Cold-resistant and crack-resistant low-smoke, halogen-free and fire-retardant polyolefin sheath material with thermoplasticity and preparation method thereof

A polyolefin sheathed, low-smoke flame-retardant technology, used in plastic/resin/wax insulators, organic insulators, electrical components, etc., can solve the problem of low oxygen index, poor low temperature resistance and crack resistance, and low processing efficiency. problem, to achieve the effect of improving high tensile strength, improving flame retardant performance and structural flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

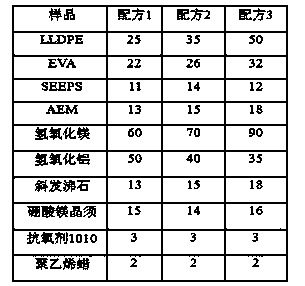

[0028] A thermoplastic cold-resistant, crack-resistant, halogen-free, low-smoke, flame-retardant polyolefin sheathing material is characterized in that it is prepared from the following components by weight:

[0029] 20~60 parts of linear low density polyethylene, 20~40 parts of ethylene-vinyl acetate copolymer, 10~20 parts of SEEPS, 10~20 parts of ethylene-acrylate copolymer, 50~100 parts of magnesium hydroxide, 20 parts of aluminum hydroxide ~50 parts, clinoptilolite 10~20 parts, magnesium borate whiskers 10~20 parts, antioxidant 1~5 parts, lubricant 2~6 parts, silane coupling agent 2~3 parts;

[0030] The antioxidants are tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl)propionic acid]pentaerythritol ester (antioxidant 1010), tri[2.4-di-tert-butylphenyl] One or more of phosphite (antioxidant 168), dilauryl thiodipropionate (antioxidant DLTP).

[0031] The lubricant is one or more of polyethylene wax, zinc stearate and polytetrafluoroethylene.

[0032] The vinyl acetate of th...

Embodiment 2

[0049] Three groups of formulas in Table 1 are prepared according to parts by weight. Then respectively according to the following steps: first quantitative magnesium borate whiskers, clinoptilolite and silane coupling agent are added to the high-speed mixer and mixed for 6min, and the stirring is stopped to obtain modified magnesium borate whiskers and clinoptilolite.

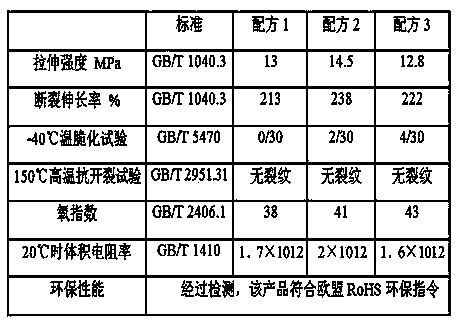

[0050] Mix the remaining components such as LLDPE in a high mixer at 80°C for 7 minutes to obtain a mixture. Then the mixture is extruded and granulated in a two-stage granulator, the temperature range of the upper stage barrel is 150~170°C, and the screw speed is about 130 rpm. The temperature range of the lower barrel is 130-150°C, and the screw speed is about 70 revolutions per minute to obtain a thermoplastic cold-resistant, crack-resistant, halogen-free, low-smoke, flame-retardant polyolefin sheath material. The main performance tests of each formulation of embodiment 2 are shown in Table 2.

[0051] Ta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com