Preparation method of nano-silica compacted concrete

A nano-silica, dense concrete technology, applied in the field of concrete production, can solve the problems of low durability of high-performance concrete, increased self-shrinkage of concrete, easy cracking, etc., and achieves low porosity, good effect and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

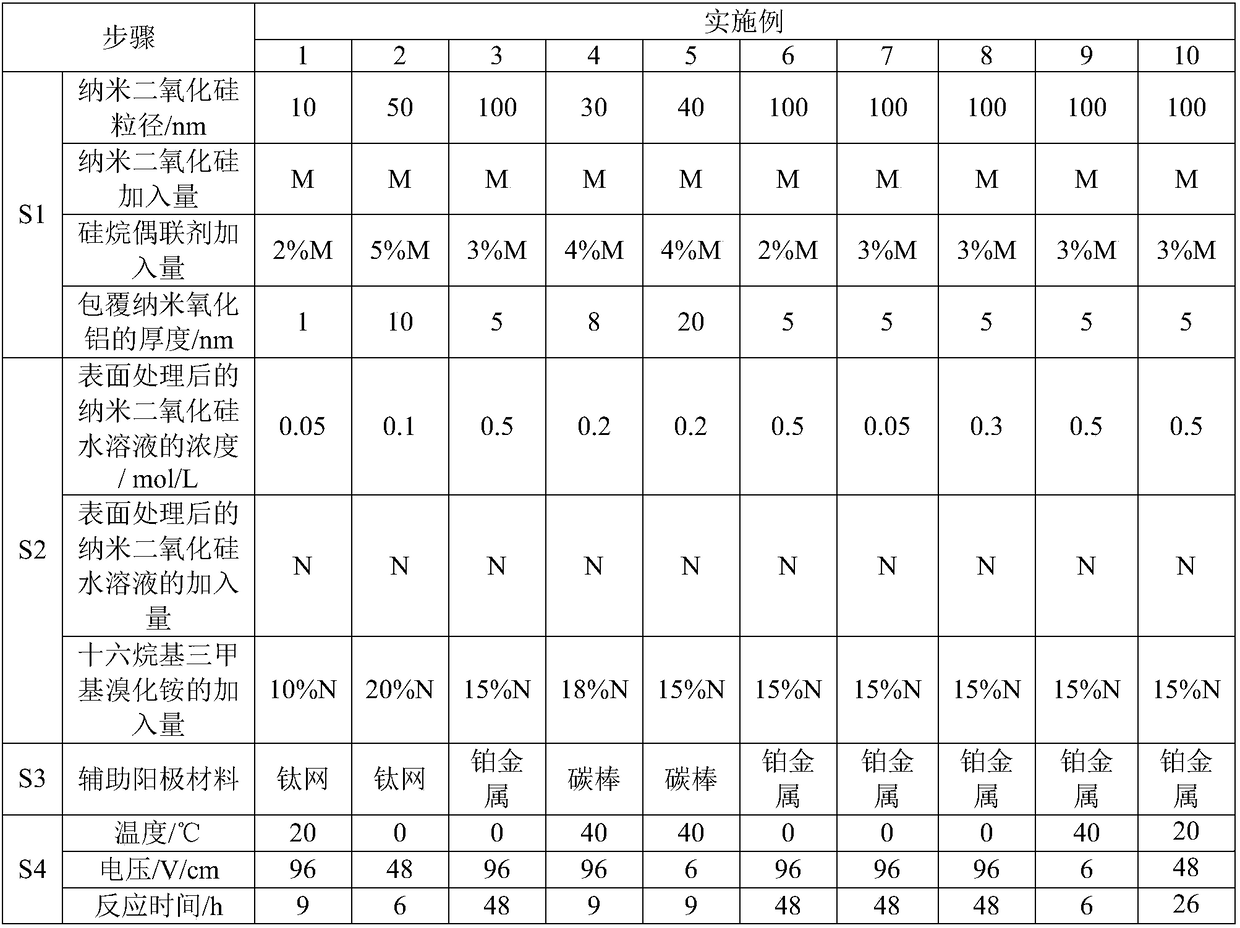

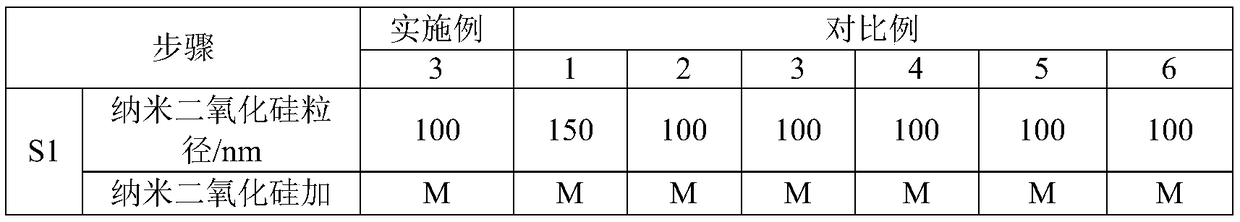

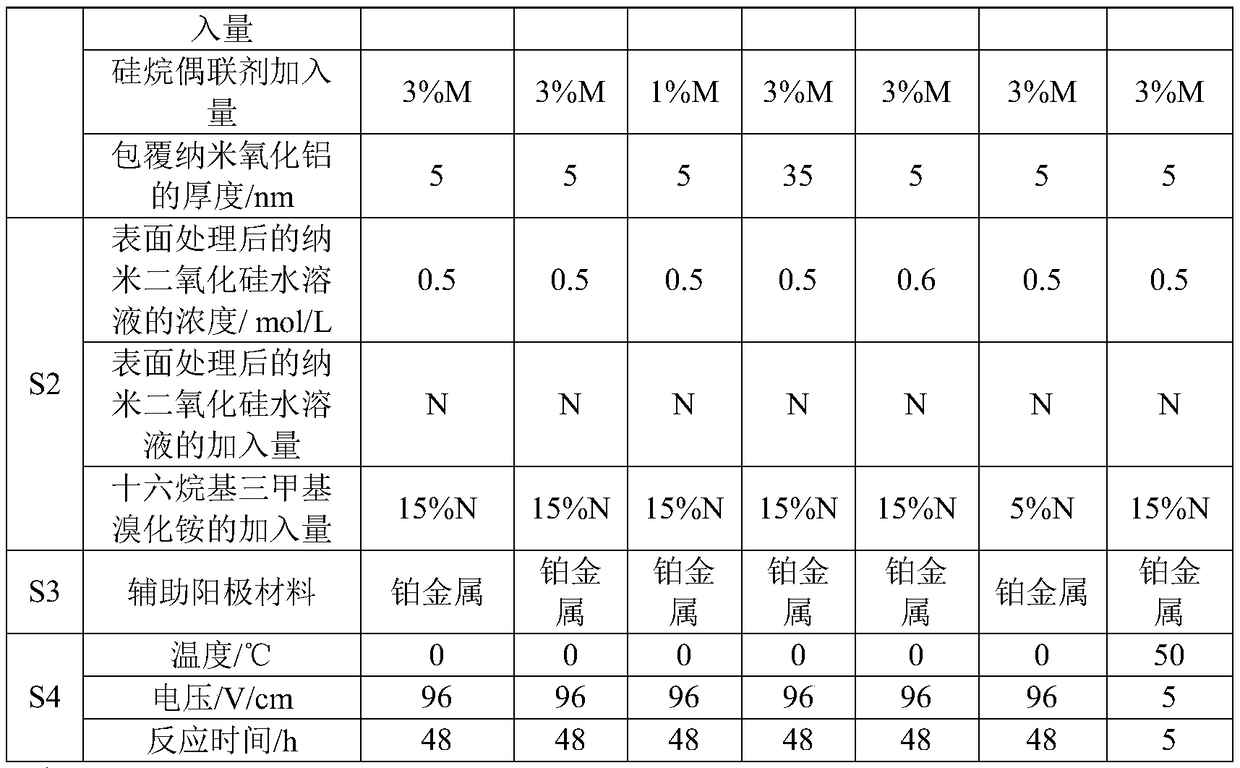

Embodiment 1~10

[0033] The preparation method of the nano-silica dense concrete described in Embodiment 1 to Embodiment 10 of the present invention is basically the same, specifically:

[0034] A preparation method of nano silicon dioxide dense concrete, comprising the following steps:

[0035] S1. Coating nano-alumina with a thickness of 1nm-20nm on the surface of nano-silicon dioxide with an average particle size of 10nm-100nm to obtain surface-treated nano-silicon dioxide; specifically:

[0036] S101. Coating a layer of nano-alumina with a thickness of 1nm-20nm on the surface of nano-silica with an average particle size of 10nm-100nm and a mass of M by using a mechanical ball milling method;

[0037] S102. Add 2%M-5%M silane coupling agent to the mixture prepared in step S101 for surface modification, so as to obtain surface-treated nano silicon dioxide.

[0038] S2. Take the surface-treated nano-silicon dioxide prepared by the step S1 with a quality of N, and prepare a nano-silicon dioxi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com