Slotting-type freezing and solidifying grinding material polishing pad and preparation method thereof

A technology of consolidating abrasives and polishing pads, applied in the direction of grinding/polishing equipment, abrasives, grinding devices, etc., can solve the problems of uneven distribution of polishing stress, low removal rate, unsatisfactory polishing effect, etc., to overcome abrasive Spill, high utilization rate of abrasive, beneficial to environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

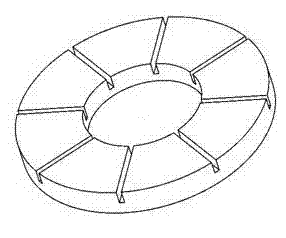

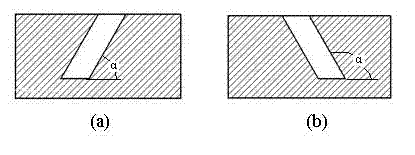

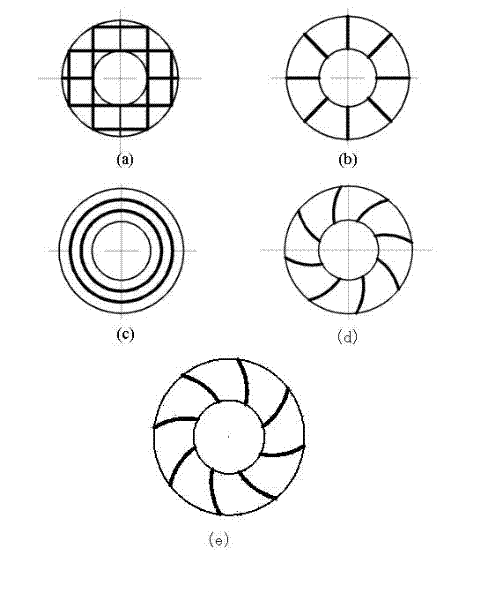

[0045] Such as figure 1 , 2 , 3, 4 shown.

[0046] A slotted frozen solidified abrasive polishing pad for polishing ultra-thin materials, made of 10kg nanometer CeO 2 (or nano-SiO 2 ) abrasive, 5kg of additives and 85kg of water (or hydrous ethanol) frozen. Before preparation, the three are mixed to form a polishing liquid with uniform dispersion and good suspension. It is then poured into polishing pad preparation molds and Figure 4The metal slotted mold shown was placed on top of the polishing solution in the polishing pad preparation mold, and then placed in a cryogenic chamber with the polishing pad preparation mold for 50 minutes and kept at -30° C. for 30 minutes. Then pour hot water on the bottom of the grooved mold to make it slightly heated and then pull it out gently, that is, to form a figure 1 The blind holes shown are 105 cm in diameter and 3 cm deep, the radial grooves are 20 mm deep and 5 mm wide, and the polishing pad is shaped like figure 1 , 2 sho...

Embodiment 2

[0053] A slotted frozen solidified abrasive polishing pad for polishing ultra-thin materials, made of 50kg nanometer CeO 2 (or nano-SiO 2 ) abrasive, 8kg of additives and 42kg of water (or hydrous ethanol) frozen. All the other are the same as the first embodiment.

Embodiment 3

[0055] A grooved frozen solidified abrasive polishing pad for polishing ultra-thin materials, made of 70kg nanometer CeO 2 (or nano-SiO 2 ) abrasive, 9kg of additives and 21kg of water (or hydrous ethanol) frozen. All the other are the same as the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com