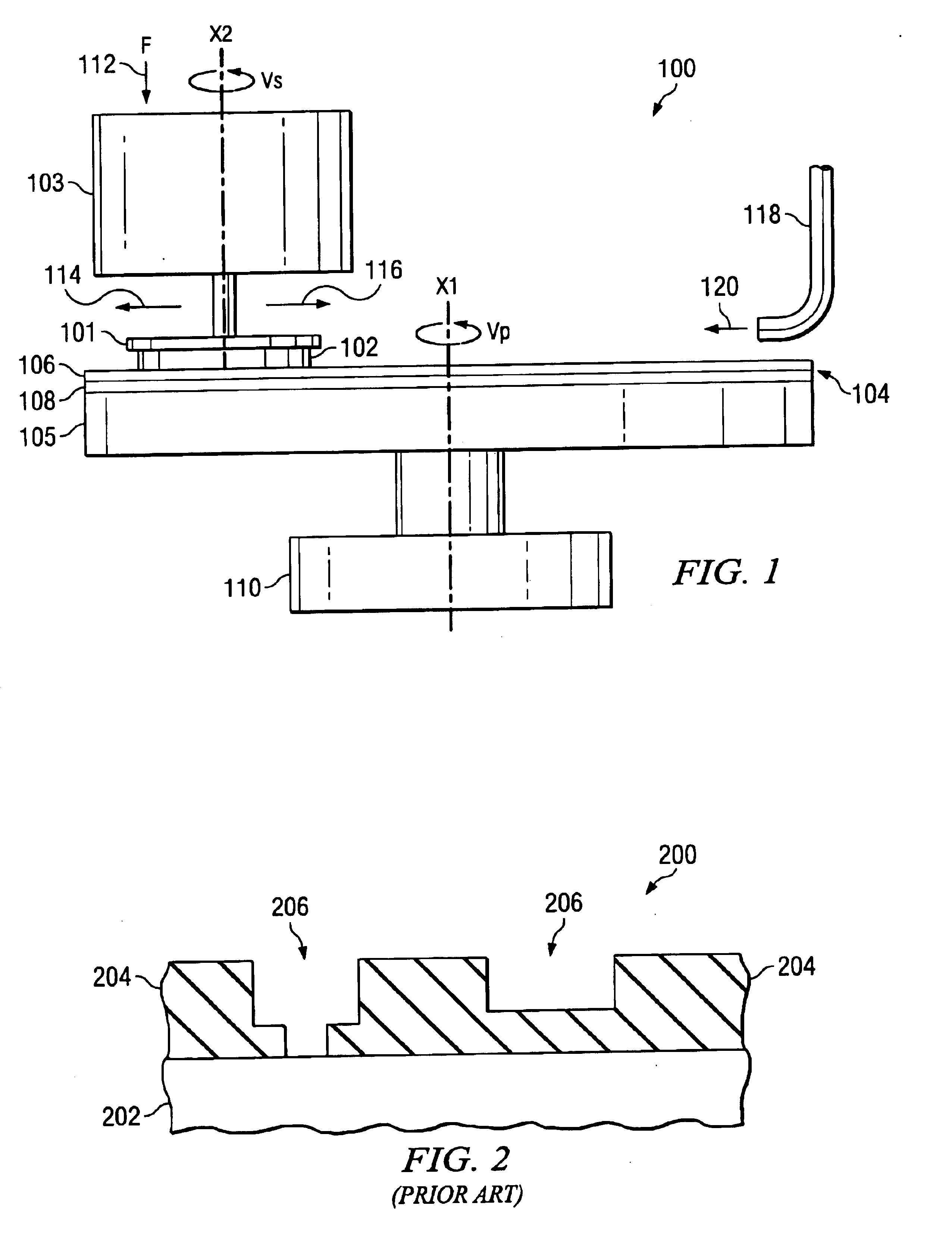

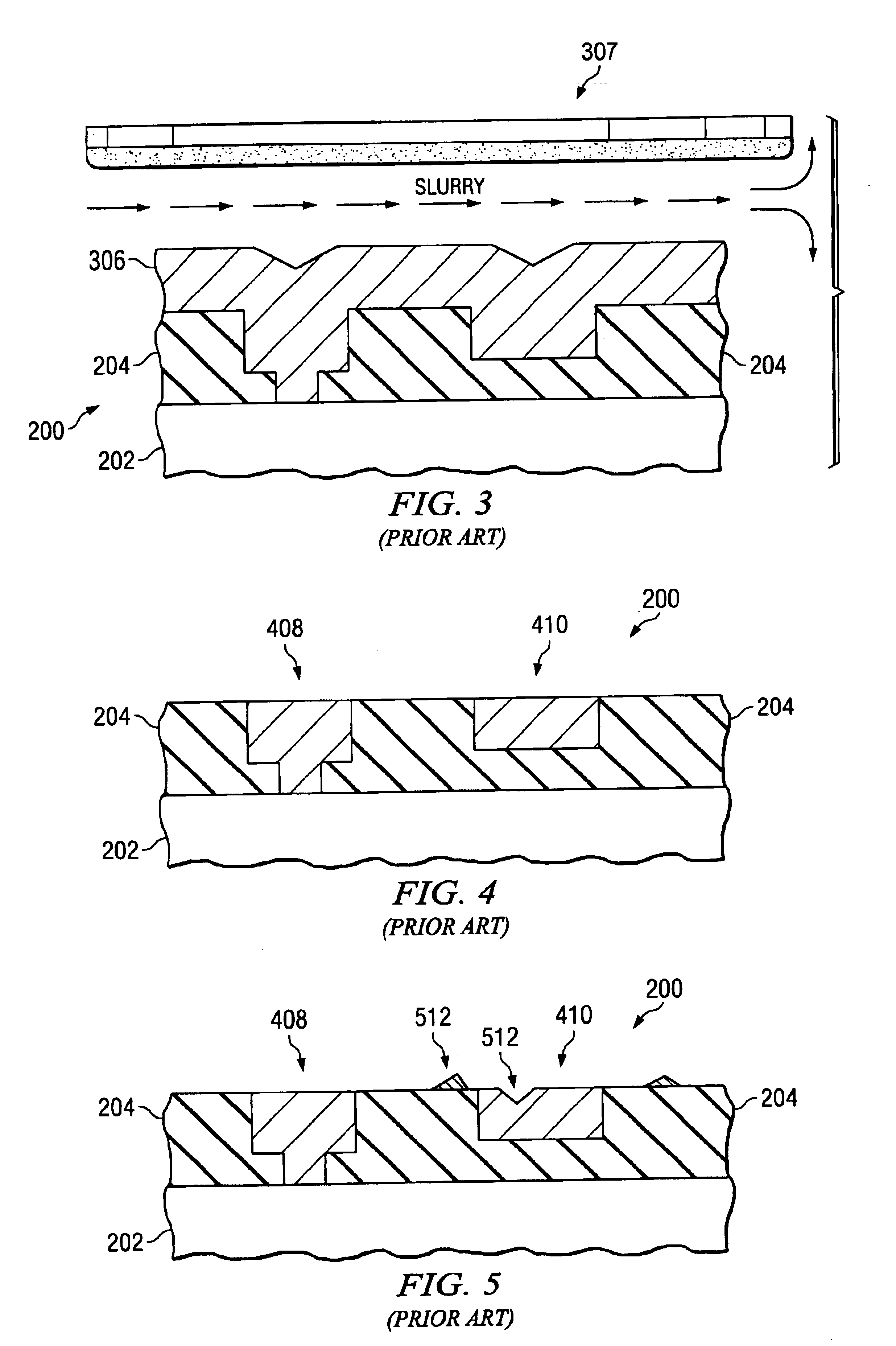

Edge-sealed pad for CMP process

InactiveUS6913527B2Improve stabilityExtended use timeEdge grinding machinesPolishing machinesCompressibilityBiomedical engineering

The present invention discloses a polishing pad that can facilitate process stability, extend length of use, and mitigate process non-uniformity and process induced defects for chemical mechanical planarization processes. The polishing pad of the present invention is a composite of a top pad and a sealed sub-pad. The sealed sub-pad has a sealing mechanism that mitigates liquid penetration into the sub-pad thereby maintaining a substantially uniform compressibility of the sub-pad and the polishing pad and extending a useable life of the polishing pad.

