Kneading method for fiber-reinforced thermoplastic resin, plasticizing device, and extruding machine

A technology of thermoplastic resin and fiber reinforcement, applied in the field of kneading, plasticizing device and extruder of fiber reinforced thermoplastic resin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

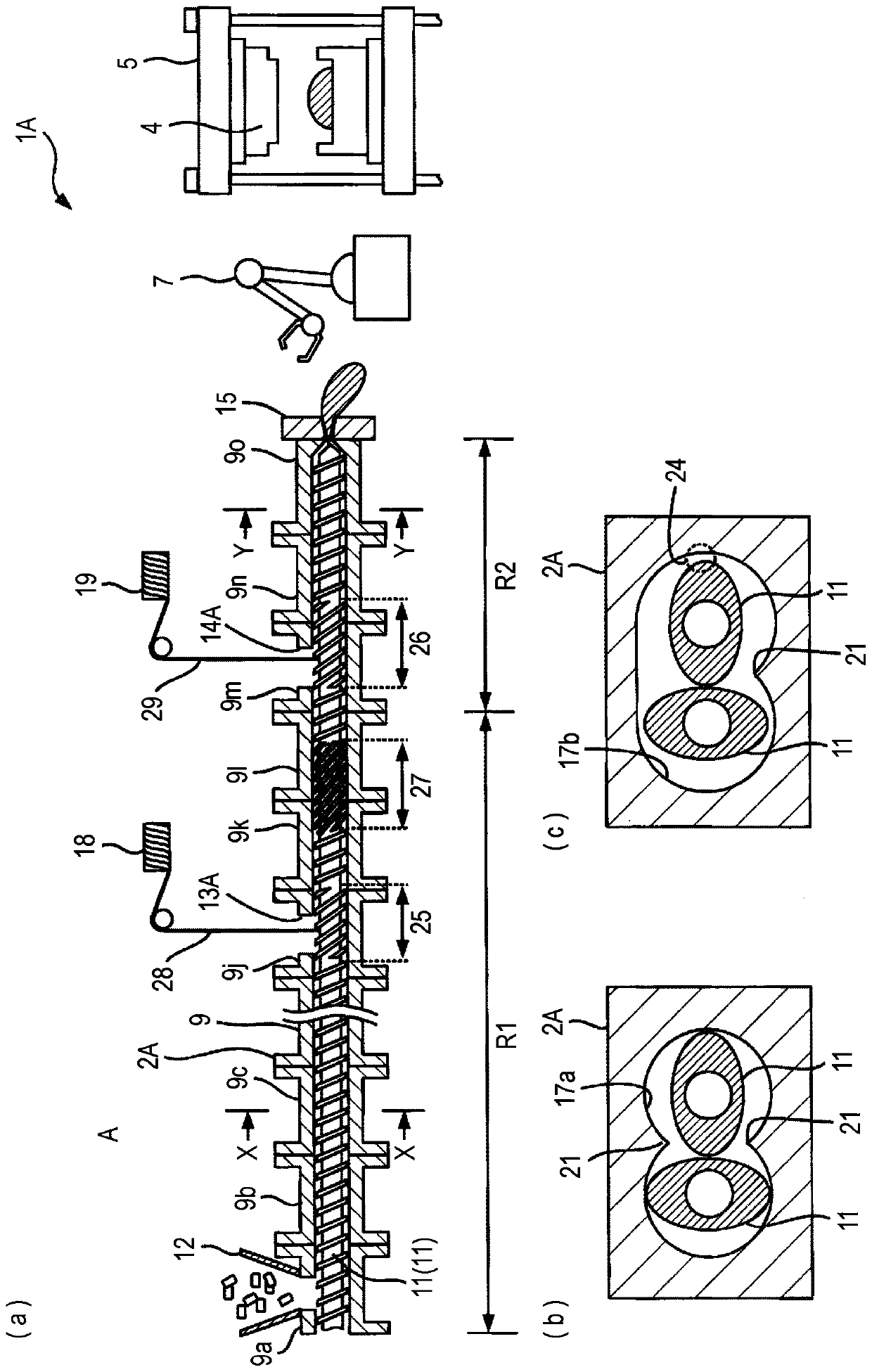

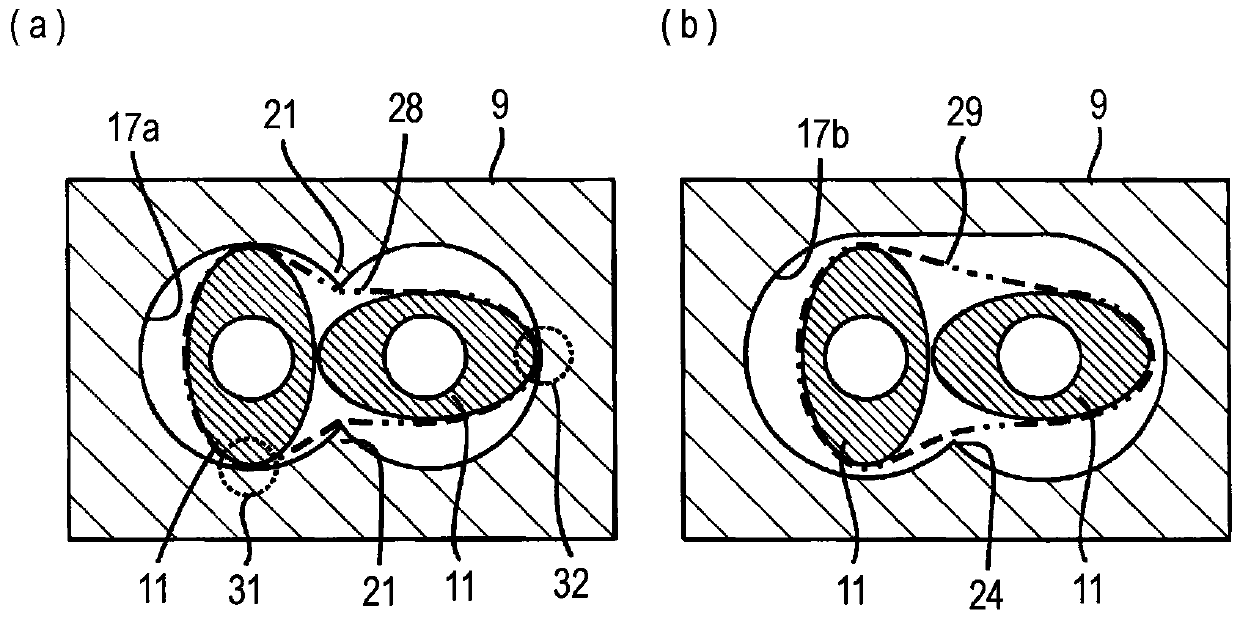

[0049] as in figure 1 The molding apparatus 1A according to the first embodiment shown in (a) is constructed of a plasticizing apparatus for obtaining a fiber-reinforced thermoplastic resin by kneading a thermoplastic resin and reinforcing fibers. That is, the molding apparatus 1A according to the first embodiment includes: the twin-screw extruder 2A according to the present embodiment; A molding die 4 for manufacturing a product; a mold clamping device 5 for clamping the molding die 4; and a mechanical arm 7 for delivering the mass extruded from the twin-screw extruder 2A to the molding die 4. Intermediate molded articles.

[0050] Similar to the twin-screw extruder in the related art, the twin-screw extruder 2A according to the present embodiment also includes: a barrel 9 formed by connecting a plurality of barrel blocks 9a, 9b, . . . ; and inserted into the barrel 9 The two screw rods 11,11. A hopper 12 is provided upstream of the barrel 9, that is, on the rear end porti...

