Foam mercury trap material and application thereof

A foam material and foam technology, applied in the field of foam mercury trapping materials, can solve the problems of complex preparation process, weak material coating, short service life, etc., and achieve the effect of simple preparation process, low cost and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Take 1g of chloroauric acid and put it in a 500mL beaker, add deionized water to make 0.01mol / L chloroauric acid aqueous solution. Get 5g nickel foam and soak it with acetone for 15 minutes, wash it with deionized water, put it in a 500mL beaker after drying, add the above-mentioned aqueous chloroauric acid solution prepared above, the quality of foam nickel and the aqueous chloroauric acid ratio are 1g: 20mL, The two carry out a chemical reaction, gold is deposited on the surface of nickel foam, and the reacted foam nickel is taken out and washed with deionized water, and dried to obtain a gold-loaded foam nickel mercury trapping material, and 0.5g of the obtained material is put into the mercury trapping tube in spare.

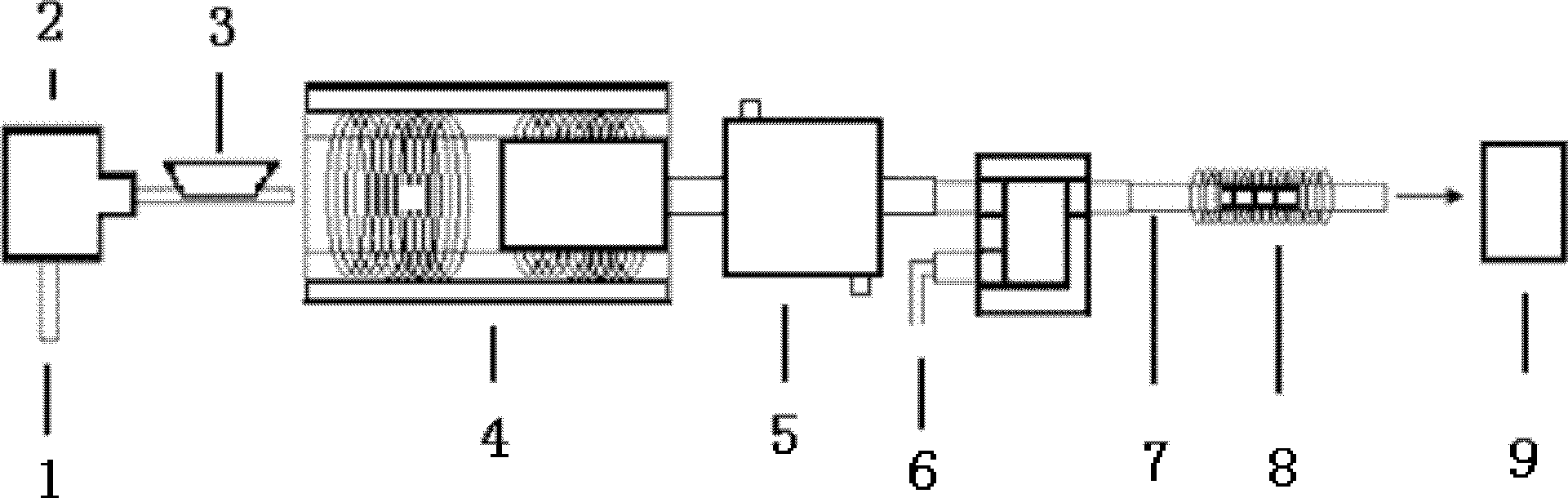

[0023] Process such as figure 1 , take 100mg soil sample and put it into the sampling boat 3, send it into the combustion furnace 4 by the sampling mechanism 2 (for sending the sampling boat into the combustion furnace), and in the combustion furnace...