Owner:TEXAS INSTR INC

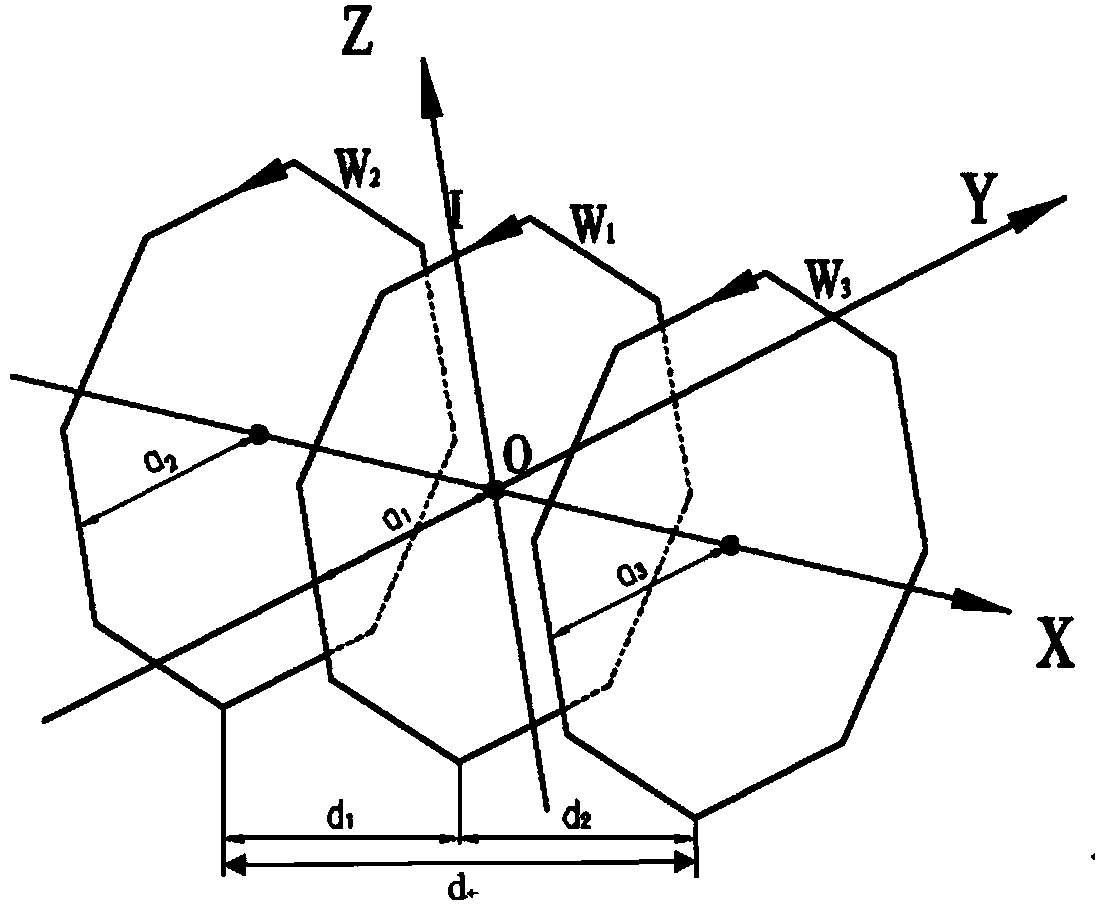

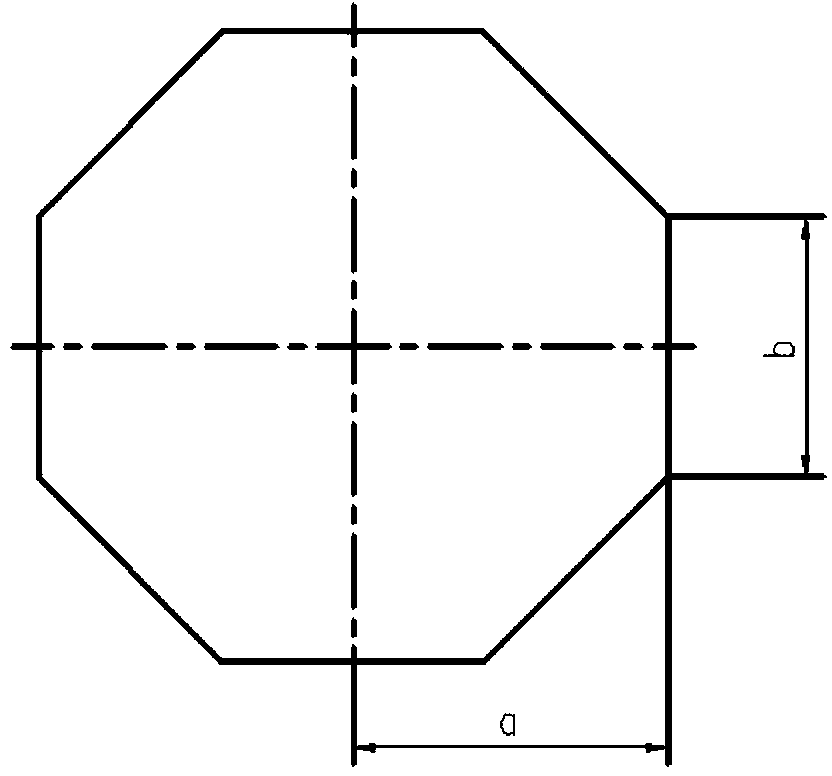

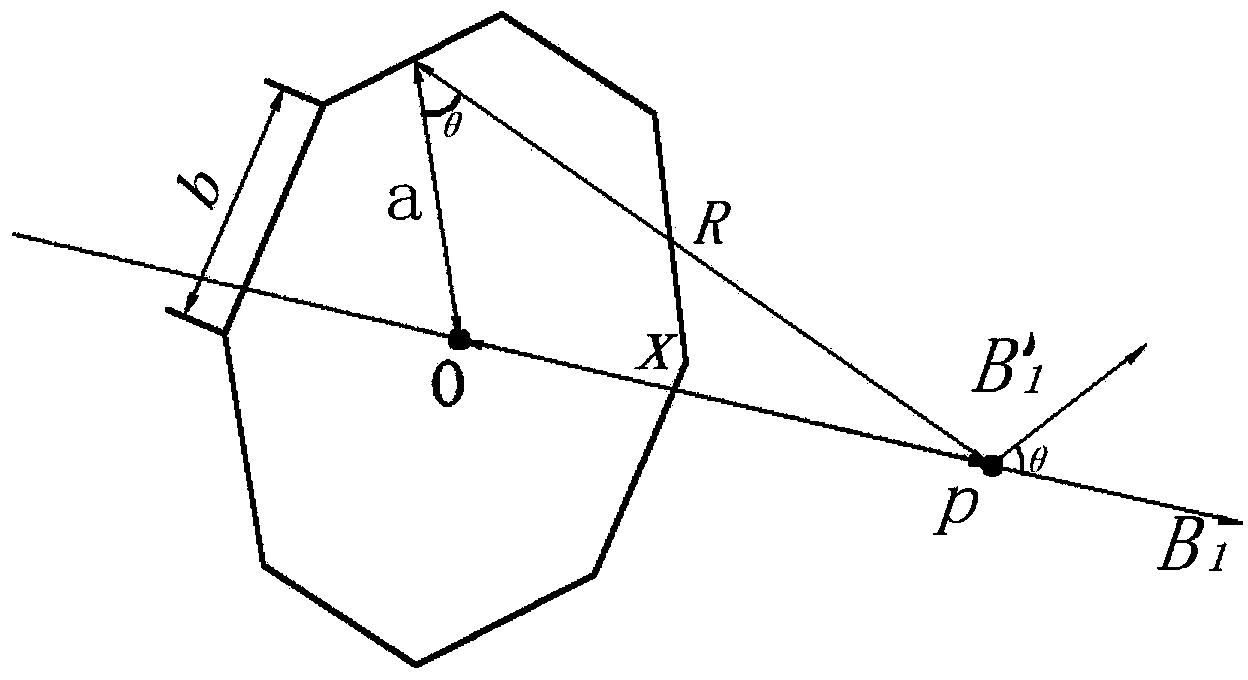

Regular octagonal tri-cyclic magnetic field coil

InactiveCN103871710AReduce non-uniformityImprove uniformityCoils manufactureCoilsPower flowHelmholtz coil

The invention discloses a regular octagonal tri-cyclic magnetic field coil which comprises three regular octagonal coils, wherein the axes of the three regular octagonal coils are coincided, and the three regular octagonal coils are same in current size and direction. Compared with a traditional Helmholtz coil, the regular octagonal tri-cyclic magnetic field coil is a six-level uniformity coil; non-uniform degree of the magnetic field is reduced by two orders of magnitudes; the uniformity of a magnetic field region created by the coil in same physical dimension is obviously increased; the regular octagonal tri-cyclic magnetic field coil has the characteristics of easiness in processing and mounting.

Owner:710TH RES INST OF CHINA SHIPBUILDING IND CORP

Structure and method for improving flow uniformity and reducing turbulence

InactiveUS7249614B2Reducing lateral turbulenceReduce trafficAerodynamic testingFluid dynamicsEngineeringMaterial Perforation

Owner:VAKILI AHMAD D

Thin-film transistor formed on insulating substrate

InactiveUS20070228469A1Run at high speedReduce non-uniformityTransistorSolid-state devicesHigh concentrationSingle crystal

There is provided a thin-film transistor that is formed on an insulating substrate, is capable of a high-speed operation, has small non-uniformity among devices, is hardly susceptible to device destruction due to high voltage, and is free from the effect of a parasitic transistor that forms at an edge part of an Si island. The thin-film semiconductor device is formed using a thin-film semiconductor provided on the insulating substrate and includes a gate region for formation of a channel region through which a drain current flows. The gate region has a ring shape in plan on the insulating substrate. High concentration impurity-doped regions are dividedly provided on an inside and an outside of the ring-shaped gate region, and the channel region is formed of a plurality of fan-shaped semiconductor single-crystal portions.

