Preparation method of cellulose acetate reverse osmosis membrane surface-modified by quaternary ammonium salt

A cellulose acetate membrane and cellulose acetate technology, applied in the direction of reverse osmosis, semi-permeable membrane separation, chemical instruments and methods, etc., can solve the problems of membrane performance deterioration, achieve low operating pressure, good application prospects, and wide application field effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

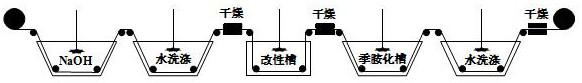

Embodiment 1

[0022] After soaking the cellulose acetate film in the aqueous phase dissolved with sodium hydroxide, immerse in the water washing tank, wash until the pH is 7.0, and then enter the modification tank after drying. The solvent in the modification tank is n-hexane, and the solute It is 4-chloromethylbenzoyl chloride, the concentration of the acid chloride solute is 0.3mol / L, it is dried after being replaced by a functional group, and then enters the quaternization tank to modify the surface of the membrane with a quaternary ammonium salt, and the quaternization The amine substance solution is housed in the tank, and then immersed in a water washing tank, the inside of the water washing tank is filled with water, and dried after washing to obtain a cellulose acetate reverse osmosis membrane modified on the surface of a quaternary ammonium salt, and the weight percentage of the amine substance is 10% solution of trialkylamine N-235, average desalination rate 94.11%, water flux 19.9...

Embodiment 2

[0024] After the cellulose acetate membrane is soaked in the water phase dissolved with sodium hydroxide, the concentration of sodium hydroxide is 0.5mol / L, then immersed in the water washing tank, washed until the pH is 6.8, and then dried and then entered into the modification tank. The solvent in the chemical tank is n-hexane, and the solute is 4-chloromethylbenzoyl chloride with a concentration of 0.1mol / L. After being replaced by a functional group, it is dried, and then enters the quaternization tank to modify the surface of the membrane with a quaternary ammonium salt. The quaternization tank is equipped with a solution of 10% trimethylamine with a concentration of 10% by weight, and then immersed in a water washing tank. The water washing tank is filled with water, dried after washing, and obtained acetic acid modified on the surface of the quaternary ammonium salt. Cellulose reverse osmosis membrane, resulting in an average desalination rate of 93.73% and a water flux ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com