Frame and formwork integrated partition wallboard with telescopic slab joints

A partition board and board seam technology, which is applied to walls, building components, buildings, etc., can solve the problems of easy cracking of joints, sound insulation and heat insulation, and unsatisfactory fire and heat preservation effects, etc. Make simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

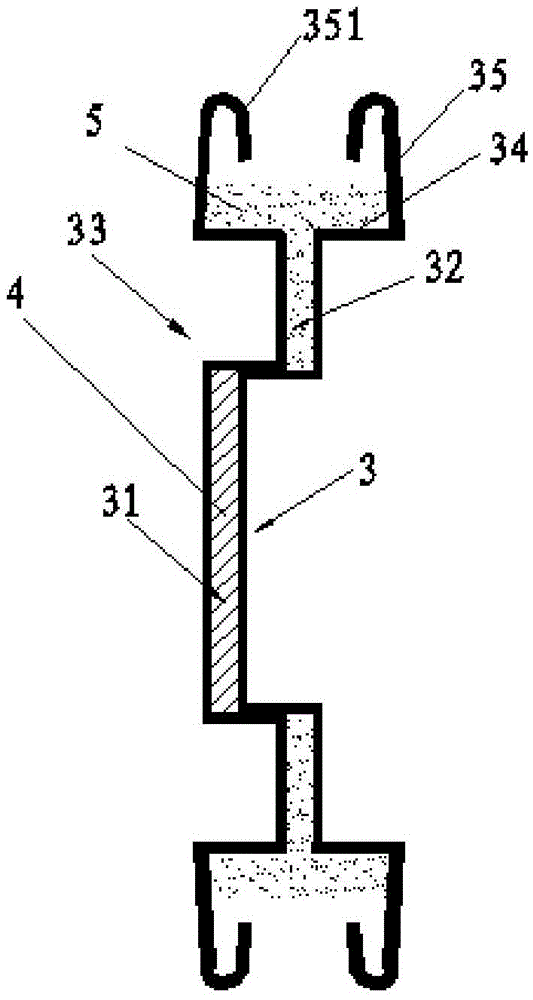

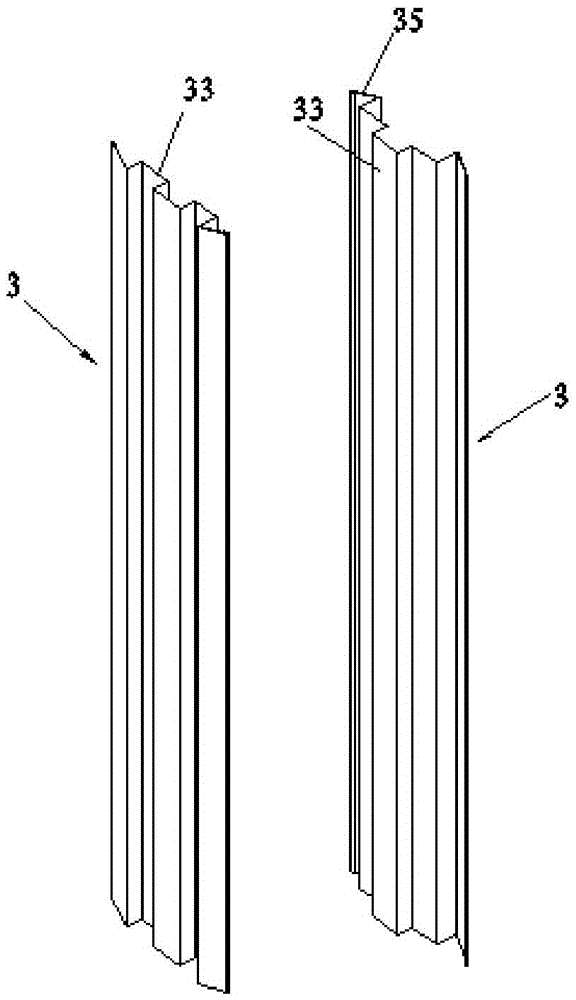

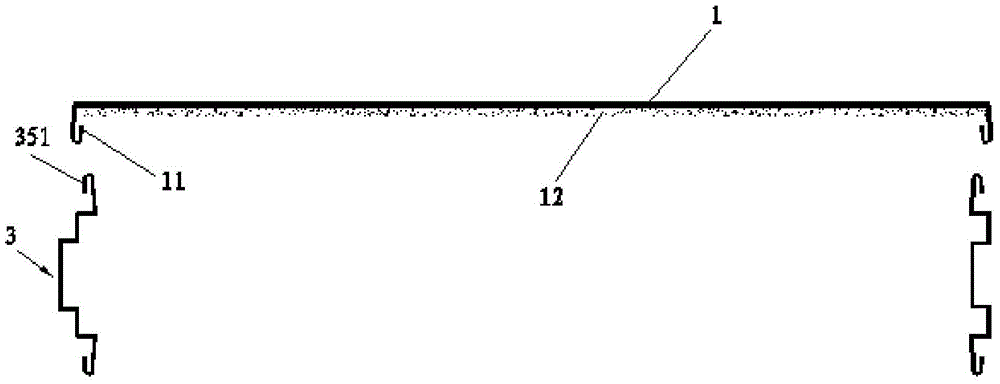

[0026] Embodiment 1: as Figure 1 to Figure 3 As shown, a frame-form integrated partition wall panel with stretchable board seams includes a frame and a wall panel connected to the frame. The wall panel includes two layers 1 and a filling layer 2 between the two layers 1. The frame The frame bar is a keel 3 with a concave-convex butt joint. The concave-convex butt joint is located on the outer surface of the keel perpendicular to the wall panels. The plates are butted together. In this embodiment, the preferred concave-convex joint part 33 is concave or convex, and the outer surfaces of adjacent keels 3 are respectively matched concave or convex.

[0027] After the two framed wall panels are butted, there is a gap between the concave-convex butt joints 33 of the two adjacent keels 3 to form a closed space 31 and a semi-closed space 32. The semi-closed space 32 is located on both sides of the closed space 31 and outside the outer surface of the wall panel The space is connecte...

Embodiment 2