Owner:NAKANO FUMIKI +5

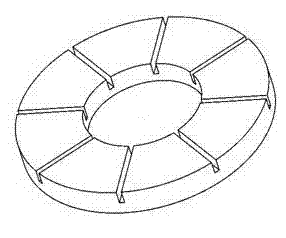

Slotting-type freezing and solidifying grinding material polishing pad and preparation method thereof

InactiveCN102335888AImprove protectionFacilitate the development of new usesFlexible-parts wheelsGrinding devicesPolishingEngineering

The invention discloses a slotting-type freezing and solidifying grinding material polishing pad, which is characterized in that the center of one surface of a polishing pad, which is opposite to a processed workpiece, is provided with a blind hole (1); the periphery of the blind hole (1) is provided with a groove (2); the diameter d of the blind hole (1) is equal to e-r, wherein e in the formula is the eccentricity of the polishing pad, r is the radius of the polished workpiece, the value of the eccentricity is always 20-105mm, the depth of the blind hole (1) is 10-20mm, the depth of the groove (2) is 50-70% of the depth of the blind hole (1), and the width of the groove (2) is 5-10mm. In the slotting-type freezing and solidifying grinding material polishing pad, different types of grooves of different shapes are manufactured on the traditional freezing and solidifying grinding material polishing pad. Various groove shapes are formed mainly by the action of a slotting die. The polishing pad can be used for polishing and machining various thin workpieces, and is especially suitable for machining heat sensitive materials, soft materials, crystal materials and the like, has the advantages of low machining cost, high machining efficiency, strong technical control capability and the like, is simple to manufacture, is environmentally-friendly.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