no. 2 example

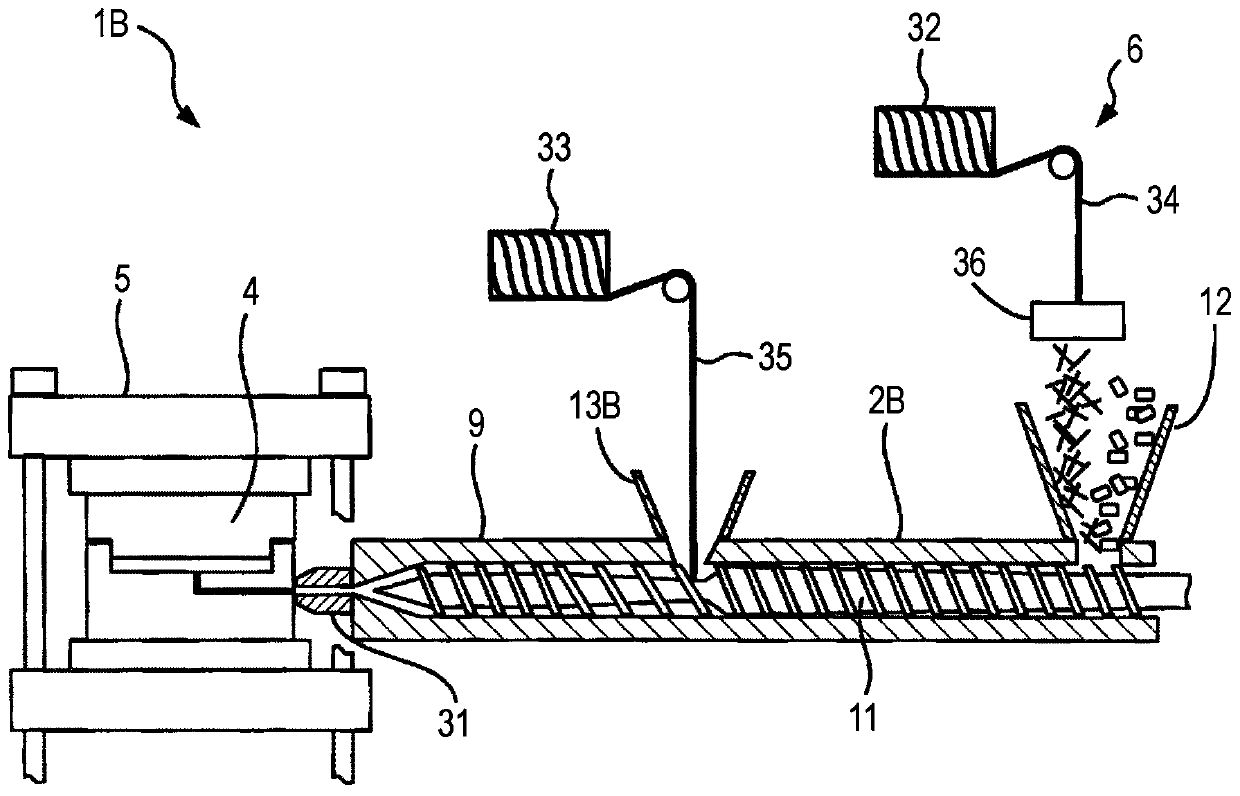

[0060] The fiber-reinforced thermoplastic resin kneading method of the second embodiment is characterized in that when the reinforcing fibers are supplied to the plasticizing device as in the first embodiment, the reinforcing fibers are supplied from two or more different places. The kneading method according to the present invention can also be performed using an injection device of an injection molding machine serving as a plasticizing device.

[0061] image 3 A molding apparatus 1B, ie, an injection molding machine, according to the second embodiment is shown. The injection molding machine, ie the injection device 2B of the plasticizing device, comprises a barrel 9 and a screw 11 driven in the barrel 9 in the axial direction and in the rotational direction. A hopper 12 is provided at the rear end of the barrel 9, and a reinforcing fiber inlet 13B is provided near the tip end. From a position at or near the reinforcing fiber inlet 13B, the gap between the hole of the barr...

no. 3 example

[0067] as in Figure 5 The molding apparatus 1C according to the third embodiment shown in (a) includes: the twin-screw extruder 2C according to the present embodiment, which is configured to plasticize the thermoplastic resin, kneading with reinforcing fibers and extruding the thermoplastic resin and the reinforcing fibers as a bulk molded article to obtain a fiber-reinforced thermoplastic resin; a reinforcing fiber supply device 3 for supplying the reinforcing fibers to the twin-screw extruder 2C; A molding die 4 for obtaining a molded product by compression molding a bulk molded product; a mold clamping device 5 for clamping the molding die 4; 2C Robotic arm 7 for extruded bulk molded articles.

[0068] Similar to the twin-screw extruder in the related art, the twin-screw extruder 2C according to the present embodiment also includes: a barrel 9 formed by connecting a plurality of barrel blocks 9a, 9b, . . . ; and inserted into the barrel 9 The two screw rods 11,11. A hop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com