Heat-set ink used for textile printing and preparation method thereof

A heat-setting ink and textile technology, applied in the direction of textiles and papermaking, ink, application, etc., can solve problems such as non-conformity, harm to human body, deformation of printed fabric, etc., and achieve excellent elasticity, high transparency, and soft hand feeling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

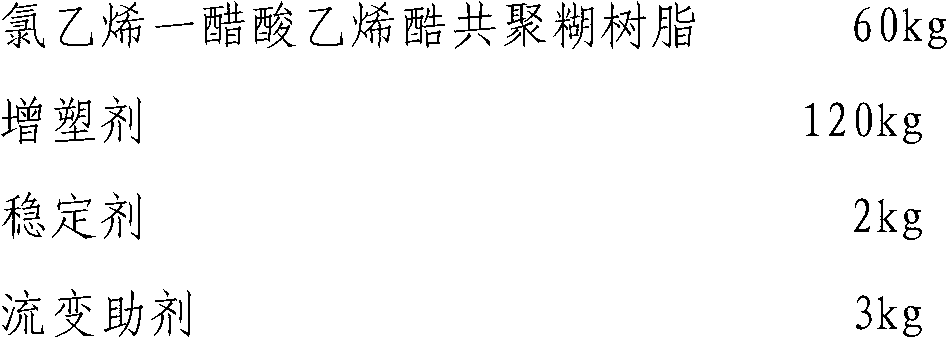

[0031] The formula is as follows:

[0032]

[0033] Vinyl chloride-vinyl acetate copolymerization paste resin is KM-31 produced by Korea Hanwha Corporation, with a degree of polymerization of 1000, a K value of 62-69, and a vinyl acetate component of 3%-8%.

[0034] The plasticizer consists of 60% of GL-300 produced by Korea LG Chem (the composition is terephthalate (DOTP)) and 40% of phenyl alkylsulfonate produced by Puyang County Yifeng New Plasticizer Co., Ltd. composition.

[0035] The rheological additive is BYK-410 produced by BYK in Germany (the component is a modified organic urea solution).

[0036] The stabilizer is AkcrosNobel environmental non-toxic calcium zinc stabilizer (liquid) (Lankros tat C 19).

[0037] The production process is as follows:

[0038] step 1. First add 120kg of plasticizer, and stir slowly with a frequency conversion dispersing mixer;

[0039] Step 2. Then add 60kg of paste resin, add slowly and stir, do not disperse at high speed and...

example 2

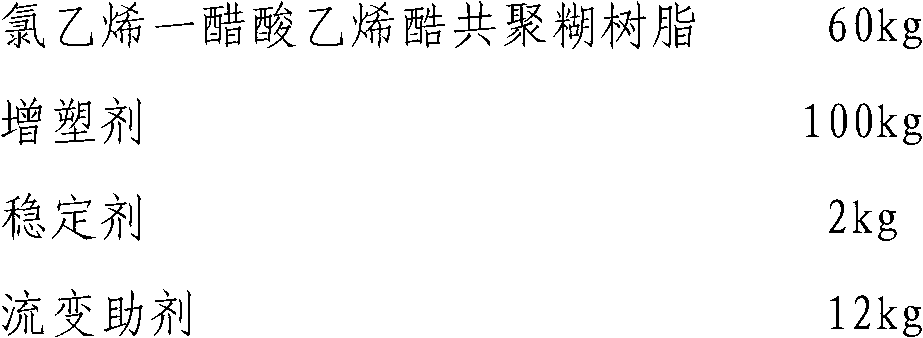

[0044] The formula is as follows:

[0045]

[0046] Vinyl chloride-vinyl acetate copolymerization paste resin is KM-31 produced by Korea Hanwha Corporation, with a degree of polymerization of 1000, a K value of 62-69, and a vinyl acetate component of 3%-8%.

[0047] The plasticizer is 80% of GL-300 produced by Korea LG Chem (the composition is terephthalate (DOTP)) and 20% of trioctyl trimellitate produced by Shandong Kexing Chemical Co., Ltd. ( referred to as TOTM).

[0048] The rheological additive is M5 produced by German Degussa Company (the composition is non-crystalline fumed silica).

[0049] The stabilizer is AkcrosNobel environmental non-toxic calcium zinc stabilizer (liquid) (Lankros tat C 19).

[0050] The production process is as follows:

[0051] Step 1, first add 100kg of plasticizer, and stir slowly with a frequency conversion dispersing mixer;

[0052] Step 2. Add 60kg of paste resin, slowly add and stir, do not disperse at high speed and cause the plast...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com