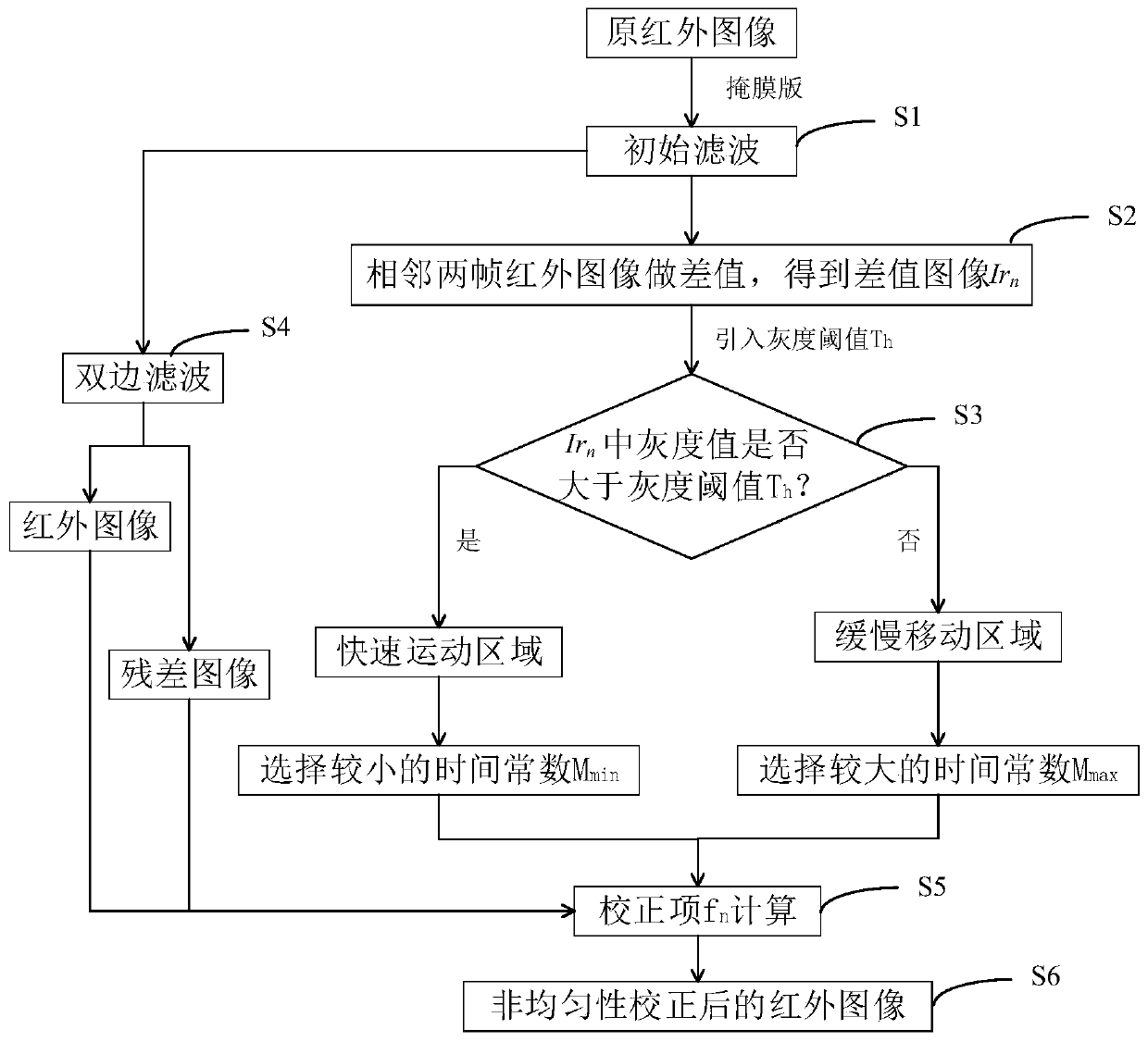

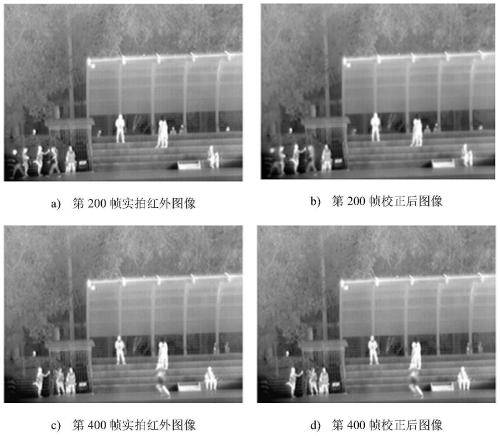

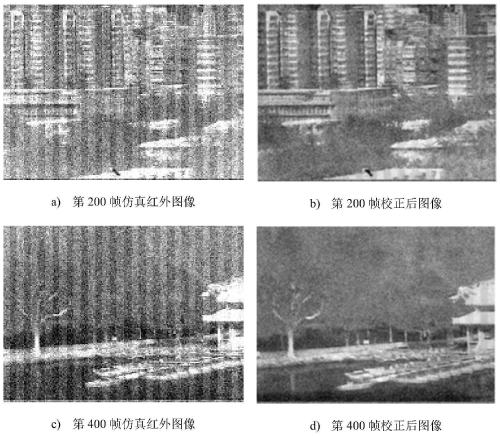

Time domain high-pass filtering method

PendingCN111080561AEnhance edge informationReduce non-uniformityImage enhancementImage analysisOpticsComputer graphics (images)

The invention discloses a time domain high-pass filtering method. The method includes the steps of carrying out preliminary filtering on an original infrared image by using a mask plate, obtaining a difference value of the two adjacent frames of infrared images after preliminary filtering to obtain a difference value image, carrying out bilateral filtering on the infrared image after preliminary filtering, obtaining a residual image after bilateral filtering, enabling the part with the gray value greater than a gray threshold value in the difference image to belong to a fast moving area, enabling the part, with the gray value smaller than or equal to