Metal corrugated thin wall stuffing mold tube

A technology of metal bellows and tire molds, which is applied to building components, floor slabs, buildings, etc., can solve the problems of large consumption of reinforced concrete, poor anti-seismic performance, and self-heaviness, and achieve improved strength and rigidity, good strength and rigidity, and Make easy effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with drawings and embodiments.

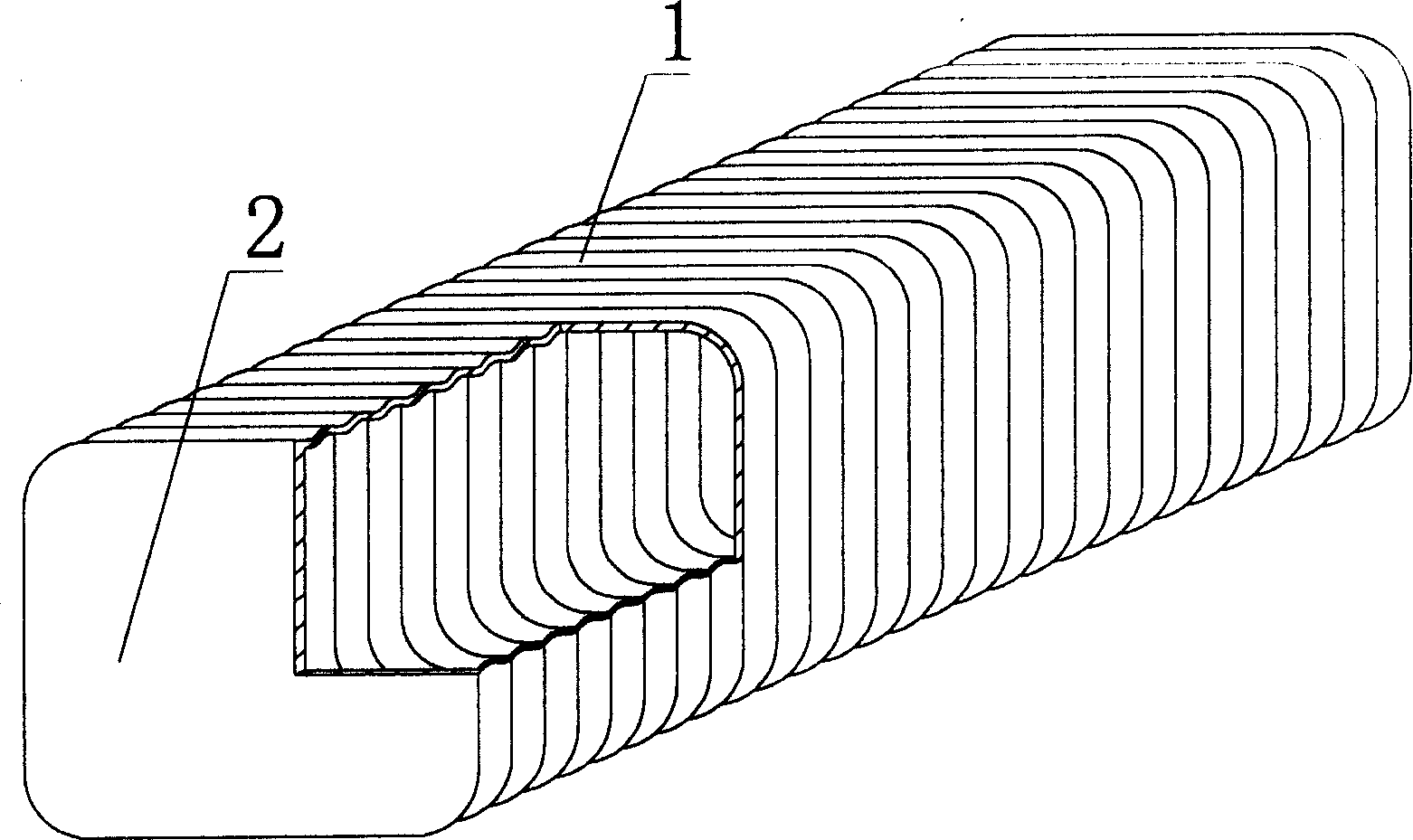

[0029] As shown in the accompanying drawings, the present invention includes a molded pipe 1 and a plug 2. The molded pipe 1 is a metal corrugated pipe, and its feature is that the cross-sectional shape of the molded pipe 1 is an arc-angled quadrilateral. figure 1 It is a structural schematic diagram of Embodiment 1 of the present invention. figure 1 Among them, 1 is a tire mold tube, and 2 is a plug. In each accompanying drawing, those with the same number have the same description. like figure 1 As shown, the cross-sectional shape of the tire mold tube 1 is a quadrilateral with arc angles.

