Method for preparing heat-insulation materials from nano-silica filled non-graphitized carbon foam

A nano-silica, non-graphitization technology, which is applied in the field of nano-silica filled non-graphitized foam carbon to prepare thermal insulation materials, can solve the problems of inability to be used in independent blocks, poor mechanical properties of aerogels, etc. Heat convection effect, improved thermal insulation, improved full permeability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

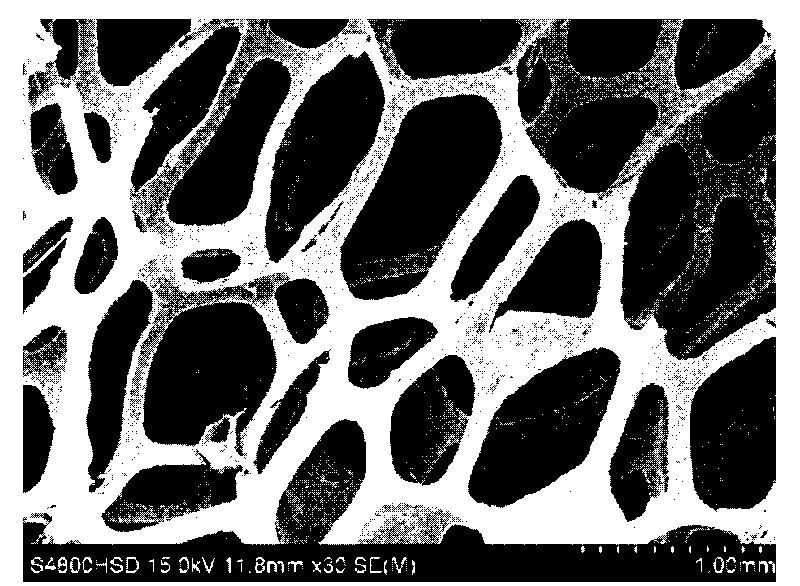

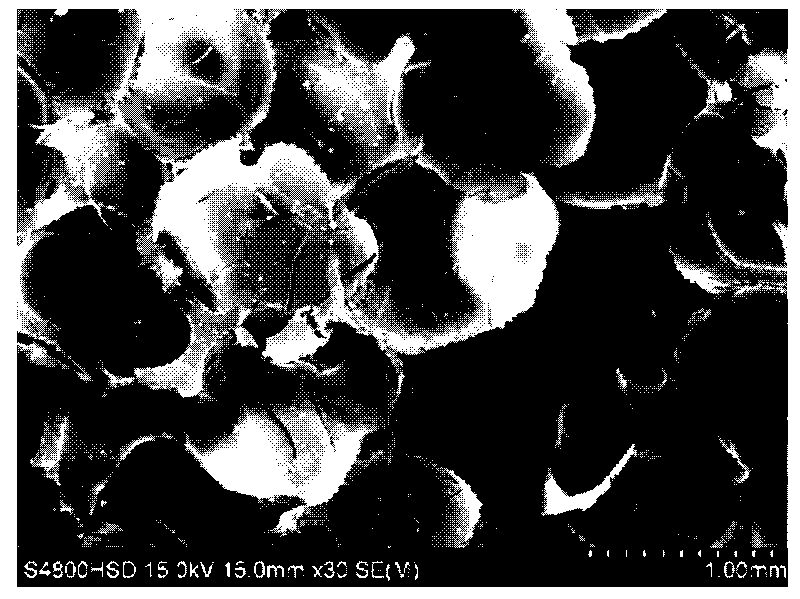

[0008] Specific embodiment 1: In this embodiment, the method for preparing heat insulating material by filling non-graphitized foam carbon with nano-silica is as follows: 1. Stir and mix ethyl orthosilicate, deionized water and absolute ethanol for 10 minutes to 15 minutes to obtain Mixture, then heat the mixture to 50°C~55°C with a water bath, then add hydrochloric acid with a concentration of 0.2mol / L~0.3mol / L to continue the reaction at 50°C~55°C for 10min~15min, then drop to room temperature , then add ammonia water with a volume concentration of 98%, and react for 10min to 15min to obtain the alcohol gel; 2. Soak the alcohol gel in the aging solution for 6 hours to 10 hours at a temperature of 50°C to 55°C, and then Wash with deionized water for 10 minutes; 3. Repeat the process of step 2 3 to 4 times to obtain SiO 2 Sol-gel; 4. Immersing non-graphitizable foam carbon in SiO 2 4-6 hours in sol-gel, SiO 2 The surface of the sol-gel liquid is covered with non-graphitizabl...

specific Embodiment approach 2

[0011] Embodiment 2: This embodiment differs from Embodiment 1 in that the average pore diameter of the non-graphitizable foamed carbon described in Step 3 is 500 μm-600 μm. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0012] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that in step 1, the temperature of the mixture is heated to 51°C-54°C. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com