the gray threshold value, of the difference image to belong to a slow moving area, determining correction items of the fast moving area and the slow moving area according to the residual image after bilateral filtering and different time constants, and correcting the original infrared image through the correction items to obtain a corrected infrared image. According to the invention, the non-uniformity of the infrared image is effectively reduced, the occurrence of ghost images is inhibited, and the correction effect is good.

Owner:SHANGHAI AEROSPACE CONTROL TECH INST

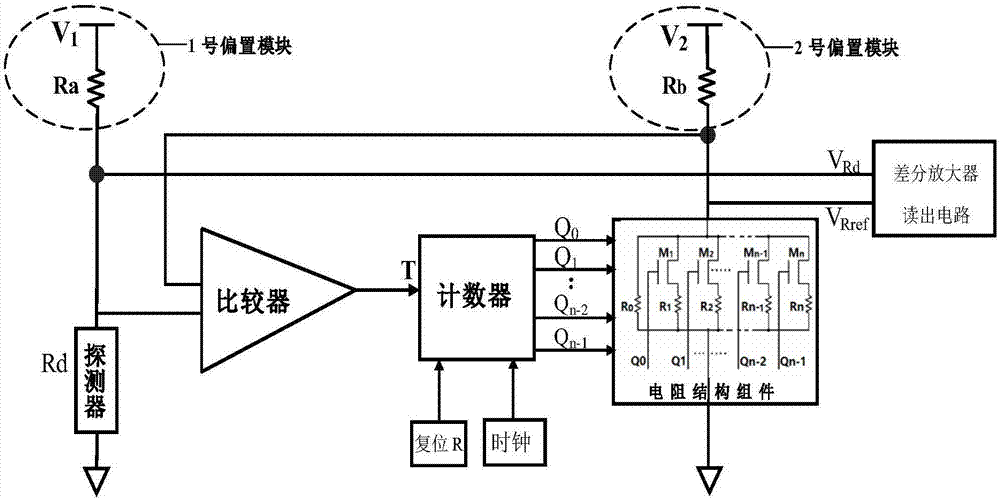

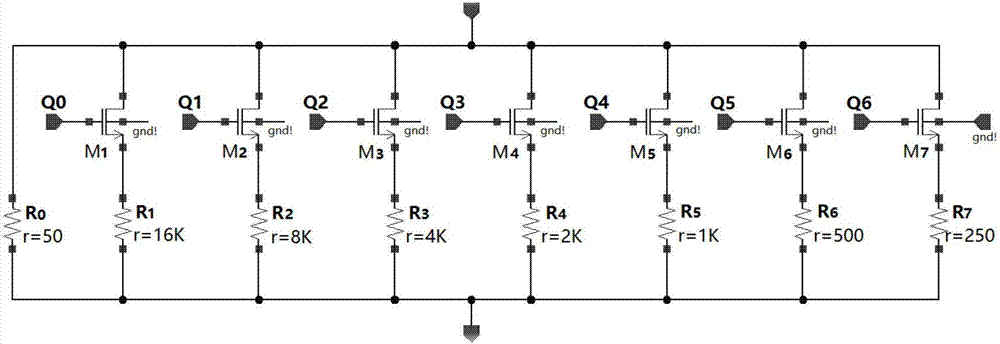

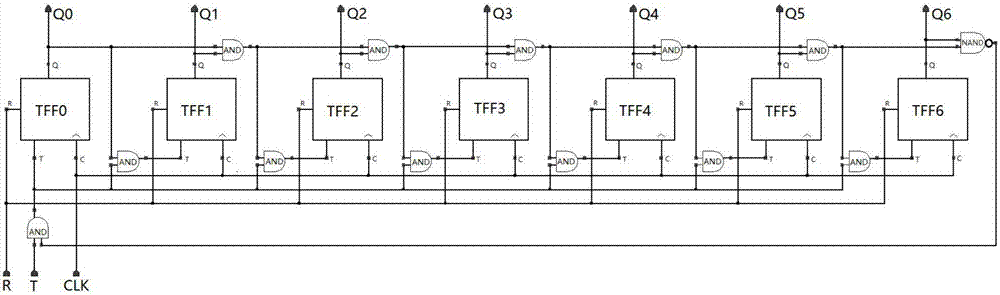

Long wave light guide infrared detector non-uniformity correction circuit

ActiveCN107192464AReduce non-uniformityReduce complexityFinal product manufacturePyrometry using electric radation detectorsElectrical resistance and conductanceLight guide

