Centering mechanism for hot melting of socket insertion type plastic pipe and pipe connecting sleeve

A centering mechanism and technology for plastic pipes, which are used in the connection of socket-type plastic pipes and connecting sleeves, and the field of centering mechanisms for hot-melting socket-type plastic pipes and connecting sleeves. Uniformity, easy deformation of pipes, etc., to achieve the effect of reliable connection, overcoming uneven connection strength, and relatively low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] Below in conjunction with accompanying drawing, the present invention will be further described:

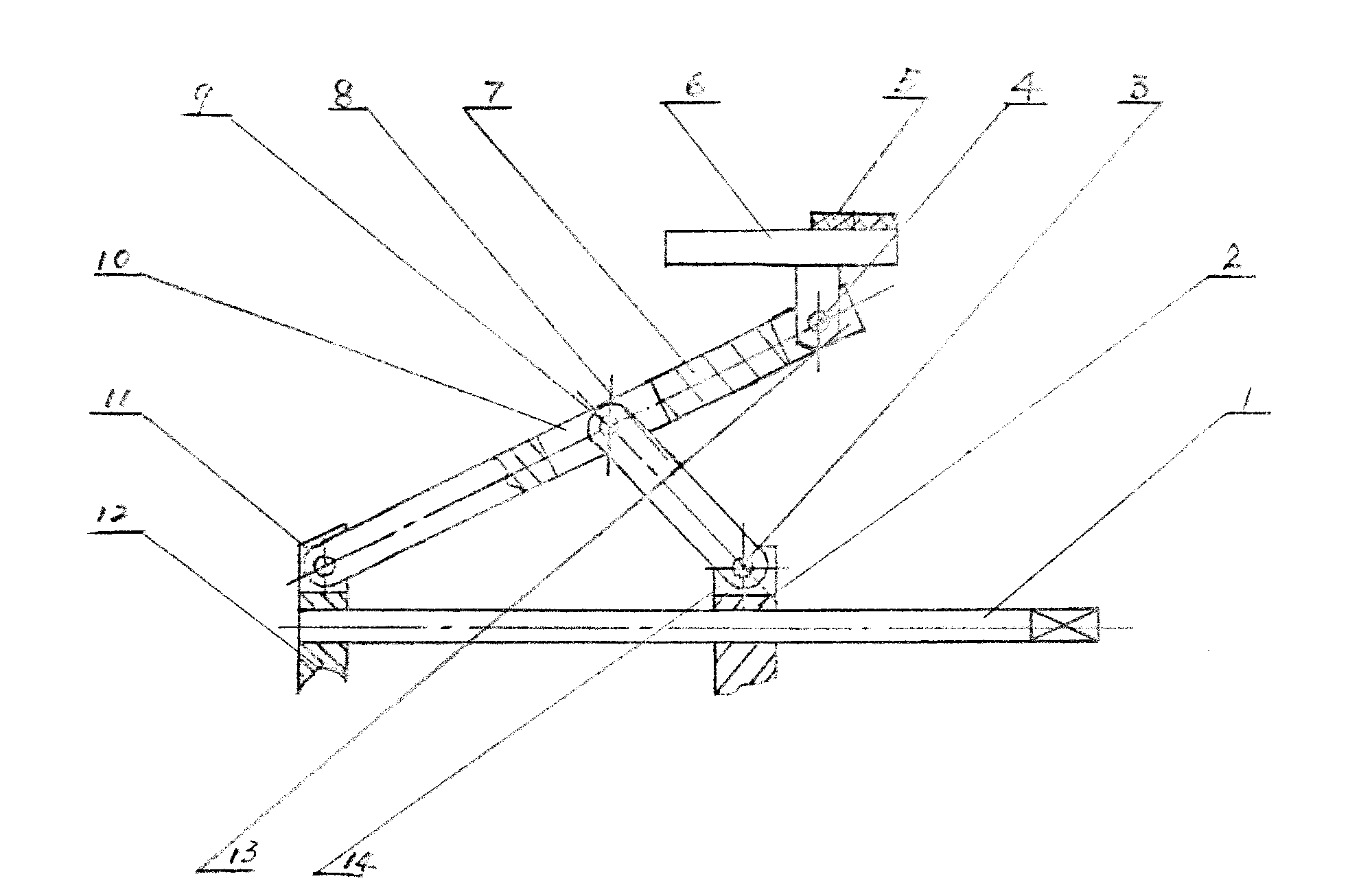

[0008] See attached figure 1 1. One end of the screw rod 1 is flexibly and fixedly connected with the umbrella head 12 which is evenly distributed with three umbrella bone grooves 11. The umbrella head 12 is flexibly connected with the umbrella rib 7 through the connecting pin 9. The screw sleeve 2 of the groove 14 is connected, and one end of the three rib supports 8 is fixed in the corresponding rib groove 10 by connecting pins 9 respectively, and the other ends of the three rib supports 8 are respectively fixed on the screw sleeve 2 by pins 3. In some umbrella rib installation grooves 14, centering claws 6 are respectively fixed in the centering claw grooves 13 at the tops of three umbrella ribs 7 by pins 4. The rear ends of the centering claws 6 are fixed with rubber pads 5. The end of the screw 1 is provided with a square head, and the screw 1 adopts a left-hand thre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com