Device system for continuously trapping CO2 in flue gas of cement kiln through hydrate method

A cement kiln and CO2 technology, applied in the direction of carbon compounds, sustainable manufacturing/processing, educts, etc., can solve the problems of inability to achieve continuous absorption, insufficient separation capacity, and low energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

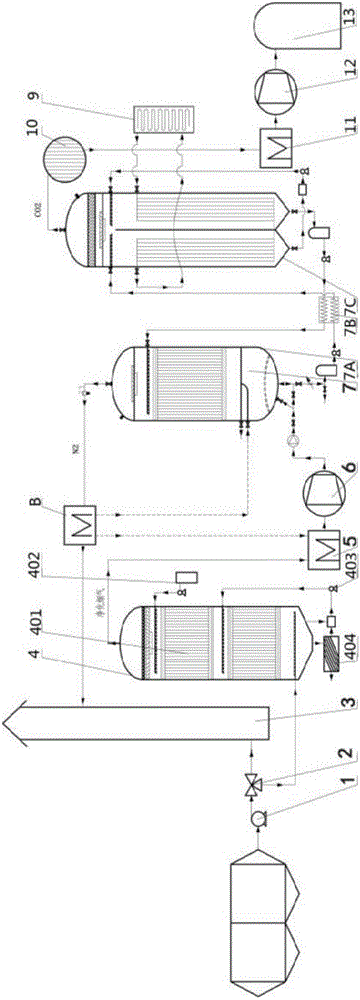

[0054] Such as figure 1 , 4 , 6, the present invention provides a hydrate method to continuously capture CO in cement kiln flue gas 2 The equipment system mainly includes tail exhaust fan 1, electric three-ventilation valve 2, chimney 3, flue gas purification device 4, cooler 5, flue gas compressor 6, CO 2 Absorption tower-regeneration tower unit 7, cold energy recovery device 8, waste heat storage device 9, dehydration dryer 10, CO 2 Cooler 11, CO 2 Compressor 12, liquefied CO 2 The storage tank 13, the electric three-ventilation valve 2 is arranged on the flue gas pipeline between the tail exhaust fan 1 and the chimney 3 connected to the kiln tail dust collector, the gas outlet of the tail exhaust fan 1 and the inlet of the electric air valve 2 The gas ports are connected, the first exhaust port of the electric three-ventilation valve 2 is connected with the flue gas inlet of the flue gas purification device 4, the second exhaust port of the electric three-ventilation va...

Embodiment 2

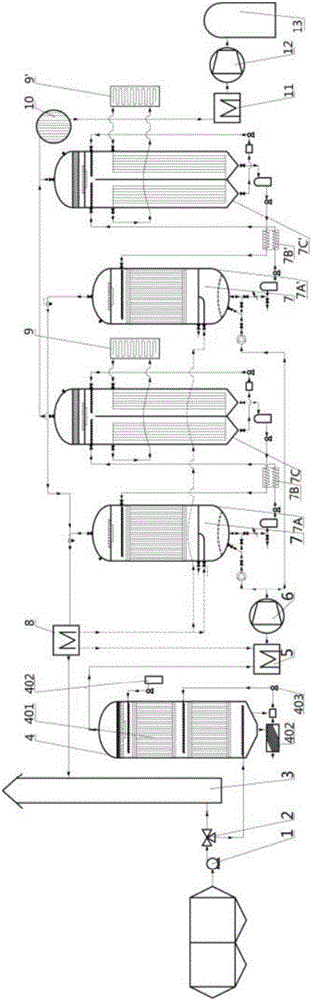

[0064] figure 2 Continuous capture of CO in cement kiln flue gas for the hydrate method described in Example 2 2 Schematic diagram of the equipment system.

[0065] Such as figure 2 , 4 , 6, the difference between this embodiment 2 and embodiment 1 is that it also includes another CO 2 Absorber-regenerator unit 7'; the other CO 2 Absorber-regenerator unit 7' with CO in Example 1 2 Absorber-regenerator unit 7 has the same structure, including CO 2 Absorption tower 7A', lean / rich liquid heat exchange device 7B', CO 2 regeneration tower 7C'; the other CO 2 The absorption tower-regeneration tower unit 7' also has a waste heat storage device 9' to provide the required energy, and the other CO 2 Absorption tower - regeneration tower unit 7' with CO 2 The absorption tower-regeneration tower unit 7 is arranged in parallel; it can double the enrichment of CO 2 Flue gas treatment capacity, effectively increase CO 2 collection efficiency.

Embodiment 3

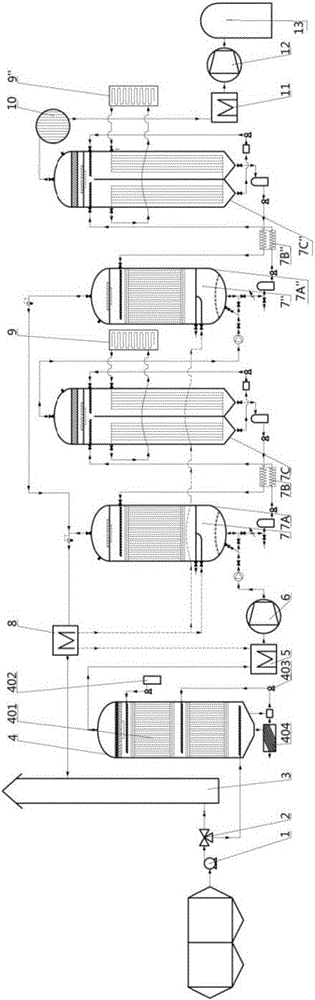

[0067] image 3 Continuous capture of CO in cement kiln flue gas for the hydrate method described in Example 3 2 Schematic diagram of the equipment system.

[0068] Such as image 3 , 4 , 6, the difference between this embodiment 3 and embodiment 1 is that it also includes another CO 2 Absorber-regenerator unit 7"; the other CO 2 Absorber-regenerator unit 7" with CO in Example 1 2 Absorber-regenerator unit 7 has the same structure, including CO 2 Absorption tower 7A", lean / rich liquid heat exchange device 7B", CO 2 regeneration tower 7C"; the other CO 2 The absorption tower-regeneration tower unit 7" also has a waste heat storage device 9" to provide the required energy, and the other CO 2 Absorber-Regenerator Unit 7" with CO 2 The absorption tower-regeneration tower unit 7 is arranged in series, which can effectively increase the CO 2 The purity of the collection.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com