The invention discloses a long wave light guide infrared detector non-uniformity correction circuit, which is used for an infrared detector sense circuit. The correction circuit comprises a resistance structure component, a counter, a comparator, and an offset module, and is used to realize the self-adapting correction of the non-uniformity of the light guide infrared detector having a correction resistance value under 200 omega. By adopting ADC and DAC methods, the circuit is used to match each detection element with an equal reference voltage to be used as an input voltage of a reference end of a differential amplifier before reading of signals, and the reference voltages are provided by the resistance structure component controlled by the counter in a voltage-divided way, and the counting of the counter is controlled by the output signals of the comparator, and in addition, the comparator is used to compare the divided voltage of the resistance structure component and the divided voltage of the detector. By adopting the circuit, the voltages of the two input ends of the differential amplifier are almost equal to each other before radiation. The long wave light guide infrared detector non-uniformity correction circuit is advantageous in that the non-uniformity is effectively corrected and reduced to less than 0.5%, and a conventional blind pixel detector design corresponding to a response element is not required, and an adapted correction range is large.

Owner:SHANGHAI INST OF TECHNICAL PHYSICS - CHINESE ACAD OF SCI

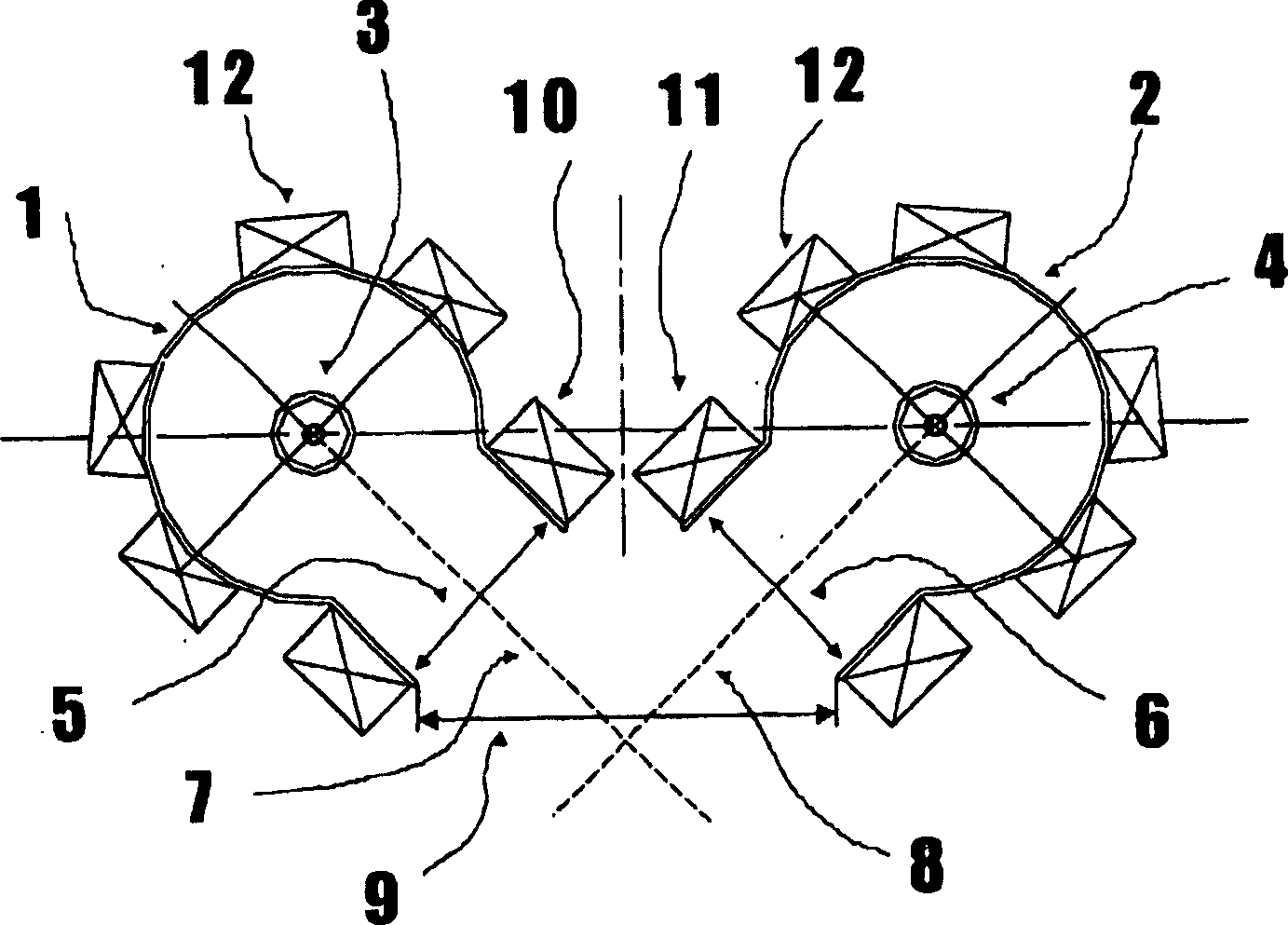

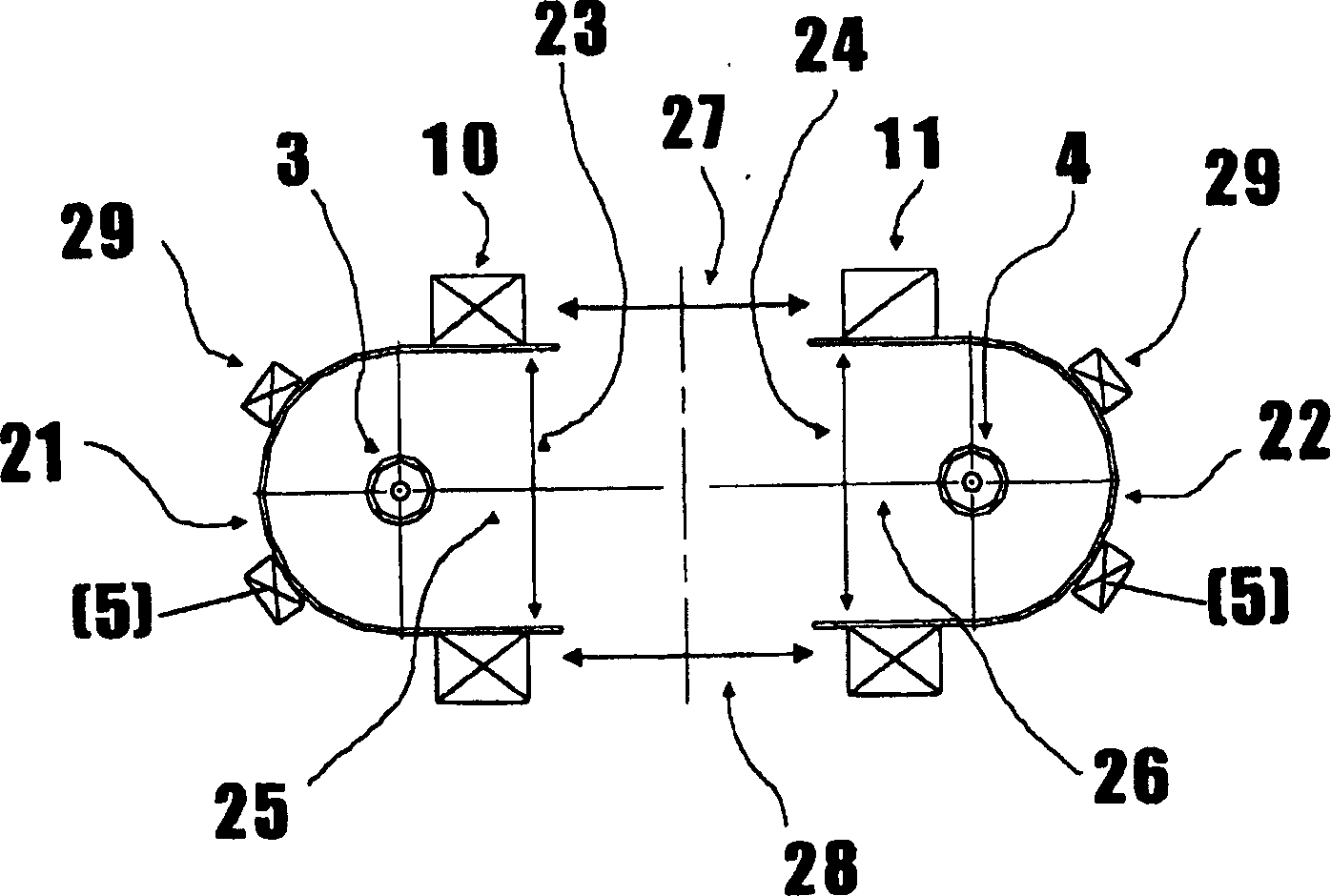

Electron cyclotron resonance (ECR) plasma source having a linear plasma discharge opening

InactiveCN1849690AEffective plasma treatmentReduce non-uniformityElectric discharge tubesPlasma techniqueElectron cyclotron resonanceParticle physics

The invention relates to an electron cyclotron resonance (ECR) plasma source having a linear plasma discharge opening ( 9, 27, 28, 30 ), comprised of a plasma chamber, inside of which a centered wave distributor is provided, and having a multi-pole magnetic field arrangement in the area of the linear plasma discharge opening. The centered wave distributor consists of at least two separate wave distributors ( 3, 4 ) that are placed inside a respective partial plasma chamber ( 1, 2, 21, 22, 32, 23 ). A linear partial plasma discharge opening ( 7, 8, 23, 24, 34, 35 ) and multi-pole magnetic field arrangements ( 10, 11, 38, 39 ) are provided on each partial plasma chamber ( 1, 2, 21, 22, 32, 23 ). The at least two linear plasma discharge openings ( 7, 8, 23, 24, 34, 35 ) are arranged with regard to one another in such a manner that, together, they form at least one plasma discharge opening ( 9, 27, 28, 30 ) of the ECR plasma source.

Owner:ROTH & RAU B V

Correcting anamolous texture and feature width effects in a display that uses a multi primary color unit scheme