Embodiment 2

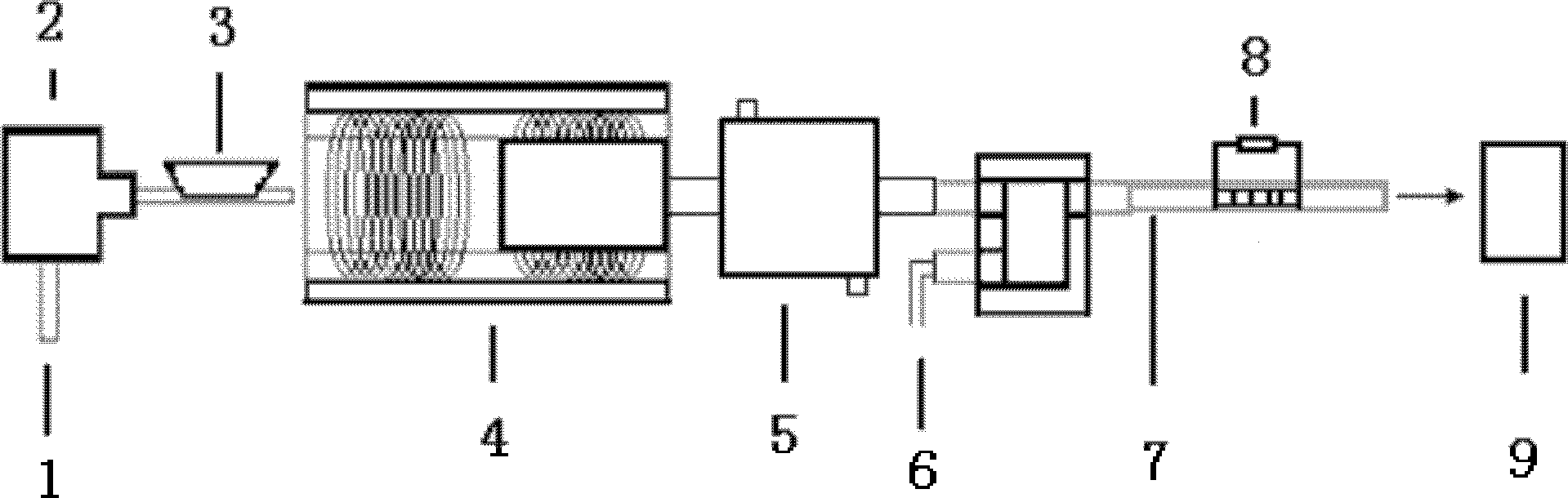

[0028] The heating method of the mercury-catching material adopts a self-heating method, and the rest of the process is the same as in Example 1. After the mercury-catching material captures mercury, a voltage is applied to the mercury-catching tube 7 with a low-voltage direct current power supply 8, and the mercury-catching material itself generates heat to complete the release of mercury, and finally Detected by an atomic fluorescence photometer 9, the process is as follows figure 2 .

