A smoke catcher for welding fume

A technology of welding fume and smoke trapping board, which is applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of large exhaust area, high energy consumption, and large exhaust volume, so as to achieve complete capture, The effect of high capture rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

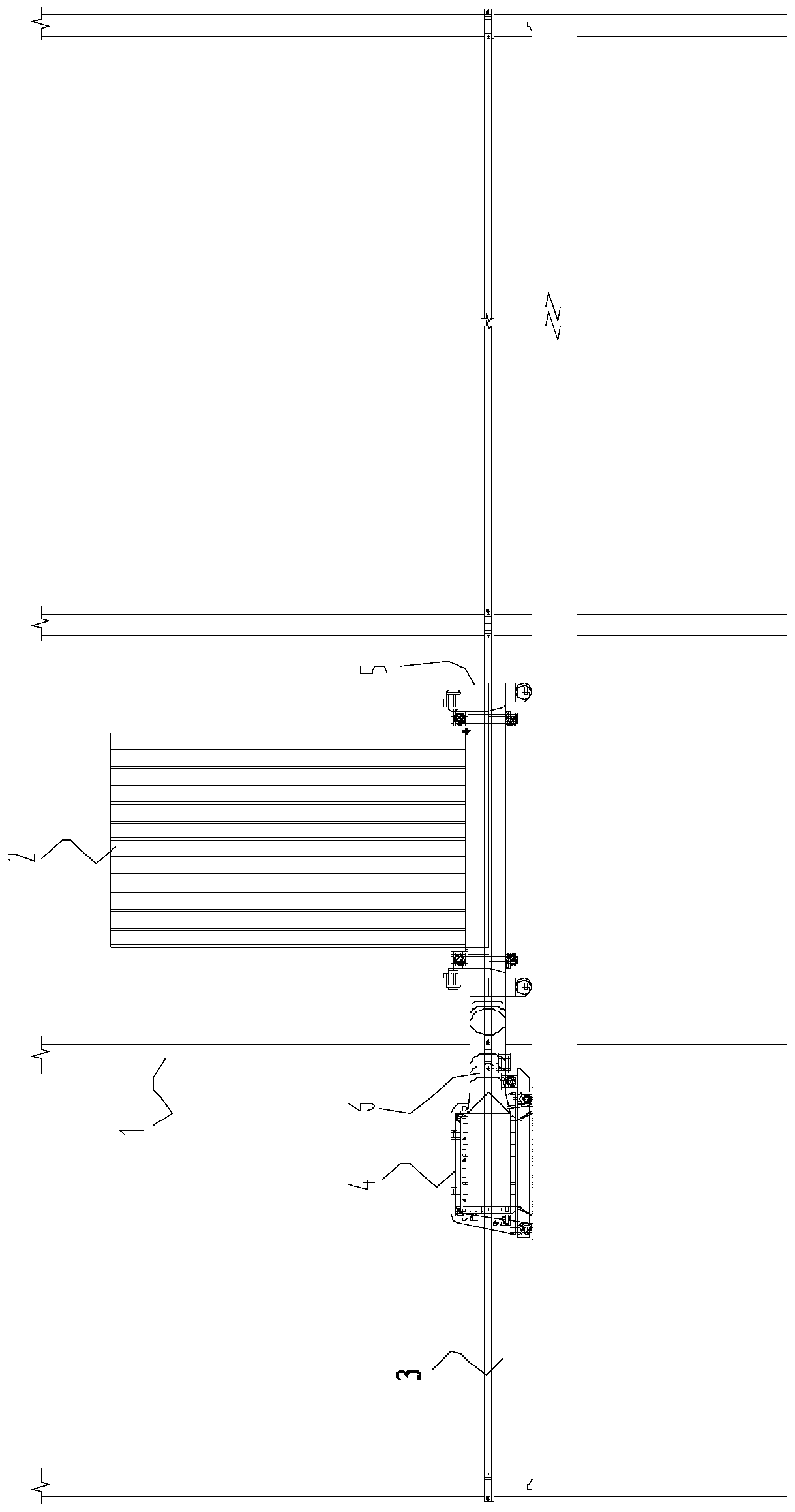

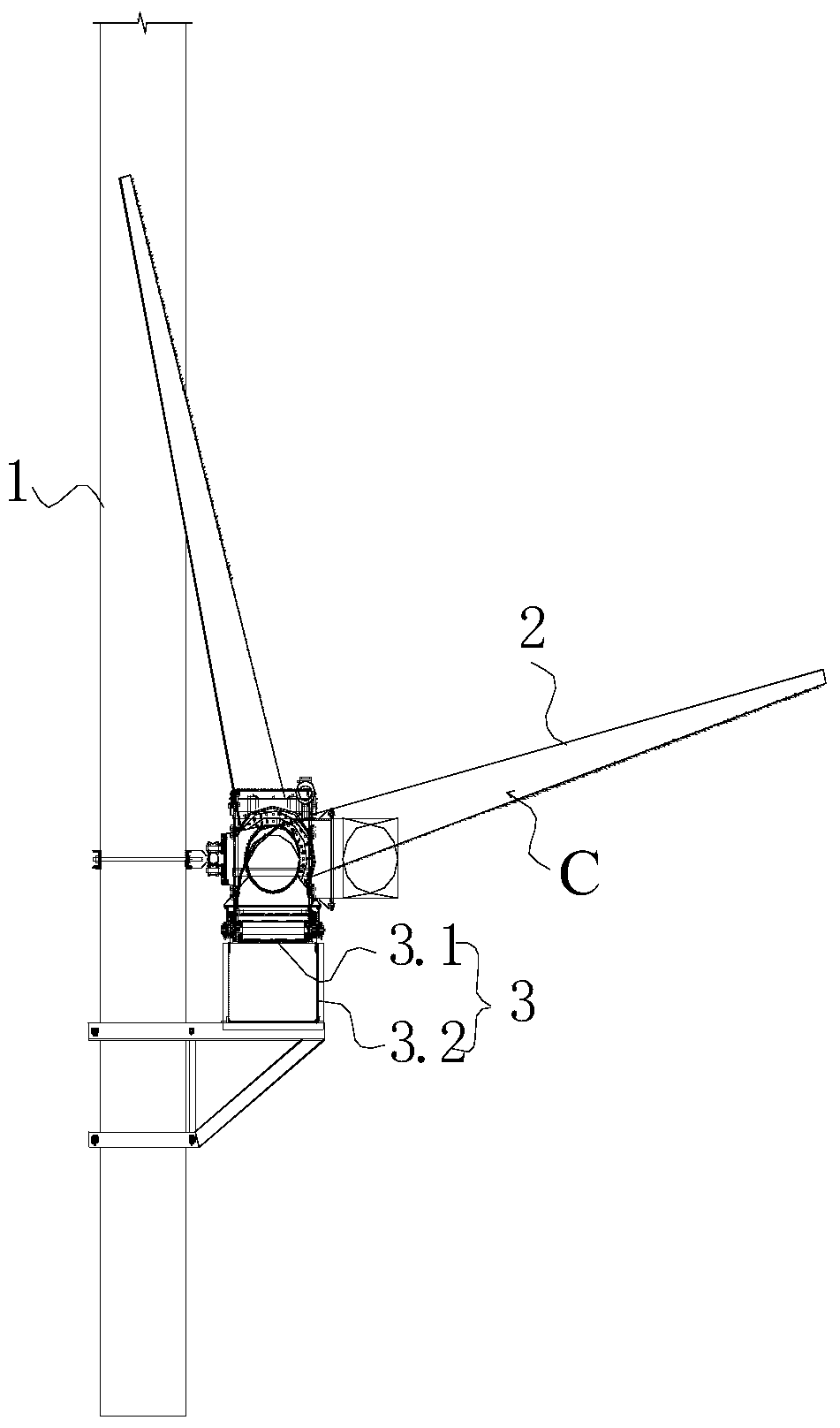

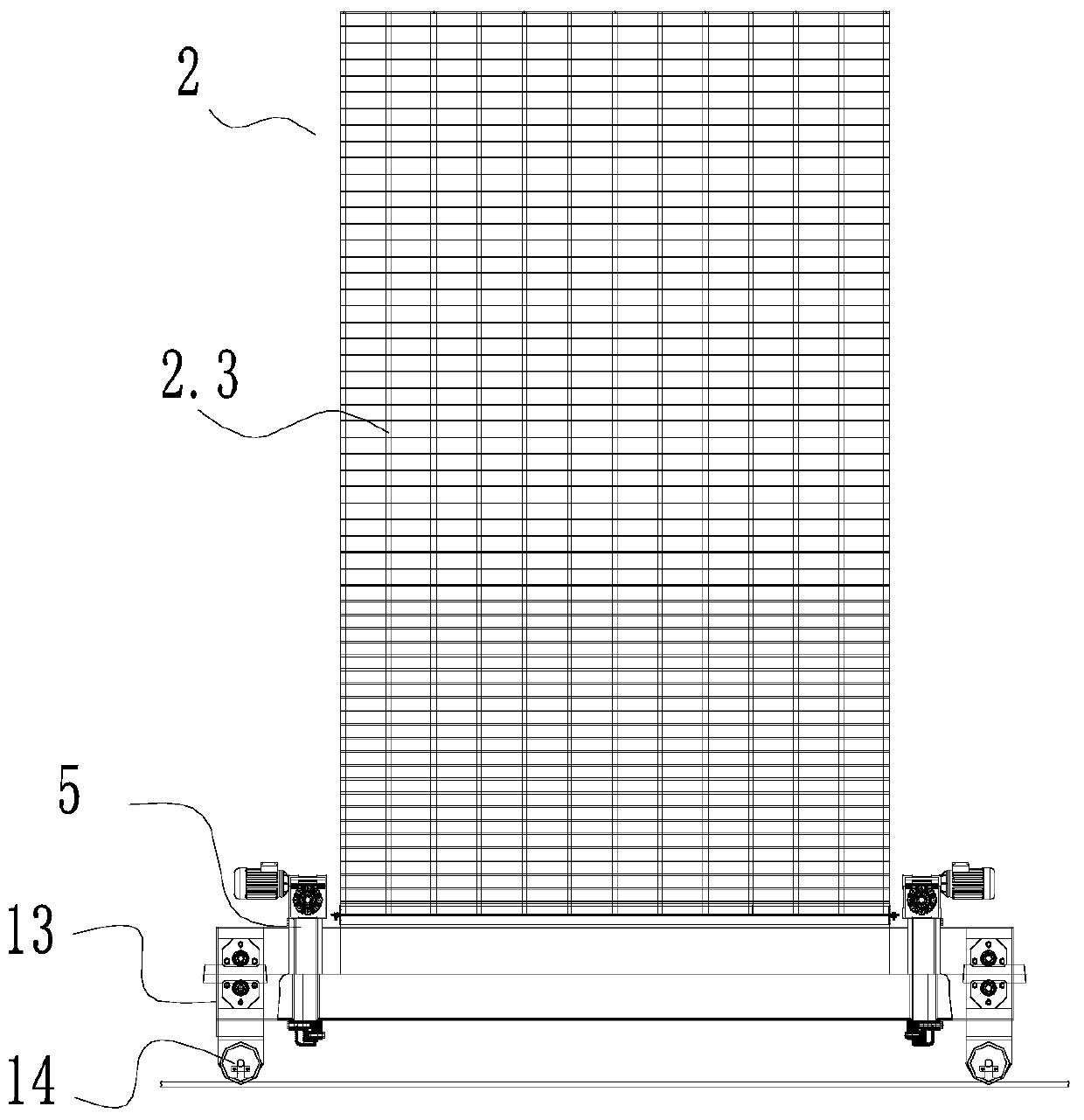

[0022] Such as Figure 1 to Figure 11 As shown, this embodiment relates to a mobile and rotating capture device for welding fume, including a smoke trap 2, a belt ventilation slot 3 and a ventilation trolley 4, and the belt ventilation slot 3 is equipped with an external negative pressure fan (not shown in the figure) , the belt ventilation groove 3 is composed of the ventilation groove body 3.1 and the sealing belt 3.2, the sealing belt 3.2 forms a detachable negative pressure seal on the ventilation groove body 3.1 under the action of the negative pressure fan; The connected transition chamber A, the smoke catcher 2 is set on the side of the ventilation trolley 4 and is driven by the ventilation trolley 4 to move back and forth along the belt ventilation groove 3 together with the ventilation trolley 4, the smoke collection chamber C of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com