Improved structure of corrugated paperboard production line

A corrugated board and production line technology, applied in the direction of mechanical processing/deformation, etc., can solve the problems of unreachable carton, high humidity of the cardboard, affecting the compressive strength of the carton, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0010] detailed description: The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

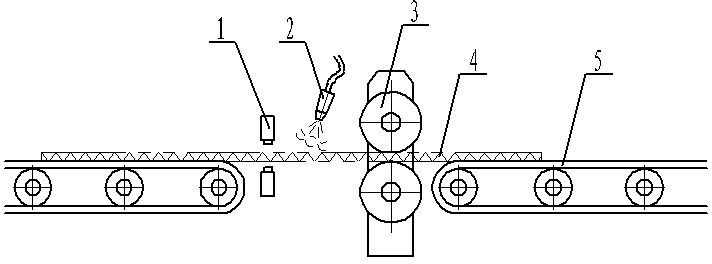

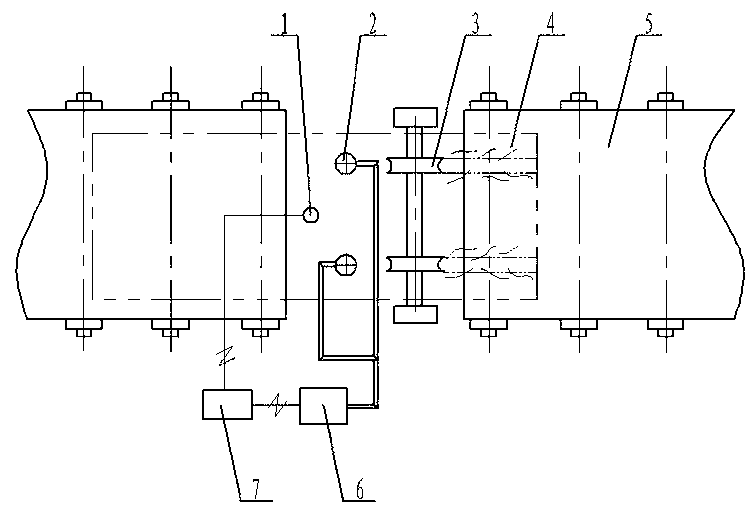

[0011] Such as figure 1 As shown: the creasing machine with two creasing wheels 3 is fixed between the two conveyor belts 5, and one of them is fixed on the frame at a position slightly higher than the conveyor belt 5 in front of the two creasing wheels 3 (in the figure Not shown) on the nozzle 2, each nozzle 2 communicates with the spray device 6 through a pipeline respectively; there is a photoelectric sensor 1 electrically connected with the controller 7 in front of the nozzle 2, and the controller 7 is electrically connected with the spray device 6.

[0012] Working principle: When the conveyor belt 5 drives the cardboard 4 to move to the position of the photoelectric sensor 1, the photoelectric sensor 1 sends a signal to the controller 7, and the controller then sends a signal to the solenoid valve (not shown in the figu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com