Method for preparing tobacco-flavored flavoring substance and electronic cigarette liquid containing the tobacco flavoring substance

A technology for cigarette aroma and tobacco, which is applied in the field of electronic cigarettes, can solve problems such as the difference in smoking experience of cigarettes, and achieve the effects of improving quality, simple device and complete capture.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

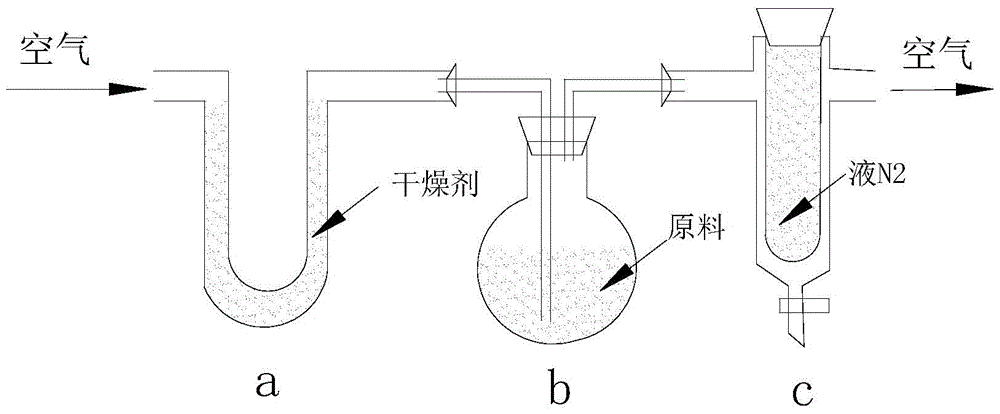

[0019] figure 1 It is a schematic diagram of the dry distillation-condensation trapping device of the present invention, the tobacco raw material is heated in the dry distillation bottle b to produce aroma components, the air passes through the drying device a and then passes into the dry distillation bottle b, and carries the aroma components into the condensation device c for condensation and capture set.

[0020] Take 30g of flue-cured tobacco shreds, spray 15g of propylene glycol on its surface, let it stand still, after the atomizer completely infiltrates the base material, place it in figure 1 In the dry distillation-condensation and trapping device, the dry distillation is carried out at 200° C., and air is blown in for purging. After the dry distillation is completed, the condensate in the condensing device is collected to obtain tobacco aroma.

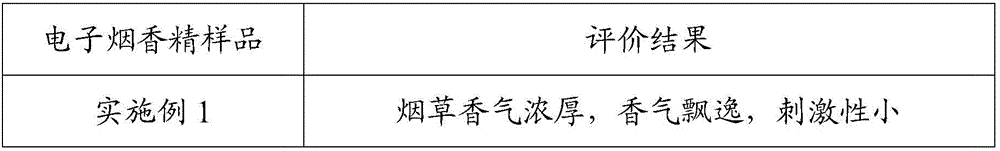

[0021] Tobacco aroma, tobacco extract, essence and solvent propylene glycol, glycerin are mixed to obtain e-cigarette flavo...

Embodiment 2

[0023] Take 20g shredded air-cured tobacco and 20g shredded flue-cured tobacco, spray 20g propylene glycol on the surface, and let it stand still. After the atomizer completely infiltrates the base material, place figure 1 In the dry distillation-condensation trapping device, dry distillation is carried out at 250° C., and air is blown in for purging. After dry distillation, the condensate in the condensation device is collected to obtain cigarettes.

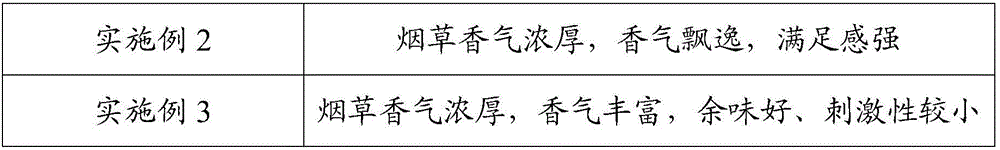

[0024] Tobacco incense, tobacco extract, flavor and solvent propylene glycol, glycerin are mixed to obtain electronic cigarette flavor, and the quality composition of each component is: 1.5% of red sun-cured tobacco reactant, 0.5% of Zimbabwean tobacco leaf extract, 1% of ethyl maltol, Di(H) ethyl ionone 1%, cigarette aroma 1%, nicotine 2%, glycerin 20%, propylene glycol 73%.

Embodiment 3

[0026] Get 30g flue-cured tobacco shredded tobacco, first spray the glycoside compound aroma precursor solution on its surface, the glycoside compound quality in the solution is 0.15g, then spray 15g propylene glycol on its surface, let it stand, until the atomizer is completely infiltrated After the primer, place the figure 1 In the dry distillation-condensation and trapping device, the dry distillation is carried out at 200° C., and air is blown in for purging. After the dry distillation is completed, the condensate in the condensing device is collected to obtain tobacco aroma.

[0027] Tobacco aroma, tobacco extract, flavor and solvent propylene glycol, glycerin are mixed to obtain electronic cigarette flavor, and the quality composition of each component is: red sun-cured tobacco reactant 0.5%, Zimbabwean tobacco leaf extract 1%, ethyl maltol 0.5%, Di(H) ethyl ionone 1%, cigarette aroma 1%, nicotine 1%, glycerin 25%, propylene glycol 70%.

[0028] Take 1ml of the above-me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com