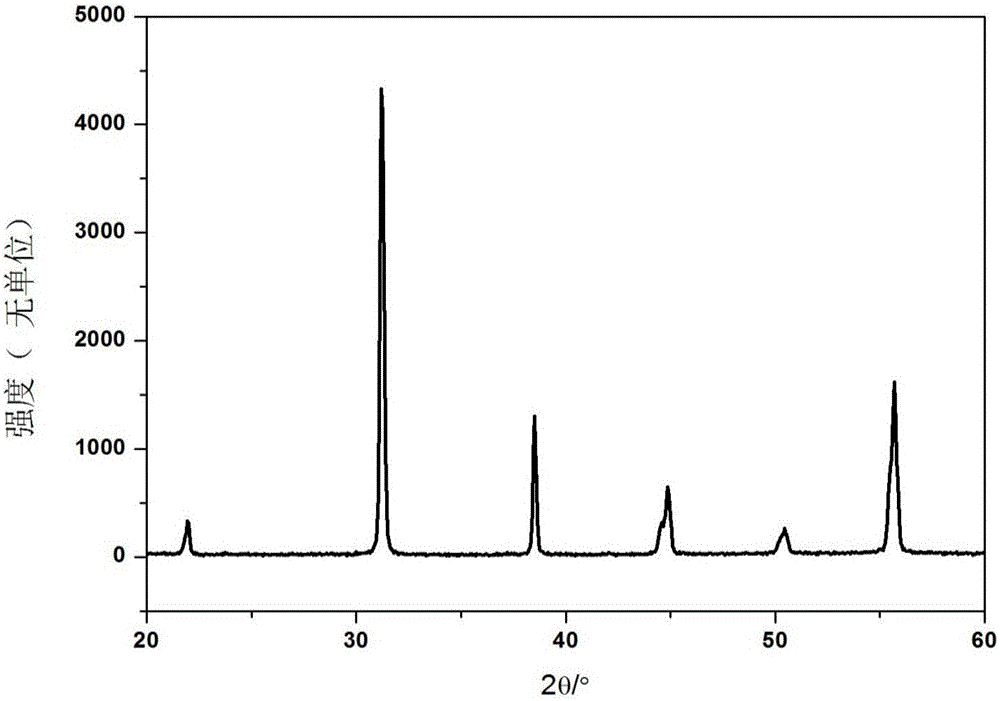

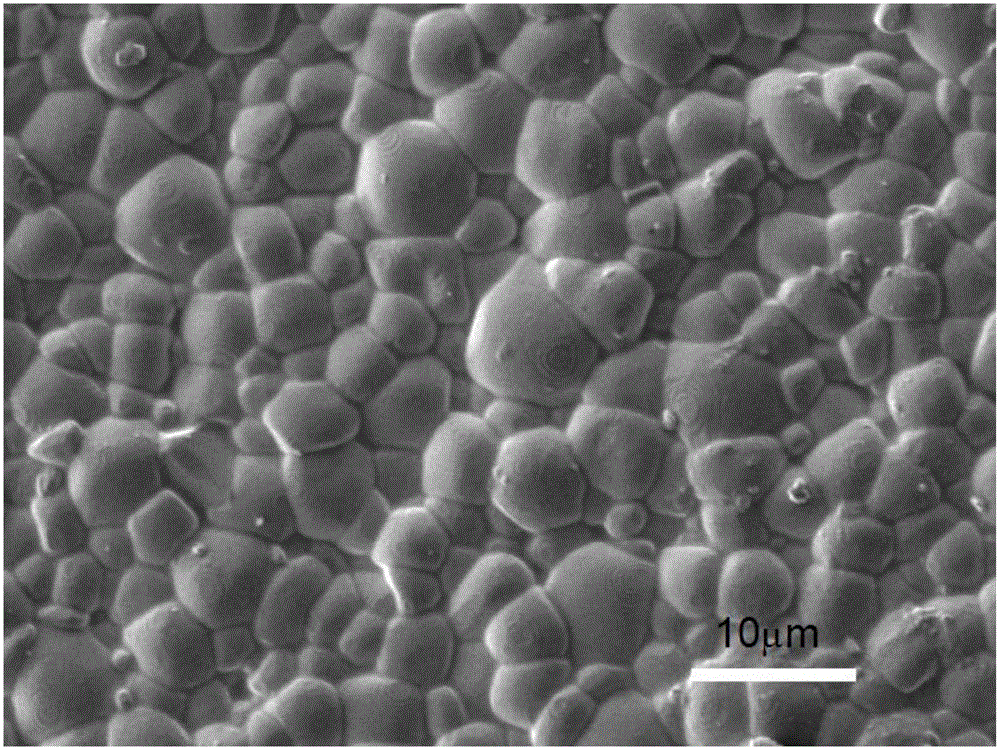

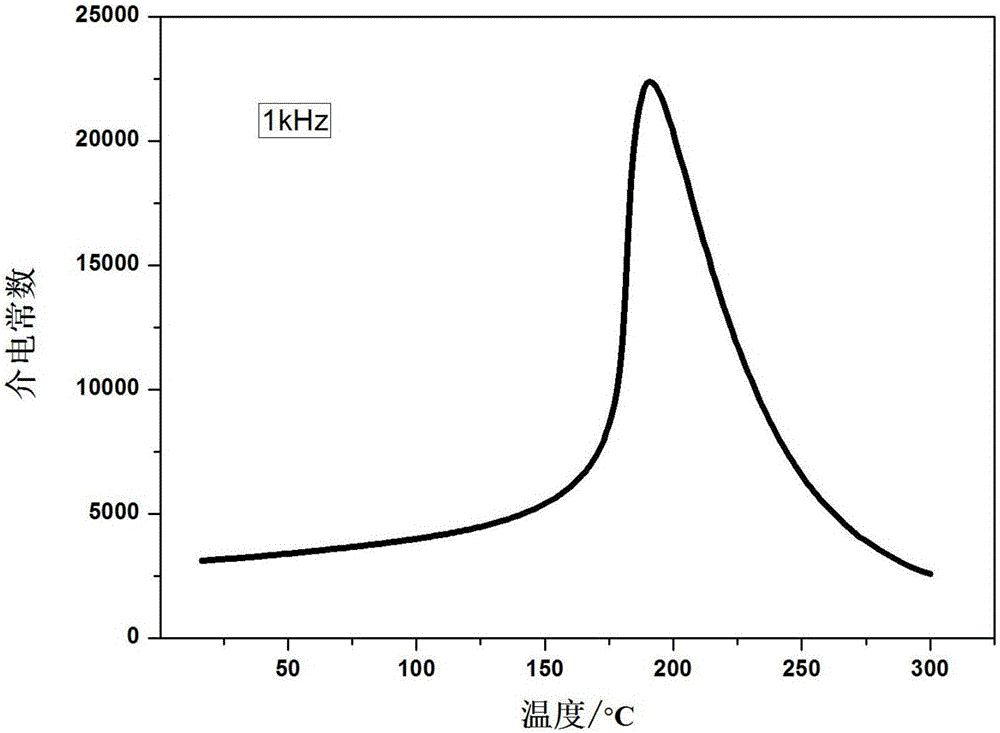

Modified lead nickel niobate-lead zirconate titanate piezoelectric ceramics and preparing method thereof

A technology of lead niobate nickelate and lead zirconate titanate, which is applied in the manufacture/assembly of piezoelectric/electrostrictive devices, piezoelectric/electrostrictive/magnetostrictive devices, circuits, etc., which can solve the problems of dielectric properties and Poor piezoelectric performance and other problems, to achieve the effect of excellent piezoelectric dielectric properties, high Curie temperature and electromechanical coupling coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A method for preparing a modified lead niobate-lead zirconate titanate piezoelectric ceramic, comprising the following steps:

[0024] (1) Ingredients: commercially available analytically pure PbO, NiO, Nb 2 o 5 、TiO 2 , ZrO 2 、Nd 2 o 3 , SrCO 3 , Y 2 o 3 and Sb 2 o 3 As a raw material, after stoichiometric proportioning, put it into a ball mill tank and use absolute ethanol as a medium to wet grind for 4 hours to obtain a wet material and dry it;

