Treatment method of Fischer-Tropsch synthesis recycle gas decarburization wastewater

A treatment method, Fischer-Tropsch synthesis technology, applied in degassed water/sewage treatment, multi-stage water/sewage treatment, heating water/sewage treatment, etc. Dealing with and other issues to achieve the effect of facilitating industrial application, realizing resource utilization, and reducing load and difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

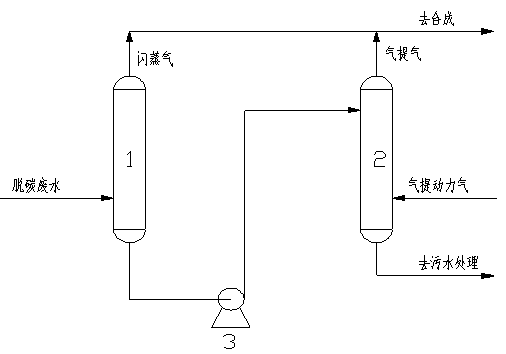

[0020] refer to figure 1 As shown, taking the waste water of a certain coal-to-oil factory (A) as an example, the process flow of the embodiment of the present invention is briefly shown.

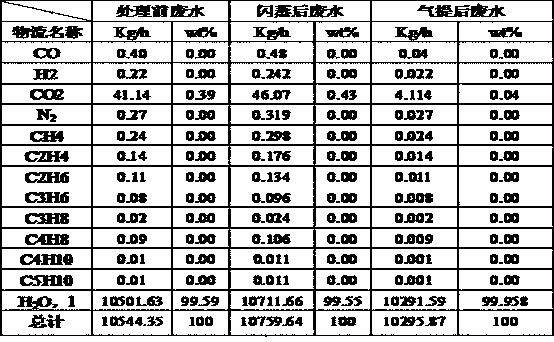

[0021] The hydrocarbon-containing wastewater (see Table 1 for composition) discharged from the bottom of the water washing tower of the circulating gas decarbonization device of a coal-to-oil plant with a pressure of 3.0MPa(a) and a temperature of 50°C is sent to the flash tower, and after decompression and flash evaporation , the treated wastewater is discharged from the bottom of the tower, and the hydrocarbon-containing gas components flashed out are discharged from the top of the tower to complete the first step. The composition of the wastewater after flash evaporation is shown in Table 1. The flash-treated wastewater is sent to the upper part of the stripping tower, and the stripping gas (hydrogen or carbon monoxide or a mixture of the two) is sent to the bottom of the stripping tow...

Embodiment 2

[0025] refer to figure 1 As shown, taking the waste water of a coal-to-oil plant (B) as an example, the flow process of the embodiment of the present invention is briefly shown.

[0026] The pressure of 2.6MPa(a) and the temperature of 35°C at the bottom of the water washing tower of the plant's circulating gas decarburization unit discharge hydrocarbon-containing wastewater (see Table 2 for composition) into the flash tower, and after decompression and flash evaporation, the treated The waste water is discharged from the bottom of the tower, and the hydrocarbon-containing gas components flashed out are discharged from the top of the tower to complete the first step. The composition of wastewater after flash evaporation is shown in Table 2. The flash-treated wastewater is sent to the upper part of the stripping tower, and the stripping gas (hydrogen or carbon monoxide or a mixture of the two) is sent to the bottom of the stripping tower. After air stripping, the unvaporized...

Embodiment 3

[0030] refer to figure 1 As shown, taking the waste water of a coal-to-oil plant (C) as an example, the process flow of the embodiment of the present invention is briefly shown.

[0031] The hydrocarbon-containing wastewater (see Table 3 for composition) discharged from the bottom of the water washing tower of the plant's circulating gas decarbonization device with a pressure of 3.2MPa(a) and a temperature of 50°C was sent to the flash tower, and after decompression and flash evaporation, the treated The waste water is discharged from the bottom of the tower, and the hydrocarbon-containing gas components flashed out are discharged from the top of the tower to complete the first step. The composition of wastewater after flash evaporation is shown in Table 3. The wastewater treated by flash evaporation is heated to 90°C by steam and then sent to the upper part of the stripping tower. Hydrogen is used as the stripping gas and sent to the bottom of the stripping tower. Gas stri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com