Flexible transparent conductive film and flexible functional element using the same

A technology of transparent conductive film and transparent conductive layer, applied in electrical components, conductive materials dispersed in non-conductive inorganic materials, electric solid devices, etc., can solve the problem of poor conductivity stability, vulnerability to environmental changes, degradation of transparent conductive layer, etc. problem, to achieve the effect of excellent flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0116] 36 g of granular ITO microparticles (trade name: SUFP-HX, manufactured by Sumitomo Metal Mining Co., Ltd.) with an average particle diameter of 0.03 μm were mixed with 24 g of methyl isobutyl ketone (MIBK) and 36 g of cyclohexanone as solvents to perform dispersion treatment. Then, add 3.8 g of urethane acrylate UV-curable resin adhesive containing hydroxyl group, 0.2 g of photoinitiator (Daroquia-1173), and a small amount of silane coupling agent, stir well, and obtain a dispersant with an average dispersed particle diameter of 125 nm. A coating solution (liquid A) for forming a transparent conductive layer of ITO microparticles. In addition, the weight ratio of conductive oxide fine particles (ITO fine particles):binder component (resin binder+photopolymerization initiator) was 90:10.

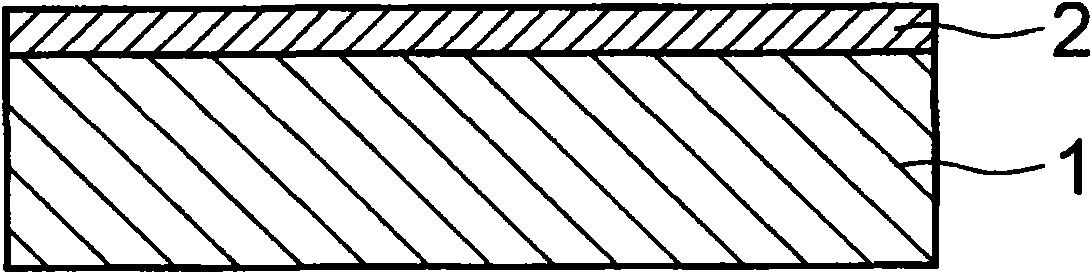

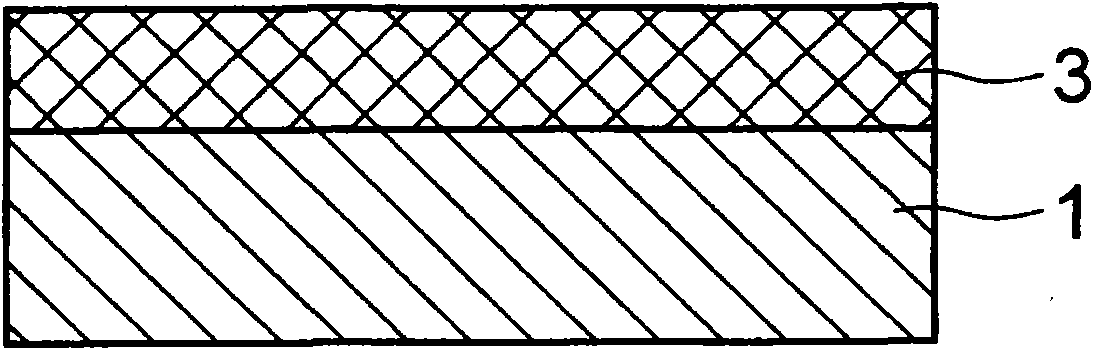

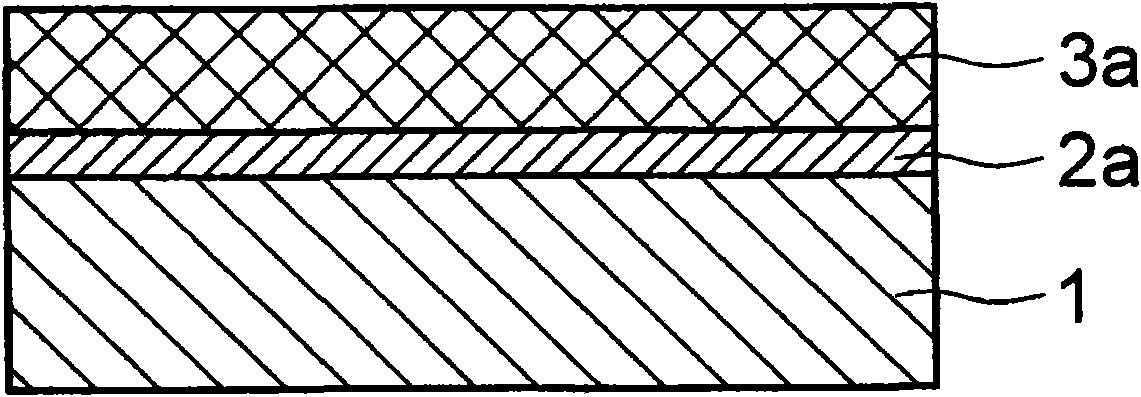

[0117] A low heat-shrinkable PET film (thickness: about 100 μm, transmittance = 89.8%, haze value = 1.9%) is subjected to corona discharge treatment as a base film, and then amorphous ...

Embodiment 2

[0132] 40 g of the same ITO microparticles as in Example 1 were mixed with 40 g of isophorone as a solvent, a small amount of dispersant was added, and dispersion treatment was performed using a paint shaker to obtain an ITO microparticle dispersion. To 40 g of this ITO microparticle dispersion liquid, add a crosslinkable acrylic polyol resin binder containing a hydroxyl group (glass transition temperature (Tg) of the resin before crosslinking: 102° C., a hydroxyl value of 29 KOHmg / g) 4.48 g resin solution dissolved in 17.14 g of isophorone, HDI-based blocked isocyanate as a curing agent (MF-K60X, solid content [curing agent component] about 60%, minimum curing temperature 90°C, NCO: 6.5 wt%, Asahi Kasei Co., Ltd.) 0.88 g and a trace amount of silane coupling agent were stirred well to obtain a transparent conductive layer-forming coating solution (B solution) in which ITO fine particles with an average dispersed particle diameter of 120 nm were dispersed. In addition, the wei...

Embodiment 3

[0139] Adopt granular ITO microparticles with an average particle diameter of 0.04 μm (trade name: FS-21, manufactured by Dowa Mining Co., Ltd.) to replace the ITO microparticles of Example 1, add isophorone and a small amount of dispersant, and carry out dispersion treatment to obtain ITO microparticles. Except for the dispersion liquid, it carried out similarly to Example 2, and obtained the coating liquid (C liquid) for transparent conductive layer formation which disperse|distributed the ITO microparticles|fine-particles of average dispersion particle diameter of 135 nm. In addition, the weight ratio of conductive oxide fine particles (ITO fine particles): binder component (resin binder + curing agent) was 80:20, and the molar ratio of NCO (isocyanate group) / OH (hydroxyl group) was 0.59.

[0140] Except for using the above-mentioned transparent conductive layer forming coating solution (C liquid) instead of B liquid, the same operation was carried out as in Example 2 to obt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com