Double lift pipe catalytic cracking method and device for modifying inferior patrol

A double riser, inferior gasoline technology, applied in catalytic cracking, cracking, petroleum industry and other directions, can solve the problem of small decrease in gasoline olefin content or sulfur content, and achieve the effect of reducing sulfur content and improving the ratio of agent to oil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

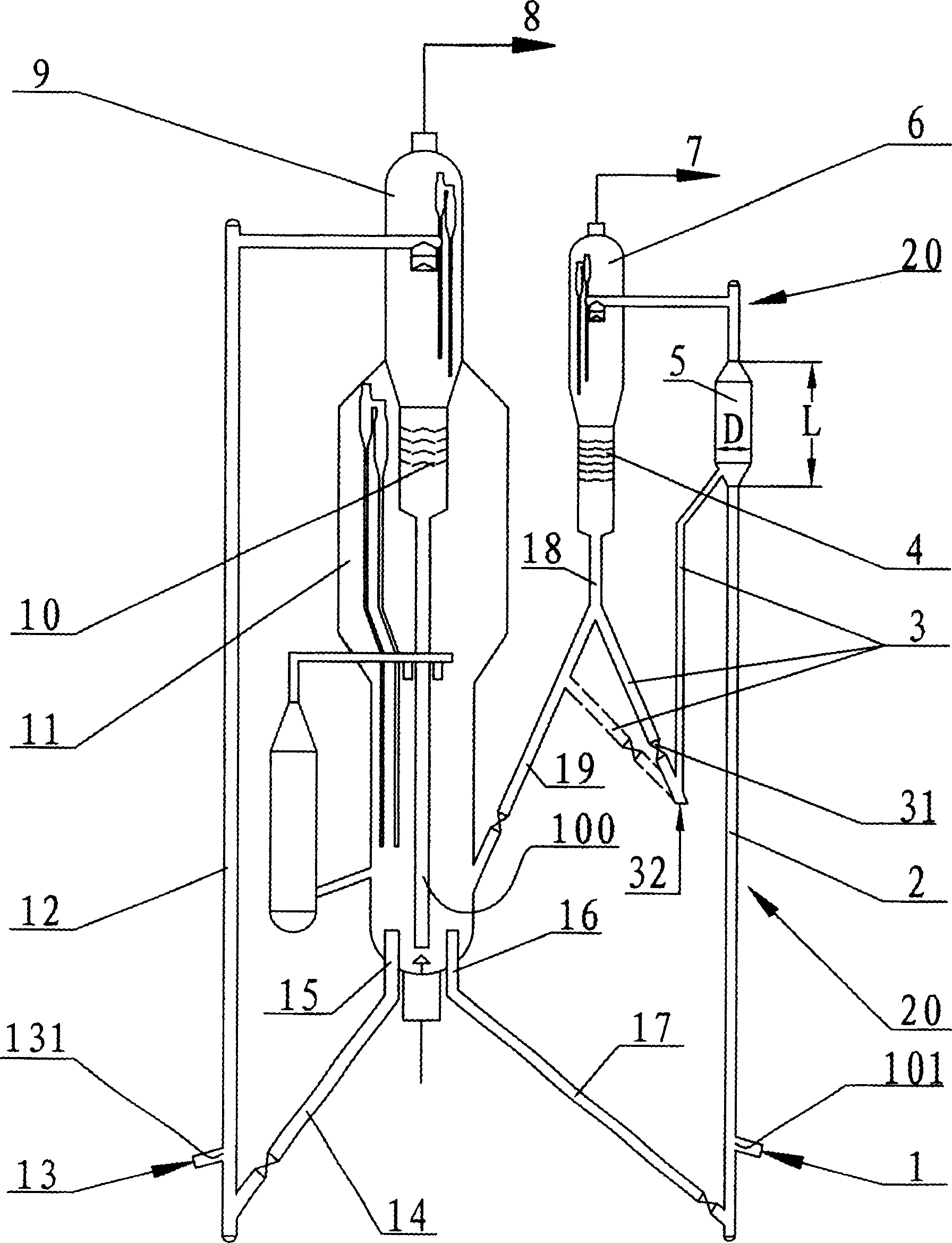

[0034] in such as figure 1 The test is carried out on the double riser catalytic cracking test device shown; the upper part of the gasoline riser reactor of this device is equipped with a bed reactor with an expanded diameter structure, and the test device is according to figure 1 A waiting catalyst delivery pipe is provided. The total length of the gasoline riser reactor is 4200mm, the length of the first reaction zone is 3000mm, and the inner diameter of the first reaction zone is Φ20mm. The inner diameter D of the cylindrical shell of the bed reactor is Φ60mm, and the length L of the bed reactor is 600mm. The delivery pipe for the raw catalyst is a metal pipe with a circular cross section, lined with a heat-insulating and wear-resistant lining; the inner diameter is Φ10mm, and the length is 5000mm. The medium of the conveying air passing into the spent catalyst conveying pipe is water vapor, and the temperature of the water vapor is 200° C. (note: the conveying air medium...

Embodiment 2~ Embodiment 5

[0037] The main operating conditions of the gasoline riser reactor are listed in Table 2, and the product distribution of the gasoline riser reactor and the main properties of the upgraded gasoline are listed in Table 3. The main operating conditions of the experimental device used in Examples 2 to 5, the processed feed and treatment capacity of the heavy oil riser reactor and the gasoline riser reactor, the catalyst used in the test, and the heavy oil riser reactor are all in Example 1. same.

[0038] As can be seen from Table 2, in embodiment 2~embodiment 5, the weight flow rate of the spent catalyst that enters the bed layer reactor through the spent catalyst conveying pipe is respectively the spent catalyst weight after stripping in the stripping section of the second settler 20w%, 30w%, 40w% and 60w% of the circulation amount.

Embodiment 6

[0043] The test was carried out on the test device used in Example 1. The heavy oil riser reactor processes Subei blended heavy oil, with a processing capacity of 30kg / d; the gasoline riser reactor feeds low-quality gasoline with gasoline produced by the heavy oil riser reactor (self-produced gasoline 2), with a processing capacity of 15kg / d d. The catalyst used in the test is LRC-99 industrial balancer, and its carbon content after regeneration is 0.09w%. The weight flow rate of the spent catalyst entering the bed reactor through the spent catalyst delivery pipe is 5w% of the weight circulation of the spent catalyst after stripping in the stripping section of the second settler. The main properties of the heavy oil riser reactor feed and the inferior gasoline feed of the gasoline riser reactor are listed in Table 1, the main operating conditions of the gasoline riser reactor are listed in Table 4, the product distribution and improvement of the gasoline riser reactor The ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com