Low-alkalinity anti-crack mortar fiber reinforced foam cement heat-preserving plate

A foamed cement, fiber reinforced technology, applied in the direction of heat preservation, hydraulic material layered products, building components, etc., can solve the problems of cracking of the reinforcement layer, low thermal conductivity, low tensile strength, etc., to increase the service life. , excellent mechanical properties, the effect of increased flexural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] A method for preparing a low-alkalinity anti-cracking mortar fiber reinforced foamed cement insulation board, the preparation steps are as follows:

[0041] (1) prepare foamed cement insulation board;

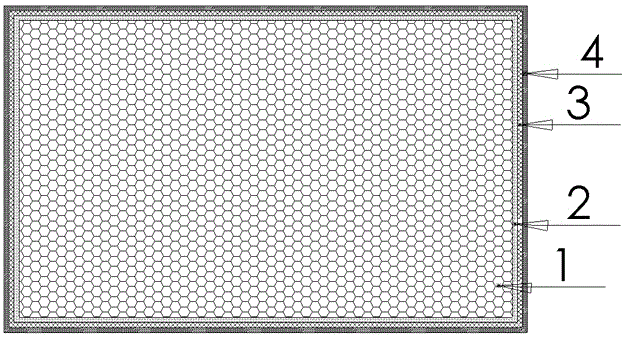

[0042](2) Apply an alkali-resistant sealing layer on the upper and lower surfaces of the foamed cement insulation board and its surroundings by spraying, roller coating, dipping or scraping, and leave it for 1-2 hours to dry.

[0043] (3) paste glass fiber mesh cloth on the upper and lower surfaces of the foamed cement insulation board coated with alkali-resistant sealing layer;

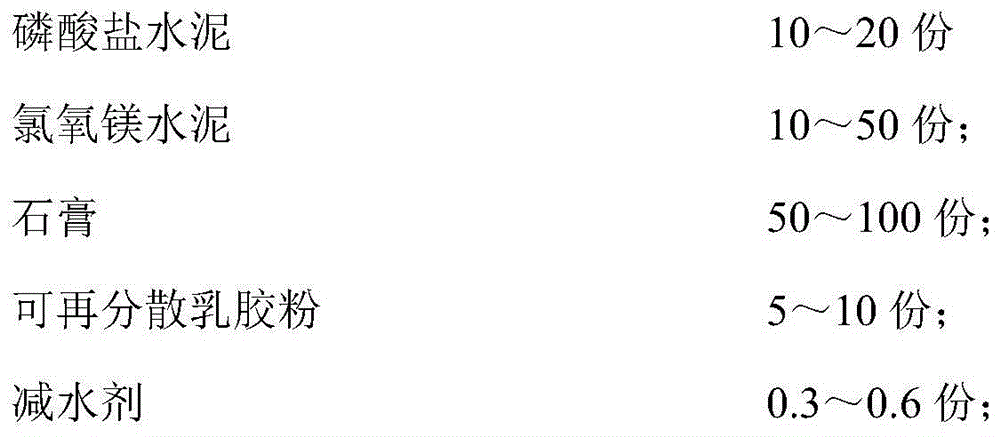

[0044] (4) Preparation of low-alkalinity anti-cracking mortar: mix magnesium oxychloride cement, gypsum, dispersible latex powder, and water reducer evenly according to the mass ratio, then add water and stir to make low-alkalinity anti-cracking glue pulp;

[0045] (5) Apply the low-alkalinity anti-cracking mortar to the upper and lower surfaces and / or four sides of the foamed cement insulati...

Embodiment 1

[0052] A method for preparing a low-alkalinity anti-cracking mortar fiber reinforced foamed cement insulation board, the preparation steps are as follows:

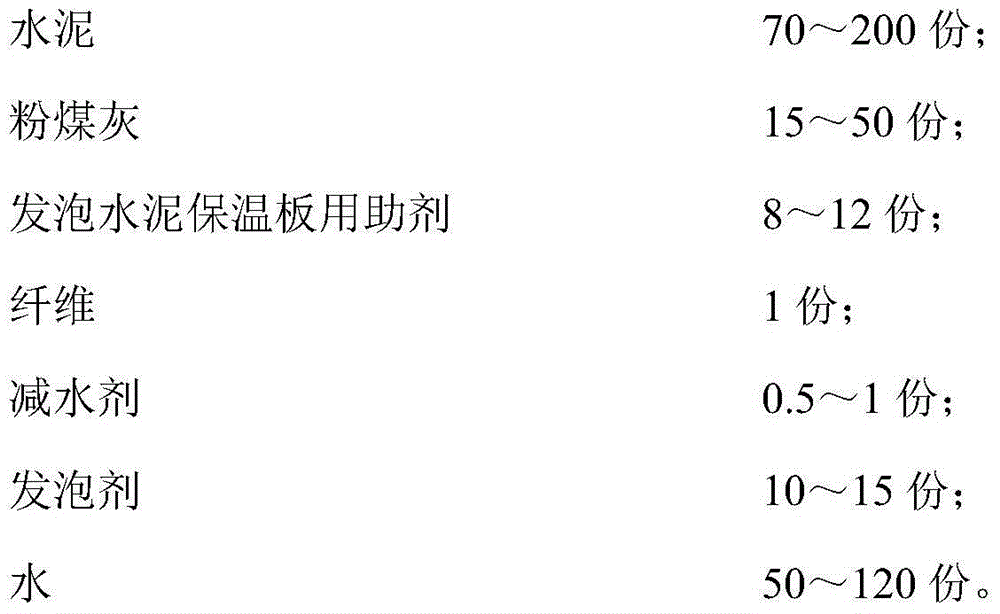

[0053] (1) Preparation of foamed cement insulation board: a. According to 80 parts of ordinary portland cement, 20 parts of fly ash, 8 parts of additives for foamed cement insulation board, 0.8 part of water reducing agent, 1 part of fiber, water 50 parts and 6 parts of foaming agent are weighed in the ratio of each component; b. Add water, water reducer, additives for foamed cement insulation boards, and fibers into the mixer and stir for 15 seconds, then add cement and pulverized coal Stir the ash for 3 minutes, then add foaming agent and stir for 6 seconds to make a slurry; c. Immediately release the slurry from the mixer into the mold. After 12 hours of hydration, the foamed cement slurry will finally set and have a certain After strength, it is demoulded, and after demoulding, it is cured under natural conditions for ...

Embodiment 2

[0059] A method for preparing a low-alkalinity anti-cracking mortar fiber reinforced foamed cement insulation board, the preparation steps are as follows:

[0060] (1) Preparation of foamed cement insulation board: a. According to 100 parts of ordinary Portland cement, 25 parts of fly ash, 10 parts of additives for foamed cement insulation board, 1 part of water reducer, 1 part of fiber, water 60 parts and 8 parts of foaming agent are weighed in the ratio of each component; b. Add water, water reducer, additives for foamed cement insulation board, and fiber into the mixer and stir for 15 seconds, then add cement and pulverized coal Stir the ash for 3 minutes, then add foaming agent and stir for 6 seconds to make a slurry; c. Immediately release the slurry from the mixer into the mold. After 12 hours of hydration, the foamed cement slurry will finally set and have a certain After strength, it is demoulded, and after demoulding, it is cured under natural conditions for 1 day to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com