Core for rubber track and rubber track

A technology of rubber track and core iron, applied in the field of rubber track core iron and rubber track, to achieve the effect of smooth bending

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

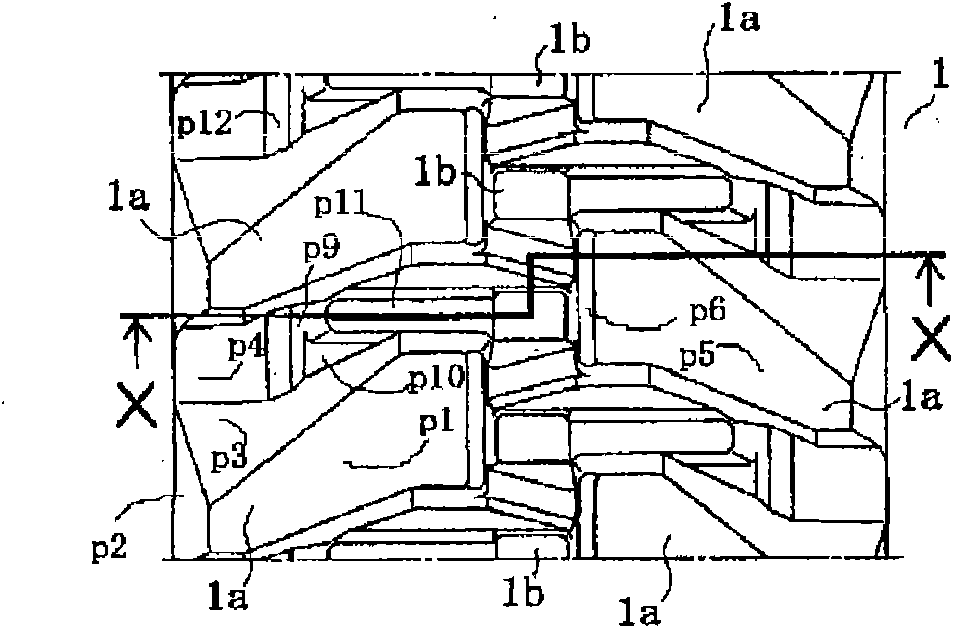

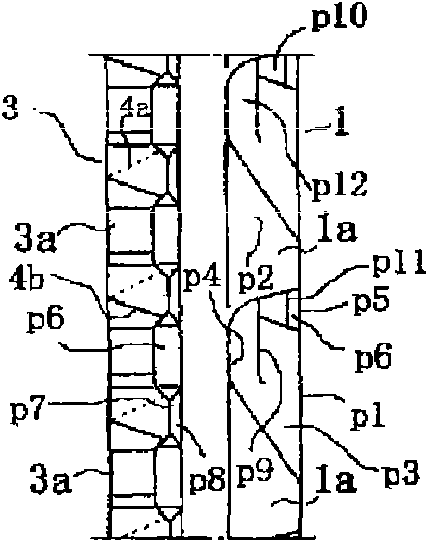

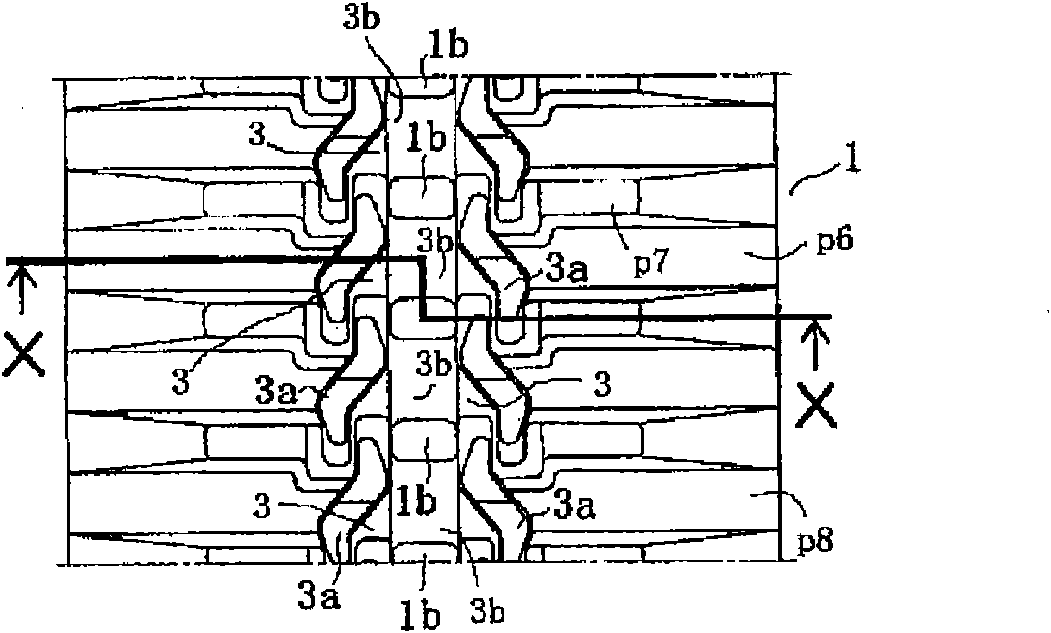

[0081] Refer to Figure 1- Figure 8 , the embodiment of the present invention will be specifically described.

[0082] Fig. 1 shows rubber track of the present invention, Figure 1A is a diagram showing a part of the outer peripheral surface (ground plane), Figure 1B It is a figure showing a part of the circumferential direction viewed from the width direction of the rubber track, Figure 1C is a diagram showing a part of the inner peripheral surface, Figure 1D to indicate along Figure 1A and Figure 1C Sectional view of line X-X in.

[0083] In the drawings, numeral 1 denotes a rubber crawler of the present invention. This rubber crawler 1 is the same as the past rubber crawler C already described, and is wound on Figure 10B The circular track traveling device M shown is used between the driven wheel A and the driving wheel S, and consists of a belt body constituting a cycle of the rubber track main body 1a, a plurality of core irons 3 embedded in the belt body, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com