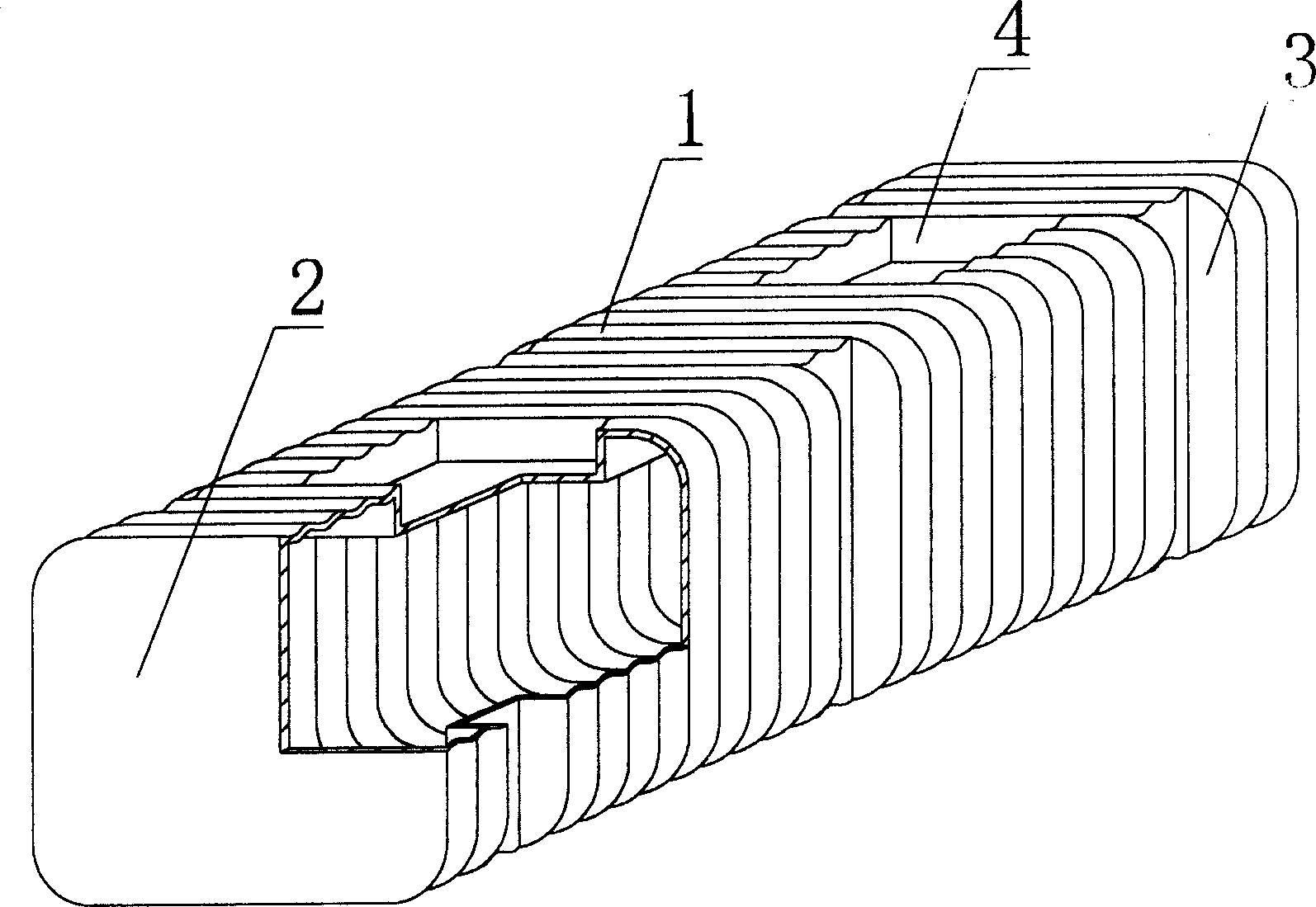

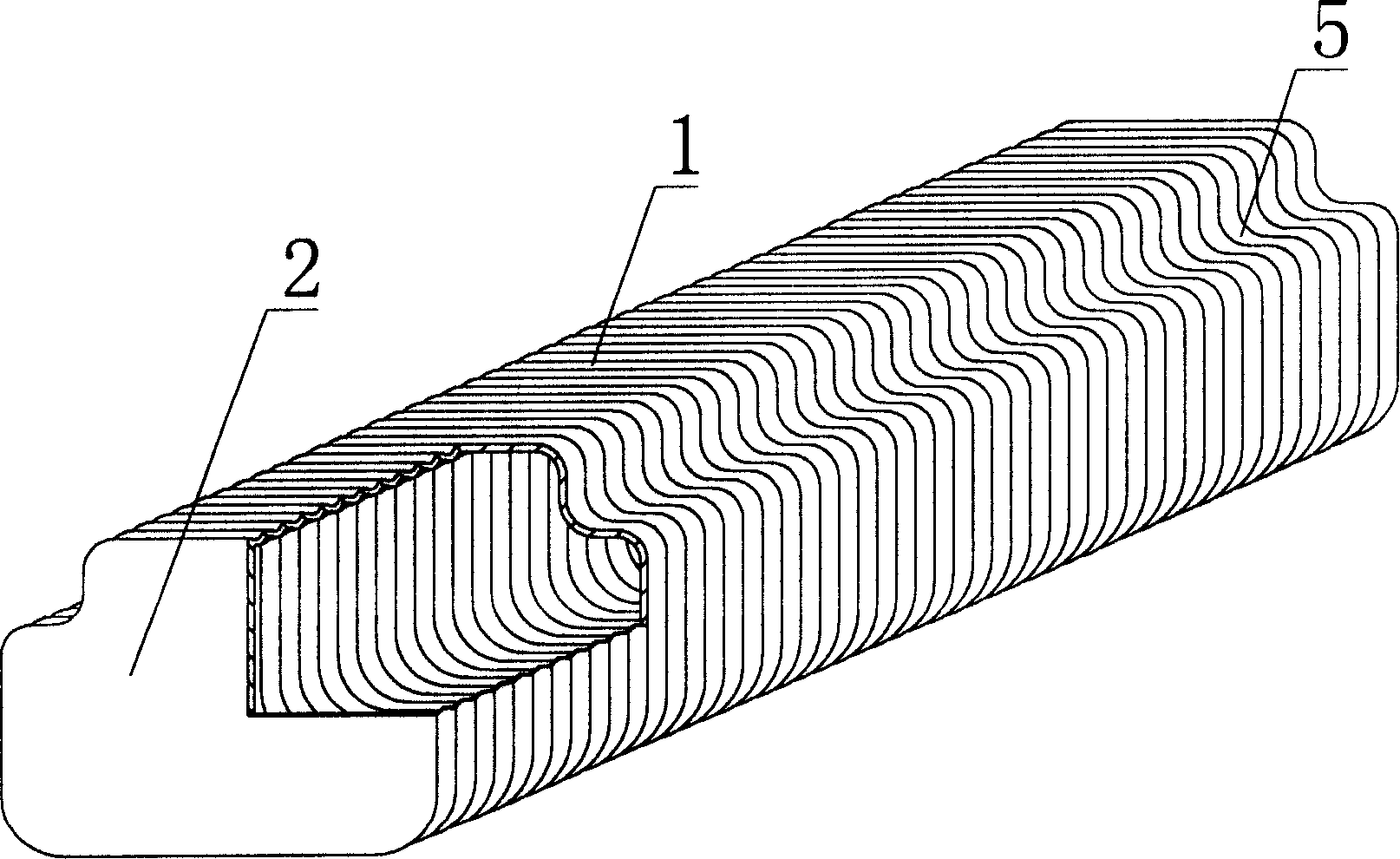

[0030] The present invention is also characterized in that the tire mold tube 1 is provided with at least one of a groove 3 , a cavity 4 or an inner corner 5 . figure 2 It is a structural schematic diagram of Example 2 of the present invention, and the tire mold tube 1 is prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com