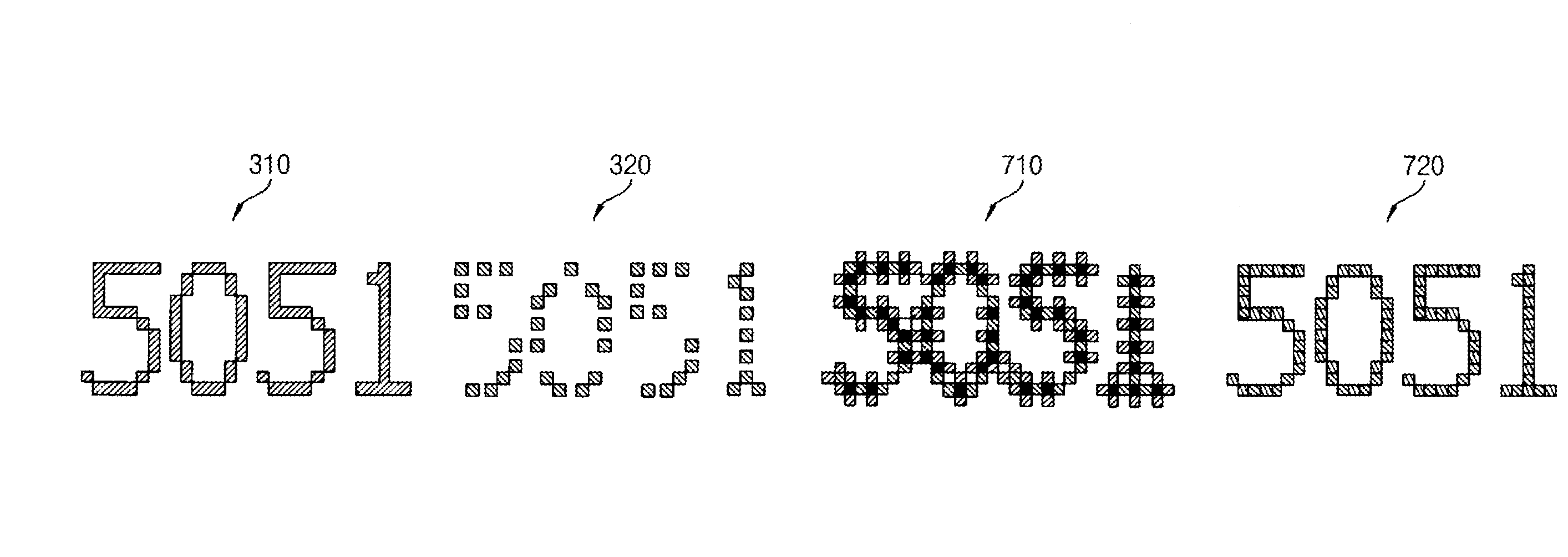

ActiveUS20140104294A1Reducing and eliminating artifactReduce artifactsColor signal processing circuitsCathode-ray tube indicatorsPattern recognitionDisplay device

A method for correcting artifact effects in a multi-primary color matrix display is provided where the display is populated by an array of red-green-blue (RGB) pixels and of non-RGB pixels. The method includes receiving all-RGB data in an all-RGB format; converting the all-RGB data into multi-primary data in accordance with a predefined multi-primary color scheme; testing for and applying one or more artifact correction modifications to each of primary colors that is not represented by all pixels, wherein the modification includes shifting of intensity production of a given non-primary color to a metameric equivalent of pixels in one or more adjacent RGB pixels.

Owner:SAMSUNG DISPLAY CO LTD

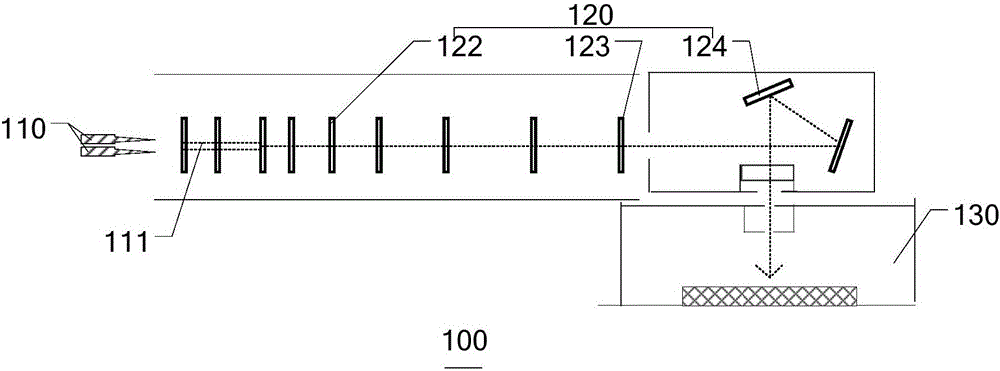

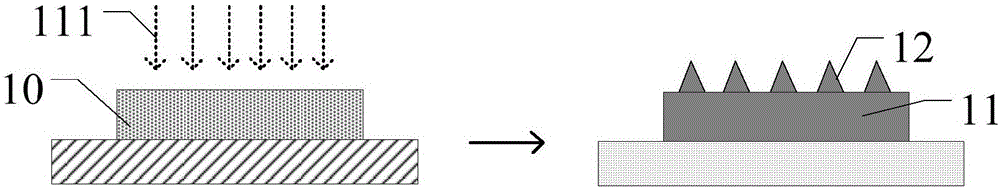

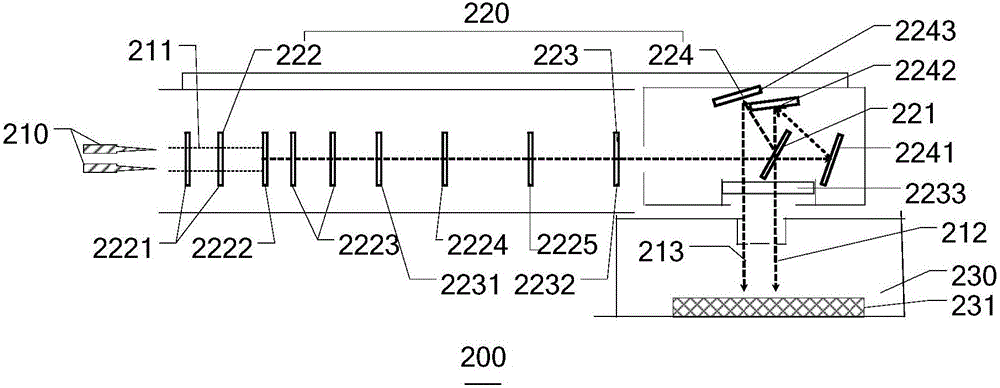

Laser annealing apparatus, preparation method of polycrystalline silicon thin film and preparation method of thin film transistor

ActiveCN106783536ASolve the large leakage currentSolve the mobilityTransistorLaser detailsBeam splitterOptoelectronics

The present invention provides a laser annealing apparatus, a preparation method of a polycrystalline silicon thin film and a preparation method of a thin film transistor. The laser annealing apparatus comprises a laser generator, optical path elements and an annealing chamber; the laser generator is configured to emit a laser beam; the laser beam is guided to the annealing chamber through the optical path elements; the optical path elements comprise a beam splitter; the beam splitter divides the laser beam into a first light beam and a second light beam, and the energy density of the first light beam is greater than the energy density of the second light beam; and the first light beam and the second light beam are guided to the annealing chamber for laser annealing. When the laser annealing apparatus is adopted to perform annealing processing on the polycrystalline silicon thin film, the non-uniformity of the surface of the polycrystalline silicon thin film can be decreased, so that the mobility of electrons and holes can be improved, and therefore, the problems of large leakage current, non-uniform mobility and non-uniform threshold voltage of the thin film transistor can be solved.

Owner:BOE TECH GRP CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com