[0030] Embodiment 2: The structure of each part of this embodiment and the connection relationship between each part are basically the same as Embodiment 1, the difference is that, as Figure 4 to Figure 6As shown, a surface layer connecting plate 36 is also provided, and the surface layer baffle plate 35 is located between the plate seam bottom plate 34 and the surface layer connecting plate 36, and the surface layer connecting plate 36 extends parallel to the surface layer 1 to the direction away from the plate seam, and the surface layer The layer baffle plate 35 is wider than the bottom plate 34 of the board seam, and the surface layer connecting plate 36 is provided with reinforcing ribs 362, and the free end of the surface layer connecting plate 36 is provided with a bend in the direction away from the wallboard surface layer 1 to form a second Three hooks 361. The surface layer connecting plate 36 forms the connecting surface connecting the surface layer 1, so that the ...

Embodiment 3

[0032] Embodiment 3: The structure of each part of this embodiment and the connection relationship between each part are basically the same as Embodiment 2, the difference is that, as Figure 7 As shown, the surface layer 1 is a lightweight decorative surface layer, and a metal stress-bearing mesh plate 8 is lined between the light-weight decorative surface layer and the filling layer 2, and the metal stress-bearing mesh plate 8 is bonded to the light-weight decorative surface layer. The two ends of described metal stressed net plate 8 are welded on the described surface layer connecting plate 36 of two keels 3, and metal stressed net plate 8 can improve the stress strength of wall panel, and two metal stressed net plates 8 Pouring filling layer 2 in between.

[0033] The wallboard of the present invention is provided with a frame, and the wallboard has a surface layer 1 and a filling layer 2, and between the surface layer 1 and the filling layer 2, a bearing intermediate laye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com