Method for reducing contents of sulfur and olefin in catalytically cracked gasoline

A technology for catalytic cracking of gasoline and olefins, applied in the petroleum industry, processing hydrocarbon oil, hydrocarbon oil treatment products, etc., can solve the problems of gasoline octane number loss and high octane number, and achieve less octane number loss and higher octane number The effect of low, low olefin content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

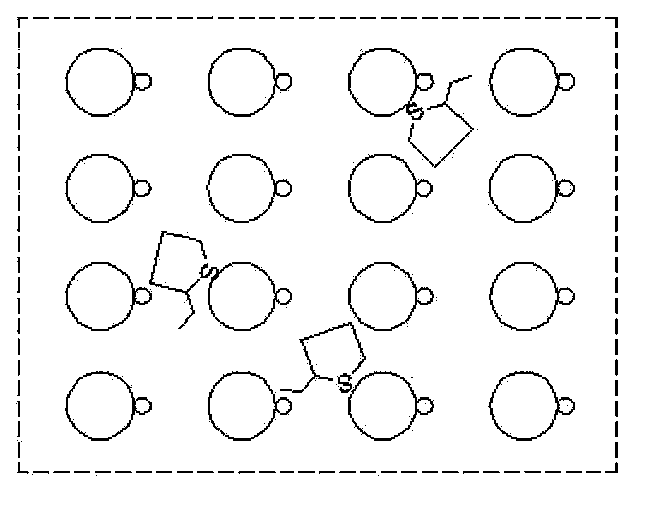

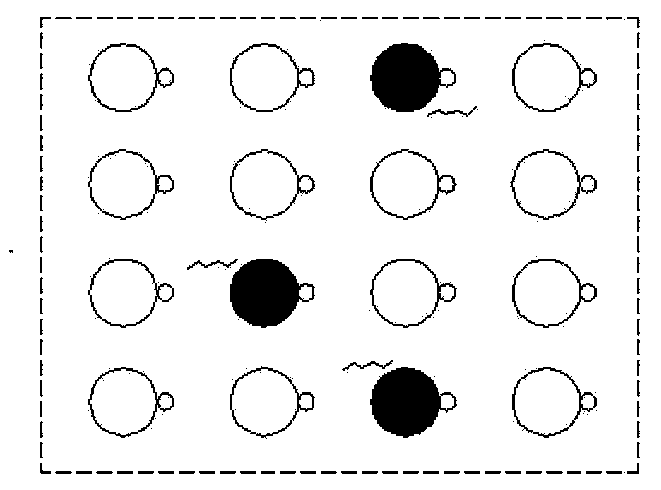

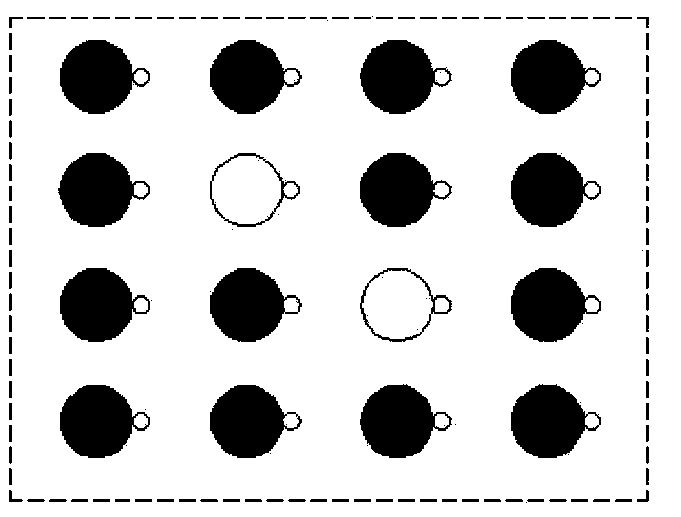

Image

Examples

Embodiment 1

[0049] Compared with Comparative Example 1, in the case of the same raw material, selective hydrodesulfurization catalyst and hydrogenation modifier, the non-hydrogenation physical desulfurization adsorbent is prepared according to Example 3 of ZL03139159.1, and the method of the present invention is adopted, Catalytic gasoline A is fractionated into light gasoline and heavy gasoline (see Table 1), and heavy gasoline and hydrogen are mixed for selective hydrodesulfurization and then hydro-upgraded. Light gasoline is subjected to non-hydrogen physical adsorption desulfurization reaction through a fixed-bed reactor, and the reaction product is blended with heavy gasoline after selective hydrodesulfurization and hydrogenation upgrading. The process conditions of non-hydrogenation physical adsorption desulfurization, selective hydrodesulfurization and hydro-upgrading are shown in Table 2, and the properties of the products are shown in Table 3. It can be seen from Table 3 that the...

Embodiment 2

[0051] Compared with Comparative Example 1, in the case of the same raw material, selective hydrodesulfurization catalyst and hydrogenation modifier, the non-hydrogenation physical desulfurization adsorbent is prepared according to Example 3 of ZL03139159.1, and the method of the present invention is adopted, Catalytic gasoline A is fractionated into light gasoline and heavy gasoline (see Table 1), and heavy gasoline and hydrogen are mixed for selective hydrodesulfurization and then hydro-upgraded. Light gasoline is subjected to non-hydrogen physical adsorption desulfurization reaction through a fixed-bed reactor, and the reaction product is blended with heavy gasoline after selective hydrodesulfurization and hydrogenation upgrading. The process conditions of non-hydrogenation physical adsorption desulfurization, selective hydrodesulfurization and hydro-upgrading are shown in Table 2, and the properties of the products are shown in Table 3. It can be seen from Table 3 that the...

Embodiment 3

[0062] Compared with Comparative Example 2, in the case of the same raw material, selective hydrodesulfurization catalyst and hydrogenation modifier, the non-hydrogenation physical desulfurization adsorbent is prepared according to Example 5 of ZL03139159.1, and the method of the present invention is adopted, Catalytic gasoline A is fractionated into light gasoline and heavy gasoline (see Table 4), and heavy gasoline and hydrogen are mixed for selective hydrodesulfurization and then hydro-upgraded. Light gasoline is subjected to non-hydrogen physical adsorption desulfurization reaction through a fixed-bed reactor, and the reaction product is blended with heavy gasoline after selective hydrodesulfurization and hydrogenation upgrading. The process conditions of non-hydrogen physical adsorption desulfurization, selective hydrodesulfurization and hydrogenation upgrading are shown in Table 5, and the product properties are shown in Table 6. It can be seen from Table 6 that the sulf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com