[0025] (2) Pre-calcination: put the dried mixed powder in step (1) in an alumina crucible, compact it, cover it, calcinate it in a box furnace at 800°C for 2 hours, and repeat wet grinding once to obtain pre-calcined powder material;

[0026] (3) Tablet pressing: After the calcined powder is ground and pulverized, then use absolute ethanol as a solvent for wet grinding for 8 hours, and after drying, add 5wt% to 10wt% polyvinyl alcohol (PVA) to granulate into fluid fine sand particles , under a pressure of 10-20MP...

Embodiment 2

[0031] A modified lead niobate-lead zirconate titanate piezoelectric ceramic, the chemical composition of which is:

[0032] Pb 1-x Ndx(Ni 1 / 3 Nb 2 / 3 ) 0.326 (Zr y Ti 1-y ) 0.674 o 3 +3%PbO+3%NiO+zwt%A; according to the preparation method of Example 1, according to different stoichiometry, wherein x=0.005, y=0.426, z=0.

Embodiment 3

[0034] A modified lead niobate-lead zirconate titanate piezoelectric ceramic, the chemical composition of which is:

[0035] Pb 1-x Ndx(Ni 1 / 3 Nb 2 / 3 )0.326 (Zr y Ti 1-y ) 0.674 o 3 +3%PbO+3%NiO+zwt%A; According to the preparation method of Example 1, according to different stoichiometry, wherein x=0.01, y=0.426, z=0.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Curie point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com