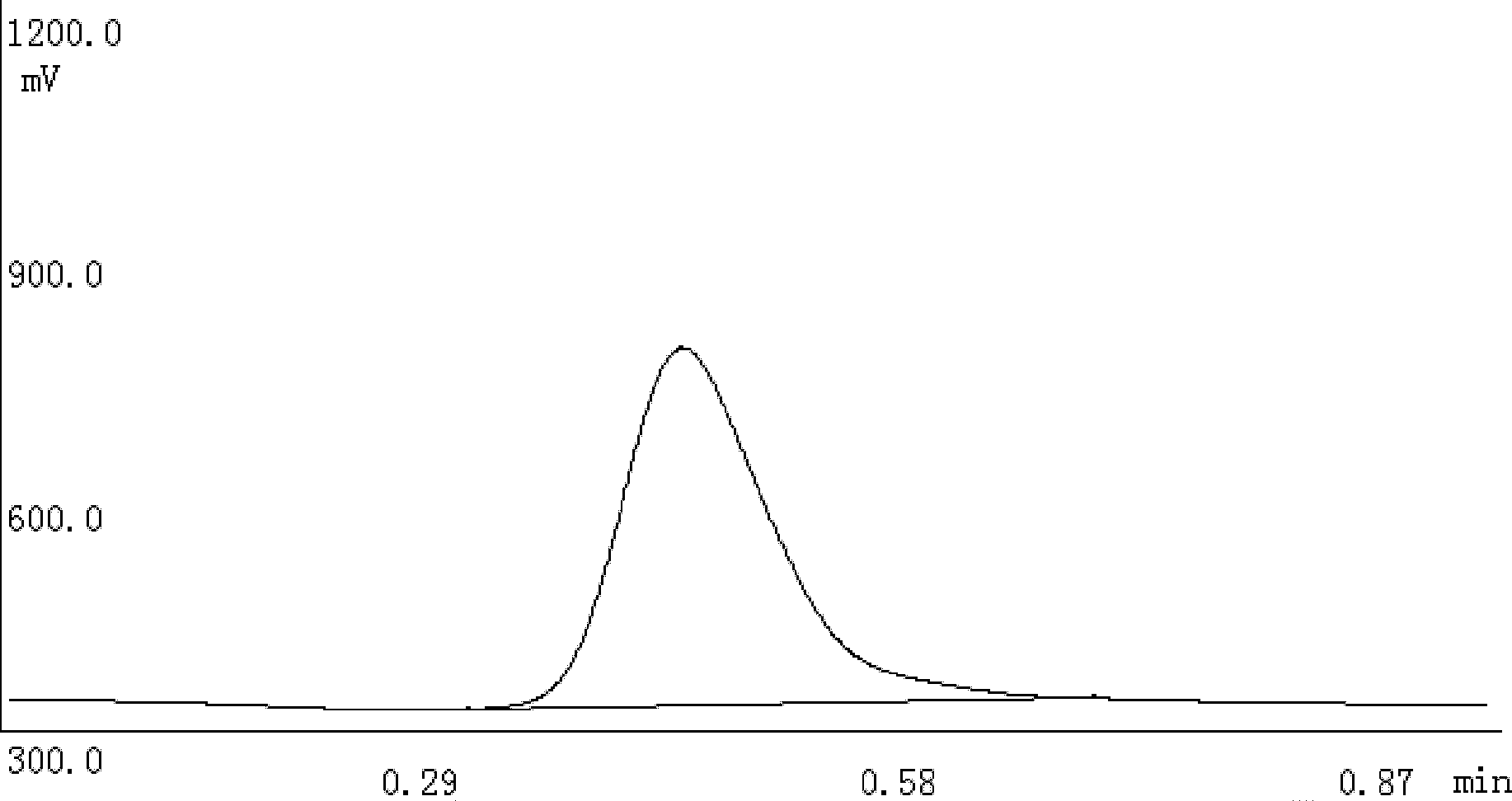

[0029] The mercury release spectrum obtained in the experiment is as follows Figure 4 As shown, it is quantified by the integral area, and the specific test indicators are shown in Table 2:

[0030] Table 2 Mercury release test index of gold-loaded nickel foam mercury capture material (mercury capture material self-heating)

[0031]

Embodiment 3

[0033] Take 1g of silver nitrate and place it in a 500mL beaker, add deionized water to make a 0.1mol / L silver nitrate aqueous solution. Take 5g of foamed tungsten soaked in acetone for 15 minutes, wash it with deionized water, put it in a 500mL beaker after drying, add the silver nitrate aqueous solution prepared above, the ratio of foamed tungsten to silver nitrate aqueous solution is 1g: 40mL, the two Carry out a chemical reaction, silver is deposited on the surface of foamed tungsten, and the reacted foamed tungsten is taken out and washed with deionized water, and after drying, a silver-loaded foamed tungsten mercury trapping material is obtained, and 0.5g of the obtained material is put into a mercury trapping tube for later use .

[0034] Concrete application in measuring mercury is the same as embodiment 1, and test index is as table 3:

[0035] Table 3 Mercury release test index of loaded silver foam tungsten mercury capture material (resistance wire heating)

[003...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com