Punchless rivetless connection device and method combined with multi-energy field

A punch-less, connecting device technology, which is applied in the field of plate connection, can solve problems such as cracking, low structural strength of riveted connection, and influence of processing joint strength and dimensional accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

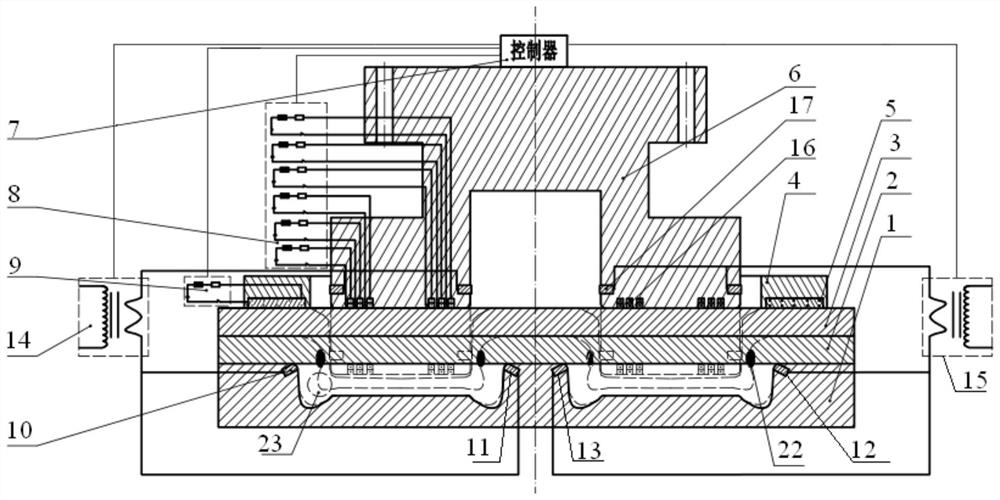

[0058] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

[0059] The present invention aims at the need to use a punch for the existing rivetless connection, and the punch will be worn after being used for many times. When the punch is worn to a certain extent, it will affect the strength and dimensional accuracy of the processed joint, and the structural strength of the rivetless connection It is not high, the stress state of the joint is unreasonable, there is stress concentration in the neck of the joint, and there are problems of cracking defects. A multi-energy field composite non-punching type rivetless connection device and method are provided.

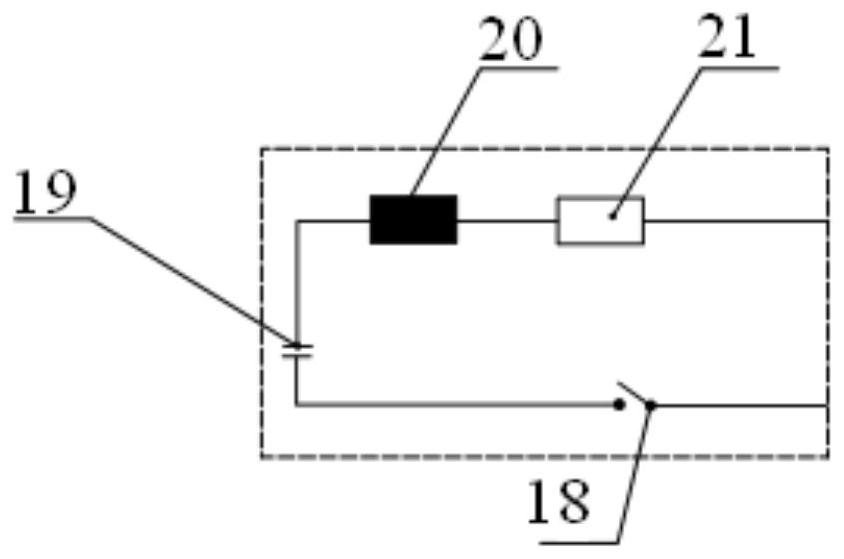

[0060] Such as Figure 1 to Figure 11 As shown, the embodiment of the present invention provides a multi-energy field composite punchless rivetless connection d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com